Diatest DIATRON 2200 User manual

DIATRON 2200

Document No. : DT2200/EN/V2

Edition: 03/2011

© Copyright : DIATEST

Hermann Költgen GmbH

Instruction Manual

DIATRON2200

Column Gauge

2

Manual DIATRON 2200

Contents

1. Introduction

1.1 General information......................................................................................................................... 4

1.2 Measuring and display features ...................................................................................................... 4

1.3 Front and rear panel ....................................................................................................................... 5

1.4 Dimensions ..................................................................................................................................... 6

1.5 Hole pattern for interconnection ..................................................................................................... 6

1.6 Technical data ................................................................................................................................ 7

2. Getting started

2.1 Delivered items ............................................................................................................................... 8

2.2 Fitting the base ............................................................................................................................... 8

2.3 Fitting the modules ......................................................................................................................... 8

2.3.1 Removal of DIATRON2200 column cover ................................................................................... 8

2.3.2 Connecting the modules .............................................................................................................. 9

2.3.3 Fitting modules in DIATRON2200 column gauges ...................................................................... 10

2.3.4 Fitting of bus terminator ............................................................................................................... 10

2.3.5 Fitting of DIATRON2200 column cover ........................................................................................ 11

2.4 Measurement input addresses ........................................................................................................ 11

2.5 Connecting several column gauges ................................................................................................ 12

2.6 Power supply connection ................................................................................................................ 13

2.7 Connecting a foot or hand switch .....................................................................................................14

2.8 Connecting adaptors for tolerance outputs ......................................................................................14

2.9 Connecting a PC, multiplexer or statistic printer .............................................................................. 15

2.10 Connection of wireless module ......................................................................................................15

2.11 Connection of probes, air plug gauges, sensors and measuring instruments ................................16

2.12 Modules at a glance .......................................................................................................................18

2.13 Power on / Self-test ........................................................................................................................18

3. Programming the column gauge

3.1 Encoder functions ............................................................................................................................ 19

3.2 Foot and hand switch functions ........................................................................................................19

3.3 Quick programming guide for programmers in a hurry .................................................................... 20

3.4 Description of calibration mode ........................................................................................................21

3.4.1 Zero adjustment / Calibration ........................................................................................................21

3.4.2 Probe set-up ..................................................................................................................................21

3.5 Description of programming mode ...................................................................................................22

3.6 Basic Setup …...................................................................................................................................27

3.7 Restoring factory settings .................................................................................................................31

3.8 Error messages / Error corrections .................................................................................................. 31

3.8.1 Operating and programming errors ...............................................................................................31

3.8.2 System error ................................................................................................................................. 32

4. Working with the column gauge

4.1 Initial start-up ....................................................................................................................................33

4.2 Measurement operation ....................................................................................................................33

4.3 Mechanical setup of inductive probes ............................................................................................. 33

4.4 Automatic zero adjustment of gauges ..............................................................................................34

4.5 Automatic gauge calibration .............................................................................................................34

4.6 Multi gauging ( C1...C8 ) ...............................................................................................……………. 34

5. The RS232 interface

5.1 Transmission format and wiring .......................................................................................................35

5.2 Data format ...................................................................................................................................... 35

5.3 Table of commands ..........................................................................................................................35

3

Manual DIATRON 2200

5.4 Requesting measured values .......................................................................................................... 36

5.5 Transfer of measured data ...............................................................................................................36

5.6 Importing measurement values into Windows applications ............................................................ 36

5.7 Importing measurement values into MS-EXCEL ............................................................................. 36

6. Male connector pin assignments

6.1 Measuring controller connectors ......................................................................................................37

6.2 Termina blocks for accessories ........................................................................................................37

7. Accessosries and order placement information ................................................................................ 39

8. Safety Instructions ..............................................................................................................................40

9. Guarantee ........................................................................................................................................ 41

4

Manual DIATRON 2200

1.

Introduction

1.1 General information

1.2

Measuring and display features

Static measuring mode

Dynamic measuring modes : Min, Max, Tir, Mean

Bore measuring mode with automatic function

Multi-gauging measuring modes :Manual or automatic selection of 1 to 8 gauges

Measuring range / Resolution : ± 3,0 mm / 0.1 µm, 0,12 / 0.00001 inches (inductive probes)

± 30 mm / 1 µm, 1,2 / 0.0001 inches (inductive probes)

24 Bit (incremental measuring systems)

Unit :

mm and inches

2-digit numeric display: Gauge number C1 … C8

Measuring input P1 … P8

Basic setup menu L0 … L9

Numeric display ranges

Relative measurements : ± 9.9999 mm / ±99.999 mm, ±.99999 inches / ±9.9999 inches

Absolute measurements : 0 to 99.9999 mm / 0 to 999.999 mm, 0 to 9.99999 inches / 0 to 99.9999

Inches

Number of grades : 1…30

The DIATRON2200 column gauge is an electronic gauge

for connecting 1 to 4 inductive probes (on request also

other modules are available).

