Sourcetronic ST1778 User manual

SOURCETRONIC −Quality electronics for service, lab and production

0-20A DC BIAS Source ST1778

User Manual

- 2 -

Edition history:

The manual will be continually revised.

In case of errors or omissions, revision of device functions, as well as technological and software

upgrades, there will be corresponding adjustments and modifications of the manual.

February, 2014............................................................................................................ver1.0

- 1 -

Content

Chapter 1 General Information ...................................................................... 2

1.1 Introduction ................................................................................................................................................. 2

1.2 Basic Accuracy ............................................................................................................................................ 2

1.2.1 Accuracy Test Requirements....................................................................................................... 2

1.2.2 Current Accuracy........................................................................................................................... 2

1.3 Accessories .................................................................................................................................................. 2

Chapter 2 Panel Description.......................................................................... 3

2.1 Front Panel Description............................................................................................................................... 3

2.2 Rear Panel Description................................................................................................................................ 5

Chapter 3 Basic Operation ............................................................................ 6

3.1 Instruction of main interface........................................................................................................................ 6

3.1.1 Diagram and instruction............................................................................................................... 6

3.1.2 Tab diagram and function instruction......................................................................................... 8

3.1.3 Keyboard diagram and function.................................................................................................11

3.2 The output command................................................................................................................................. 12

3.2.1 Start............................................................................................................................................... 12

3.2.2 Stop............................................................................................................................................... 12

Chapter 4 Command interface......................................................................13

4.1 ST1778 RS232C........................................................................................................................................ 13

4.2 SCPI commands......................................................................................................................................... 13

4.2.1 General command set................................................................................................................ 13

4.2.2 ST1778 sub-system commands............................................................................................... 13

2

Chapter 1 General Information

1.1 Introduction

ST1778 DC Bias Current Source adopts high-performance MPU and can provide a constant current

ranging from 0A to 20A. The maximum current output can reach 0-120Aby connecting up to five slaves.

ST1778 can be used with most of Sourcetronic’s L meters and LCR meters. ST1778 provides a

convenient and practical DC Bias Current Source for AC+DC overlap inductor measurement and

magnetic material analysis.

1.2 Basic Accuracy

1.2.1 Accuracy Test Requirements

Within two year since factory calibration;

Environment temperature: 255°C;

Relative Humidity: ≤80%;

Power supply is regulated by a line-voltage regulator;

Warm up time: more than 15 mins.

1.2.2 Current Accuracy

Range (A)

Resolution (mA)

Accuracy

0.000~1.000

5

±(1%+5mA)

1.025~5.000

25

±2%

5.1A~20.0*n (n=1~6)

100

±3%

1.3 Accessories

Current output clip

The standard test clip and output line is ET-07-2 and ET-54. (Note: when the current is greater than 40A,

please do not use it as the current output.)

Footswitch

The standard footswitch is ST1801-001.

Link line

Each ST1778S slave is equipped with a SlaverLink.

Test Fixture

The standard high frequency test fixture is ST26004E-1.

