Dickey-John Instalab 600 Series User manual

Instalab Series 600 Analyzers

11001-1360-200512

i

TABLE OF CONTENTS

Safety Notices ......................................................................................................1

Introduction ..........................................................................................................3

Models ...............................................................................................................................4

Features .............................................................................................................................4

Optional Accessories .........................................................................................................5

Specifications .....................................................................................................................5

Theory Of Operation ..........................................................................................................7

Installation ............................................................................................................9

Printer Connection .............................................................................................................9

Serial Port Configuration ..................................................................................................10

Connector Contacts .........................................................................................................10

Calibration ..........................................................................................................13

Gathering A Sample Set ..................................................................................................13

Samples Required For Calibration ...................................................................................13

Sample Collection ............................................................................................................13

Product Characteristics ....................................................................................................14

Sample Moisture Content ................................................................................................14

Sample Storage ...............................................................................................................15

Developing Calibrations ...................................................................................................15

Regression Data Collection .............................................................................................16

Developing Calibrations With Computer And Regression Program .................................17

Sample Preparation ...........................................................................................19

Grinding Samples ............................................................................................................19

Mixing Samples ...............................................................................................................19

Loading Standard Sample Cup (Dry Powder Samples) ..................................................19

Instalab Series 600 Analyzers

11001-1360-200512

ii

TABLE OF CONTENTS

Operation ........................................................................................................... 23

Operator Controls ............................................................................................................ 23

Basic Operating Concepts ............................................................................................... 27

Mode Selection ................................................................................................................ 30

Analyzing Samples For Data Collection - Modes 1.0, 1.1, 1.2, and 1.3 .......................... 32

Calibration Entry - Mode 2 ............................................................................................... 33

Calibration Storage .......................................................................................................... 34

Calibration Modification And Deletion - Mode 2 .............................................................. 35

Product Name Assignment .............................................................................................. 36

Constituent Number Assignment ..................................................................................... 40

Printing Products And Constituents With Stored Calibrations - Mode 2.1 ....................... 41

Printing User Programmable Product Names - Mode 2.2 ............................................... 41

Printing Programmable Constituent Names - Mode 2.3 .................................................. 42

Printing Product Name Assignments - Mode 2.4 ............................................................. 43

Collecting Reference Or Raw Sample Data - Mode 3 ..................................................... 43

Testing Display, Printer, And Drawer Operation - Mode 3.5 ........................................... 44

Continuous Reference Data Collection - Mode 3.6 ......................................................... 45

Bias Adjustment ............................................................................................................... 45

Display Resolution Modification - Mode 4 ....................................................................... 46

Reference Log Sequencing Selection - Mode 4.1 ........................................................... 47

Entering and Storing Machine Title - Mode 6 .................................................................. 48

Running Reference Logs And Base Gain Settings - Mode 8 .......................................... 49

Disabling Printer Handshaking - Mode 9 ......................................................................... 50

Enabling Printer Handshaking - Mode 9.3 ....................................................................... 50

Date Entry - Mode -1 ....................................................................................................... 50

Troubleshooting ................................................................................................ 51

Maintenance ....................................................................................................... 55

Checking Air Filter ...........................................................................................................55

Cleaning Reference Disk And Sample Drawer ................................................................ 55

Cleaning Aperture Glass ................................................................................................. 56

Fuse Replacement .......................................................................................................... 57

Appendix ............................................................................................................. 59

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

1

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards.

This Safety Alert Symbol identifies important

safety messages in this manual. When you see

this symbol, carefully read the message that

follows. Be alert to the possibility of personal

injury or death.

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in equipment damage.

!

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

2 SAFETY NOTICES

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

INTRODUCTION 3

INTRODUCTION

Quality in design and construction of the Instalab 600 Series ensures the

most reliable Near Infrared Reflectance (NIR) results available. The rotating

sample cup virtually eliminates the problems associated with sample

non-homogeneity - studies indicate up to 3 times better than integrating

sphere and other types of data collection technology. Reliability is further

enhanced by a reference design that incorporates the entire optical system.

An exclusive DICKEY-john feature, Optigain®, enables the user to adjust

the gain for low-reflectance samples. Another exclusive, thermoelectrically

cooled detectors, maximizes both sensitivity and dynamic range.

The Instalab 600 Series is designed and built for trouble-free operation in

virtually any environment - from the lab to the production line. The optics

chamber is completely sealed and thermally isolated. An integrated,

computerized self-test mode continuously monitors instrument performance

and pinpoints errors. Calibrations are stored in a non-volatile EEPROM

system that doesn’t rely on battery backup. Automatic self-test procedures

verify correct operation after each sample.

