DIAMOND GEAR WORM GEAR User manual

2021

DIAMOND Gear Company, LTD.

Installation,

Maintenance, &

Operation Manual

WORM GEAR

pg.1

WORM GEAR

Installation, Maintenance,

& Operation Manual

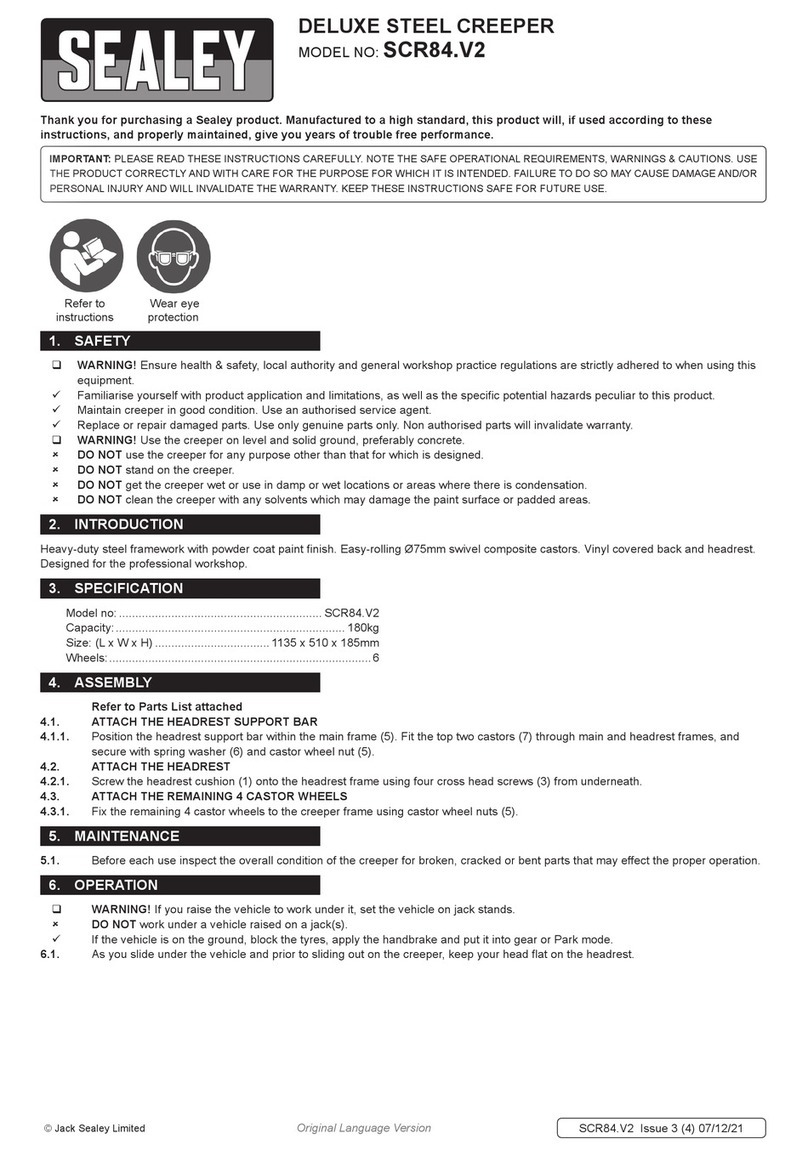

INSTRUCTIONS

This is an instructional manual which provides general installation, operation, and maintenance

for Diamond Gear manual worm gear operators.

Diamond Gear worm operators are designed to be used on ball, butterfly, plug, and damper applications;

generally for 90 degree applications. Diamond Gear operators are designed to transmit the rated output

torque by transmitting input force through the input shaft by the handwheel or other input device.

