Diamond Products CB700 User manual

OPERATIONS MANUAL

MODEL :

CORE DRILL

SAFETY

To maintain the operation safety,

make sure to read and understand

this instruction book BEFORE

operating this equipment.

CB700

DIAMOND

PRODUCTS

SAFETY

1. When operating the drill, be sure to wear proper safety gear, such as safety

glasses, dust mask, glove, and hearing protection. A hard hat is also

recommended.

2. Never operate unless proper footing and balance is possible at all time.

3. Wear proper apparel. Do not wear loose clothing or accessories. Keep hair

and body parts away from openings and moving parts.

4. Wet coring bits MUST be used with water. Flow should be kept at sufficient

rate and volume.

5. Use ONLY diamond impregnated core bits with this drill.

6. Do not force the machine. Use the drill properly and as intended.

7. Anchor bolts should always be used to secure the base on a cracked,

uneven or vertical surfaces.

8. Maintain alertness while operating the machine. Failure to maintain

attention, by the operator, may lead to serious injury.

9. Do no operate the machine when you are tired or while under the influence of

drugs, alcohol or any medication.

10. Use common sense when operating any power tool.

1

11. Keep work area clean and well lit.

12. Never operate this unit when flammable materials or vapors are present.

Electrical devices produces sparks or arcs which can cause a fire or explosion.

13. Do not expose the drill to rain or wet conditions to minimize electric shock.

14. Do not obstruct motor air intake or outtake to maximize performance.

15. Before beginning work, familiarize self with the work site and its

surrounding. Take notice of circumstances which may impede work or traffic,

observe soil conditions (good bearing or not) and take measures to ensure

safety (e.g. the shielding of road works from public traffic).

16. Take measures to ensure that the drill is in a safe and trouble-free condition

to operate. Use the drill only when all protective devices (i.e. guards, noise

absorbers, emergency-off devices) are in place and in working order.

17. A visual check of the machine must be made at least once a shift to ensure

that early signs of problems are noticed. Any such indication (including

changes in machine performance or behavior) must be reported to the

appropriate supervisor.

18. In the case of a malfunction, stop the drill immediately, unplug and secure it.

Fix the problem as soon as possible.

19. To stop and start the drill follow the operating instructions and observe any

indicator lights.

20. Keep the drill out of reach of children.

2

21. Make sure power is in “OFF” position before plugging in power cord to

prevent any accidental activation.

22. If cord/plug is damaged do not operate.

23. Plug should be of proper type to mate to outlet. Never modify the plug in any

way. Adapter plugs should not be used either for grounded power tools. Power

received must be as specified on the drill nameplate.

24. Be sure to connect the plug to a properly grounded receptacle to reduce the

risk of electric shock.

25. To reduce the risk of electrical shock, we recommend the use of GFCI and to

refer servicing to a qualified professional. Avoid body contact with earthed or

grounded surfaces such as metal objects.

26. Before operating, be sure the activated drill will be of no danger to anyone.

Check to make sure all adjusting key or wrench were removed.

27. When machine is plugged in do not leave it unattended. Unplug prior to

servicing, when changing accessories, and when not in use.

28. Never carry machine by cord. Do not pull cord to unplug. Keep cord away

from heat, sharp edges and oil.

29. When using an extension cord, make sure it is in good condition and heavy

enough to carry the current drawn by the machine. Refer to the extension cord

table in the “Electrical Specifications” section for the correct gauge depending

on the desired cord length and the machine’s horsepower and voltage.

30. Service on the drill should only be performed by a qualified technician.

3

HEALTH WARNING

1. Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contain chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

A. Lead from lead-based paints

B. Crystalline silica from bricks, cement and other masonry products

C. Arsenic and chromium from chemically-treated lumber

2. Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: Work in a well

ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

4

UNPACKING

1. Open the carton containing the drill motor. Remove the drill and place it on a

flat, level working area. Be sure that the followings items are removed before

discarding the carton:

A. Size 36 Open box wrench

B. Size 48 Open box wrench

5

SETUP

1. Mounting the Drill Motor

A. Attached to the drill body is a universal mounting block. Study the block

and drill stand carriage mounting holes. If it is determined the block is not

required, remove it so that the drill may mount properly to the carriage.

B. First install the appropriate key size into the available key way. Next line up

the mounting holes from the drill motor to the holes on the carriage. The screws

must pass through the carriage first then into the motor body.