3

Chapter 2 Panel Description

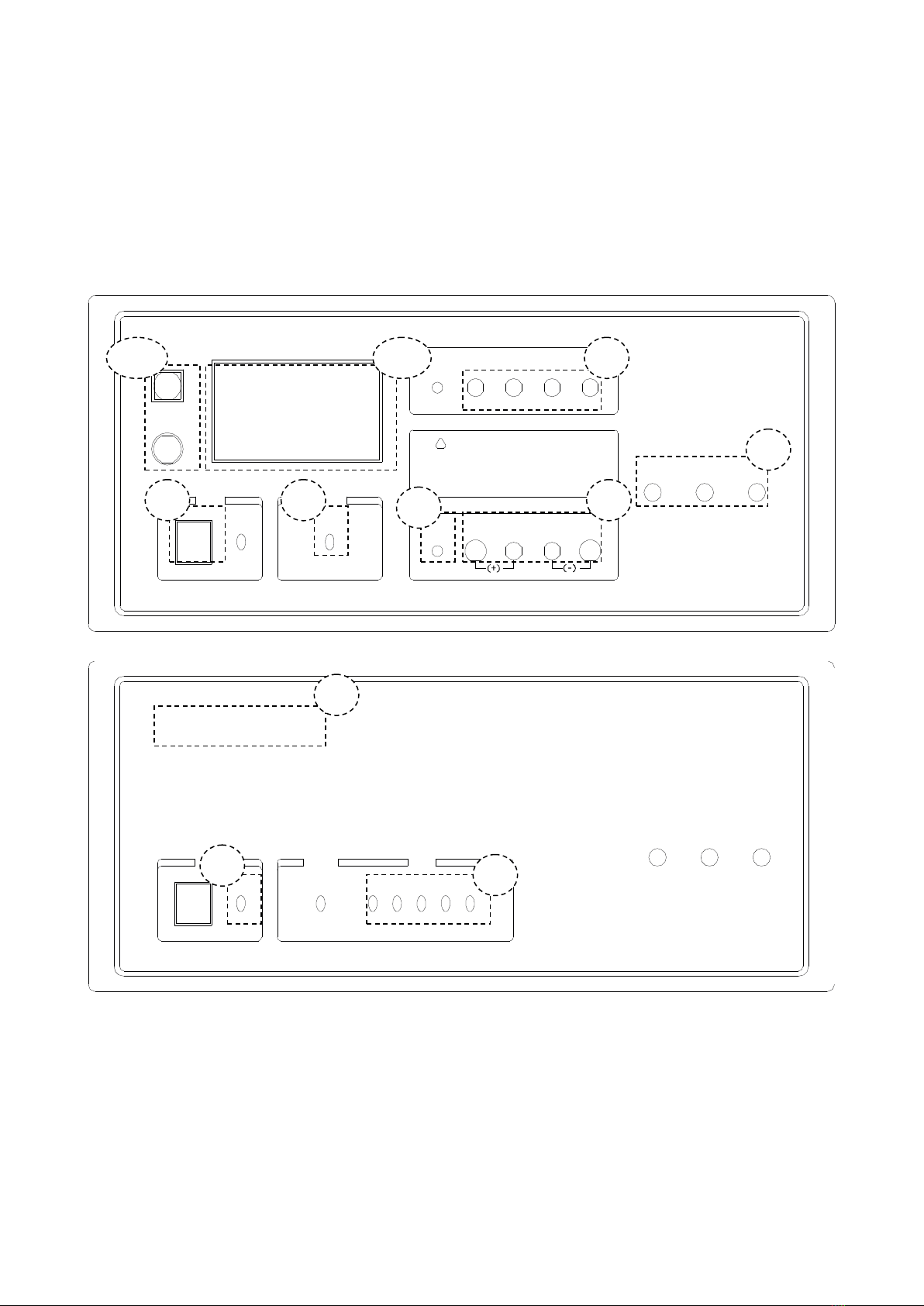

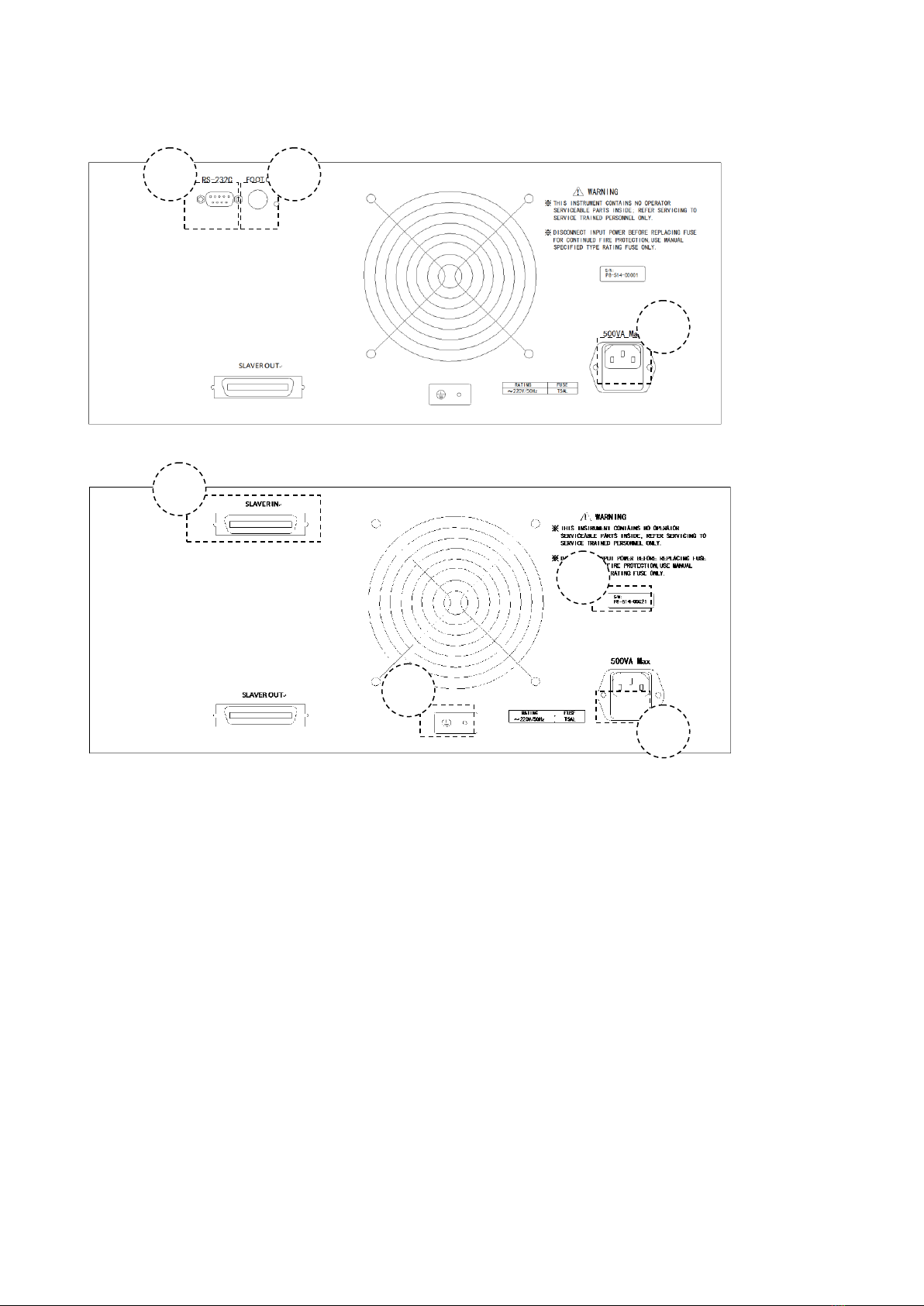

2.1 Front Panel Description

POWER DC BIAS

ON

BIAS CURRENT SOURCEST1778

ON

Achtung:

COM

HD HS LS LD

POTCUR

HPOT

H L CUR

L

GND

Lesen Sie vor Inbetriebnahme die Bedienungsanleitung.

