Diatip CD 600 Economy User manual

Midhage Diatip AB May 2003

1

RETIPPING SYSTEM

CD 600 Economy

For core bit diameters and lengths 35 – 600 mm

Operators Manual

Midhage Diatip AB May 2003

2

DECLARATION OF CONTENTS

Assembly for CD 3

Core bit holders 3

Operating instructions and how to cut of the worn part of the drill bit and

make notches

4

Changing the Matrix and Knife 7

Maintenance 8

Serial number and patent number plate 9

Warranties 9

Adapters 9

Segment- and Index plate Guide 11

Guide on matrixes and knives 12

Straight off Cutting Guide 13

Fittings

Column extension with extra 900 mm

Midhage Diatip AB

Hallandsvägen 21

Box 1020

SE - 269 21 Båstad

Sweden

Tel. + 46 (0) 431 710 09

Fax. + 46 (0) 431 754 07

E-mail: [email protected]

Internet: www.diatip.com

Midhage Diatip AB May 2003

3

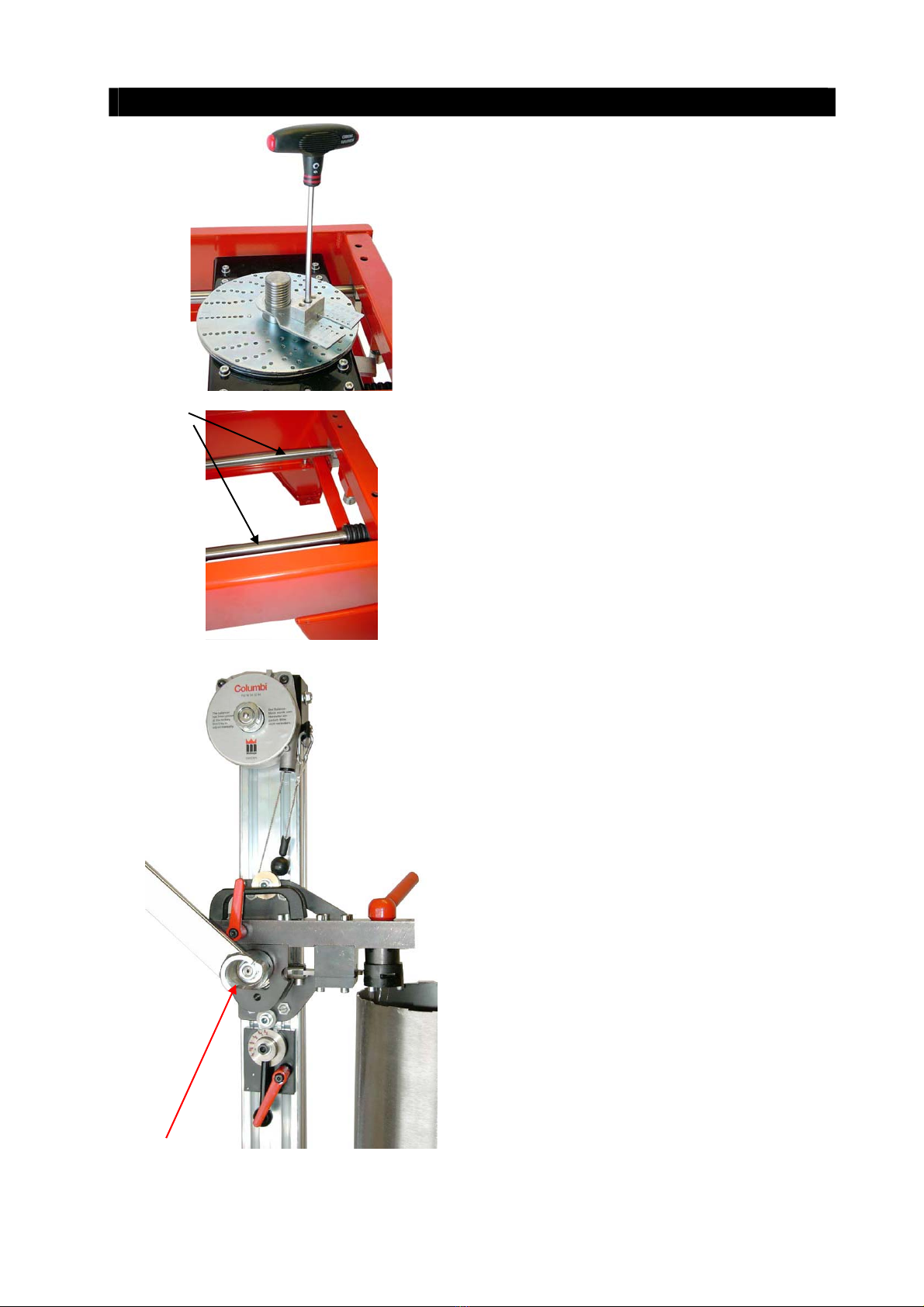

ASSEMBLY FOR COLUMBI CD 600

1

The column is demounted when

delivering.

2

Mount the column with enclosed fittings

at the holder as follows;

Above = 2 bolts with square plates to

fit in to the profiles

Underneath = 2 taps with brass nuts

3

Glue on the two plastic covers on top of

the column and mount the legs

CORE BIT HOLDERS

UNC (1 ¼”) core bit holder

CRI 28 PIXIE (28mm) core bit holder

The CD is equipped either with an UNC

threading or a CRI 28 PIXIE threading

(only for Scandinavia)

Adapters – see page 9 (Optional)

Midhage Diatip AB May 2003

4

OPERATING INSTRUCTIONS and HOW TO CUT OFF THE

WORN PART OF THE DRILL BIT AND MAKE NOTCHES

Segment guide Index pin holder

1

Decide the number of segments that

should be rebrazed on the new rim of the

core bit. Adjust the index pin holder on

the scale that positions the pin over the

index plate. (Refer to the segment guide

located at the end of this manual).

2

Select the side (A or B) of the indexing

plate that corresponds to the core bit

dimensions.

Index plate – this image shows side B

Make sure the surfaces are clean before

placing the index plate on the blank base

plate. Then place the index pin holder in

position over the index plate.