The column gauge allows the manual or automatic selec-

tion of 1 to 4 gauges, including static and dynamic meas-

uring programmes and the optional selection (grading) of

workpieces in up to 30 classes.

Highly sophisticated measuring programmes allow a quick

and simple calibration with 1 or 2 masters.

Two numeric displays allow the output of absolute meas-

ured values, comparative deviations or the classification of

workpieces as well as the corresponding gauge numbers.

The 3-colour column display with superimposable toler-

ance limits gives a fast overview over the tolerance result

of the workpieces and is an ideal tool for quality checks of

workpieces in mass production.

The new Bus system of the DIATRON2200 provides solu-

tions for more sophisticated measuring applications

through the simple interconnection of several column

gauges.

5

Manual DIATRON 2200

Numeric display 6-digit

Programming menu

Rotary encoder

Numeric display 2-digit

Dynamic mode display

Column display ranges

± 5.0000 mm ± 0.50000 ″

The 3-colour column display ( red, green, yellow )

± 1.5000 mm ± 0.15000 ″features an

automatic colour selection according

± 0.5000 mm ± 0.05000 ″to the tolerance limits.

± 0.1500 mm ± 0.01500 ″

A maximum of 4 tolerance limits can be programmed.

± 0.0500 mm ± 0.00500 ″

The tolerance limits are output as coloured marks inside

± 0.0150 mm ± 0.00150 ″

the column display.

± 0.0050 mm ± 0.00050 ″

The column display ranges can be set to AUTO or to a fixed range in the BASIC SETUP menu. In the AUTO mode the

column gauge automatically selects the optimal column display range depending on the given tolerance limits. The selected

column display range is shown in the measuring mode on the numeric display by pressing the Encoder button

for more than 2 seconds. User-defined column display ranges can be programmed with the PC software DT2200_PC.EXE.

1.3

Front and rear panel

RS232 connector

Foot / Hand switch and

tolerance outputs

Power supply

100...240 VAC

Tolerance limits (4)

