DiamaPro Systems SCR-84 User manual

OWNER’S MANUAL

SCR-84

WALK-BEHIND FLOOR SCRAPER

OPERATION & MAINTENANCE MANUAL

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

WARRANTY REGISTRATION CARD

Form must be completed and submitted within 30 days from the date of purchase.

Customer Information

First and Last Name

Company Name

Address City State Zip Code

Phone Number Email

Machine Information

Machine Type Machine Model

Serial # Purchase Date (dd/mm/yy)

DiamaPro Systems®

3343 Peachtree Road NE

Suite 145 #24

Atlanta, GA 30326

470-977-2323 nwww.diamaprosystems.com ninfo@diamaprosystems.com

INTRODUCTION

This manual guarantees the safe and ecient use of the machine. This

manual is part of the machine and has to always be kept near the machine

and be accessible for the operating personnel at all times.

The operating personnel have to have carefully read and understood this

manual before any work commences. Prerequisite for safe working is the

compliance with all the safety and handling instructions in this manual.

Furthermore, the local accident prevention regulations and the general

safety conditions for the use of the machine are applicable.

Illustrations in this manual are for the purpose of explanation and may

dier from the actual design of the machine.

When passing the machine on to third parties this manual must be includ-

ed. All of the instructions and technical specications in this manual have

been written in compliance with current technical norms and regulations

together with our many years of knowledge and experience.

Disclaimer: DiamaPro® Systems and its aliates take no responsibility

for any damage, injury or death resulting from the incorrect or unsafe use

of this product. Use of this product should be undertaken by competent

persons only. It is the operator’s responsibility to ensure that the following

safety procedures are followed. If you are unsure, do not operate this

product.

IT IS THE OPERATORS RESPONSIBILITY TO READ THIS MANUAL

AND USE THE MACHINE IN A SAFE MANNER: Failure to follow written

instructions and warnings symbols depicted in this instruction manual and

on the machine may result in serious injury or death for the user and other

persons. Read, understand and follow all the instructions, warnings, and

general safe work practices, which are depicted on the machine and in the

instruction manual at all times.

Always disconnect machine from power before servicing.

Maintenance, replacement or adjustment of parts can cause

serious injury or death to the user or other persons, if the machine

is connected to the power supply while servicing.

Keep the cable away from the blade to avoid damaging the cable.

DO NOT run over or damage the power cord, this can cause a

dangerous electric shock.

The machine is constructed for use in dry environments only.

Danger of electric shock. Do not expose the machine to water or

rain.

Connect to 120V AC power only.

Connecting the machine to an incorrect power supply can cause

damage to the machine and injury to the user and persons in

proximity.

1. SAFETY

1.1. Electrical Safety

Extension Cord– Only use machine with 12 gauge or larger

and 50’ or less length of cord.

Use of extension cords that are too small or too long can cause

dangerous overloading of the cord and machine resulting in poten-

tial re and electrical hazards.

Electrical cables and plugs must be kept in good condition

and replaced by trained electrical technicians when damaged

. Whether it is due to normal wear or abuse electrical cables and

plugs can wear out and expose operators and persons in proximity

to danger of electrocution or burn. Inspect all electrical cables and

plugs before use, worn or damaged electrical cables and plugs

must be replaced by a trained electrical technician.

Never operate with a damaged cable or plugs.

Replacement of worn or damaged cables or plugs must be

completed by a qualied person.

Improperly connecting the grounding wire can result in risk of

electric shock.

Check with a qualied electrician if you are in doubt as to whether

the outlet is properly grounded. Do not modify the plug on the

machine. Never remove the grounding prong from the plug or ex-

tension cords. Do not use the tool if the cord or plug is damaged.

If the plug will not t the outlet, have a proper outlet installed by a

qualied electrician.

Do not use machine when cable is damaged. Do not move the

machine by dragging the cable. Utilization with a damaged cable

can cause an electric shock.

The operator has to be instructed to the use of the machine

before operating.

Failure to observe the information in this instruction manual before

use, adjustment or maintenance could cause serious injury to

persons or property.

Read all security statements. Be sure that data plate and

warning labels are mounted / xed to the machine.