When mounting the core bit the guide pin

should always lay in one of the holes of

the Index plate

2 1

3

Lock the core bit by sliding the core bit

attachment to the end of the slides

(opposite from cutter head). Then twist

the barrel clockwise until the level (1) in

the bottom reach the stop bolt (2). Turn

the barrel so it is fasten properly on to the

core bit attachment. When demounting

the barrel do the same procedure but the

opposite way

Midhage Diatip AB May 2003

5

4 The matrix A1 has three different radii.

Choose which radius is suitable for the

core bit. (Position "D" is only for the 16

mm or 20 mm matrix):

Ø 55-90 mm A

Ø 90-200 mm B

Ø > 225 mm C

Ø > 35 mm D

See also the red plate on the tool set

The matrix A2 and A3 are for radii >/= 35

mm resp. >/= 45 mm

To change position of the matrix loosen

the handle which locks the matrix and

lower enough for the guide pin on the

bottom of the head to come free

VERY IMPORTANT

Guide Pin

5

Be sure that the guide pin on the bottom

of the cutter head fits into the hole on top

of the matrix for the new position

6

Tighten the handle clockwise. After the

matrix is secured in position carefully

check that the cutting knife moves freely

into the matrix.

Midhage Diatip AB May 2003

6

A Balance

block

B

E D F C

7

8

9

10

Loosen the locking lever (A) on the tool.

Lower the cutter head over the edge of

the bit (use the handle (B)) until the

cutting knife (C) is below the worn part of

the barrel and the matrix is inside the

barrel. Make sure that no segment parts

remain where the cut is to be made.

Lock the cutter head in position by

turning the lever (A). (The lever is spring

loaded and can be positioned by lifting

the handle from the shaft and then

turning.)

Move up the height adjuster (D) close to

the wheel (E) underneath on the cutting

tool and lock the lever (F).

Cut the slots for the segments as the

index pin drops into position on the index

plate. Turn the bit clockwise to prevent

unscrewing from the threaded bolt on the

mounting attachment.