Measuring module for 1, 2

or 4 inductive probes

3-colour column

Bus terminator

6

Manual DIATRON 2200

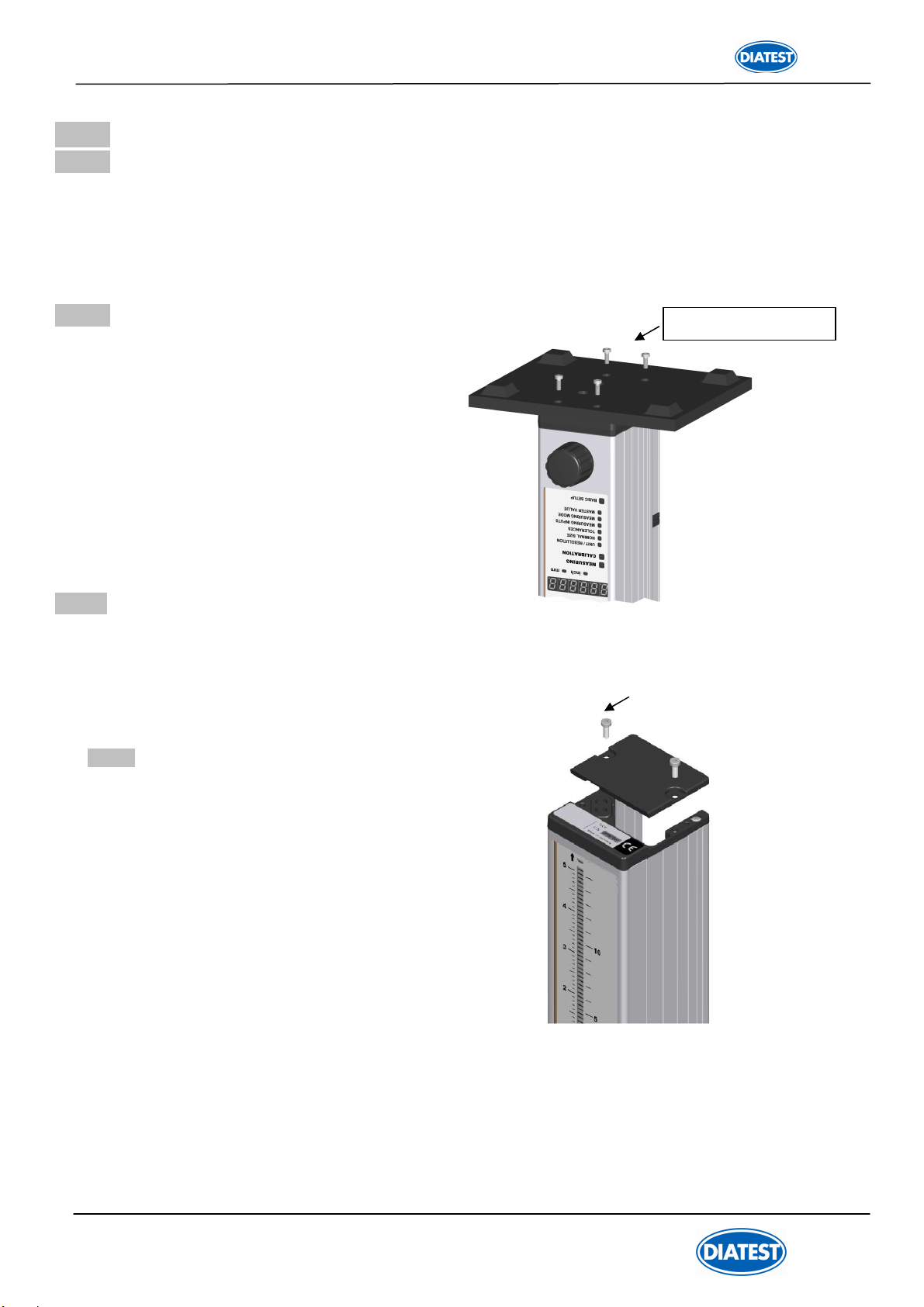

1.4 Dimensions

1.5

Picture: Column display with base

Picture: Column display with base

7

Manual DIATRON 2200

1.6 Technical data

Mechanical characteristics

Case

Base plate Aluminium anodised, plastic top and bottom parts

Aluminium powder-coated

Front panel Plexiglass

Control element Rotary encoder with button

(16 detents / rotation)

Dimensions W x H x D / Weight 56 x 418.5 x 86 mm / 1340g ( incl. Base plate

( DIATRON2200 incl. Base plate, power supply and interface

modul= 1650g )

Electrical characteristics

Power supplies

Primary switched power supply 100 to 240VAC, 45 to 60Hz

Max. power consumption 2.5 VA ( without measuring modules )

Display

Numeric display Column display

Scale with 103 and 2 LEDs for “out-of-range” display,

3-colour, with automatic colour selection and

programmable tolerance marks

Numeric display

6-digit and 2-digit LED displays: 7.62 mm, red

LEDs

Mode, Einheit, Programmiermenüanzeigen 17 LEDs, red

Connections

Interface (RS232)

9-pin SUB-D port, hardware: EIA RS232 standard,

data format corresponds to OPTO RS232

2 trigger inputs / tolerance outputs

(Ft 1 / Ft 2) 9-pin SUB-D port

Trigger input for external contacts and serial

output for OC3, OE3 and OP3 adapters

Measurement parameters

Measuring range / Resolution

± 99,9999 mm / 0.1 µm, ± 4,00000 / 0.00001 inches

± 999,999 mm / 1 µm, ± 40,0000 / 0.0001 inches

Resolution Auflösung

16 bits ( analogue ),

24 bits ( incremental measuring systems )

Sampling rate Messrate 50 measurements per second

For measurement error specifications, linearity, hysteresis and temperature drift please refer to the technical

data pertaining to the measuring module in question

Bus

Bus

9-pin SUB-D male (input) / female ( output ),

Hardware: EIA RS485 Half Duplex, automatic addressing,

max. of 64 clients, max. Bus length 1200 m

Environmental condition

Operating temperature range 0 ... 50°C

Storage temperature range -30 ... +60°C

Protection Front panel IP65 ( CEI / IEC 529 )

Rear panel depending on the measuring modules

Electromagnetic compatibility (EMC)

Electromagnetic compatibility ( EMC ) Generation of interference according to EN50081-2

Resistance to interference according to EN50082-2

8

Manual DIATRON 2200

2. Getting started

2.1 Delivered items

Column gauge, base with 4 screws ( M3x8 ) for fixing, instruction manual, programming card, and

a 2.0 mm Allen key.

Further accessories, such as measuring controllers, power supply modules, measurement

modules, foot switches, or adaptors according to shipping order.

Please check the shipment for completeness and keep the packaging.

2.2

Fitting the base plate

Use the Allen key ( included in shipment )

to fixate the screws of the base and set

the column gauge on a solid base.

!!! Do not overtighten screws !!!

2.3

Fitting the modules

The DIATRON2200 column gauge has been developed for use in modules and provides for the connection

of 1 to 4 (8) probes. The respective modules of the this series can be fitted to the rear panel of the

DIATRON2200 to connect probes (pls. ask).

2.3.1 Removal of DIATRON2200 column cover

Use the Allen key ( included in

shipment ) to undo and remove both

retaining screws of the column cover.

Then remove the column cover.

4 x DIN 7984 M3 x 8

9

Manual DIATRON 2200

A DIATRON2200 column gauge that comprises modules is configured in a fixed order. If one single

DIATRON2200 is to be configured, the power supply model ( 1 ) always has to be fitted first, followed by

the measuring controller module ( 2 ) and then finally ( starting with no. 3 ) the measuring and interface

modules in no fixed order. The address designation ( Ch.1 to Ch.8 ) of the connected sensors or measur-

ing instruments determines the order. The DIATRON2200 column gauge can read a maximum of 8 con-

nected sensors or measuring instruments.

If several DIATRON2200 are to be connected, the adaptor cable ( 1 ) is to be fitted first, followed by the

power supply module ( 2 ), then the measuring controller and finally the measuring and interface module in

no fixed order.