Bei hohen Strömen kann es zu einer Abschaltung

aufgrund von Überhitzung kommen.

!

START

STOP

SINK SOURCE MG

O

_

Front panel of host machine

POWER DC BIAS

0-20A

BIAS CURRENT SOURCE

ST1778S

SLAVE

SINK SOURCE MG

ONON 1 2 3 4 5

O

_

Front panel of slave

1) Power Switch

When the switch is in the “I” position, all operating voltages are applied to the instrument. In the

“0” position, no operating voltages are applied to the instrument.

2) POWER LED

The power led is lightening after power on.

3) OUTPUT LED

When the instrument starts outputting, the output led of the main machine lights up; when the

10

11

7

8

5

6

3

2

1

4

9

4

output current of the slave reaches 20A, the output led of the slave lights up.

4) LOGO/MODEL

Logo and Model

5) OUTPUT PORT

6) GND

The GND terminal is tied to the instrument’s chassis. If using a three-phase socket, this GND

terminal is connected to the ground directly. If a large current fixture is used, this GND terminal

can be connected to that fixture in order to provide protection.

7) TEST INPUT

This port is used for connecting LCR or L meters, supplying the test signal and returning the

test access from the DUT through AC coupling.

8) TEST OUTPUT

This port is used for connecting the DUT, combining the signal load from the upper input port

and the bias current through the DUT.

9) SLAVE NO. LED

This led indicates the number of slave.

10) BUTTON

This button is used for controlling the start and stop of the current output manually.

11) SCREEN

This screen indicates the working condition of the instrument and it includes all the operation

functions via touch screen.

5

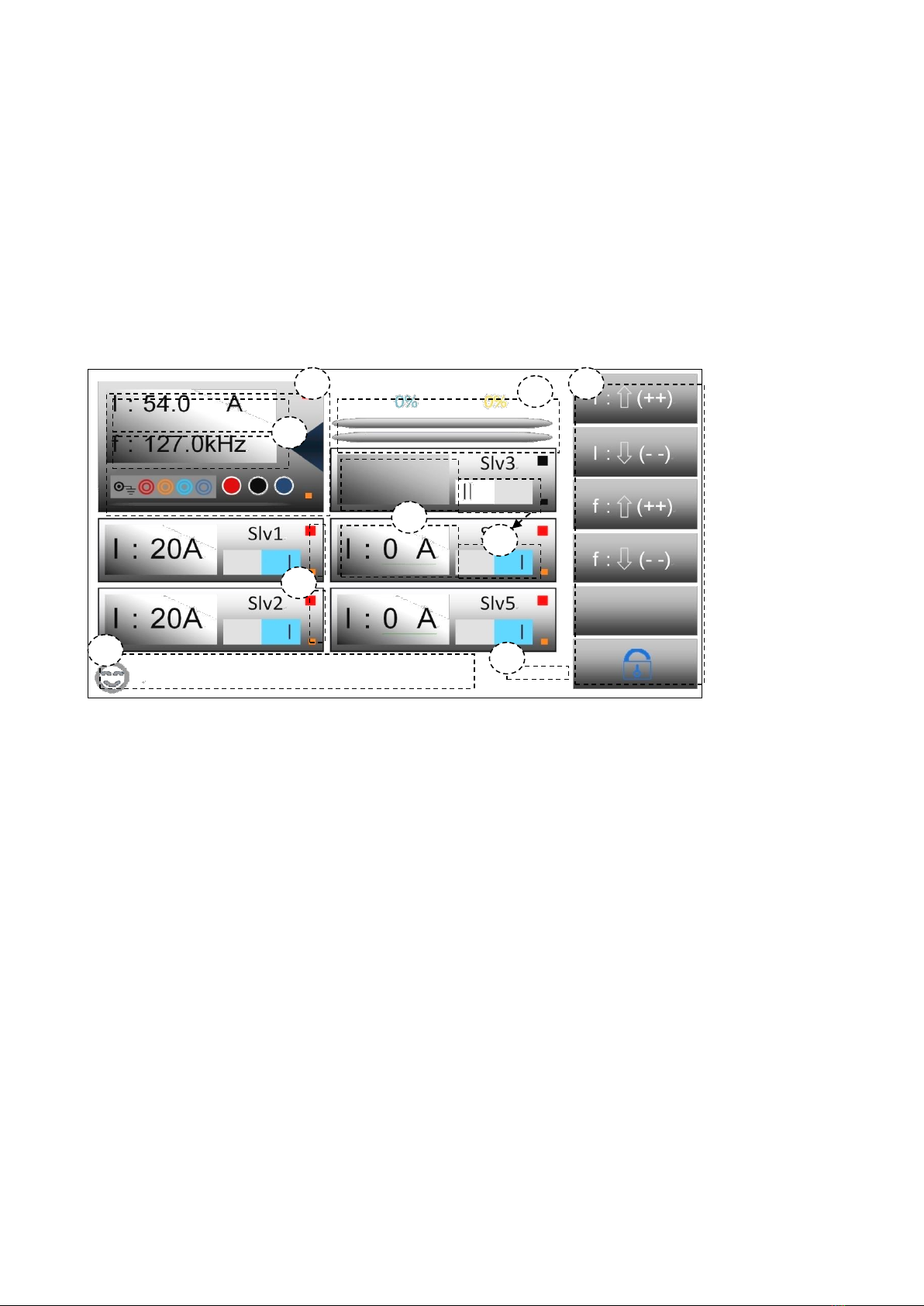

2.2 Rear Panel Description

Rear panel of host machine

Rear panel of slave

1) SERIAL PORT

Following the SCPI instruction set to control the output of the bias current and set its

parameters.

