Grizzly G1201 User manual

Other Grizzly Power Tools manuals

Grizzly

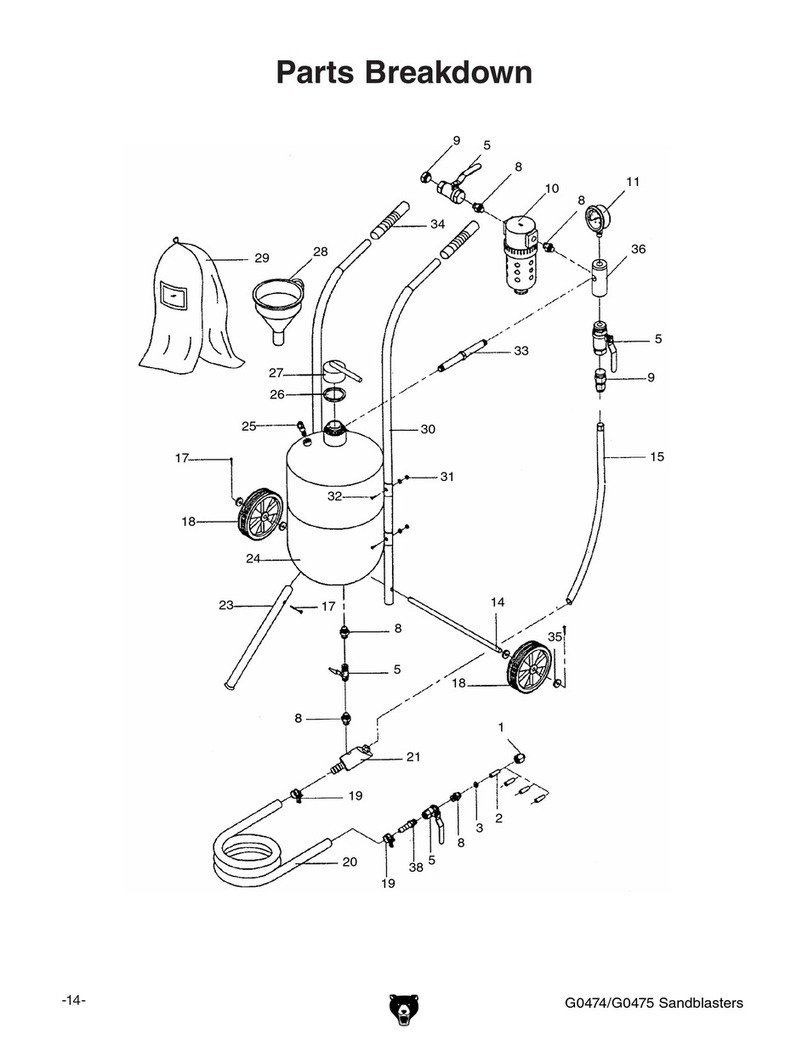

Grizzly G0475 Quick start guide

Grizzly

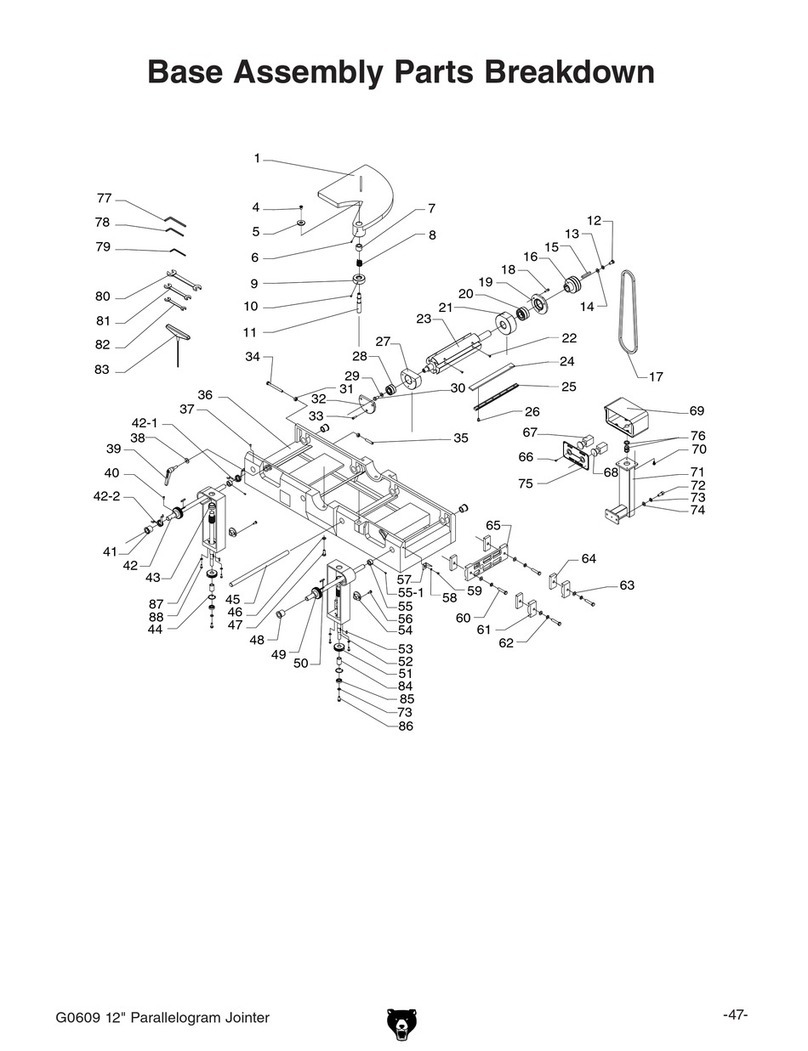

Grizzly G0609 Quick start guide

Grizzly