The unique sampling system makes the Instalab adaptable to nearly any

solid or semi-solid substance. Replaceable filters allow the instrument to be

adapted, easily and economically, for nearly any substance and any

constituent, making the Instalab 600 Series ideally suited for both

development work and for dedicated instrument use. The replaceable filter

feature also allows any change in filter configuration developed by a

research scanning instrument to be easily implemented in satellite Instalabs

for networking.

Near Infrared (NIR) technology offers an important alternative to wet

chemistry, an alternative with a world of applications: control of incoming

raw materials, process control, research, and many more. Virtually any solid

or semi-solid material may be analyzed by the DICKEY-john NIR method.

With sufficient calibration data, the Instalab will provide accuracy

comparable to laboratory results. In fact, in daily operation, the Instalab is

much more repeatable and precise than typical laboratory testing since

operator technique is less crucial and instrument error is minimal.

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

4 INTRODUCTION

Figure 1

Instalab Unit

MODELS

•MODEL 660A utilizes the universally accepted standard set of six

wavelengths commonly used to measure moisture, protein, starch, oil,

etc. in food products.

•MODEL 610FGA includes ten selected filters designed specifically for

use in measuring properties in feed and grain.

•MODEL 610SBA includes ten selected filters designed specifically for

use in measuring properties in soybeans, wheat, and corn.

•MODEL 610MCA includes the ten most commonly used filters for NIR

applications in food, feed, grain, meat, and dairy applications.

•MODEL 610A CUSTOM permits the user to choose four specific filters

from a selection of over 50 available wavelengths to supplement the

six standard filters, allowing dedicated calibration for special product

applications.

FEATURES

Features of the Instalab 600 Series Analyzer features include:

• Memory capabilities allow storage for 52 calibrations.

• Selectable moisture basis constituent concentration may be give “as

is”, at dry basis, or at a preselected moisture basis. A combination of

moisture basis may also be selected using the various formats

available.

• Keyboard selected wavelengths.

• Sample presentation system provides rotating sample cup for

averaging of sample reflectance and less susceptibility to particle size.

• System provides for sample cup interchangeability.

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

INTRODUCTION 5

• Digital microprocessor circuitry provides fast, easy field changes to

incorporate alternate data treatments as they become available.

• Circuitry ensures excellent long and short term stability due to

elimination of electrical drift.

• Circuitry ensures stable, nonvolatile storage of calibration constants

without dependence on an alternate power source such as batteries.

• Thermoelectrically cooled photo detector eliminates errors associated

with temperature changes within the detector.

• Field-proven, long life tungsten-halogen light source.

• Completely sealed optics chamber minimized effects of dust.

• Modular construction for ease of service.

• Self-test provision eliminates operator error, continuously verifies

operational status, and speeds servicing of the unit.

• Diagnostic modes for fault isolation.

• High speed operation.

•OPTIGAIN

®feature allows user to select optimum gain characteristics

for products with low reflectance characteristics.

OPTIONAL ACCESSORIES

Optional accessories include:

• Printer - produces a permanent record of results and calibrations.

• Regression and Data Collection Package - allows the operator to

develop custom calibrations (when used with IBM and IBM-compatible

personal computers).

• Optical Filters - additional optical filters are available to provide greater

flexibility over a wider range of constituents.

SPECIFICATIONS

The Instalab is a rugged, self-contained optical reflectance instrument,

designed to quickly and accurately measure the percent of constituent

concentration (moisture, protein, oil, starch, fiber, ash, etc.) in a wide range

of commodities common to the grain, feed, and food industries.