One power supply module can support up to 3 DIATRON2200 column gauges in this way. If more than 3

DIATRON2200 are interconnected, an additional power supply module has to be fitted for the fourth

DIATRON2200.

Extensions cables can be used at any point between the individual modules, if needed. Sensitive signal

leads from inductive probes, configurations can hence be avoided. The total maximum length of all exten-

sion cables must not exceed 1200 m.

2.3.2 Connecting the modules

(1) Push both red levers of the first module against the stop and rotate to the stop

( set up )

.

(2) Connect modules.

(3) Rotate back both red levers to lock the modules while pressing them together.

Follow steps (1), (2) and (3) to connect the modules one after the other.

The following table indicates the installation sequence of the modules.

Position 1 is the bottom position later on, and is screwed to the base of the DIATRON2200 column

gauge.

!!! Important : The bottom module must be equipped with bolts to do so.

Position Module

1 Connection cable

( only if interconnecting several column gauges )

2

power supply modules

3

measuring controller module

4 measuring and interface modules

Important :

Should an module already be equipped with bolts

( e.g. when using an connection cable )

,

please replace the bolts with 2 cross-recessed screws

( included in shipment )

in order to en-

able connecting of modules.

(1) (2) (3)

10

Manual DIATRON 2200

2.3.3 Fitting modules into the DIATRON2200 column gauge

Once the modules have been connected, they are slid into the DIATRON2200 column section as a

package from the top and are then screwed to the column base using both cross-recessed screws.

!!! Do not overtighten screws !!!

If modules have already been fitted into the DIATRON2200 column and additional modules are to

be installed, then all previously fitted modules must be removed first.

Loosening and removing previously fitted modules :

The modules are screwed to the DIATRON2200 base by means of 2 screws. At first both cross-

recessed screws must be loosened by using a suitable screwdriver in order to remove the fitted

modules. Two lock washers keep the screws in place and they remain in the DIATRON2200

base. The base does not need to be removed. Once both screws have been completely loos-

ened, the modules can be slid to the top of the column and removed from it.

After removal of the initially fitted modules, additional modules

can be added. Afterwards the complete module package can be

slid into the DIATRON2200 column section. Finally the module

package is screwed to the column base.

2.3.4 Fitting of bus terminator

Prior to inserting the modules into the column profile, the bus terminator connector is attached to

the vacant port of the last module and screwed to it.

If the last module has not been fitted with bolts to fix the terminator connector, both cross-recessed

screws will have to be removed and replaced with bolts.

The bolts are included in the shipment !!!

Remove modules

Loosen screws

11

Manual DIATRON 2200

About the bus terminator :

The purpose of the bus terminator is to terminate the bus lines electrically, to seal the open port,

and to provide information on the function and the power supply of the column gauge.

The “VCC” LED lights up when the power supply to the column gauge is secured. The “VCC” LED

will be extinguished, if the power supply module has been overloaded due to external consumers,

such as digital probes with high current consumption, or as a result of voltage drops due to long ex-

tension cables. The design, however, allows adding power supply modules

between any gauging and interface modules at will, to compensate voltage drops.

The “RUN” LED lights up, when the self-test of all modules has finished successfully.

The “RUN” LED will not light up and will thus signal that the could not be completely checked, if

more modules have been fitted than can be addressed by the column gauge.

Note : The “RUN” LED will not issue an error message in this case, but instead signalises the

incomplete self-test of modules that cannot be addressed.

2.3.5 Fitting of DIATRON2200 column cover.

Place the column cover on top of the DIATRON2200

and fix with two Allen screws ( M3 x 8).

!!! Do not overtighten screws !!!