2) LINK PORT

The special link port for daisy-chaining slave devices.

3) FOOT CONTROL INPUT

Foot control input interface.

4) DATA PLATE

Provides the information of Serial number and name of manufacturer.

5) GND

Connect the ground lead.

6) FUSE SOCKET

Used for installing the power fuse to protect the instrument.

This instrument uses a 220V/5A fuse. If using foreign power, please replace the fuse to

110V/8A and change the internal electric source jumper.

7) POWER SOCKET

1

3

2

4

5

6

7

6

It is used for inputing theAC current. Please use the three-phase socket.

Chapter 3 Basic Operation

3.1 Instruction of main interface

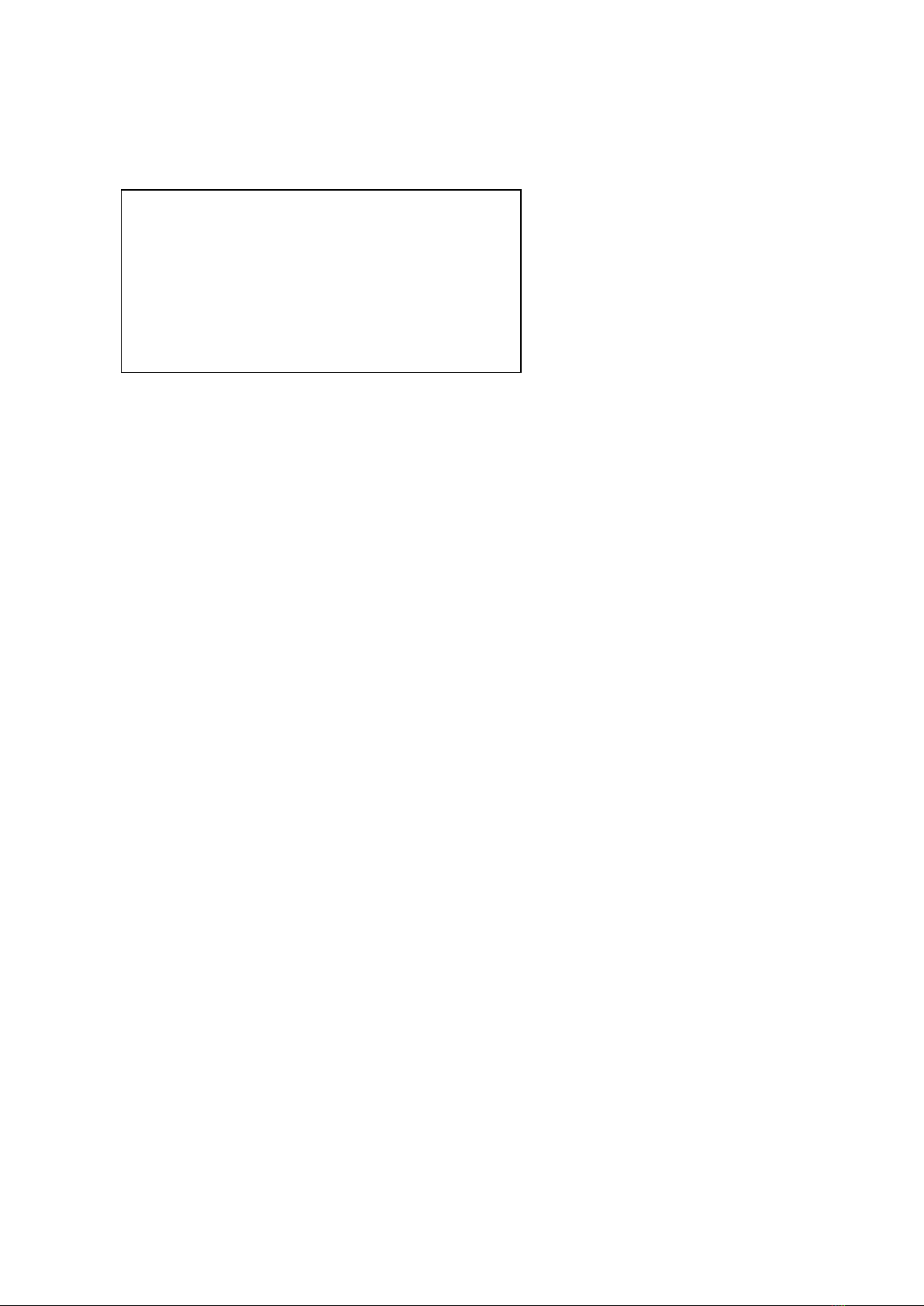

3.1.1 Diagram and instruction

1. In this zone, tap to enter the management windows, the detailed description follows in next part.

2. The primary and secondary parameters are displayed in this zone (Total current and frequency), tap it

to enter the current and frequency setting (The keyboard has calculating function, and supports dual

display and input-protection, which means double-confirm of input parameter). The detailed description

is in the next part.

3. Indication of output adjusting progress, after step-scanning, the light yellow percentage indicator

which is the first progress bar from the top will display the percentage of each adjustment, when the

instrument is operating, the first progress bar is used with light yellow color. When step scanning is off,

the bar will keep the default status, and the percentage will also keep 0%. The water blue indicator which

is the second progress bar from the top will display the percentage of total adjustment. When instrument

is operating, the second progress bar is used with water blue color. In either operating mode, even if the

output is started, the indicator will work.