C. Once the screw are tighten, look at the assembly from the side. Both the drill

motor and carriage mounting face must sit flush against each other.

D. The carriage must be properly adjusted to the drill stand column. Check that

the drill motor is secure by shaking the motor using moderate force. No

movement should be possible. If movement is felt independent from the

column, the carriage needs to be adjusted. See the drill stand manual for proper

adjustment instructions.

2. Installing a Core Bit

A. Raise the mounted drill motor to the proper height. The core bit should be

able to sit directly underneath the spindle.

B. Apply grease to the spindle thread to prevent corrosion and easier core bit

removal.

C. If a copper washer or slip collar is available, slide it onto the spindle.

NOTE: The drill motor should not be plugged in and the spindle should be static

when following any of the following procedures!

6

D. Lastly position the core bit directly underneath the spindle and screw it on.

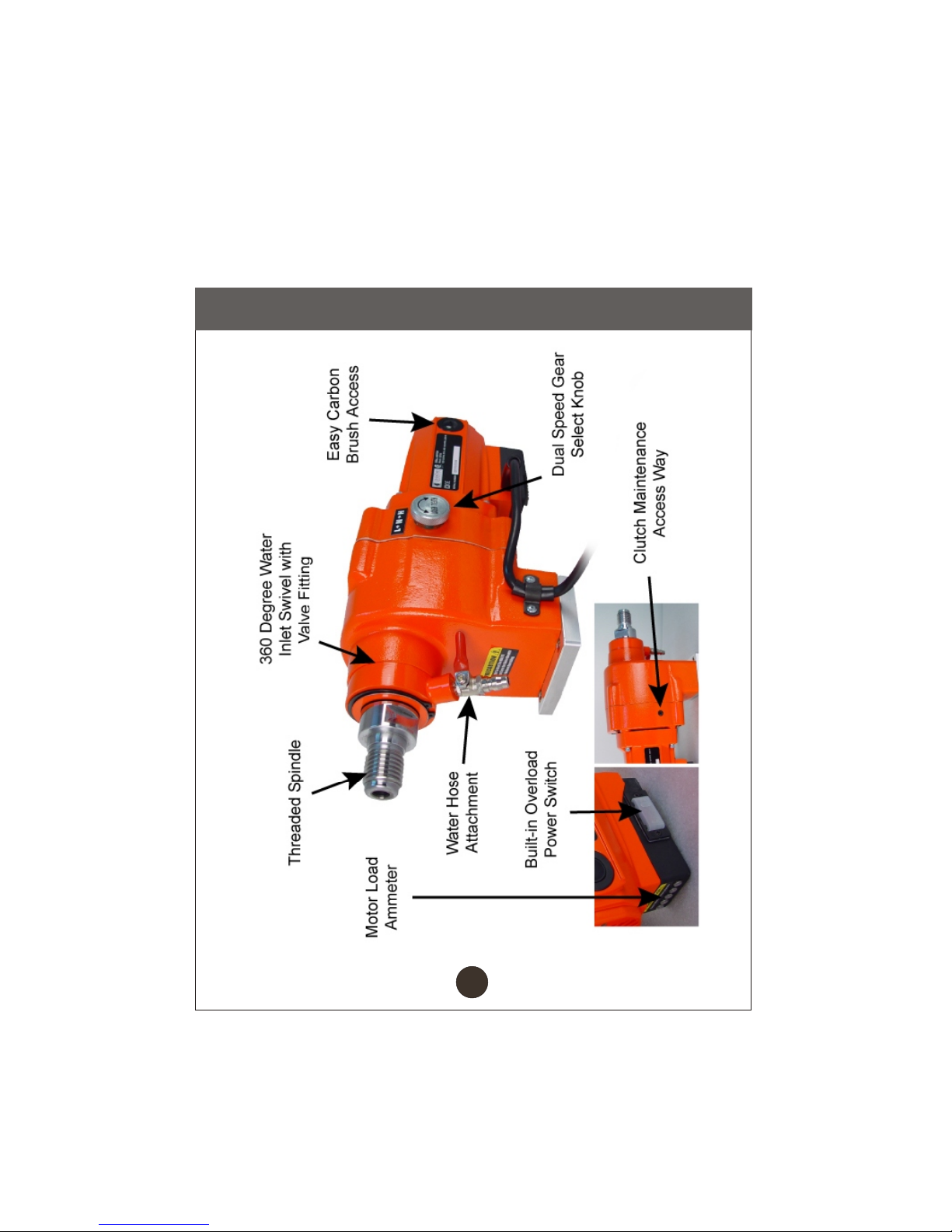

3. Setting the Proper Spindle Speed

A. Located on the side of the drill motor is a circular speed select knob.

Loosen the knob by rotating it counter-clockwise.