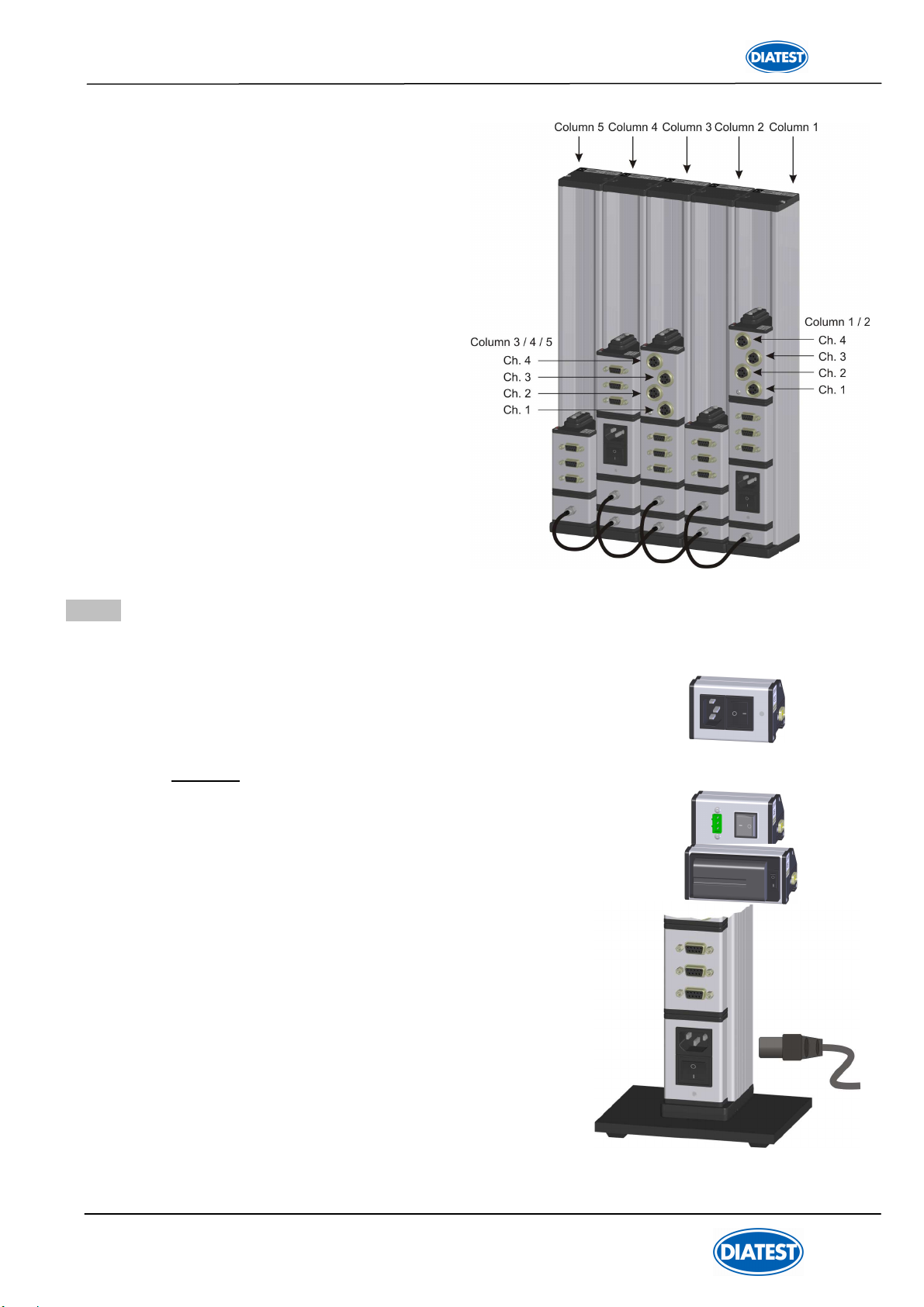

2.4. Measurement input addresses

The measurement inputs are referred to

as Ch.1 to Ch.8 for subsequent programming.

The bottom measurement input is always

Ch.1. It is possible to connect more than 8

measurement inputs, the DIATRON2200 column

gauge, however, can only address and read in

the first 8 inputs.

Note :

When connecting further column gauges via adapter cables,

the measurement inputs ( Ch.1 to Ch.8 )of the first column

gauge are also available at the subsequent column gauges

and are referred to as the same addresses. Therefore, there

is no complex behaviour to pay attention to when program

ming.

When connecting several column gauges, please take

into account the following facts:

A further measuring module in a series of column gauges

will interrupt the connection to the previous measuring

modules, and make available its inputs for the subsequent

column gauges, including the one it is fitted into.

See also example 2 on page 13 of this manual.

Ch. 7

Ch. 6

Ch. 5

Ch. 4

Ch. 3

Ch. 2

Ch. 1

Ch. 8

Bus terminator connector

Measuring

controller

module

Power supply

module

12

Manual DIATRON 2200

2.5 Connecting several column gauges

Adapter cables are utilized to connect several column gauges.

The adapter cables fulfil two tasks :

1.) Transferring the supply voltage from the first column gauge to the next.

One power supply module can supply power to a maximum of 3 column gauges, depending on the connected

probes, sensors and measuring instruments. The number of column gauges decreases, if the current con-

sumption of the connected measuring instruments exceeds 200 mA. As shown in Example 2, power supply

modules can be added at will. Each module performs the function of supplying power up to the next power

supply module

.

2.) The measurement inputs Ch.1 to Ch.8 of the first column gauge are made available for the sub-

sequent column gauges.

The measurement inputs are passed on to the subsequent column gauges via the adapter cables. The data

flow direction within the adapter cable is always from the thinner adapter housing towards the thicker adapter

housing. A further measuring module in a series of column gauges will interrupt the connection to the previous

measuring modules, and make available its inputs for the subsequent column gauges, including the one it is

fitted into. See also example 2 on page 14 of this manual.

Mechanical connection of column gauges : The housing connector underneath the column cover

serves to link together the column gauges. Take the

connector out of its storage and screw it together with

the column cover.

!!! Do not overtighten screws !!!

Example 1 : connecting 3 column gauges

The three-column gauges are linked together via two

adapter cables. The adapter cables are always fitted in

the first position

( bottom

slot )

, whereat the thinner

adapter section is always fitted to the first column

gauge. When using several adapter cables make sure

that the thinner adapter section is fitted in the first posi-

tion, with the thicker adapter section of the arriving ca-

ble directly above it. The power supply module of the

first column gauge supplies all three column gauges

with power. The measurement inputs Ch.1 to Ch.4 are

available at all three column gauges.