4. Virtual keyboard, there are 5 functions from top to down: current increase, current decrease;

frequency increase, frequency decrease; blank ; lock and unlock touchscreen. In the page, if touch is

unlocked, all 5 keys can be used to 1 2 3 4 6 5 7 8 9 operate the tester, in any condition, Key 6 can be

used to lock and unlock the touch function

1

2

3

4

6

5

7

8

9

7

5. Sub-frame parameter display, when the slave is not powered or connected or not started up, the zone

is blank; when it is powered and connected, and user starts it up, the zone is lighted, also the value of

output current is displayed. Generally, the current is distributed automatically, if the slave is assigned as

one of the output drivers, then it displays 20A, if not, it is 0A.

6. Virtual switch, click the zone to switch on and off, if sky blue “I” is displayed, it means user has set the

slave as active, and when it is connected and powered, the display is as No. 5 above and LED indication

is as No 7 zone, then it will be included in the driver distribution; if gray “II” is displayed, it means the user

has deactivated this slave and it is not available for current distribution.

7. Virtual display LED displays the status of power supply and running state. The bigger LED indicates

the STATE, the smaller LED indicates the connection and POWER status; if the slave is not connected

or powered, then all LEDs are black; if the slave is connected and powered, but not activated by the user,

then only POWER is lighted; if there is no problem, user can use it as one of the distributed drivers; if all

is finished, then the display is like No.5. and the STATE LED is lighted; if this slave is not distributed or

system is not in output status, the LED is red; if the slave outputs current, the LED is green.

8. Real time clock display (RTC)

9. The zone display real time message; currently only 2 messages are supported to display now, if user

needs, we can add more.

8

3.1.2 Tab diagram and function instruction

Tab—parameter setting

Tab—file management

1

2

3

4

5

6

7

8

9

10

11

13

12

14

15

16

9

Tab—system setting

1. Label function, used to indicate the current label function.

2. Label, used to distinguish the current label and indicate the name, the current label is always on top, if

you want to switch, just click the naked zone to switch.

3. Close button, click to close the tab.

4. Functional icon for the current line, only for indication and click is allowed, after clicking, there is some

menu, like small keyboard or options .etc.

5. Parameter and content in current line, click is allowed, then there is an entity which can fit the

description in Zone No.4, foot control mode is not fit for the current description, so there is no any menu

or options.

6. External control button, the virtual button is only included in the parameter setting in figure 3.1.2.1, all

lines in this page include the buttons, and click any of it to get an external controlled options, the options

is fit as the description in Zone No.7.

7. Virtual external control key, only included in the parameter setting in figure 3.1.2.1, which is used to

control the increase and decrease of the parameter or switch, long press is allowed to fast increase and

decrease or switch.

8. File No. noted box, which can show the file No.

9. File name display, the file name can be revised in this zone.

10. File stored date and time display.

11. File noted box, when click, if there is file in this serial no. then you can make a note, otherwise, can’t.

Then there is a green tick in the noted file.

18

17

19

20

22

21

10

12. In this zone, there are virtual options and keys, the arrow key is used to turn the page or turn to the

front or end page. Other 5 options can be clicked to get the menu or functions. From left to right, there

are file storage, 18 17 19 20 22 21 file load, page no. and page switch, file search and delete functions.

13. Function menu, which will be pointed out in Zone No. 14.,15.,16.

14. In this zone, there is small input keyboard, which is used to obtain the file name, date, file no. After

the input is over, there is some notes whose description will be shown in zone No.15.

15. Click is available here, which contains the information input by user. If the box is green, it means

user has input information, if click this zone, then user’s information will be deleted.

16. The zone is virtual key, which is used to confirm or give up the inputted information.

17. Click is available in this zone, which is used to display the system setting and its status, after click,

there is optional menu, which is fit as Zone No. 18.

18. System setting menu, if click the zone out of the menu, it means user confirm the updated setting.

19. If click this zone, the switch is finished, the zone means virtual page up zone.

20. If click this zone, the switch is finished, the zone means virtual page-down zone.

21. Click there, it will show the date, if click, there is data setting keyboard.

22. Click there, it will show the time, if click, there is time setting keyboard.

11

3.1.3 Keyboard diagram and function

1

2

3

4

5

6

7

8

9

11

10

12

Keyboard—character

Keyboard—calendar setting

3.2 The output command

3.2.1 Start

1. Use START to control the output, long press can generate long pulse beeper.

2. Use foot switch to control the output, there are 5 modes, the mode can be revised in parameter

setting

Edge_U: Rising edge trigger

Edge_D: Falling edge trigger

Level: Level trigger

Hold: Hold the switch, it means output

3.2.2 Stop

1. Use STOP to control the output, long press to generate the long pulse beeper. When instrument is in

output status, press STOP to stop the output, and when the STOP key is pressed, instrument will cut the

internal relay to cut off the current path.

2. Use foot switch to stop the output.

Edge_U: Rising edge cut

Edge_D: Falling edge cut

Level: Level cut

Hold: Hold the switch, it means cut

17:23:45

13

Chapter 4 Command interface

4.1 ST1778 RS232C

As the most serial ports, ST1778 is not strictly based on RS-232, and uses only a minimal subset of the

9 pins. Only three wires are actually used:

Signal

Abbr.

Pin No.