B. Slide the knob to the left for low speed (600RPM) or to the right for high

speed (1200RPM) coring.

C. After selecting the required speed, lock the knob by rotating it clockwise.

4. Attaching a Hose to the Water System

A. Pre-attached to the swivel collar is a male quick-disconnect water fitting

with a built water control valve. The swivel assemble allows a hose to attach to

the drill motor from any angle rotated about the spindle axis. Water will be fed

through the spindle and down the core bit.

B. Attach a water hose with the proper female quick-disconnect fitting to the

drill motor’s water inlet.

C. Allow water to flow through the system to make sure flow is continuous and

the rate is sufficient. Shut-off the flow by turning the valve on the swivel collar.

7

FEATURES

8

Model

Spec

VOLTAGE

POWER

SPEED

PHASE

APPLICABLE

BIT DIAMETER

WEIGHT

CB700

115V (60Hz)

3HP (2.2kW), 20A

600 ~ 1200 RPM

1" (25MM) ~ 8" (203MM)

48 LBS (21.8 KG)

SPECIFICATIONS

1

9

OPERATION

1. Coring Operation

A. Place water collecting ring in place as necessary.

B. Make sure the drill stand is properly secured to the work surface. If not

follow the instructions provided in the drill stand manual.

C. Check that the spindle speed is at the correct setting. If not adjust as

instructed in the “setup” section.

NOTE: The motor must be OFF and the spindle must not be in motion when

changing the speed setting. Failure to follow these conditions can result in gear

or motor damage.

D. Turn the water valve on the drill motor on. There must be sufficient flow of

water to the core bit.

E. Activate the drill and allow the spindle to achieve peak RPM before letting

the bit engage the work surface.

F. During the initial portion of the coring process, the bit may wander. Apply a

light amount of force at first until the bit appears to have cored out a groove.

G. While coring do not apply too much downward force. Refer to the motor

load ammeter as reference. To achieve constant even and sufficient force, keep

the yellow LED lit. Do not allow the red LED to become lit.

WARNING: Warning do not core upwards!

10

H. When the coring process is complete, the material removed or inner core

may become lodged inside the bit. Leave the drill running and raise the drill from

the work surface.

I. Turn off the drill and turn the water valve on the drill motor off.

11

MAINTENANCE

1. General Rules

A. Always clean the machine before performing any maintenance/repair.

B. A clean machine makes visual inspection for problems easier to notice.

2. Steps to Follow When Cleaning

A. Please do not use aggressive cleaners (i.e. containing solvents). Do not use

high-pressure water jets, aggressive detergents or solutions and liquids with a

temperature exceeding 86ºF! Use a fluff-free cloth only.

B. For the sake of safety, no water/cleaning liquid/vapor may penetrate into the

electric motor, connectors/plugs, switches, etc. Cover all apertures, holes in the

housing, connectors or plugs, etc. or seal them with adhesive tape!

C. Use a cloth which may be lightly moistened only for removing dust and dirt.

Hard packed dirt can be removed with a soft brush.

D. After cleaning, remove all covers and adhesive tape! All screws/nuts which

you may have loosened must be tightened again! After wet cleaning, try the

machine on a power outlet which is equipped with a power breaker (i.e. fault

current circuit breaker). If the fault current circuit breaker cuts the power supply,

the machine must be inspected by an authorized dealer prior to use!

WARNING: For your safety, before performing any maintenance on the drill turn

OFF the power switch and UNPLUG the power cord.

12

3. Carbon Brush Replacement

A. Unplug the drill motor before proceeding any further.

B. Locate the carbon brush caps found near the air inlet of the motor housing.

They are on opposing sides. Remove the caps using a flat screw driver. The

brushes contact leads should pop out as soon as the caps are off; if not, use the

screw driver to nudge them out.