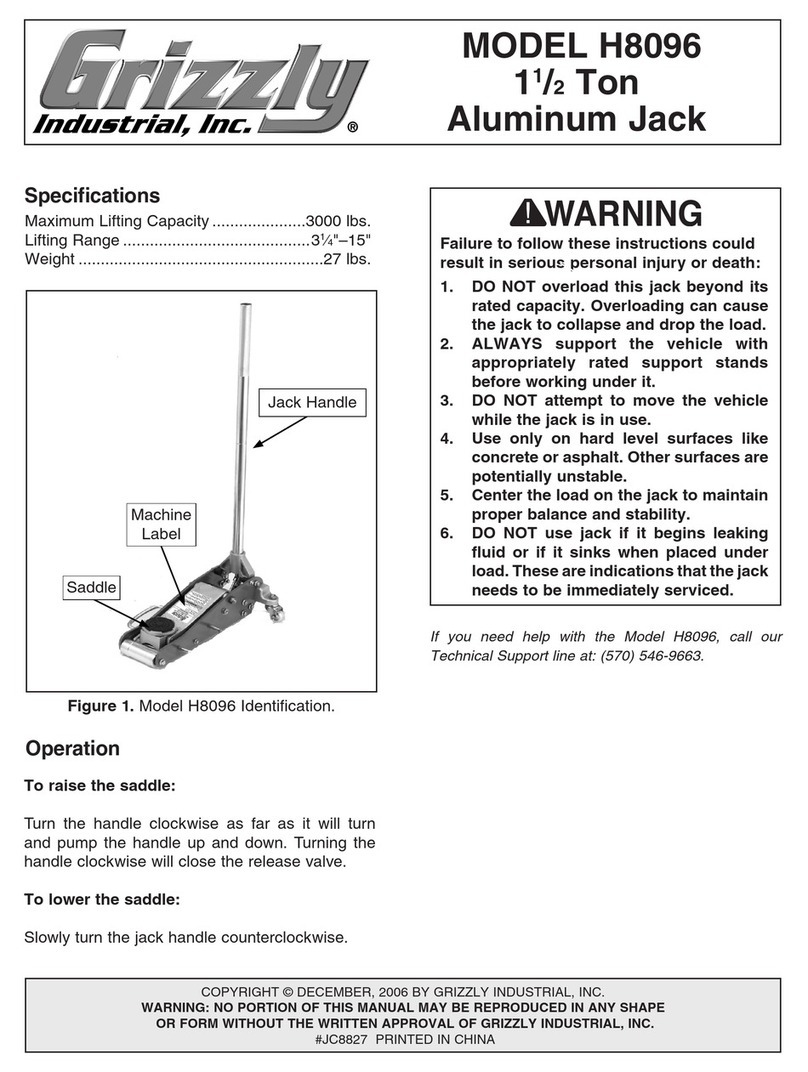

Grizzly H8096 User manual

Grizzly

Grizzly T27665 User manual

Grizzly

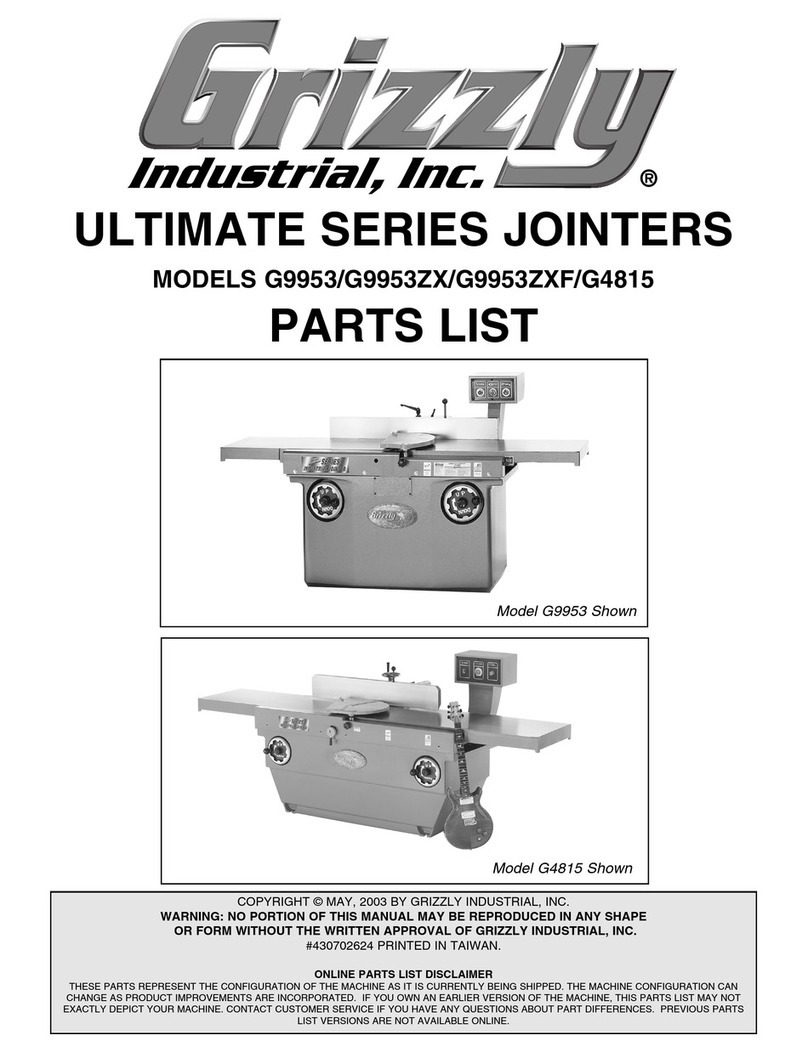

Grizzly G4815 User manual

Grizzly

Grizzly G0611X User manual

Grizzly