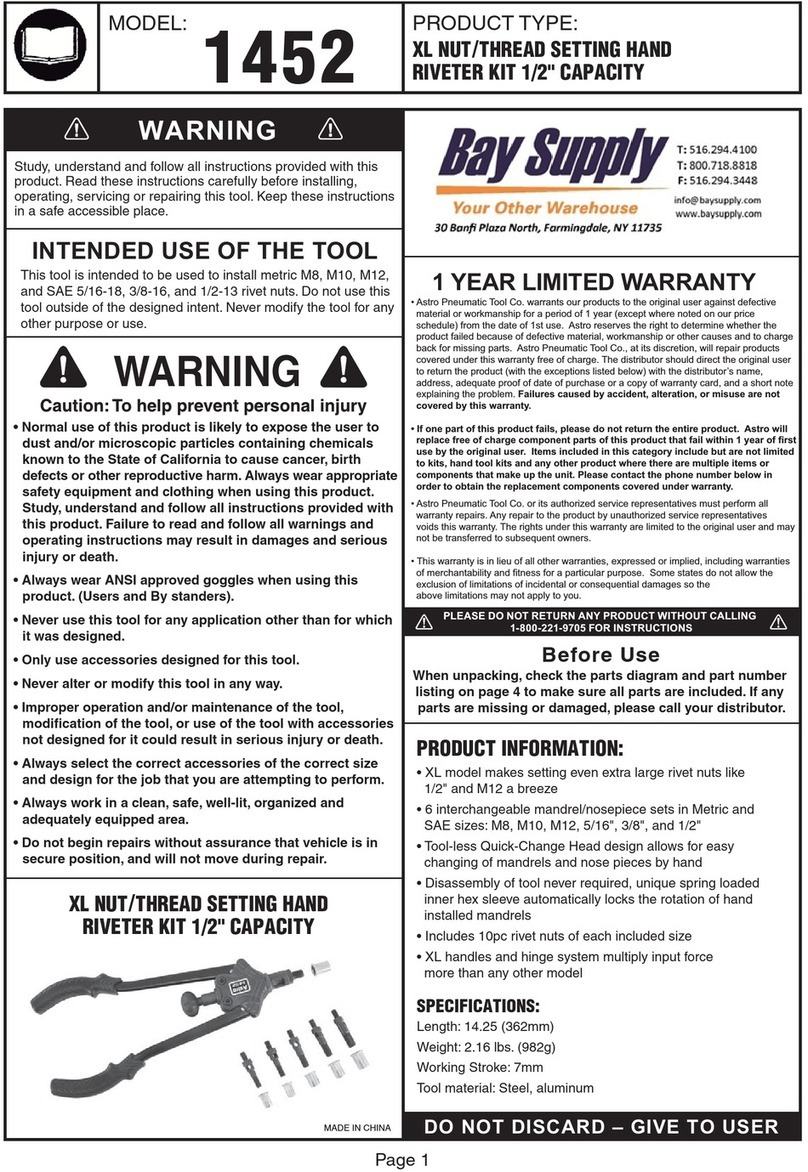

INSTALLATION

Verify that mounting patterns and output bore have been machined correctly. Check for burs

on valve stem and inside gear to ensure easy installation.

1. Make sure that both the valve and gear are in the same position (Open or Closed)

2. Removing the gear indicator will make it easier to install the gear and line up input bore with the

valve stem.

3. Line up stem shaft on the valve with the output bore of the gear. Reassure that both gear

operator and valve are in the same open or closed position. Carefully lower gear operator over

the valve stem onto the valve mounting pad.

Make certain your hands and fingers are clear between the gear operator and

mounting pad.

4. Align the mounting holes on the bottom of the gear operator with those on the mounting pad or

bracket on the valve.

If the holes are not aligned you might need to rotate the handwheel clockwise or

counterclockwise until you reach the proper alignment.

5. DGC recommends grade 5 or better bolting when securing the gear operator to the valve

mounting pad and or bracket. If the operator is provided with tapped holes in the base, fasten

the operator to the valve by passing bolts through the mounting flange of the valve into the base

of the operator.

6. Reinstall gear indicator ensuring the arrow on the indicator corresponds with the proper position

of the valve.