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

6 INTRODUCTION

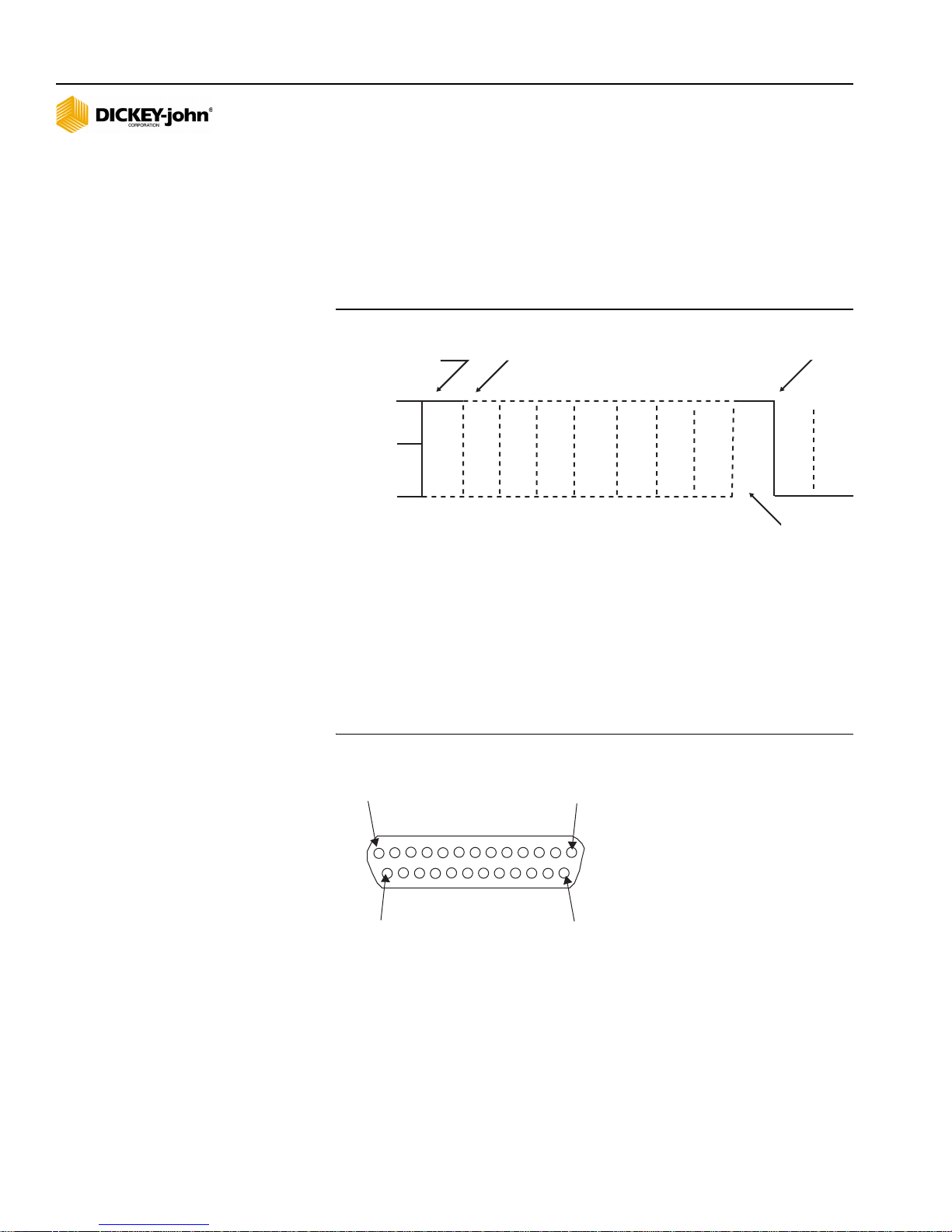

Figure 2

Dimensions

•Weight - 65 lbs/29.5 kg

•Dimensions - (Height) 13.62 in/34.6 cm, (Width) 22.25 in/56.5 cm,

(Depth) 16.35 in/41.5 cm

•Power Requirements - 102-132 VAC, 47-63 Hz or 187-242 VAC,

47-53 Hz

•Wavelengths - 6-10 (Customer Replaceable

•Storage Capacity - 52 Constituent Matrix

•Serial Computer Interface - Standards RS-232-C

•Printer - Optional

•Accuracy - Exceeds federal specifications for NIR instruments

•Sample Integration Technique - Rotating cup

•Filter Bandpass - 10 nm

•Light Source - Tungsten Halogen

•UL Listed/CSA Certified - yes (110v version)

•Calibration Storage - Non-volatile EEPROM (Electrically Erasable

Programmable Read Only Memory)

•Typical Analysis Time - 10 seconds

•Detector - Thermoelectrically cooled lead sulfide

•Reference Measurement - Through entire optical system, against

ceramic disk

•Gain Setting - Customer-adjustable, using Optigain feature

•Diagnostics - Self-test, automatically after every sample

16.35"

TOP VIEW

22.25"

FRONT VIEW

1.52"

19.25" 16.35" 3.50"

13.62"

SIDE VIEW

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

INTRODUCTION 7

THEORY OF OPERATION

The Instalab uses NIR technology and a statistical math treatment to predict

the percent of constituent concentration within a sample. Research has

proven certain constituents absorb light energy at specific wavelengths. For

instance, moisture absorbs the 1.94 µm (micrometer) band of near infrared

light (NIR), protein absorbs the 2.18 µm band and oil, the 2.31 µm and 2.33

µm bands. By bombarding a sample with a very narrow band of light at a

specific wavelength of NIR light, analysis of a sample can be predicted. The

light energy absorbed by the sample is inversely proportional to the

reflected light.

