System Overview

6 Document Number: D1000092200 B

Qualitative Analysis of Small Molecules

This application involves MS analysis of low molecular weight (typically less than

1000 amu) compounds such as drugs and their metabolites. This is for the

purpose of identification and structural characterization of the chemical

compounds in a sample such as urine or other bodily fluid. In addition, this

general application is used when the researcher wants to know what molecular

weight species are in the sample.

The typical scan type used for this application in the 4000 QTRAP system is an

EMS (Enhanced MS) scan for intact molecular weight analysis. For more detailed

structural analysis using tandem mass spectrometry, EPI (Enhanced Product Ion)

and MS3 (MS/MS/MS) scans are performed.

Qualitative Analysis of Proteins and Peptides

This application involves determination of molecular weights and sequences of

protein and peptide samples. This is for the purposes of identification of the

compounds and structural characterization. This general application is used when

the researcher wants to know what molecular weight species and what sequences

of peptides or proteins are in the sample.

The typical scan types used for this application in the 4000 QTRAP system are

EMS (Enhanced MS) and EMC (Enhanced Multi-Charge) scans for intact

molecular weight analysis. ER (Enhanced Resolution) scans are used to obtain

higher resolution molecular weight information such as determining the charge

state of a multiply charged peptide ion. This allows for more accurate

identification of the sample using protein database searching. For more detailed

structural analysis using tandem mass spectrometry (MS/MS), EPI (Enhanced

Product Ion) scans are performed.

How the System Works

The 4000 QTRAP®system has a number of enhanced modes of operation. A

common feature of the enhanced modes is that ions are trapped in the Q3

quadrupole region and then scanned out to produce full spectrum data. Many

spectra are rapidly collected in a short period of time and are significantly more

intense than spectra collected in a comparable standard quadrupole mode of

operation.

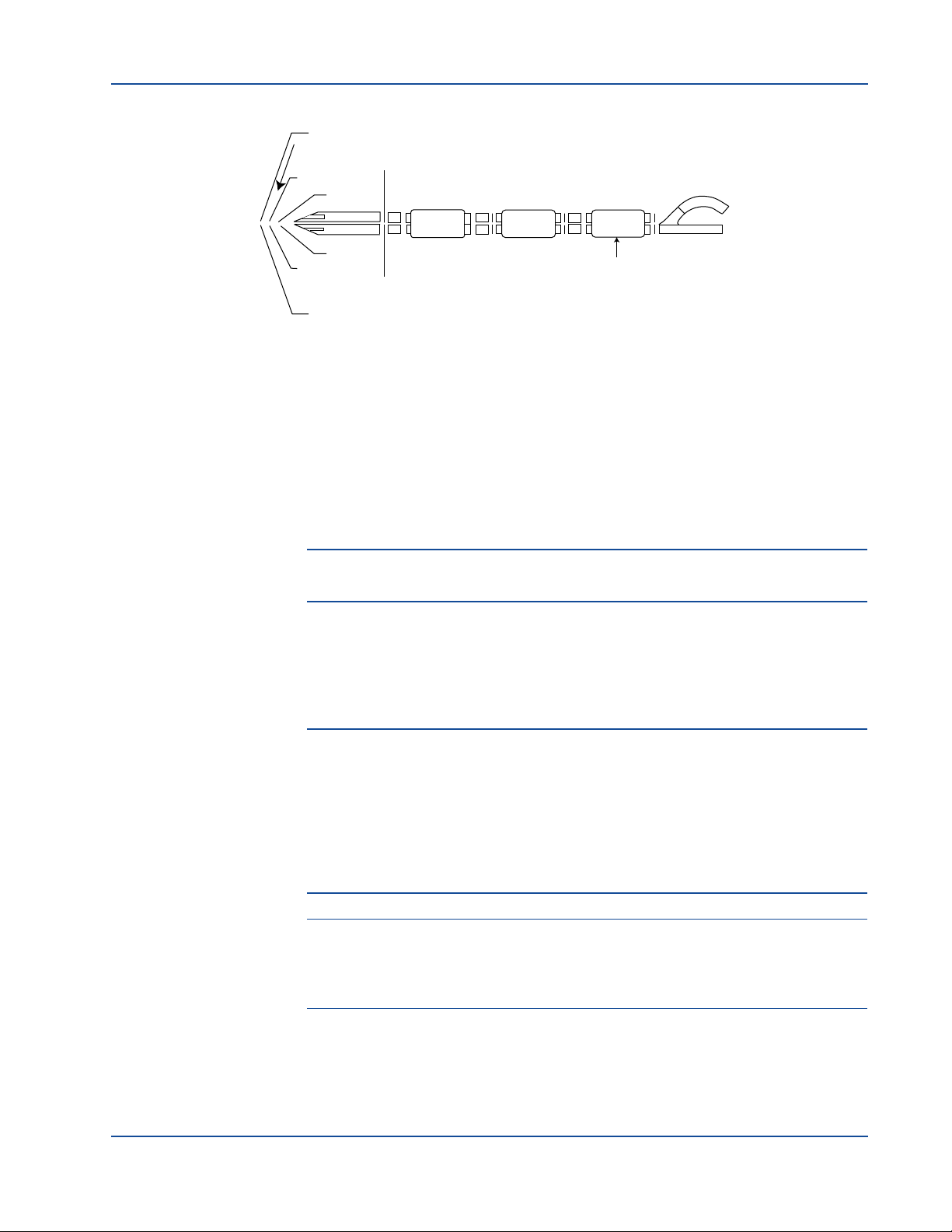

During the collection phase, ions pass through the Q2 collision cell, where CAD

gas focuses the ions into the Q3 region. The Q3 quadrupole is operated with

only the main RF voltage applied. Ions are prevented from passing through the

Q3 quadrupole rod set and are reflected back by an exit lens to which a DC

barrier voltage is applied. After the fill time elapses (a time defined by the user, or

determined by the Dynamic Fill Time feature), a DC barrier voltage is applied to a

Q3 entrance lens (ST3). This confines the collected ions in Q3 and stops further

ions from entering. The entrance and exit lens DC voltage barriers and the RF

voltage applied to the quadrupole rods confine the ions within Q3.

During the scan out phase, the voltage on the exit lens and the auxiliary RF

voltage are ramped simultaneously with the main RF voltage for increased

resolution and sensitivity. An auxiliary AC frequency is applied to the Q3

quadrupole. The main RF voltage amplitude is ramped from low to high values,

which sequentially brings masses into resonance with the auxiliary AC frequency.

When ions are brought into resonance with the AC frequency, they acquire