C. When installing the new brushes, make sure they fit snuggly into the slots.

Do not modify the replacement brushes (i.e. file them down) or use non OEM

brushes, as it may damage the armature and in doing so voids the manufacturer

warranty.

D. Perform steps one through three in reverse to reinstall the caps. Note do not

over tighten the caps are they may be damaged.

4. Adjusting the Mechanical Clutch

A. Unplug the drill motor before proceeding any further.

B. If, while coring, the clutch slips when the ammeter only illuminates the green

or yellow LED indicator, then the clutch nut needs to be tightened.

C. To begin a special tool is needed to engage the clutch. Contact your nearest

authorized distributor or service center for parts.

D. Locate the four recessed socket head screws holding the gear housing

together and remove them.

13

E. Gently pull the gear housing apart. Only a small separation is needed to fit

two flat screw drivers into the housing’s gap. The screw drivers should be

inserted in opposing directions. Gently apply an even amount of force on both

tools to complete the housing separation.

F. Using the supplied open box wrench, hold the spindle in place.

G. Insert the torque wrench with a compatible clutch tool onto the gear

housing clutch nut as shown below. Rotate the wrench clockwise until the gauge

reads 20N-m

I. With the clutch nut properly tightened, reassemble the housing. To

reassemble press the two halves of the housing together. Make sure the

orientation and internal components mate correctly. Now sit the drill on the

motor’s back side so the spindle faces upwards. Using a mallet lightly tap the

housing closed. Every so often turn the spindle to guarantee the gears are

meshing together instead of interfering. Force must be distributed evenly

around the housing to keep the two halves level as they come together.

J. Reattach the four screws to complete the gear housing assembly.

.