Operator and persons in proximity must wear proper personal

protective equipment including eye-protection, ear protection,

closed toe shoes, N95 minimum dust mask and hearing

protection. Removal of ooring materials and performing main-

tenance on machine can cause hazardous ying debris, airborne

dust, hazardous debris on walking surfaces, and loud noises.

Keep arms, feet and clothes away from the operating machine

parts.

Moving parts of the machine can cause serious injury or damage.

Operator must know what type of material is being removed.

Flooring can be composed of material that is harmful to be

exposed to, especially in the form of air born dust. Some of these

dangerous materials including asbestos and lead must not be

removed by machine and must only be re-mediated by licensed

professionals.

SPARE PARTS

Only use original spare parts and accessories specially made

for this machine. DO NOT USE NON ORIGINAL EQUIPMENT

MANUFACTURES PARTS FOR REPLACEMENT. Failure to use

original parts can cause early failure or potentially dangerous fail-

ures or operating conditions. The manufacturer assume no liability

for damages / injury caused by after-market parts.

When replacing spare parts or electrical components, the technical

data specied by the manufacturer must be observed and original

spare parts must be used. Do not use machine if connecting ca-

bles or components are not in good operating condition.

WORK SAFETY

The scraper SCR-84 is built according to the state of the art and

the recognized safety-technical rules and must only be used for its

intended purpose in safe working environment.

Mandatory Action

Warning/Caution

General Safe Condition

Prohibited Action

1.2. Operator Warnings

1.3. Usage

Improper use of the machine can cause injury / damage to the op-

erator, property, bystanders, and the machine itself. When working

with the machine the operator must pay attention to other persons

in the work space. It is not recommended to use this machine

around children due to the unavoidable hazard of an unprotected

sharp blade at a low height. If the machine fails in any manner, it

must be switched o immediately and disconnected by unplugging

the power cord from the power supply then lock the cord end and

tag the machine until repaired.

INTENDED USE

The scraper SCR-84 is intended exclusively for light duty removal

of bonded oor coverings such as linoleum, rubber, carpets and

vinyl coverings installed in dry areas on at walking surfaces. Any

other use is considered to be improper and the manufacturer is

not liable for damage or injury caused by improper use.

Do not use non standard blades not approved by the

manufacturer. Do not use machine on wet surfaces.

A powerful stripper for small and medium-sized areas. Works on wooden

or concrete surfaces and will remove virtually any substance adhering to

the oor.

SPECIAL FEATURES:

- adjustable cutting angle

- adjustable handle

- machine runs very quiet with reduced vibration

- big wheels ensure easy mobility on job sites

- foldable handle for easy transport

The vibration level may dier from the indicated value during use

depending on the blade size and type of material being removed.

Do not use the machine continuously for more then 120 min.

Prolonged exposure to vibration can cause injury to hands and

arms. Take frequent breaks, wear vibration reducing gloves, en-

sure machine is in good repair so vibration is kept to the lowest

amount possible.

Machine is sold with 6mm hex wrench for installing blades.

The SCR-84 is delivered in transport position.

For instructions on setting to the working position, see Section

3.2: Adjusting Handle Height.

The height of the handle can be adjusted in three positions.

- Remove the locking pin

- Adjust handle to preferred position and re-install locking pin

2. PRODUCT INFORMATION

2.1. Technical Description

2.2. Technical Data

POWER SUPPLY

DRIVE SYSTEM

MOTOR SIZE

CUTTING ACTION

WEIGHT

DIMENSIONS (LxWxH)

110 V

MANUAL

1 HP

ORBITAL

84LBS

22 X 13 X 43 IN

2.3. Standard Accessories

3. SETUP

Handle Bar

ON/OFF Switch

Handle Angle Adjustment

Working Angle Adjustment

Front Weight

Cutting Head/Blade Holder

with Material Deector

3.1. Machine Description

3.2. Adjusting Handle Height

FIG 3-A

3-A

A steep / aggressive angle works best for removing glue and

for thin materials. A low / less aggressive angle is best for most

removal situations. The type of sub oor can also change what

working angle is best. Typically a high aggressive angle will not

work well on a wood sub oor, but will work ne on concrete.