Grizzly T32957 User manual

Grizzly

Grizzly AGS 3680 D-Lion Operating and installation instructions

Grizzly

Grizzly G0612 User manual

Grizzly

Grizzly G0495X User manual

Grizzly

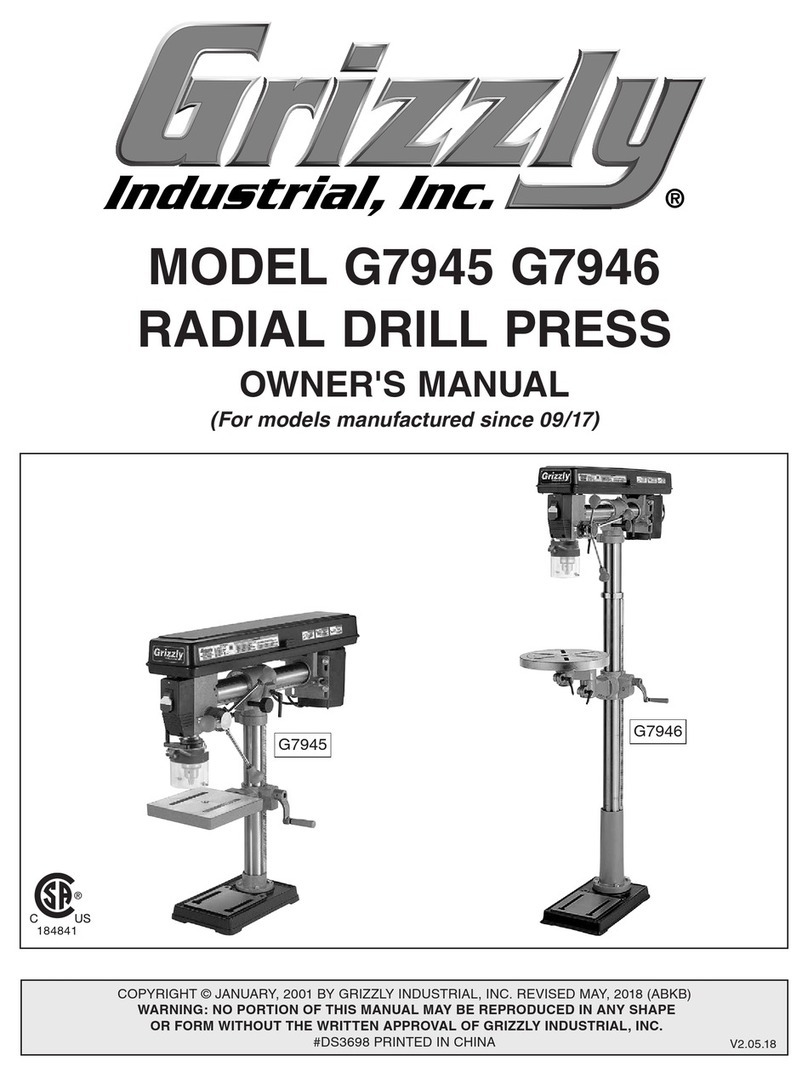

Grizzly G7945 User manual