13

Manual DIATRON 2200

2.6 Power supply connection

There are three modules available to supply the column gauge with power :

1. Standard

Switched-mode power supply featuring wide range

voltage input from 100 to 240 VAC, 45 to 60 Hz

Optional:

2. DC to DC converter for input voltage range from 9 to 32 VDC

3. Rechargeable battery (accu-pack) module for battery-operated systems.

The module allows quick battery replacement. Rechargeable batteries

with capacities of 1850 / 4000 and 5500 mAh are available.

( Example : DIATRON2200 with 2 inductive probes and a 4000 mAh battery

Pack can operate for approx. 12 to 15 hours )

First read the sticker information on the fitted power

supply module and then check whether the module is

suitable for your mains voltage respectively DC voltage.

Use the enclosed power cable to connect the DIATRON2200.

Important !!! Insert device plug into grounded

outlet only

Example 2 : connecting 5 column gauges

The five column gauges are linked together via four

adapter cables. The cables are always fitted in the

bottom positions, as shown

in the illustration. The measurement inputs are

passed on from the thinner adapter section towards

the thicker adapter section. When using several

adapter cables make sure that the thinner adapter

section is fitted in the first position, with the thicker

adapter section of the arriving cable directly

above it. The power supply module of column 1

supplies columns 1, 2 and 3 with power. The power

supply module of column 4 interrupts the further

power supply from column 1 and supplies columns 4

and 5 with power. The measuring module in column

1 makes available the measurement inputs ( Ch.1 to

Ch.4 ) for columns 1 and 2. The measuring module

in column 3 interrupts the connection to the meas-

urement inputs from column 1 and makes available

its own measurement inputs at columns 3, 4 and 5.