Height adjuster

G

11 After the first round, loosen the locking

lever (A) and raise smoothly the cutter

head by lifting up the handle (G) to the

required depth of the notched seats 0 – 5

mm (0” - .197”).

Each line on the scale corresponds to

approximately 1 mm.

Lock the cutter head in its new position

with the lever (A) and, this time, cut

between the slots which were cut for the

segments. Cut all the way around and the

top of the core bit can easily be removed.

Now ready for brazing!

1:st round 2:nd round Remove the worn part

slots notched seats

Midhage Diatip AB May 2003

7

CHANGING THE MATRIX AND KNIFE

1

Remove the existing matrix by turning the

handle counter clockwise. Place the

cutting handle so that the blade stays in

its back position.

2

Loosen the allen screw which holds

existing blade. Pull it out and replace with

the new cutting blade and re-tighten.

3

Insert the new matrix. If the replacement

matrix and blade is the 16 mm or 20 mm

size the arrow on the top must then point

to the "D" position. Tighten the handle.

Guide Pin

4

Be sure that the guide pin in the bottom of

the cutter head fits into the hole on the top

of the matrix.

5

By moving the cutting handle back and

forward, check to make sure that the

blade slides accurately into the matrix and

tighten the handle clockwise.

Midhage Diatip AB May 2003

8

MAINTENANCE

1

Adjust the height of the guide pin if the bit

runs heavily, or too easily, between the

stops on the indexing disc.

H

2

Keep the sliding shafts (H) clean from

concrete dust and cutting parts. Lubricate

the shaft now and then.

I

3

Lubricate the excenter wheel by the

cutting handle (I) now and than.