Grizzly

Grizzly G9298 User manual

Grizzly

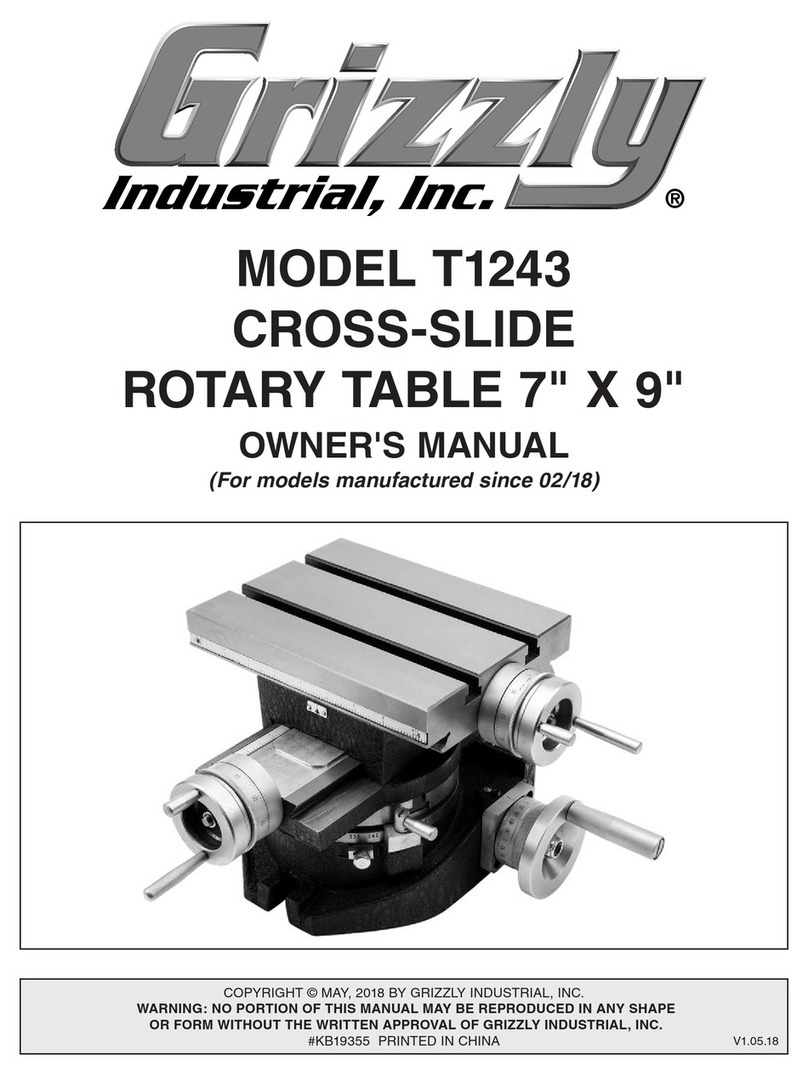

Grizzly T1243 User manual

Grizzly

Grizzly G0611X Quick start guide

Grizzly

Grizzly G1049 User manual

Grizzly

Grizzly G9901 User manual