- Loosen the clamping lever on the wheel assembly

- Lift on the handle to raise the back the of the machine, the wheel

assembly will slide keeping the wheels in contact with the oor

- Tighten the clamping lever again to hold the machine in the

desired position.

Regardless of the working angle, the handle bar should always be

adjusted to the user’s belt height.

- bevel up for concrete.

- bevel down for wood or soft sub-oors.

- Narrow blades reduce the amount of eort required to

push the machine.

Dull blades reduce the performance of the machine. Sharpen or

replace the blades as needed.

CAUTION! Sharp blades are dangerous. Wear protective gloves

when changing or sharpening blades. Use the supplied extend-

ed wrench to keep hand safely away from the edge of the blade

when installing on machine.

1. Place a block under the front

of the machine

2. Loosen the two bolts with the

extended bolt wrench and

replace the blade.

It is not necessary to remove the bolts

Be sure that the blade is far enough under the blade-holder, to

insure a secure hold.

USE ONLY ORIGINAL BLADES

3-B

3-C

FIG 3-B

3.3. Adjustment of Working Angle

FIG 3-C

3.4. Choice of Blade

3.5. Change Blade

FIG 3-I

FIG 3-J

3-I

Always wear gloves and safety

glasses.

It is not necessary to remove the bolts.

1. Sharpen the blade mounted to the

machine. Using hand grinder, block

up front of machine so blade is o the oor. Only grind on the

original beveled edge maintaining factory angle. Machine

works best with a single-sided bevel. Sharpen the blade with 5”

or smaller diameter disk with 120 or ner grit.

Be careful not to catch disk on edge or

corner of blade.

Blade sharpened “bevel down”

Blade sharpened “bevel up”

Sharpening with a ne-toothed le

2. Blade can also be eectively sharpened

on a bench grinder or while secured in a

vice. Follow all the same instructions

listed above.

1. After blade is installed plug in 12 gauge or heavier cord to 15amp

minimum 120v power source and connect to the machine.

2. Press the green power button on the handle and the machine will start.

Keep blades sharp! Sharpening blades frequently will signicantly

increase productivity and ease of use. Keep your work area clean

and clear of debris. Always wear eye and ear protection when

working with the machine.

Vinyl, Rubber, PVC, Direct Glued Carpet

Pre-score the ooring by cutting it into

strips approximately the width of the

blade. Pre-scoring carpet / sheet goods

allows for easy handling of the removed

material and reduces the amount of eort

required to break the adhesive bond.

For materials with a strong bond use a low blade

angle. A second pass with a high blade angle can be

used to remove residual adhesive.

If working over a wood sub-oor, a high

blade angle will cause the blade to dig in.

A very sharp blade at a low angle can be

used to remove adhesive or a secondary

process such as sanding with course

paper may be required.

For soft coverings that are attached with

a strong bond self scoring blades with

vertical cutting wings can be used.

3.6. Sharpening the Blade

FIG 3-K

FIG 3-L

FIG 3-M

4. OPERATION

4.1. Start the Machine

4.2. Removal of Floor Coverings

FIG 4-B

FIG 4-C 4-B

4-C

5. TROUBLESHOOTING

FAULT REMEDY

Machine will not start n Ensure outlet has power, check for damage in cord,

Noise from motor n Look for damage to fan cover on top of motor

Rattling noise from machine n Check for proper torque on wheel axles and legs, parts should

be easy to move but not loose. Pull bottom cover and check for

broken isolators or bad cutting head bearing.

Machine is hard to push n Sharpen the blade, set blade to low angle, switch to smaller

blade

Frequent trip of circuit breaker n Try to nd a dierent circuit

n Replace extension cord, use shorter and or heavier

gauge extension cord.

6. MAINTENANCE / CARE / REPAIR

Before startup:

Check the guards, electrical components and cords for damage

Check wheel assembly , bottom cover, and cutting head are secure and in good working order

Check the blade - Blades can become dull very quickly and cause signicant decrease in performance

When putting the machine away:

Unplug extension cable from machine and power source

Remove the blade from the machine and put in a safe place

Prolonged exposure to corrosive environments, high humidity, and direct sunlight will cause premature wear and failure to metal, plastic and

rubber components. When not in use, store the machine under cover in a clean dry place.