Phone: 713.590.0270 Fax: 713.590.0278 Toll Free: 1.877.811.4258

13750 Hollister Road Houston, Texas 77086

www.diamond-gear.com

pg.2

WORM GEAR

Installation, Maintenance,

& Operation Manual

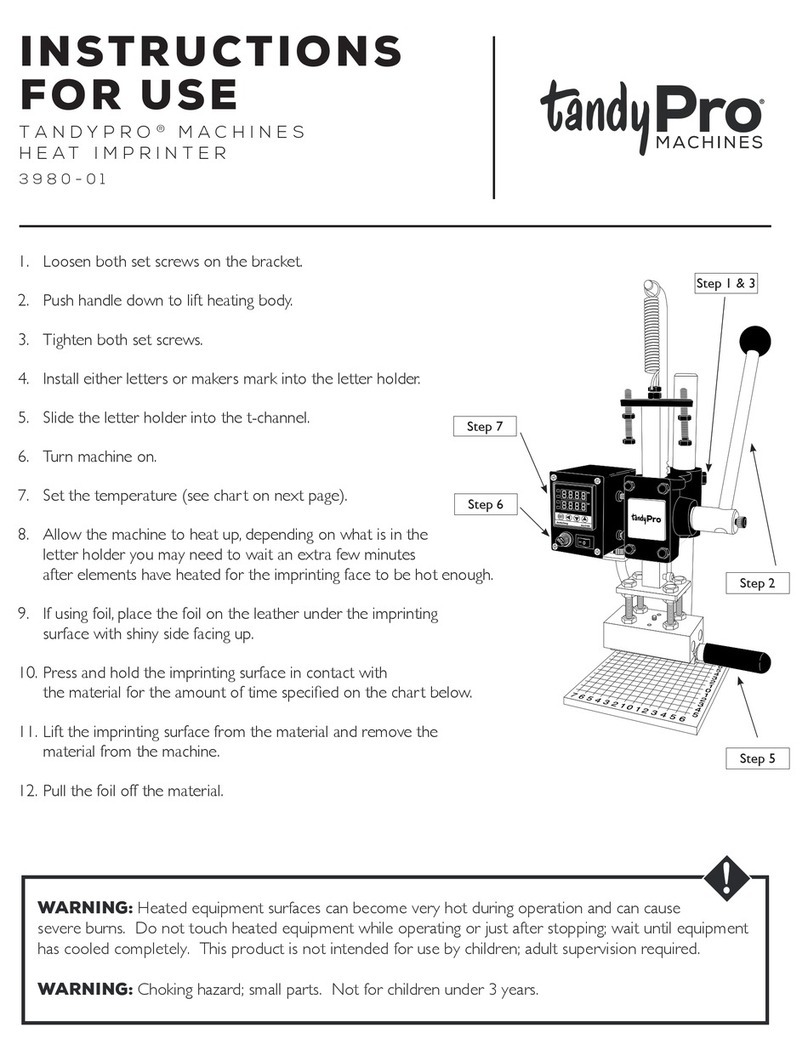

SETTING ADJUSTMENT SCREWS

1. Rotate the handwheel to move the valve to the fully closed position. Set the adjustment screw by

turning it clockwise until you feel it hit the segment inside the gear then lock the adjustment screw by

using the lock nut provided.

2. Rotate the handwheel to move the valve to the fully open position.

If the valve is installed and you cannot see if the valve is fully open, you can count the

number of rotations of the handwheel to make sure you reach 90 degrees.

Ex: (if your gear has a 100:1 ratio. You would rotate your handwheel 25 times to reach 90 degrees)

3. Set the adjustment screw by turning it clockwise until you feel it hit the segment inside the gear. Lock

the adjustment screw by using the lock nut provided.

Note: Due to the differences in individual valves, the indicator may not line up exactly with the

open/closed markings on the cover. Proper settings must be determined by the position of the

valve disc, ball, plug, etc.

SAFETY &OPERATION

Do not use handwheels, cheater bars, or motors devices larger than recommended by

the factory. This could cause damage to the gear operator or possibly the valve and

will void the manufactures warranty.

Gear operators are sized based on torque information provided by valve manufactures. Over time

some applications may cause the valves to become more difficult to operate. If the operator becomes more

difficult to operate,check the following:

Does the gear have proper lubrication? Some valve applications like plug valves also need lubrication if this is the

case also check that the valve has proper lubrication.

Make sure the valve is clear of any obstructions.

Check to see if the pressure across the valve has changed. This could have an adverse effect on the valve torque.

Phone: 713.590.0270 Fax: 713.590.0278 Toll Free: 1.877.811.4258

13750 Hollister Road Houston, Texas 77086

www.diamond-gear.com

pg.3

WORM GEAR

Installation, Maintenance,

& Operation Manual

STORAGE

Diamond Gear operators don’t have a “shelf life” but ensure that the gears are ready when you are DGC recommends they

be stored in a clean, dry area protecting the input shafts and output bores from getting damaged.

MAINTENANCE

Moving mechanical parts are lubricated with special grease that ensures safe operation. Diamond Gear

recommends that you inspect your gear annually for any wear that may occur, check gears and bearings for

lubrication and add if necessary.

Please keep in mind that some gears may need to be inspected more often depending on

application and environment.

In order to inspect the gear housing you will have to remove all the bolts that secure the indicator and housing

cover. Once these bolts are removed you can remove the indicator plate and cover to inspect the inside of the

gear.

Diamond Gear operators are lubricated for life in most application instances. Depending on the environment

and application some additional lubrication may be required.

Below you will find DGC standard gear requirements suitable for most applications:

NLGI Grade 2

Operating Temperature: -10 to 350 degrees F

Timken Load (lbs) 65 or better

Phone: 713.590.0270 Fax: 713.590.0278 Toll Free: 1.877.811.4258

13750 Hollister Road Houston, Texas 77086

www.diamond-gear.com

pg.4

WORM GEAR

Installation, Maintenance,

& Operation Manual

WORM GEAR ASSEMBLY

Phone: 713.590.0270 Fax: 713.590.0278 Toll Free: 1.877.811.4258

13750 Hollister Road Houston, Texas 77086

www.diamond-gear.com

REV_0

A

Ad

d

j

j

u

us

st

tm

me

en

n

t

t

S

Sc

cr

re

ew

ws

s

L

Lo

oc

ck

k

N

Nu

ut

t

Table of contents