Grizzly

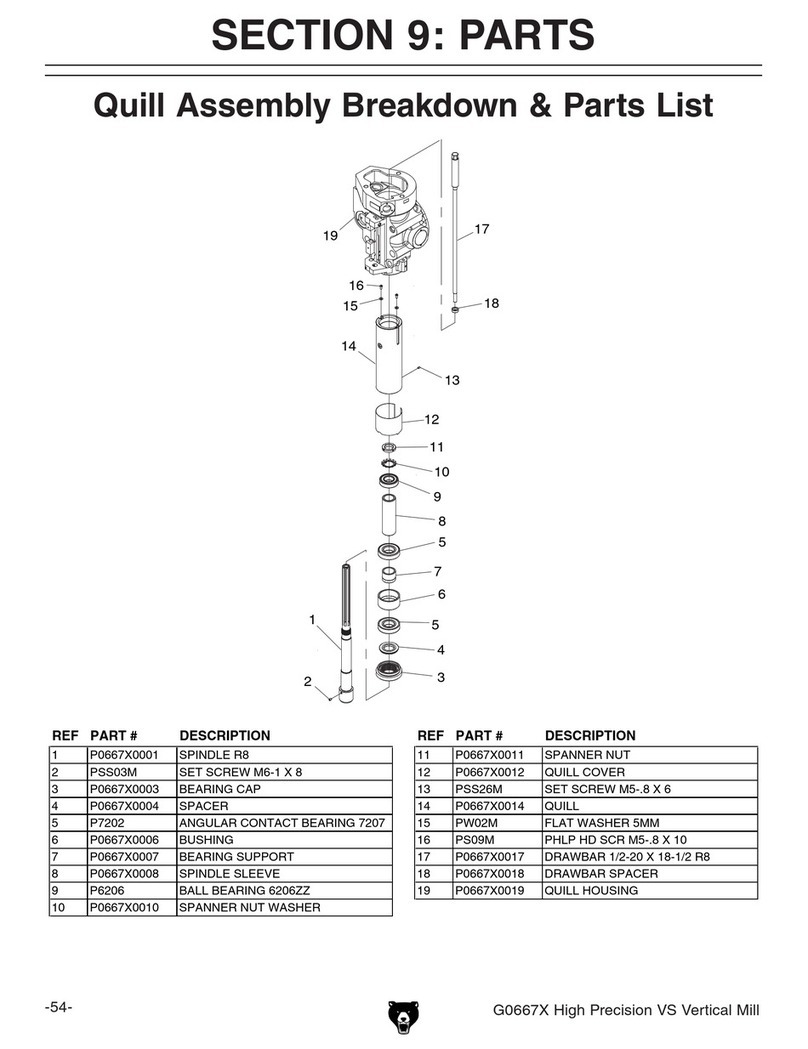

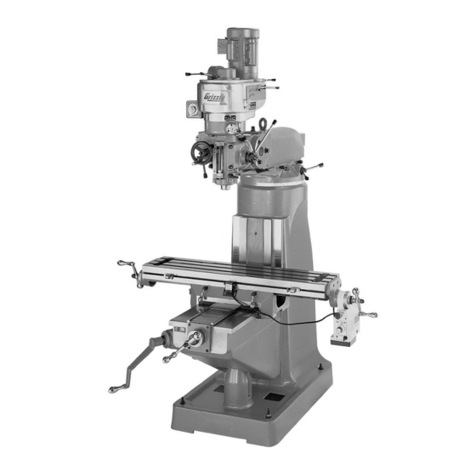

Grizzly Vertical Mill G0667X User manual

Grizzly

Grizzly G9901 User manual

Grizzly

Grizzly H5503 User manual

Grizzly

Grizzly G0836 User manual