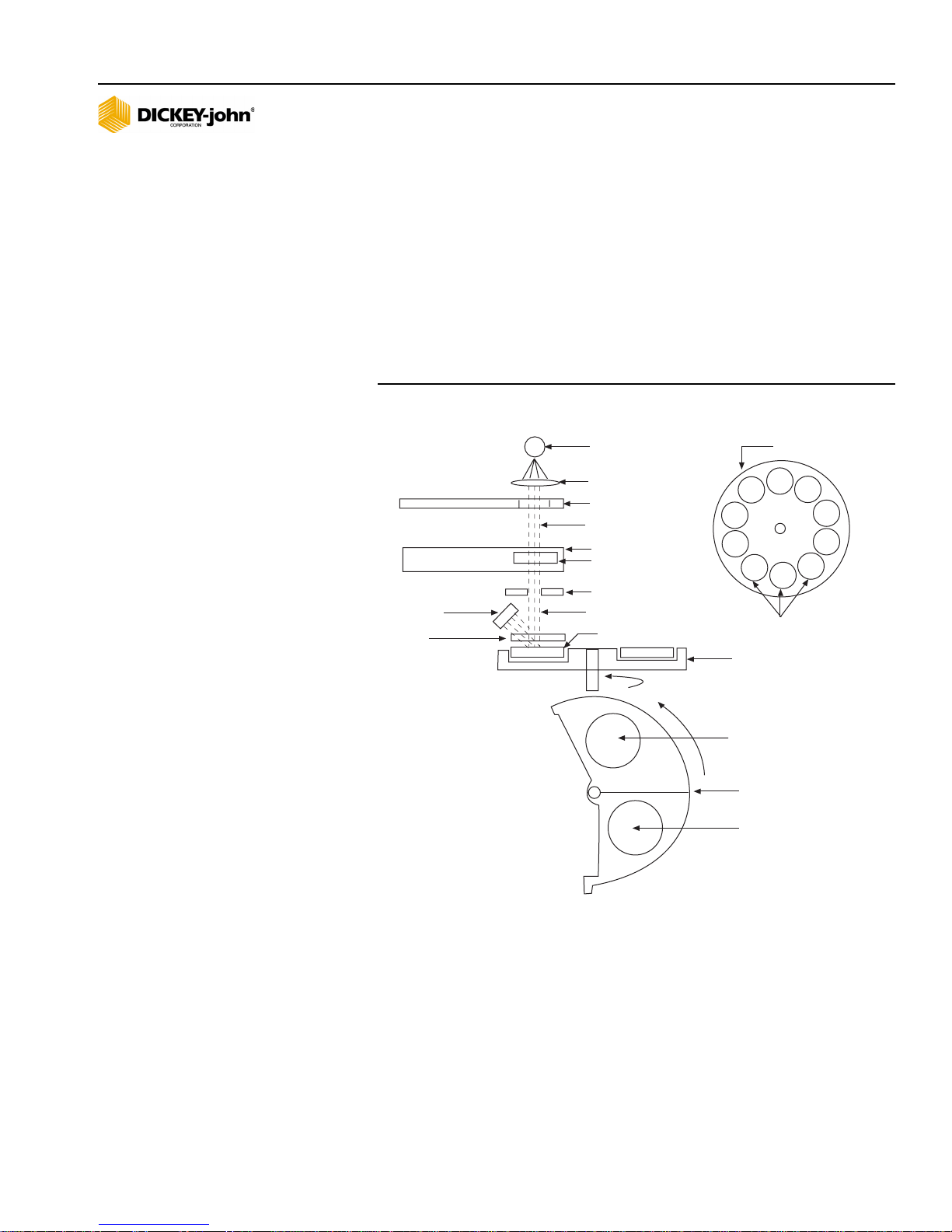

Figure 3

Operational Diagram

Detector

Glass

Broadband Light

Lens

Chopper Disc

Chopped Broadband Light

Filter Wheel

NIR Filter

Aperture

Narrowband Light

Reference Disc

Sample Drawer

(Side View)

Fixed Reference Disc

Sample Drawer

(Top View)