Perform maintenance, repair, or cleaning on the machine with the blade removed and no power connected.

NEVER use a pressure washer or garden hose to clean the machine. If dicult cleaning is required the use of conventional degreaser, cleaners,

adhesive removers and a cloth is the recommended method. Take care to not remove or deface any safety , warning, or instruction labels.

DO NOT modify, remove, or render inoperable any guards or safety elements of the machine.

If the plug of the machine needs to be replaced the manufacturer recommends not to use assembly style plugs.

The machine is designed to have a molded plug and cable to ensure long life and maximum safety from electrical hazards. Only use original

replacement parts and have them installed by a trained electrical professional

Dispose of the machine in accordance with all local laws and ordinances..

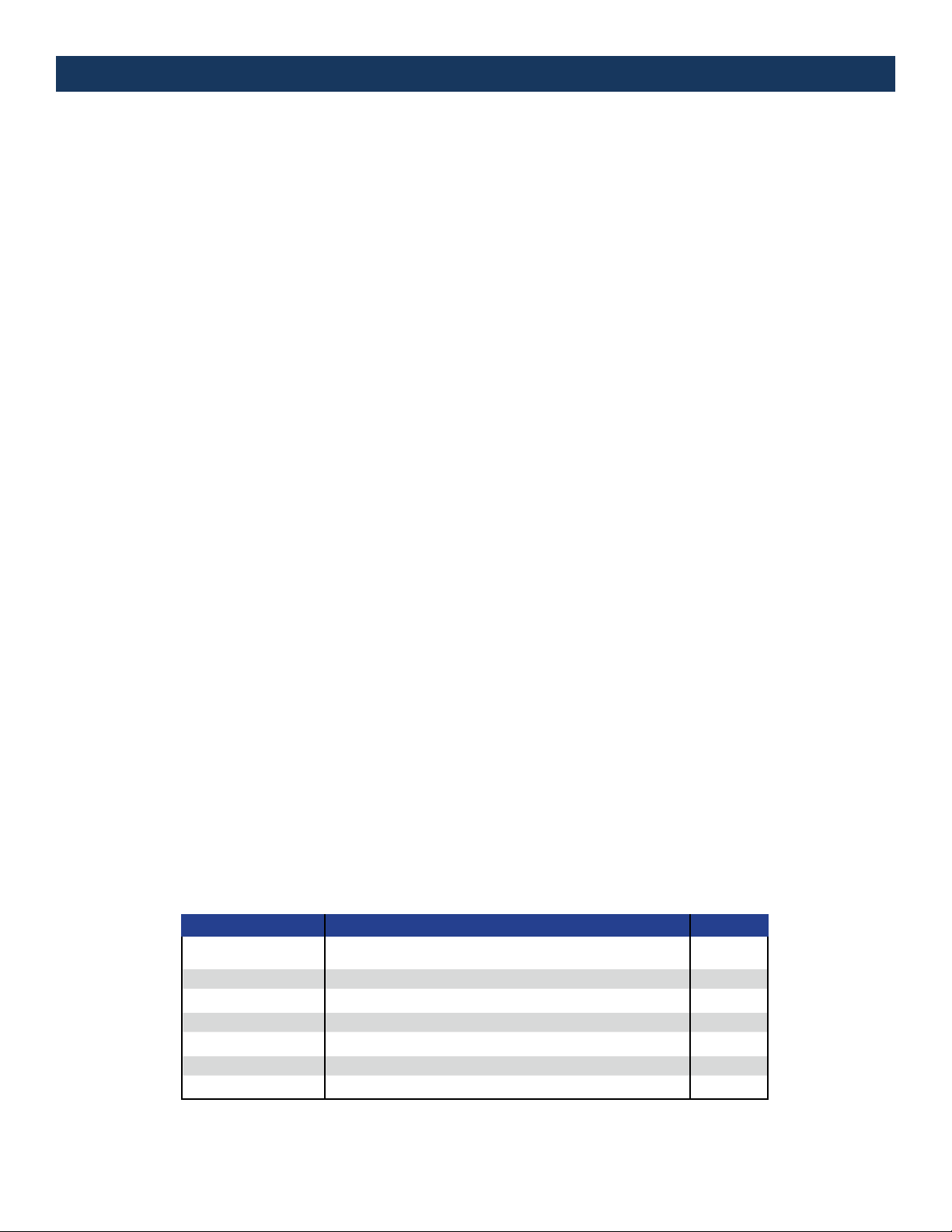

7. REPLACEMENT PARTS

RECOMMENDED REPLACEMENT PARTS

PART NO. DESCRIPTION QTY.

DP-SCR-10251

DP-SCR-10426

DP-SCR-10470

DP-SCR-10427

DP-SCR-10172

DP-SCR-10449

DP-SCR-10448

DP-SCR-10146

DP-SCR-10469

DP-SCR-10477

DP-SCR-10478

ON/OFF SWITCH

MOLDED PIGTAIL

CABLE FROM SWITCH TO MOTOR

STRAIN RELIEF

HANDLE PIN

FLAT RUBBER GRIP

ROUND RUBBER GRIP

CUTTING HEAD FLANGE BEARING

ISOLATOR

NYLON WASHER

NYLON WASHER

1

1

1

1

1

1

2

1

4

2

2

8. PARTS BREAKDOWN & PARTS LIST

ELECTRICAL COMPONENTS

PART NO. DESCRIPTION QTY.

DP-SCR-10467

DP-SCR-10470

DP-SCR-10426

DP-SCR-10251

DP-SCR-10471

DP-SCR-10192

DP-SCR-10427

ELECTRIC MOTOR

CABLE FROM SWITCH TO MOTOR

MOLDED PIGTAIL

ON/OFF SWITCH

RUBBER GROMMET

SWITCH PLATE

STRAIN RELIEF

1

1

2

1

1

1

1

8. PARTS BREAKDOWN & PARTS LIST

CUTTING HEAD & WHEELS COMPONENT

PART NO. DESCRIPTION QTY.

