3

Table of contents

1 Important information ........................................................................................................ 5

1.1 Used symbols and indications .................................................................................... 5

1.1.1 Warning words. .................................................................................................... 5

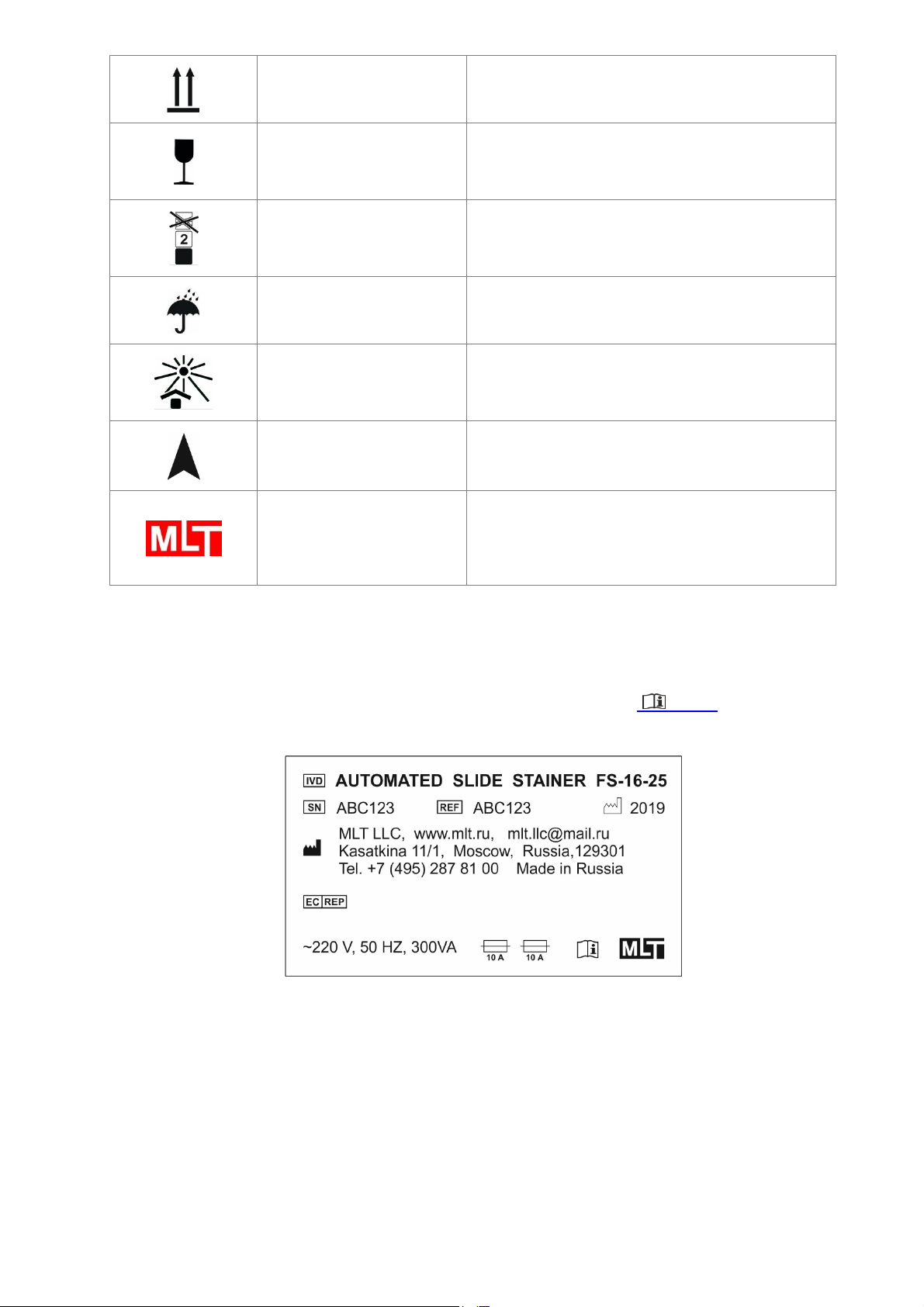

1.1.2 Symbols. .............................................................................................................. 6

1.1.3 Stainer label. ........................................................................................................ 7

1.1.4 Designation of menu sections, touch screen buttons, and operational actions. ... 8

1.2 Intended use ............................................................................................................... 9

1.3 Compatibility with reagents and accessories of other manufacturers ......................... 9

1.4 Qualification of personnel ........................................................................................... 9

2 Safety ............................................................................................................................. 10

2.1 General safety statements ....................................................................................... 10

2.2 Special safety statements ........................................................................................ 10

3. General characteristics .................................................................................................. 12

3.1 Description of Stainer ............................................................................................... 12

3.1.1 Construction of Stainer. ......................................................................................... 12

3.1.2 Accessories: troughs and racks. ........................................................................ 15

3.1.4 Micro SD card and micro SD card slot. ............................................................. 16

3.1.5 Working principle of Stainer. .............................................................................. 16

3.2 Technical data .......................................................................................................... 18

3.3 Environmental conditions ......................................................................................... 18

3.4 Delivery set ............................................................................................................... 19

4. Unpacking and installation of Stainer ............................................................................ 20

4.1 Site requirements ..................................................................................................... 20

4.2 Unpacking of Stainer ................................................................................................ 20

4.3 Connection of Stainer ............................................................................................... 22

5. Operation and control of functioning .............................................................................. 25

5.1 Main menu, menu structure ...................................................................................... 25

5.2 Menu section «TECHNIQUES»: programming of new techniques, editing of

parameters of previously downloaded techniques.......................................................... 26

5.3 Menu section «CONFIGURATION»: programming and control of the configuration,

performing of service functions....................................................................................... 32

5.3.1 Setting the interval of the introduction of racks into the process. ....................... 36

5.3.2 Menu section «SERVICE». Performing of service functions. ............................. 38

5.4 Menu section «PROCESS»: loading and unloading of racks. Processing of racks

with slides according to a given technological program .................................................. 40