14

Manual DIATRON 2200

Ft1

Ft2

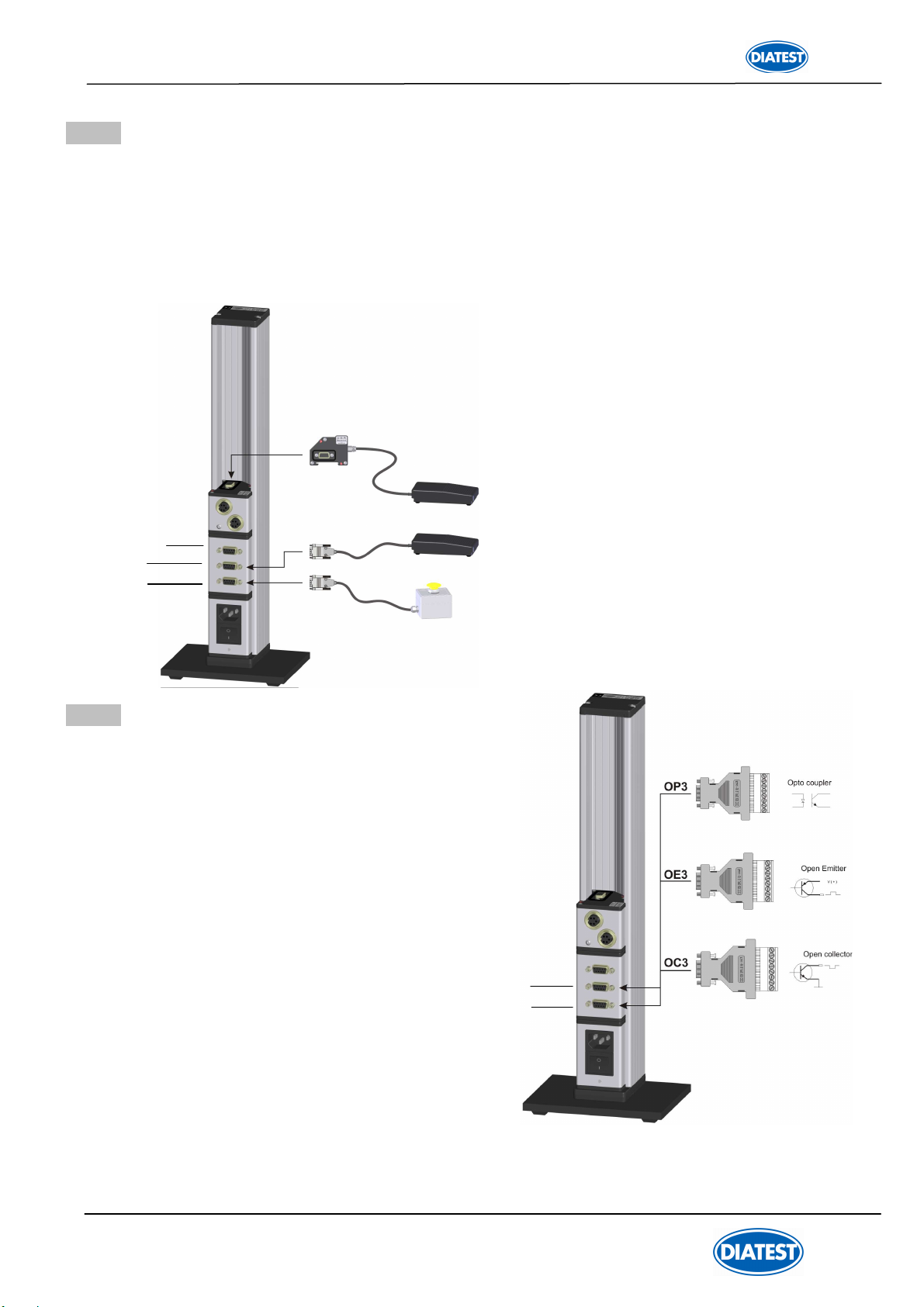

2.7 Connecting a foot or hand switch

The foot or hand switches are connected to the Sub-D ports Ft1 and Ft2 of the measuring controller.

A third switch input is available, if an foot or hand switch is used. The foot or hand switch can

be added at any place behind of the.

The functions of the foot or hand switches can be configured in the “BASIC SETUP”

menu ( L3 -L5 ).

Important !!!

Secure all connections by screwing them tight.

Plug-in connector pin assignments :

see Chapter 6

2.8 Connecting adapters for tolerance outputs

The adapters for the tolerance-controlled

outputs are connected at the rear of the

column gauge to the Ft1 or Ft2 Sub-D ports

of the measuring controller.

A total of 5 tolerance-controlled outputs are available:

1. Upper tolerance limit ( red ) exceeded

2. Upper intervention limit ( yellow ) exceeded

3. Measured value OK

4. Below lower intervention limit ( yellow )

5. Below lower tolerance limit ( red )

Types of connection adapters (on request):

Open collector adapter

Open emitter adapter

Optocoupler adapter

For

adapter pin assignment of OC3 / OE3 / OP3

see Chapter 6; for more information on adapters

see Data Sheets.

RS232

foot switch

Ft2

Ft1

15

Manual DIATRON 2200

2.9 Connecting a PC, multiplexer or statistic printer

A PC

( COM 1… 8, USB )

, a multiplexer or a statistic printer can be connected at the rear panel of the

column gauge via the RS232 Sub-D port of the measuring controller.

See Chapter 6 for RS232 pin assignment !!!

Select connection cable or adapter according to

.. . the interface of the PC, multiplexer, statistic printer,

or other recording device.

DT2200-K-RS232 cable....

RS232 connection cable for PC COM1 to COM8 interface

DT2200-K-USB cable .......

USB connection cable for PCs incl. driver software for emulation of

COM1 to 127 interfaces

RSD-Adap

Connection cable with interface converter to Mitutoyo Digimatic output

( cable converts RS232 output to DIGIMATIC output )

RSA-Ada

adapter with digital / analogue converter to output analogue voltages to a terminal block

( adapter converts RS232 output to ±10V analogue output )

2.10 Connection of wireless module

PC-RS232 cable

PC-USB cable

RSD-Adap ( Mitutoyo Digimatic)

RSA-Adap ( analogue output of measured values, ± 10V ))

RS232

RS232

The wireless module is connected at the

rear of the column gauge to the RS232

port. The wireless module enables the

wireless transmission of measured values

to PCs.

16

Manual DIATRON 2200

2.11 Connection of probes, sensors and measuring instruments

The modular design in conjunction with the measuring and interface modules makes it possible

to connect virtually any probe, sensor or measuring instrument to the column gauge. A maximum of 8

measurement inputs can be handled by the DIATRON2200. It is possible to connect more than 8 inputs,

however, the additional inputs are ignored. The RUN LED on the bus terminator connector does not light

up, if the surplus modules cannot be completely addressed

( see page 10, Information on Bus Terminator )

. The

measuring and interface modules can be combined in any order and allow the simultaneous connection of

different types of sensors

( inductive, digital, etc. )

. For an overview of measuring and interface modules see

Chapter 2.12.

Important !!! Reliable measurements can only be guaranteed,

if the connections have been screwed tight,

so that the contact to the probe shielding is good.

Example 1 : Connection of inductive probes

Prior to connecting the probes, check whether the

probe types correspond to the type designations

listed on the module. Secure the connectors by scre-

wing them tight.

Example 2 : Relocation of measuring and interface modules

Extension cables can be utilized to perfectly adapt meas-

urement configurations with modules to spatial requirements.

The extension cables can be used to interconnect any mod-

ules and reach a maximum length of 1200 m.

Use genuine

extension cables and bus terminators only !!!

Note :

The DIATRON2200-Bus is based on an RS485 interface and has

been developed for the demands of rough industrial use.

Bus terminator

17

Manual DIATRON 2200

Example 4 : Connection of different probes, gauges, sensors and measuring instruments

The example depicts a DIATRON2200

configuration for connection of

2 inductive probes,

2 incremental probes with

1Vss output,

2 Mitutoyo dial gauges

and one calliper gauge ( Sylvac, Tesa,

Mahr, etc. ) with Opto RS232 output.