Rotating Sample

NIR Filters

Filter Wheel

Top View

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

8 INTRODUCTION

Figure 3 illustrates the basic mechanical functions used in irradiating a

product sample. A broadband Tungsten-halogen lamp produces a light

source that is rich in near infrared (NIR) wavelengths. Beneath the lamp, a

lens aligns the light into parallel rays. A chopper wheel periodically

interrupts the focused light beam, resulting in an alternating signal to the

detector, thus enhancing the stability of the reading. The chopped light

passes through NIR filters to allow only selected bands of near infrared light

to pass and irradiate the sample. An aperture blocks all outside light and

allows only a column of filtered light through to the sample. The sample

absorbs part of the near infrared light while reflecting the remainder. A

detector reads the amount of reflected light, amplifies the signal, and

converts the voltage level into a digital form for further processing.

There are six optional NIR filters installed in the filter wheel on a standard

Instalab unit. Up to four additional filters may be supplied on more

advanced models or added later as field modifications. The filters are

successively rotated into place over the sample to irradiate it with discrete

wavelengths of near infrared energy. The measured reflectance energy for

each filter is converted to a machine logarithm that is used along with the

calibration constants to predict the constituent concentration.

Where:

KA is the bias adjustment for the calibration.

KO is the coefficient for the first filter position

LOG is the first filter’s machine logarithm of the reciprocal reflectance

(absorption)

K1 is the coefficient for the second filter position

LOG is the second filter’s machine logarithm of the reciprocal

reflectance (absorption)

The sample drawer has two sections. One section is used for the sample

and one section is used for a Ceramic Reference Disk. When the sample

drawer is open between analyses, all the optical filters that are used in the

calibration are successively positioned over the Ceramic Reference Disk.

The gathered reflectance data, at each of the selected wavelengths, is a

measure of the total available light. When the drawer is closed, the light

reflected from the sample at each of these wavelengths is measured again.

The machine logarithms used in the regression equation are the log ratio of

sample reflectance data to the reflectance data gathered from the ceramic

reference disk.

% CONTITUENT = KA + KO X LOG ( ) + K1 X LOG (

1/R0

1/R1+...+Kn+LOG ( )

1/Rn

1/R0

()

1/R1

()

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

INSTALLATION 9

INSTALLATION

Prior to shipment, the unit was inspected and found to be free of

mechanical and electrical defects. After the Instalab is unpacked, inspect

the unit for damage that may have occurred during shipping. Save all

packing materials until the inspection is complete. If damage is found,

immediately file a claim with the carrier and notify your DICKEY-john sales

representative.

The Instalab should be installed and maintained in a level position and in a

location where it is protected from rapid changes in ambient temperature.

Also, the Instalab and printer (optional) must not be used in hazardous

(classified) locations as defined in Article 500 of the NFPA Handbook of the

National Electrical Code.

If a printer (optional) is installed, it should be placed on the right side of the

Instalab so as not to obstruct the air vents on the instrument.

Connect the power cord to a 3-wire (grounded) 120 VAC, 60 Hz outlet. If the

unit is optionally configured for 220 VAC, 50 Hz, connect the power cord to

an appropriate 220 VAC outlet.

Proper grounding must be made to ensure the safe and proper

operation of the unit.

The grounding pin on the power cord plug is connected to the

Instalab enclosure. If an adapter with a grounding wire is used,

make sure that the grounding wire is connected to a good earth

ground. Otherwise, a shock hazard may be present. Do not use a

3-pin to a 2-pin adapter.

PRINTER CONNECTION

The optional printer connects to the Instalab through a connecting cable

that is terminated at each end with a 25-pin connector. These connectors

plug into receptacles at the rear of the printer and the Instalab. The printer

has its own 3-wire power cord and plug.

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

10 INSTALLATION

SERIAL PORT CONFIGURATION

The serial port conforms to the EIA/TIA RS-232-E standard and is

configured as Data Communications Equipment (DCE). The data out is at

RS-232-E levels and polarity with a 1200 Baud rate. Each ASCII character

is described as consisting of a start bit, 8 data bits, no parity bit and 1 stop

bit or 7 data bits space parity and 1 stop bit.