Midhage Diatip AB May 2003

9

SERIAL AND PATENT NUMBER PLATE

1

The serial number plate is placed inside

the bas frame on the short side

WARRANTIES

Warranties

1

2 years on the machineries except on

wear-out parts such as knives and

matrixes

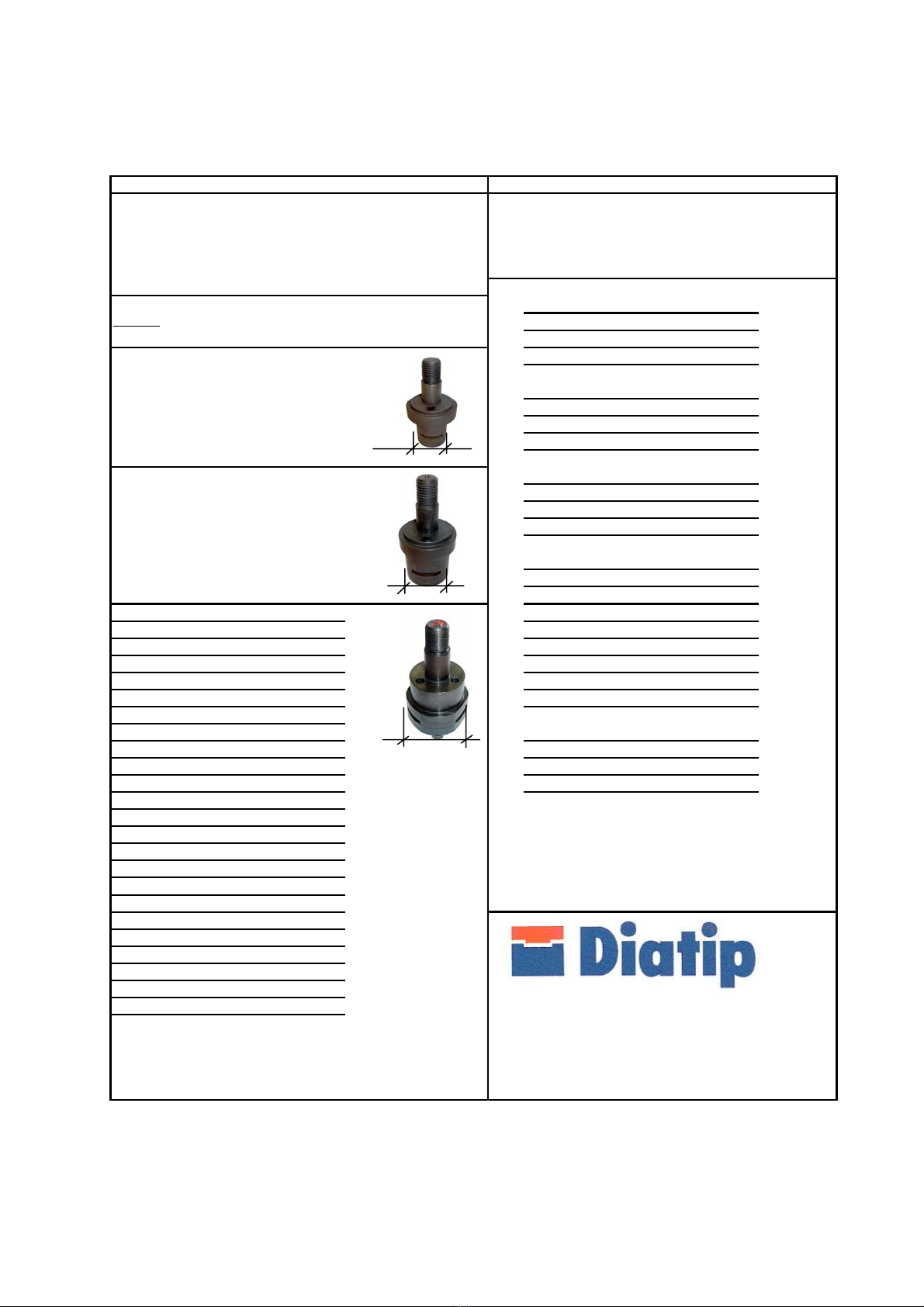

ADAPTERS (Optional)

1

Adapter - from PIXIE CRI 28 mm to

UNC 1 ¼” (Optional)

Article No 010103

2

Adapter – from UNC 1 ¼” to PIXIE CRI

28 mm (Optional)

Article No 010301

3

Changeover Adapter with inside

threading - PIXIE CRI 28 mm to UNC ½”

(Optional)

Article No 010102

4

Changeover adapter with inside

threading – UNC 1 ¼” to UNC ½”

(Optional)

Article No 010302

5

Changeover adapter with outside

threading - PIXIE CRI 28mm to UNC

½ “ (Optional)

Article No 010201

Midhage Diatip AB May 2003

10

6

Changeover adapter with outside

threading – UNC 1 ¼” to UNC ½”

(Optional)

Article No 010203

Fittings

7

Column extension (option) with extra

900 mm

Article No 191 004

Midhage Diatip AB May 2003

11

Segment and Matrix Guide Index System April 2002

for 24 mm and 25,4 mm (1") length for 4-34 segments

of Diamond Segments (for 20 mm resp. 16 mm Plate A + B, 2 sides

segment length about 15% resp. 30% more segments Fork with Guide Pin numbered 4-34

are needed) No. of Guide Pin

Up to outer diam. 31,75 mm (1 1/4") of the core drill, mainly segments position

diamnond rings are used

Core Bit 4A4

*

OUTER diam. No. of 5A5

*

in mm segments Matrix used 6A6

*

7A7

*

8A8

From 35 and larger 4-5 A2 9A9

*

only for 16-20 mm segment length 10 A10

30 mm 11 B11 *

one slot

12 A12

13 B13 *

14 A14

15 A15

From 45 and larger 4-5 A3

for segments upto 25,4 mm (1") 16 A16

40 mm 17 B17 *

one slot 18 A18

From 55 and larger 4-6 19 A19

60-85 A5-6

90 A6-7 20 B20

22 B22

100 B7-8 A1 24 B24

110 B8-9 26 B26

115-132 B9-10

138 B9-11 48 mm 28 B28

150-160 B10-12 30 B30

165-180 B12-14 with three slots, 32 B32

200 B13-15 three diameters 34 B34

and a red arrow

225 C16-18 for position *Use only every second hole in the disc

250 C17-20 A,Bor C

275 C18-20 (see the middle Core Bits with more than 34 segments

300 C19-24 column next) 36 upto 68 segments - cut a second time

350 C20-28 between the indexed slots - beginning

400 C22-30 at A18 upto B34.

450 C24-30

500 C26-32

550 C28-34

600 C30-38

650 C32-40

700 C34-42 Midhage Diatip AB Tel.: +46 431 710 09

With 3-side seats in the tube, the lower number of segments Hallandsvägen 21 Fax: +46 431 754 07

