DESCRIPTION

The Thermatel Mass Flow Transmitter Model TA1 provides

high performance measurement of the mass flow of air and

other gases. Using a heated sensor, the mass flow is deter-

mined by accurately measuring the temperature difference

between the heated sensor and the reference sensor. Heat

transfer is due to the mass of the gas flowing past the sen-

sor providing a measurement of the mass flow rate.

The advanced microprocessor provides accurate tempera-

ture compensation as the process temperature changes.

Each instrument is factory calibrated in a NIST flow standard

to provide highest level of accuracy. The electronics permit

the user to configure the instrument for the pipe or duct size,

zero and span, units of measurement, alarms, and other user

specific requirements.

The instrument provides two 4–20 mA output signals; one for

flow measurement, and one for temperature. Each 4–20 sig-

nal can be configured from the instrument.

PRINCIPLE OF OPERATION

The flow element of the TA1 Mass Flow Transmitter

utilizes a heater and two resistant temperature detectors

(RTDs). The heater and the active RTD are contained in one

sensor; the second sensor contains the reference RTD and a

mass balancing element.

The reference RTD measures the temperature of the process

where the flow element is installed. A constant power is pro-

vided to the heated sensor. The active RTD measures the

temperature of the heated sensor. The electronics measures

the temperature difference between the active and reference

RTD.

There is an inherent non-linear relationship between the tem-

perature difference and the mass flow rate. The micro-

processor-based electronics convert the temperature differ-

ence signal to provide a linear measurement of the mass flow

rate. The electronics also provide advanced temperature

compensation which automatically adjusts the flow meas-

urements for changes in process temperature.