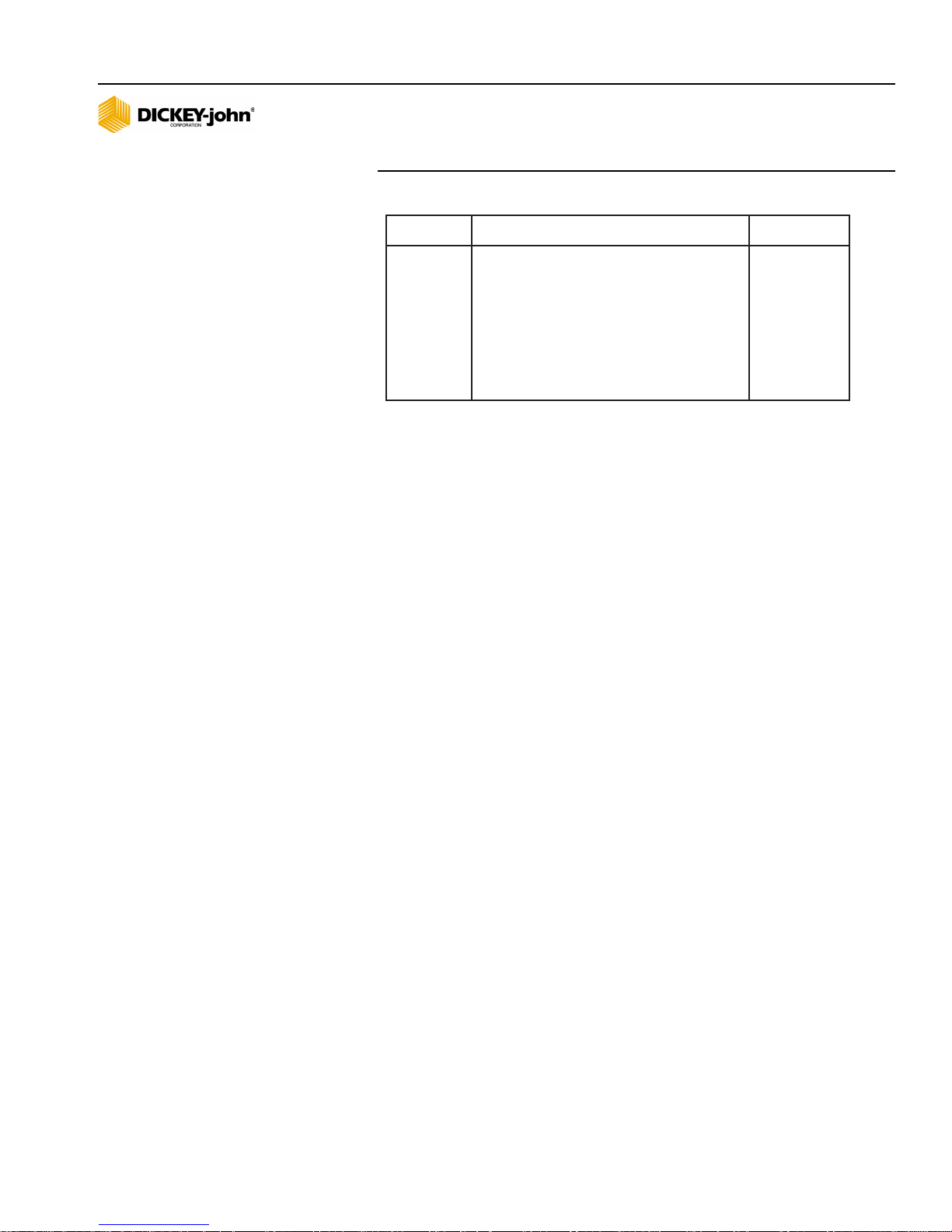

Figure 4

ASCII Character Bit Identification

CONNECTOR CONTACTS

Each line consists of 16 characters followed by a carriage return and a line

feed. Each transmission is terminated by a line consisting of sixteen equal

signs ( “=” ), a carriage return, and a line feed followed by 2 lines each

consisting of sixteen blanks ( “ “ ), a carriage return, and a line feed.

Figure 5

Connector Contacts

Space + 12 V

0V

Mark - 12V

Start Bit LSB Stop Bit

Space Parity

or Bit # 8

Pin 1Pin 13

Pin 14Pin 25

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

INSTALLATION 11

Figure 6

Connector Pin Assignment

Pin Number Data Communications Equipment Signal Direction

1 Frame Ground Bidirectional

2 Data in (TXD) In

3 Data Out (RXD) Out

4 Request to Send/Ready for Receiving (RTS) In

5 Clear to Send (CTS) Out

6 Instrument ON (DCE Ready) (DSR) Out

7 Signal Ground Bidirectional

8 Instrument ON (Rec'd line signal detector) (DCD) Out

20 Ready (DTR) In

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

12 INSTALLATION

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

CALIBRATION 13

CALIBRATION

GATHERING A SAMPLE SET

Satisfaction with the performance of the Instalab is largely dependent on the

care taken in gathering, selecting, and preparing samples for calibration.