14

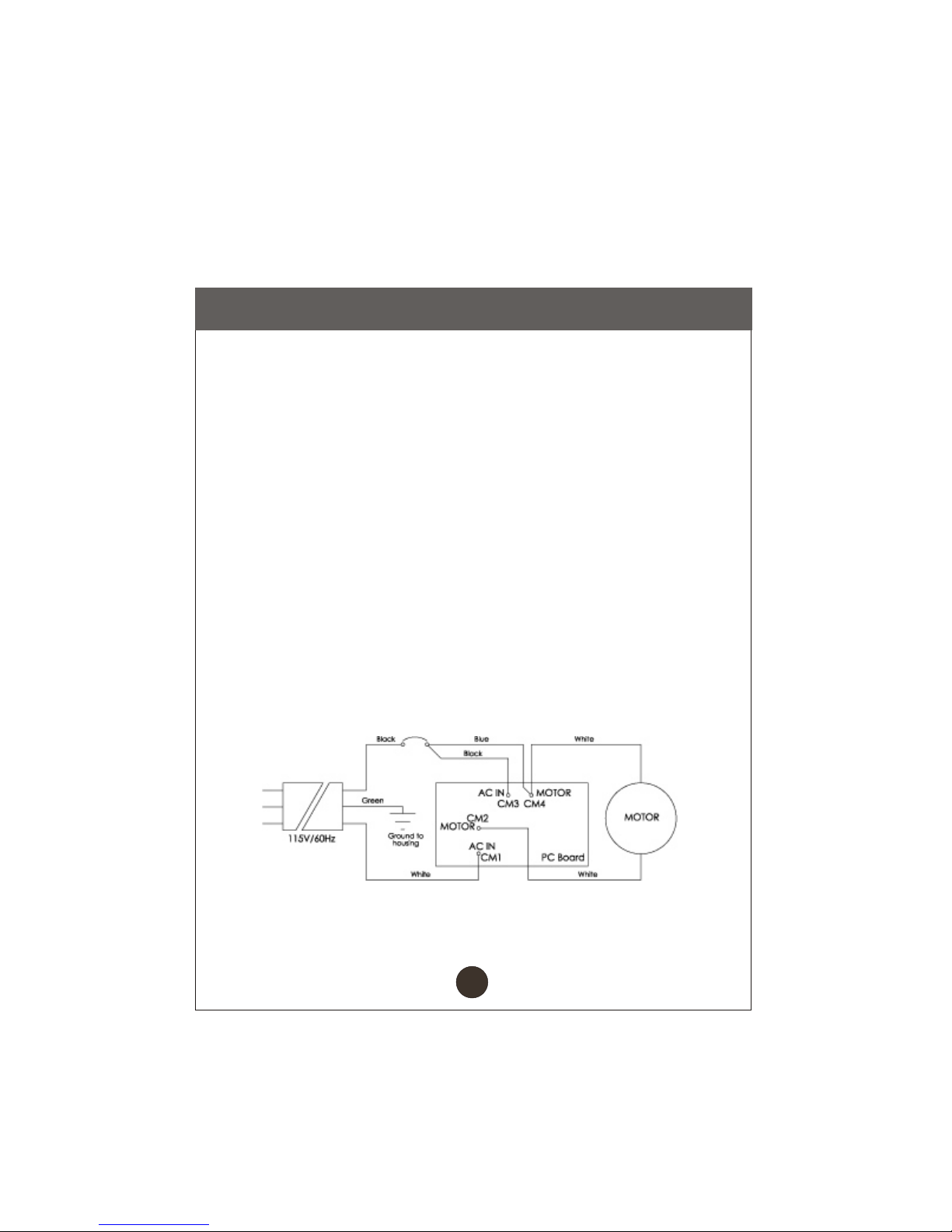

WIRING DIAGRAM

1. Electrical Specifications:

3HP (2.2kW)

115V

20A

600~1200 RPM

60Hz

1 Phase

2. Recommendations

A. It is recommended that a 20 amp circuit be used while operating this drill

machine. This will prevent any loss of power or interruption.

B. Always plug the motor as close as possible to the power source while

operating. This will allow you to receive optimum electricity.

3. Electrical Wiring Diagram

15

TROUBLESHOOTING

Problem: Bit is jammed while coring.

Possible Cause: Debris is lodged between core and bit.

Solution: Rotate bit in both directions using spanner to release

debris then inspect bit.

Possible Cause: Drill stand is not secured to work surface.

Solution: Reset base and secure properly using vacuum base or

anchor.

Possible Cause: Diamond rims have worn away.

Solution: Replace core bit.

Problem: Coring speed has reduced.

Possible Cause: Bit has encountered rebar.

Solution: Adjust feed pressure to avoid motor overload.

Possible Cause: Diamonds have glazed over.

Solution: Dress diamond rim on bit and check water feed rate.

Possible Cause: Diamond rims have worn away.

Solution: Replace core bit.

Possible Cause: New core bit.

Solution: Core at a slow rate during first 2-3 coring cycles.

Problem: Core bit appears to sway.

Possible Cause: Shaft was been damaged.

Solution: Replace shaft and check bearing arrangement.

Possible Cause: Bit is deformed or damaged.

Solution: Replace core bit.

Possible Cause: Chips are attaching to the bit.

Solution: Inspect core bit and increase water flow rate.