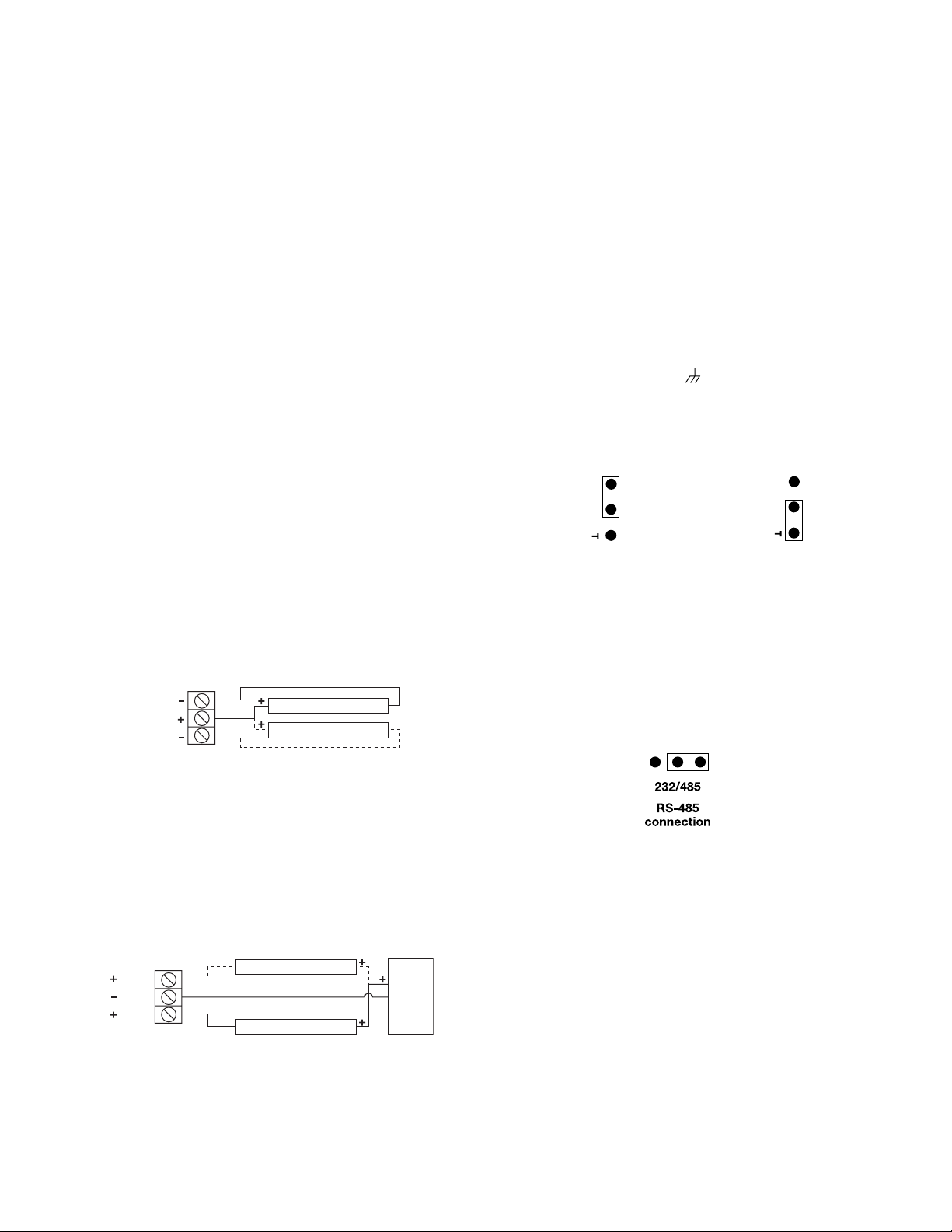

The 4–20 mA output signal can be adjusted to provide max-

imum resolution of flow measurement over the desired range

of the instrument. A separate 4–20 mA signal provides an

output signal of the process temperature. Both 4–20 mA sig-

nals can be wired for either active or passive operation. Refer

to wiring section, pages 4 and 5.

Optional relays provide low or high flow alarm indication and

can be used for diagnostics.

UNPACKING

Unpack the instrument carefully, making sure all components

have been removed from the packing material. Inspect all

components for damage, and report any concealed damage

to the carrier within 24 hours. Check the contents of the car-

ton, making sure it agrees with the packing slip and the pur-

chase order. Verify that the model number imprinted on the

nameplate matches the number on the packing slip and the

purchase order. Report any discrepancies to the factory.

Check and record the serial number for future reference

when ordering parts.