The calibration process is essentially one in which the instrument is “taught”

to relate specific reflectance data to know chemical reference analysis of a

selected set of samples. If the Instalab is “shown” a sample with reflectance

characteristics unlike those included in the selected sample set, less

accurate predictions may result. It is also important that the calibration

sample set include all combinations and concentrations of constituents,

whether all constituents are of immediate interest or not. This is necessary

because in reflectance spectroscopy, the reflectance at any given

wavelength is influenced to some degree by each constituent present in the

sample.

SAMPLES REQUIRED FOR CALIBRATION

The number of samples necessary to perform a multiple linear (least

square) regression varies. At least 30 samples are recommended for

calibration and an independent set of samples (approximately the same

number) are required to test the calibration.

SAMPLE COLLECTION

Calibration samples must be collected from the same point in the process

that the Instalab monitors. It has been found that within a multistage

process, the product may have different characteristics at different points in

the process. If the Instalab is to monitor several different points of the

process, separate calibrations may have to be developed for each point that

is to be monitored.

For a processed product, a good time to collect samples (for a wide range

of constituent concentration) is when the plant is running under abnormal

conditions or the operation is just returning to normal. Taking samples at

frequent intervals during these periods usually produces a sample set with

a good range and combination of constituents not always found under

normal plant conditions.

Selection of a sample set for calibration may frequently be aided by using a

“rough” calibration such as a calibration for a similar product to segregate

samples and to ensure a set of samples across the desired range of interest

are collected. This technique reduces the number of samples that have to

be analyzed by the more cumbersome reference methods.

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

14 CALIBRATION

PRODUCT CHARACTERISTICS

Variations in product characteristics such as color, hardness, and the

amount of hull or foreign material may necessitate separate calibration

constants for determinations. The color and hardness may affect the

amount of light that is absorbed by the product and the amount that is

reflected. The amount of hull and foreign material may affect the particle

distribution causing different sized particles to be unevenly distributed

throughout the sample.

SAMPLE MOISTURE CONTENT

The moisture content of a sample is important since the concentration of the

remaining constituents (expressed as a percentage of the total weight) is a

function of the moisture content. Consider, for example, a product with the

following analysis:

Moisture 7.0%

Oil 8.0%

Protein 72.0%

If this same sample is dried to 3% moisture, the analysis becomes:

Moisture 3.0%

Oil 8.34%

Protein 75.1%

If this change in moisture occurred between the time the laboratory

reference analysis and Instalab analysis is performed, one would wrongly

conclude that there is a 3.1% difference in protein determinations.

The prediction equation utilizes reflectance measurements at specific

wavelengths to predict the moisture, protein, oil, etc., with as little

interference from other parameters or constituents as possible. To minimize

errors due to moisture changes, samples should be analyzed for moisture

on the same day that they are analyzed by the Instalab. Other constituents

may be analyzed later as long as the constituent concentration is expressed

on the moisture basis of the original sample presented to the Instalab.

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

CALIBRATION 15

SAMPLE STORAGE

Care must be exercised in sample storage and handling to minimize

moisture loss. Tins with “slip-fit” lids should be sealed with vinyl tape. Glass

jars with tight fitting screw lids may be satisfactory, but it is desirable to

choose jar sizes to minimize the dead air space above the sample. Some

materials cannot be stored for long periods of time without undergoing

changes in composition. This is especially true of some high oil products.

Chemical and biological degradation of samples may be slowed by keeping

the samples refrigerated. Refrigerated samples should be allowed to return

to room temperature before analysis. If samples have been stored for a long

period of time, it is advisable to redetermine the moisture and convert the

analysis of the other constituents to a present moisture basis before using

the sample for Instalab calibration or bias adjustments. Ziplock plastic bags

(of at least .004” thickness) are recommended for sample storage when

storage is necessary. For moisture levels of 16% or greater, double bag

each sample.

DEVELOPING CALIBRATIONS

There are three ways to obtain a calibration. DICKEY-john has developed

some universal calibrations for certain products. These may be obtained

from your DICKEY-john sales representative. Calibrations may be

developed by using the optional Regression and Data Collection Package,

or the user may use their own computing facilities to develop a calibration.