18

Manual DIATRON 2200

2.12 Modules at a glance

The modules shown below provide an overview of measuring and interface modules that can be connected

to the DIATRON2200 column gauge.

2.13 Power on / Self-test

Every time the column gauge is switched on, a self-test will automatically be performed in order to check all

system components. If an error is detected during the self-test, the numeric display will indicate an error

message.

If the display remains dark, after the DIATRON2200 column gauge was switched on, check both, the VCC

and RUN LEDs on the bus terminator connector.

Both LEDs must be lit !!!

VCC - LED is lit if the supplied voltage is within allowed tolerance values.

RUN - LED is lit if the internal self-test for all modules has finished successfully.

See Chapter 2.3.3 for more information

A display test routine runs subsequently, during which all display elements are switched on, one after the

other. This enables the user to check the function of the display elements. Once the column test has been

completed, information on the release of the software is shown on the six-digit numeric display.

Note :

The RS232 interface of the column gauge is not active while the self-test is running.

19

Manual DIATRON 2200

3. Programming the column gauge

The rotary encoder on the front panel is used to make all settings and carry out any programming.

During programming the user is guided through the individual menus, step by step, and prompted by the

LED and numeric displays. The programming procedure follows a logic structure and becomes self-

explanatory after studying it briefly.

Abbreviations used :

Encoder : Rotary encoder with pushbutton function

CW : Turn rotary encoder clockwise

CCW : Turn rotary encoder counterclockwise

3.1 Encoder functions

Turning the encoder By turning the encoder clockwise ( CW ) in the Measuring Mode, you can switch

to the Calibration Mode or the Programming Mode.

In the Calibration or Programming Mode, the flashing value or function can be al-

tered by turning the encoder.

CW - increases the value or moves to the next function.

CCW - reduces the value or returns to previous function.

Pushing the encoder By pushing the encoder button in the Measuring Mode, the function selected

under Basic Setup is executed.

Programming is carried out in the “BASIC SETUP” menu, section “L2” - Encoder key

function in measuring mode.

Push the encoder button in the Calibration or Programming Mode to accept the

programmed value or the flashing setting respectively.

Push and hold The six-digit numeric display indicates the column display range in the

for > 2 sec. Measuring Mode.

The programmed value of the corresponding, flashing menu LED is displayed for 1

second in the Programming Mode.

This is only valid for the values of “NOMINAL SIZE” and “MASTER VALUE”.

Pushing and Turning Switches to and from the activated gauges C1 to C8 in the Measuring Mode.

The gauges ( C1 to C8 ) are activated in the “BASIC SETUP” menu, section “L0” –

Activate / deactivate gauges.

3.2 Foot and hand switch functions

The column gauge allows connecting up to 3 foot or hand switches. The functions of the particular switches

can be assigned in the “BASIC SETUP” menu, sections L3 to L5.

20

Manual DIATRON 2200

Menu selection and programming

1. Turn the encoder clockwise ( CW ) to switch to the programming mode.

Turn the encoder counterclockwise ( CCW ) to exit the programming mode.

2. The respective display element that can be changed flashes in the programming mode.

3. Turn the encoder to alter the flashing display element. ( CW →+1 or go to the next function;

CCW →-1 or go to the previous function ).

4. Push the encoder button to accept or confirm a flashing setting.

Menu overview

E

En

nt

tr

ry

y

o

of

f…

…

E

En

nt

tr

ry

y

o

or

r

s

se

el

le

ec

ct

ti

io

on

n.

..

..

.

Perform zero adjustment or calibration

Menu for mechanical adjustment of probes

mm (0.0001 / 0.001 ) / inches ( 0.00001 / 0.0001 )

Programming of the column display

Zero point of column display

Tolerance values 1 to 4 as relative deviations from nominal size

Activation of measurement inputs for the selected gauge,

Coefficients and linking of measurement inputs Ch.1 to Ch.8

Static measurement

Dynamic measurement ( Min, Max, TIR, Mean, Bore )

Standard value for zero adjustment

Standard values for gauge calibration

Basic setup

L0. - Activate / deactivate gauges

L1. - Gauge selection by auto recognition ( on / oFF )

L2. - Encoder button function in measuring mode

L3. - Foot / hand switch Ft1 function in measuring mode

L4. - Foot / hand switch Ft2 function in measuring mode

L5. - Function of foot / hand switch in measuring mode

L6. - RS232 output control

L7. - Column display setup ( column range, column starting point )

L8. - Setting the grading mode ( classification )

L9. - Setting password protection

For quick help during programming use the programming reference card !!!

The card provides useful information and is a valuable source of information for daily work with

the column gauge.

First-time users of the column gauge should carefully read the instructions given in the following

chapter, which provides detailed information on the individual programming steps.

Users with basic knowledge of the column gauge should turn to the following chapter for reference.

3.3 Quick programming guide

Unit / Resolution

Nominal size

Tolerances

Measuring mode

Master value

Calibration mode

Measuring inputs

Table of contents