Thermatel®

Mass Flow Transmitter

Model TA1

Instruction Manual and Parts List

TABLE OF CONTENTS PAGE

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

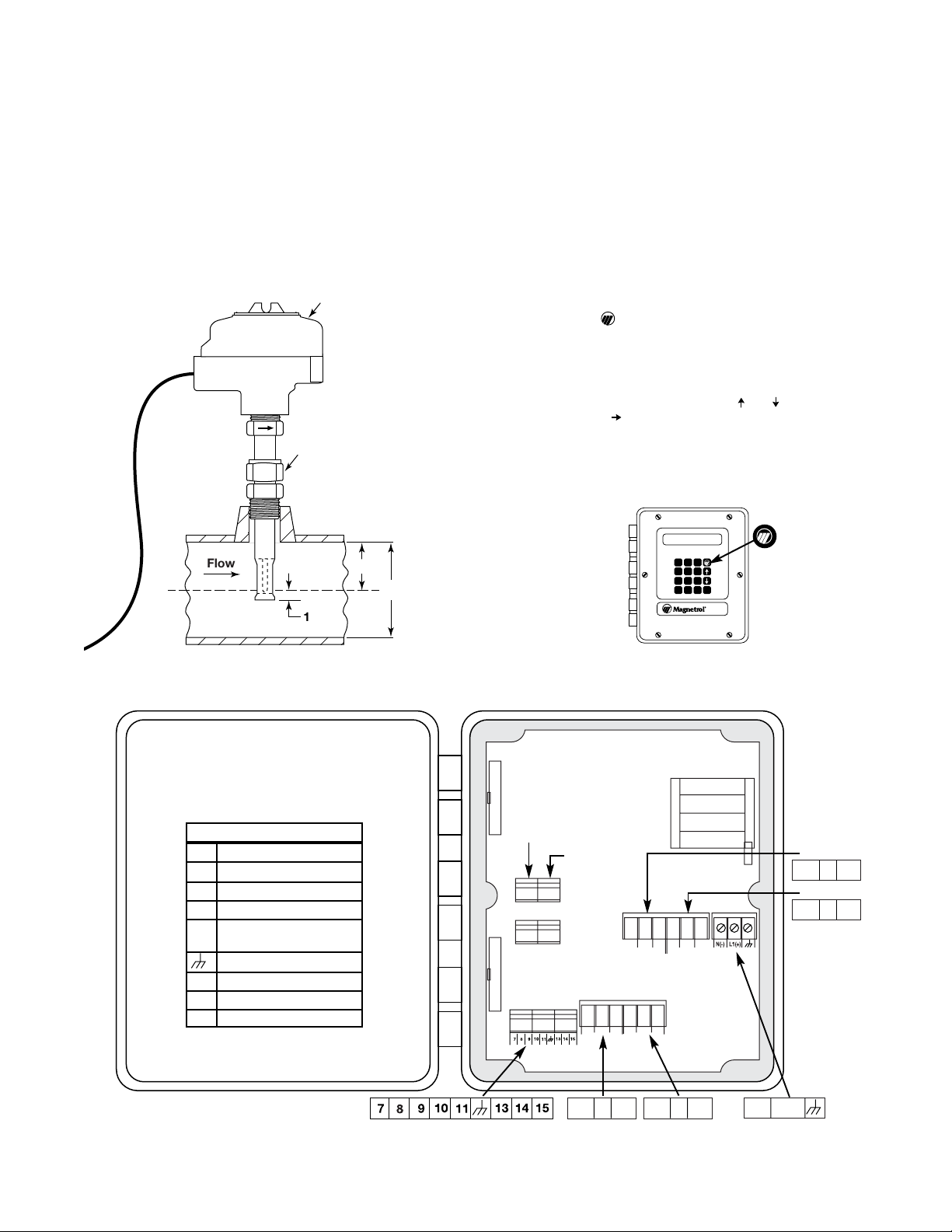

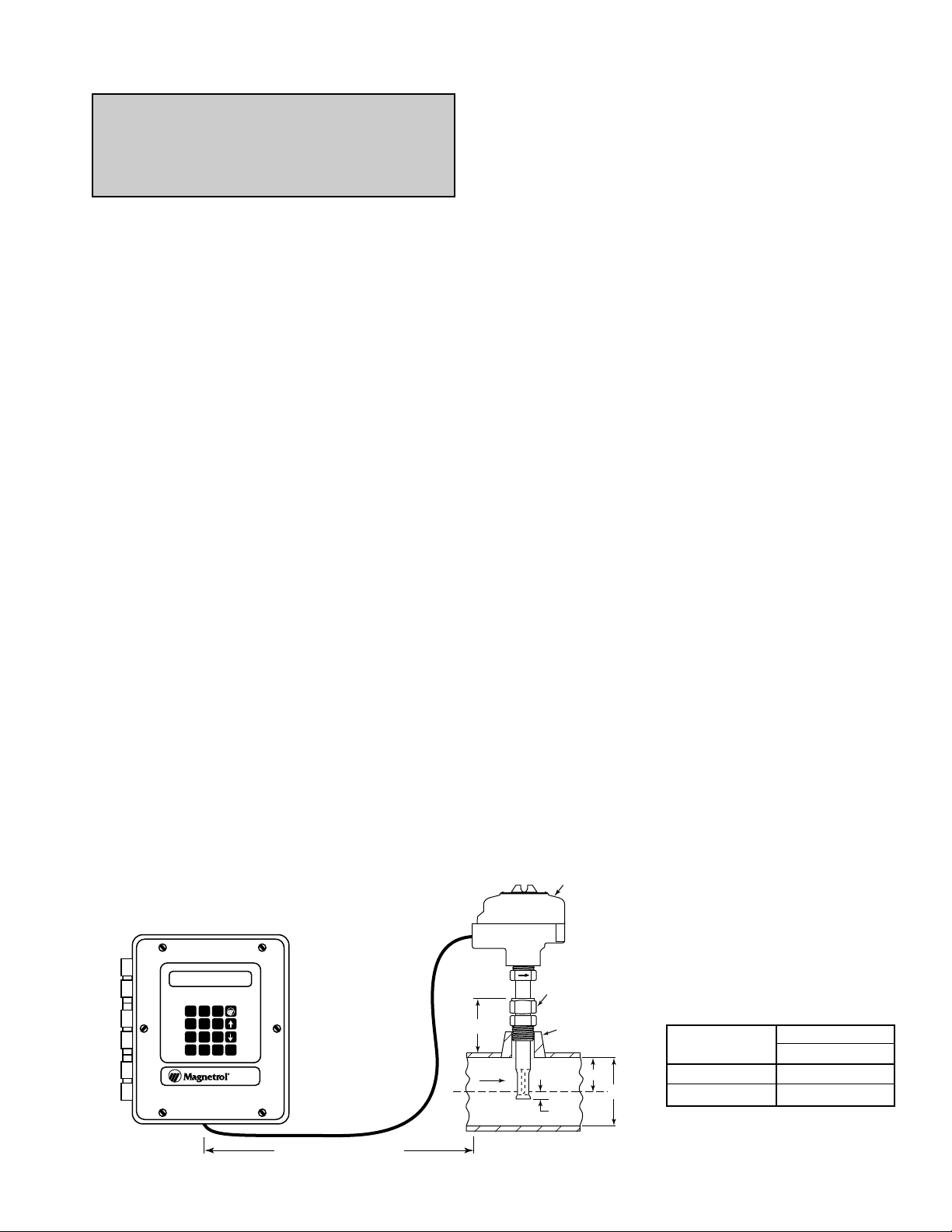

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electrostatic Discharge Handling Procedure . . . . . . . . . . .4

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Digital Communication RS-485/Modbus Protocol . . . . . . .21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31