Send data

TXD

3

Receive

data

RXD

2

Ground

GND

5

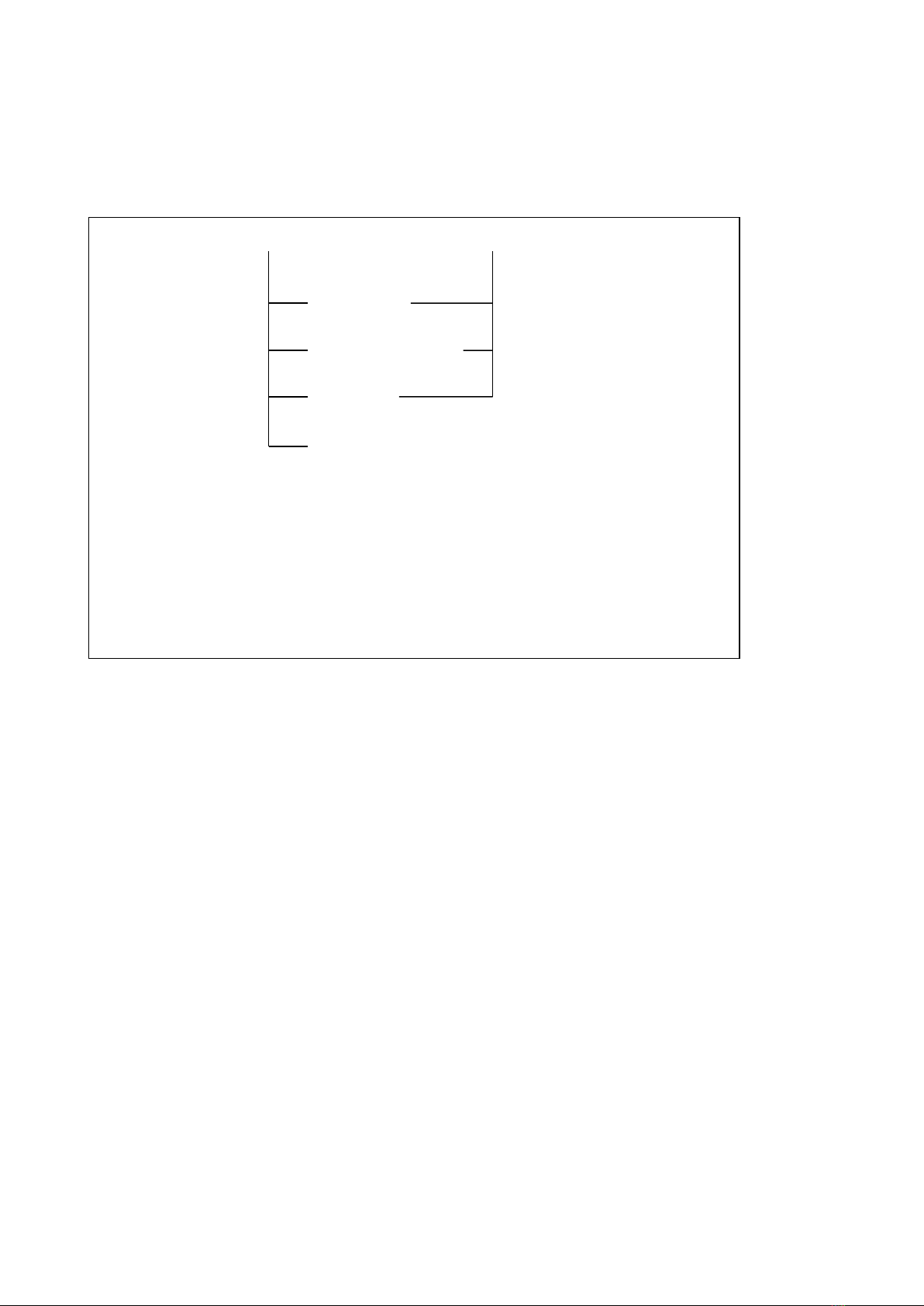

The connection of instrument and PC:

TXD(2)

PC RXD(3)

GND(5)

(2) RXD

ST1778

(3) TXD

(5) GND

As seen in the figure above, the pin definition of ST1778 is different from the 9-pin configuration in IBM

AT. Connection has to be 1:1, no crossover of Tx/Rx. Users can order a serial port cable from

Sourcetronic.

4.2 SCPI commands

<NR1> :Integer, as: 123。

<NR2> :fixed-point, as: 12.3。

<NR3> :floating point, as: 12.345……。

<LF> :Command terminator (Enter), which is 0x0A as a hexadecimal number or 10 in decimal. The

terminator should be added after all commands, otherwise, the instrument stays in waiting status. When

there is data returned, each data is terminated as <LF>.

4.2.1 General command set

*IDN?

Check the manufacturer, model, edition and firmware revision date. The returned format is as below:

“Sourcetronic,ST1778,V1.0.6,@2013.12”

*STA

Start the output.

*STO

Stop the output

4.2.2 ST1778 sub-system commands

The following is the root command set for the SCPI sub- system

●DEVIce ●MEMOry ●PARAmeter ●REMOte ●STATe ●SWITch ●SYSTem ●WORKing

14

1. DEVIce sub system command set

DEVIce is used to inform if ST1778 follows Sourcetronic standard with the communicated instrument.

Different settings will cause different system action: If Sourcetronic standard is used (TH), there is no

return if a parameter is changed; if switch to common mode (COMMon), all activity will be reported

back to the controller (default is common).