DP-SCR-10146

DP-SCR-10475

DP-SCR-10469

DP-SCR-10200

DP-SCR-10477

DP-SCR-10478

DP-SCR-10205

DP-SCR-10206

CUTTING HEAD FLANGE BEARING

ECCENTRIC

ISOLATOR

AXEL BOLT

NYLON WASHER

NYLON WASHER

NYLON INSERT LOCK NUT

WHEEL

1

1

1

1

1

1

1

1

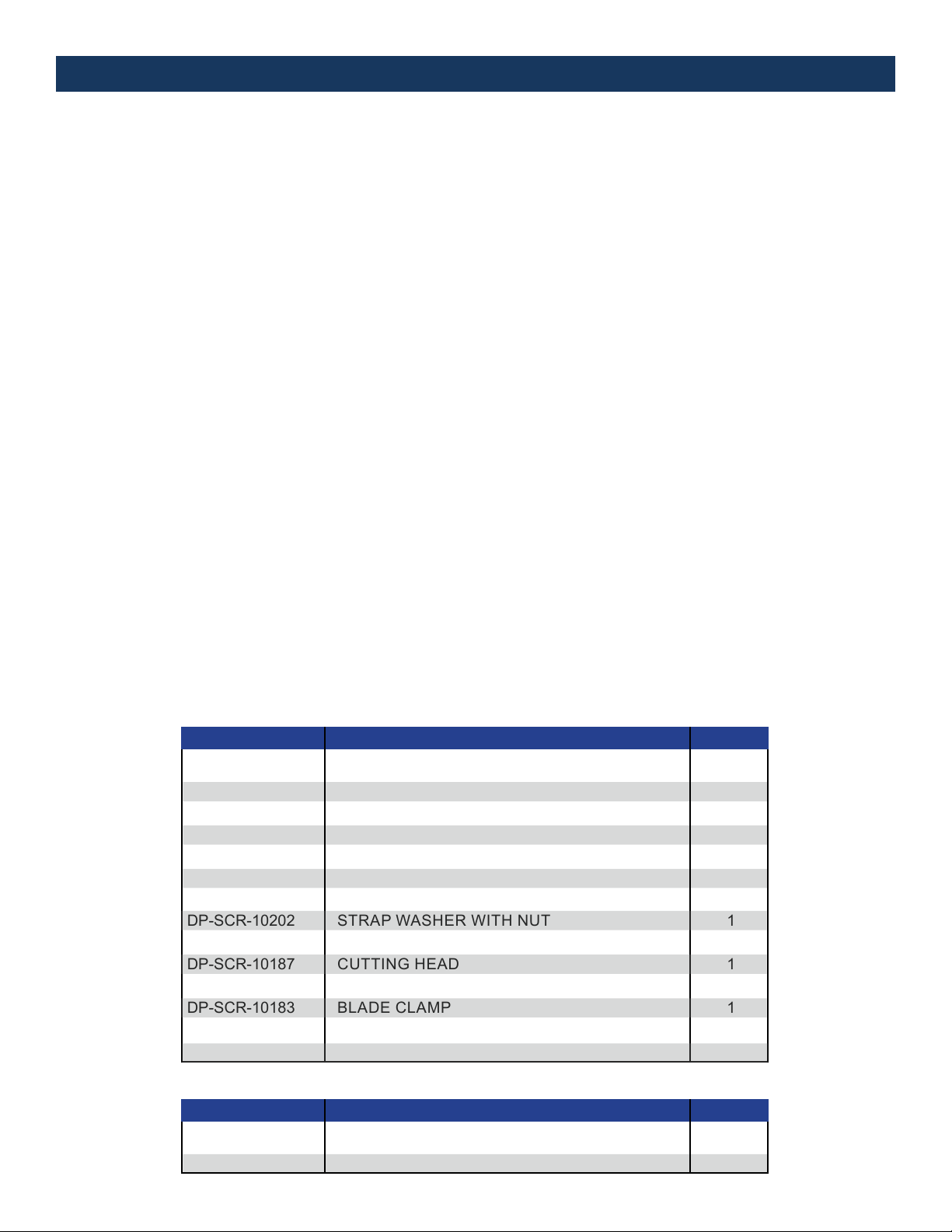

8. PARTS BREAKDOWN & PARTS LIST

CUTTING HEAD AND DRIVE COMPONENTS

PART NO. DESCRIPTION QTY.

DP-SCR-10472

DP-SCR-10306

DP-SCR-10473

DP-SCR-10449

DP-SCR-10448

DP-SCR-10172

DP-SCR-10474

WRENCH HOLDER

HEX WRENCH (FOR BLADE CLAMP)

TUBE CAP

FLAT RUBBER GRIP

ROUND RUBBER GRIP

HANDLE PIN

OPERATION INSTRUCTIONS PLATE

1

1

1

1

1

1

1

PART NO. DESCRIPTION QTY.

DP-SCR-10198

DP-SCR-10199

DP-SCR-10195

DP-SCR-10191

DP-SCR-10196

DP-SCR-10200

DP-SCR-10201

DP-SCR-10202

DP-SCR-10184

DP-SCR-10187

DP-SCR-10185

DP-SCR-10183

DP-SCR-10197

DP-SCR-10205

FRAME

HANDLE

WHEEL LINKAGE

STRAP

WHEEL SPACER

AXEL BOLT

PLAIN STRAP WASHER

STRAP WASHER WITH NUT

HANDLE BOLT

CUTTING HEAD

BOTTOM COVER

BLADE CLAMP

590 CUT WEIGHT

NYLON INSERT LOCK NUT

1

1

2

2

1

1

1

1

1

1

1

1

1

1

8. PARTS BREAKDOWN & PARTS LIST

FRAME KIT PARTS

ANCILLARY PARTS

PART NO. DESCRIPTION QTY.

DP-SCR-10206

DP-SCR-10146

WHEEL

CUTTING HEAD FLANGE BEARING

2

1

DiamaPro® Systems

3343 Peachtree Road NE

Suite 145 #24

Atlanta, GA 30326

470-977-2323

Table of contents