can be chosen. When changing the matrix: S- 269 21 Båstad (Sweden)

Check and make sure that the cutting knife moves

freely into the matrix. E-mail: diatip@midhage.se

Internet: www.swede.com/midhage

Midhage Diatip AB May 2003

12

04-2002

For Matrices with horizontal Knives

Segment slots/openings for

lengths CD 7-28

A

From outer-Ø 55 mm (2 1/4") >

(and larger)

(3 different radiis)

A

20 mm Art. No 550520 800520

A1: The outer dia of the

24 mm "- 550524 800524

Matrix = 48 mm

25,4 mm "- 550525 800525

From outer-Ø 35 mm (1 3/8")

16 mm Art. No 350516 800516

20 mm "- 350520 800520

A2: The outer dia of the

Matrix = 30 mm

Also for other lengths of segments from 5-19 mm - ask for offer!

From outer-Ø 45 mm (1 3/4")

24 mm "- 500524 800524

25,4 mm "- 500525 800525

A3: The outer dia of the

Matrix = 40 mm

For B and C below it is neccessary with 0-90º rotative

knife support. From serial 20 of the CD 7-28 the

B

For Segments Matrices with vertical Knives

and Carbide slots/openings

teeth, grooves B

etc. From Ø25 mm (1") > (and larger)

width

3 mm Art. No 250320 800320

C

Matrices with different angles 0-90º C

of slots/openings

e.g. 5º, 30º, 45º or according to wishes - from Ø35 mm.

A3

Cutting Tools for Retipping Diamond Core Bits

- Guide on Matrices and Knives -

A1

A2

151509

DITEQ P/N:

Midhage Diatip AB May 2003

13

April 2002

Straight Off Cutting Guide

For all countries in the world except the U.S.A. For U.S.A. only

with with with

dia of the circum- 20 mm 24 mm dia of the circum- 1"

core bit ference knife - knife - core bit ference knife -

(mm) (mm) set set (inches) (inches) set

35 110 651 3,140 4

45 141 861 1/4 3,925 4

55 173 981 1/2 4,710 5

60 188 10 81 3/4 5,495 6

65 204 11 92 6,280 7

70 220 11 10 2 1/4 7,065 8

75 236 12 10 2 1/2 7,850 8

80 251 13 11 3 9,420 10

85 267 14 12 3 1/2 10,990 11

90 283 15 12 4 12,560 13

4 1/2 14,130 15

100 314 16 14 5 15,700 16

110 345 18 15 5 1/2 17,270 18

115 361 19 16 6 18,840 19

132 414 21 18 6 1/2 20,410 21

138 433 22 19 7 21,980 22

8 25,120 26

150 471 24 20 9 28,260 29

160 502 26 21 10 31,400 32

165 518 26 22 12 37,680 38

170 534 27 23 14 43,960 44

175 550 28 23 16 50,240 51

180 565 29 24 18 56,520 57

200 628 32 27 20 62,800 63

24 75,360 76

225 707 36 30

250 785 40 33

275 864 44 36

300 942 48 40

350 1099 55 46

400 1256 63 53

450 1413 71 59

500 1570 79 66

550 1727 87 72

600 1884 95 79

Table of contents

Popular Lathe manuals by other brands

Grizzly

Grizzly G9729 instruction manual

Grizzly

Grizzly G0632 owner's manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN ED1000F user manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN ED 1000G operating instructions

Ranger Products

Ranger Products RL-8500 Installation and operation manual

Oneway

Oneway 1224 owner's manual