UNIVERSAL CALIBRATIONS

Contact your DICKEY-john sales representative for specific information

concerning the products that have universal calibrations. If there is a

calibration that fits your particular needs, use the following procedure to

enter, store, and test the calibration. Adjust the machine bias to make the

predictions agree with the reference analysis.

1. Enter the calibration using Mode 2 (refer to OPERATION).

2. Randomly gather 20 samples at different times of the day from the

same point of the operation the Instalab will be monitoring.

3. Grind and mix each sample and divide each mixed sample into three

parts: two parts for laboratory analysis and one part for the Instalab

analysis.

4. Perform the laboratory analysis separately, comparing the results. Do

not use samples whose laboratory analysis differ enough that the

accuracy is suspected.

5. When both analyses for the same samples are close enough to assure

laboratory accuracy, average the two results.

6. Log the laboratory analysis and Instalab analysis on the INSTALAB

BIAS ADJUSTMENT WORKSHEET.

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

16 CALIBRATION

Figure 7

Example Of Instalab Bias Adjustment Worksheet

Twenty laboratory analyses were preformed and all were of sufficient

accuracy. They were logged under STANDARD ANALYSIS. The Instalab

analyses were also logged. Each column was added, then divided by the

number of samples (SUM ™ N). The Instalab average is then subtracted

from the laboratory’s analysis. This result, “.25” in the previous example, is

the amount of Bias Adjustment required to make the Instalab percent

analyses agree with the laboratory determinations. Refer to MODE 4 for

procedures on adjustments.

REGRESSION DATA COLLECTION

Refer to the manual entitled REGRESSION AND DATA COLLECTION

PROGRAM for specifics on how samples are gathered and prepared, then

perform the regression as explained in the manual. After development is

complete, calibration constants are entered into nonvolatile memory by

using MODE 2 and stored by using MODE 5.

Instalab Bias Adjustment Worksheet

Date: _____________________________ Instalab Serial #: _____________________

Product: ___________________________ Grinder Serial #: ______________________

CONSTITUENT CONSTITUENT CONSTITUENT CONSTITUENT

Sample # (N) Standard

Analysis

(%)

Standard

Analysis

(%)

Standard

Analysis

(%)

Standard

Analysis

(%)

Instalab

Analysis

(%)

Instalab

Analysis

(%)

Instalab

Analysis

(%)

Instalab

Analysis

(%)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Sum

Average

(Sum÷N)

Standard Average

Minus Instalab Average

Equals Bias Change Req'd

Hard Red Wheat

Protein (.2)

10.56

11.02

13.57

12.20

11.67

13.30

12.82

11.60

10.98

12.90

12.37

13.42

10.20

11.06

12.07

12.35

13.50

11.17

11.11

12.07

10.31

10.77

13.32

11.95

11.42

13.05

12.57

11.35

10.73

12.65

12.12

13.18

9.95

10.81

11.82

12.10

13.25

10.92

10.86

11.82

239.95

12.0

234.95

11.75

12.0

11.75

.25

OPERATOR’S MANUAL

Instalab 600 Series Analyzers

11001-1360-200512

CALIBRATION 17

DEVELOPING CALIBRATIONS WITH COMPUTER

AND REGRESSION PROGRAM

When the user develops calibrations using his facilities, the machine logs

become the independent variables. The laboratory reference analyses

become the dependent variables. After allowing 48 hours for the Instalab to

warm up, enter the Reflectance Data Collection Mode that provides the best

data to obtain machine logs. Develop the Calibration Constants (KA, K0,

K1, ... Kn). After calibration constants are developed, they are entered into

nonvolatile memory using MODE 2 and stored using MODE 5.

Table of contents

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific Applied Biosystems ProFlex PCR System quick reference

IET Labs

IET Labs GenRad 1403 Series Operation manual

Thermo Scientific

Thermo Scientific invitrogen EVOS XL Core quick reference

Agilent Technologies

Agilent Technologies 1290 Infinity II user manual

AB Sciex

AB Sciex 4000 QTRAP Hardware guide

SCHOTT

SCHOTT ACE Series owner's manual

Neuation

Neuation iROLL PR35 Product user manual

OMEGA AIR

OMEGA AIR TACm Series Installation and operating manual

Specac

Specac Golden Gate GS10500 Series user manual

Sourcetronic

Sourcetronic ST1778 user manual

BABYBELLE

BABYBELLE BBS05 Instructional manual

Sartorius stedim

Sartorius stedim Sartobind Phenyl nano 3 ml operating instructions