Command tree:

:MODEl control SCPI command

Command:DEVIce:MODEl <SCPI mode><LF>

<SCPI mode>:

COMMon set SCPI system as common mode, any activity from instrument will return

parameters, it is a default mode.

TH set SCPI system as Sourcetronic mode.

E.g :Send_Command(”DEVI:MODE TH”); set instrument to enter Sourcetronic mode

Return command: ”1778”

2. MEMOry sub system command set:

MEMOry sub system command set can realize the remote operation to local file system. The

separator can be any of “,.:-”, it will be expressed as <DELI> in the command tree, please note to

change it to one of the above allowed delimiters in real operation. In command tree, <NR1> should

be in the range of 1~99

Command tree:

:DELEte delete the file

Command: MEMOry:DELEte <number string><LF>

<number string>:

<NR1> 1~99

<DELI> separator“,.:-”

E.g.:Send_Command (”MEMO:DELE 1,5.16,21:34,75,94-97”); delete the file of No.1, 5, 16, 75, 16

to 21 and 94 to 97.

:SAVE save the current setting

Command: MEMOry:SAVE <number string><LF>

MEMOry—— :DELEte —— <NR1><DELI><NR1>…

:SAVE

:READ <NR1>

:LOAD

DEVIce:MODEl COMMon

TH

15

<number string>:

<NR1> 1~99

<DELI> separator“,.:-”

E.g.:Send_Command (”MEMO:SAVE 1,5.16,21:34,75,94-97”); save the file of No.1, 5, 16, 75, 16 to

21 and 94 to 97.

:READ read file

Command: MEMOry:READ <number><LF>

<number>:

<NR1> 1~99

E.g.:Send_Command (”MEMO:READ 5”); read the No.5 file, the description is as:

File head

Description

Format

Content

byte

Valid flag (dirty)

WORD

0 invalid/‘D’valid

2

Serial No. (No.)

WORD

1~99

2

(name)

STRING

‘0’~’9’/’A’~’Z’/’a’~’z’

16

(time)

TIME

‘0’~’9’&’-’&’:’

20

(addr)

DWORD

number

4

Total

44

File body

Description

Format

Content

(byte)

Current setting

MULTIPLE

ASCII

44

Frequency setting

MULTIPLE

ASCII

44

Step setting

MULTIPLE

ASCII

44

Delay setting

MULTIPLE

ASCII

44

Foot control setting

MULTIPLE

ASCII

44

Total

220

The details of each setting:

Single setting

Description

Format

Content

(byte)

Data

FLOAT

NUMBER

4

Name

STRING

’A’~’Z’/’a’~’z’

16

Character string

STRING

‘0’~’9’/’A’~’Z’/’a’~’z’

20

Chinese character addr.

MULTIPLE

ASCII

4

Total

44

:LOAD used to load the existed file

Command: MEMOry:LOAD <number><LF>

<number>:

<NR1> 1~99

E.g.:Send_Command(”MEMO:LOAD 5”); load No.5 file.

16

3. PARAmeter sub system command set

PARAmeter sub system command set is used to remote adjust the parameter.

Command tree:

:CURRent set the output current (unit:A), ”?” can inquire the current.

Command: PARAmeter:CURRent <number><LF>

<number>:

<NR3> 0.0~20.0*(n+1)(n means the quantity of slaves) floating number.

E.g.:Send_Command(”PARA:CURR 17.6”); set the current as 17.6A.

:DELaY set the time interval of scanning step(unit:ms), “?”can inquire the delay

Command: PARAmeter:DELaY <number><LF>

<number>:

<NR3> 0.0~3600000.0

E.g.:Send_Command(”PARA:DELY 100”); set the time interval of scanning step as 100ms。

:FREQuence set the frequency(unit:kHz), “?”can inquire the frequency

Command: PARAmeter:FREQuence <number><LF>

<number>:

<NR3> 0.0~2000.0

E.g.:Send_Command(”PARA:FREQ 300”); set the frequency as 300kHz.

:STEP set the step adjustment(unit:A), “?”can inquire the step

Command: PARAmeter:STEP <number><LF>

<number>:

<NR3> 0.0~20.0*(n+1)(n means the quantity of slaves) floating number.

E.g.:Send_Command(”PARA:STEP 2.1”); set the step as 2.1A。

:FOOT set the foot control mode(there are 5 modes), “?”can inquire the mode

PARAmeter —— :CURRent —— <NR3>

:DELaY

:FREQuence

:STEP

:FOOT EDGeD

EDGeU

HOLD

LOCKed

VOLTage

17

Command: PARAmeter:STEP <string><LF>

<string>:

EDGeD set the valid mode as down edge

EDGeU set the valid mode as up edge

HOLD set the valid mode as hold

LOCKed set the mode as lock, it means turn off

VOLTage set the mode as level

E.g.:Send_Command(”PARA:FOOT EDGD”); set the mode as down edge trigger

4. REMOte sub system command set

REMOte sub system command set is used to remote control the lock and unlock of system

Command tree:

Command: REMOte <string>

<string>:

LOCKed

UnLOCked

E.g.:Send_Command(” REMO ULOC”); unlock the system

5. STATe sub system command set

STATe sub system command set is used to remote inquire the state of host and system.

Command tree:

:HOST inquire the state of host, add“?” at the end.

Command: STATe:HOST?<LF>

E.g.:Send_Command(”STAT:HOST?”); obtain the state of host.