16

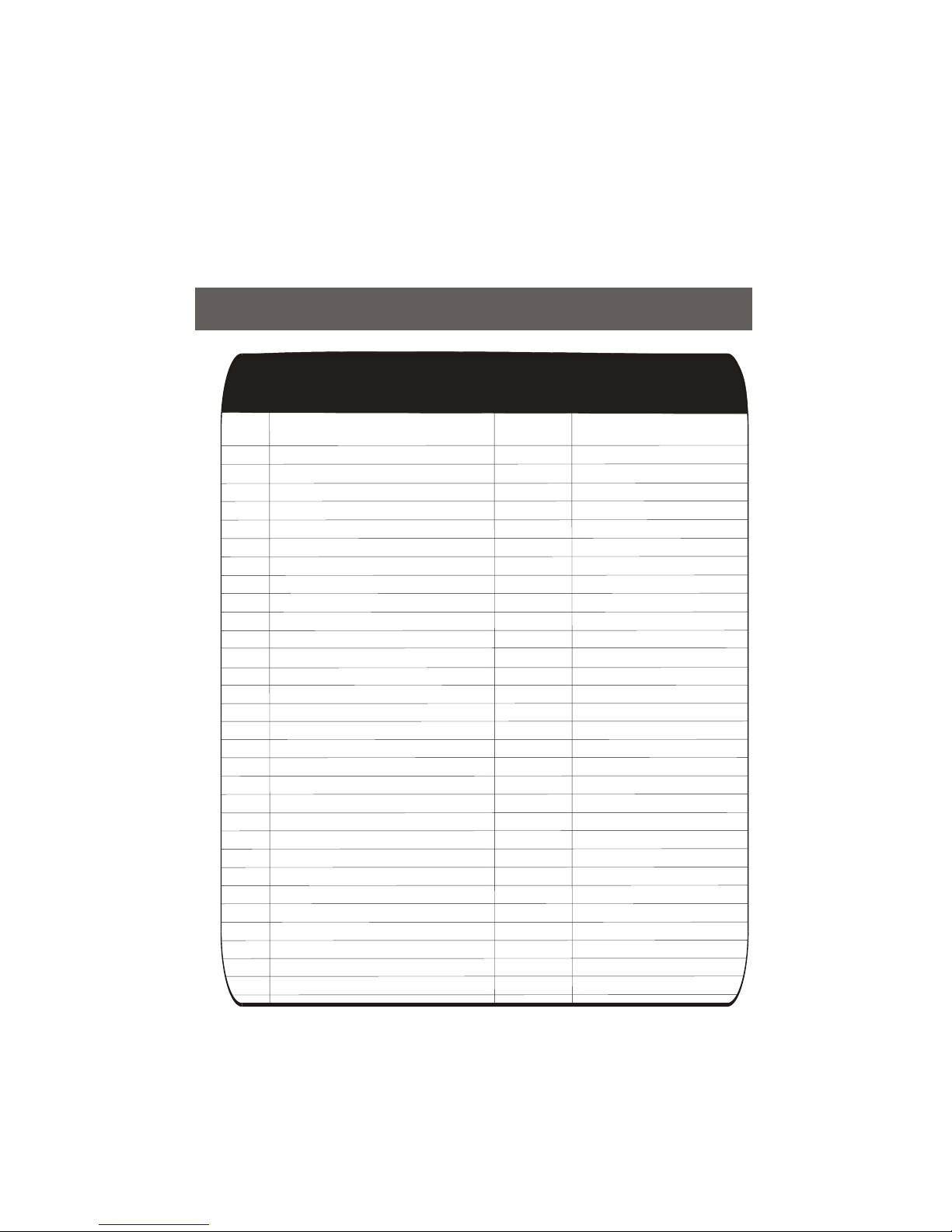

CB700

EXPLODED VIEW

PARTS LIST

CB700

Gear case

Main shaft

Bearing 6206ZZ/C2

Bearing 6206LLU

Snap ring R62

Snap ring S30

Metal collar

Brass collar 35x29x12

First gear

Metal collar

Snap ring S28

Shift ring

Shift lever

O-ring

Metal collar

Brass collar 28x22x9

Second gear

Metal collar

Snap ring S22

Bearing 6202Z

O-ring 60x2.0

Water supply cover

Snap ring S63

Water cock

Bearing 6201Z

First pinion

Woodruff key 5x5x12

Snap ring

Third gear

Seal 48x34x8

ITEM# QTY PART NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

2

2

1

1

1

3

1

1

1

1

6063050

6063051

6063052

6063053

6063054

6063055

6063056

6063057

6063058

6063059

6063060

6063061

6063062

6063063

6063064

6063065

6063066

6063067

6063068

6063069

6063070

6063071

6063072

6063073

6063074

6063075

6063076

6063077

6063078

6063079

PARTS LIST

CB700

Second pinion

Metal collar

Forth gear

Plate

Friction plate

Brass collar

Fifth gear

Disk spring 35.2x18.3x2.0

Metal collar 5T

Fine U-nut

Diaphragm

Socket head cap screw

M8x1.25x60L

Spring washer

M8 ODx13.6 ODx1.8T

Speed change knob

Rubber washer

Plug

Baffle

Bearing 6201LLU

Armature

Bearing 6200ZZ

Filling ring 6200

O-ring

Field

Round head phillip screw -

cone point M5x85

Spring washer 5MM

Flat washer 5MM

Motor house

ITEM# QTY PART NO.

31

32

33

34

35

36

37

38

39

40

41

41-1

41-2

42

43

44

45

46

47

48

49

50

51

52

53

54

55

1

1

1

1

1

1

1

4

1

1

1

4

4

1

1

1

1

1

1

1

1

1

1

2

2

2

1

6063080

6063081

6063082

6063083

6063084

6063085

6063086

6063087

6063088

6063089

6063090

6063091

6063092

6063093

6063094

6063095

6063096

6063097

6063098

6063099

6063100

6063101

6063102

6063103

6063104

6063105

6063106

Table of contents

Other Diamond Products Drill manuals