Definition of returned data (include a byte):

When the following bit is 1, it means the state is on or valid

Bit1: if charge

Bit2: if working

Bit3: if over heat

Bit4: if over load

STATe —— :HOST

:WORKing

:SLAVe——<NR1>,<NR1>…

REMOte—— LOCKed

UnLOCked

18

Bit5: if unbalance

Bit6: if set this set

:WORKing obtain the working state, add “?”at the end.

Command: STATe:WORKing?<LF>

E.g.:Send_Command(”STAT:WORK?”); obtain the working state.

Definition of returned data:

“preparing”: the system is in prepare

“stop”: the system is in stop, waiting for trigger or other thing happen

“running”: system is in output state

:SLAVe obtain the state of slave, add“?”at the end.

Command: STATe:SLAVe <string>?<LF>

<string>:

<NR1> 1~5

“,” ID character

E.g.:Send_Command(”STAT:SLAV 1,2,5?”); obtain the state of slave no.1, 2, 5.

Definition of returned data (each slave includes 2 bytes):

When the following bit is 1, it means the state is on or valid (each byte should deduct ASCII

character’0’, then can get the real data)

Bit1: if charge

Bit2: if working

Bit3: if over hear

Bit4: if over load

Bit5: if unbalance

Bit6: if setup the set

6. SWITchsub system command set

SWITchsub system command set is used to check if user has started the setting of slave

Command tree:

:SLAVe control the state of slave

Command: SWITch:SLAVe <string>

<string>:

:TurNOfF turn off the slave

Command: SWITch:SLAVe:TurNOfF <string>

<string>

NR1 1~5

“,” ID Interval

E.g.:Send_Command(”SWIT:SLAV:TNOF 1,2,5?”); turn off the slaves No. 1, 2, 5.

:TurNON turn on the slave

Command: SWITch:SLAVe:TurNON <string>

<string>:

SWITch——:SLAVe——:TurNOfF——<NR1>,<NR1>…

:TurNON

Table of contents

Popular Laboratory Equipment manuals by other brands

SynOptics

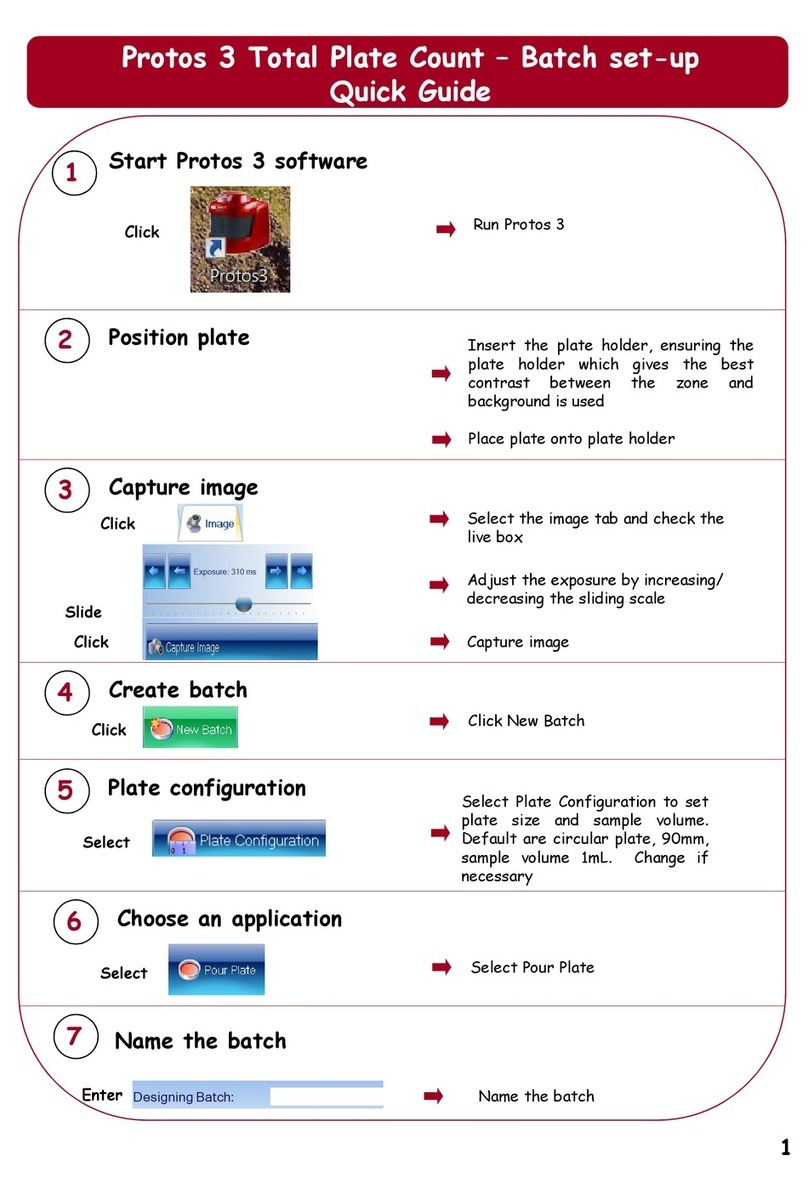

SynOptics SYNBIOSIS Protos 3 quick guide

Lightmed

Lightmed TruScan Pro Operator's manual

DENTAURUM

DENTAURUM 090-606-00 Instructions for use

FuturaSun

FuturaSun ZEBRA Pro Series Safety and installation manual

Fisher Scientific

Fisher Scientific fisherbrand 850 user manual

Infors HT

Infors HT Labfors 5 operating manual