Dieffematic EKOS M1 230 User manual

INSTRUCTIONS: EKOS M1 230

TECHNICAL SPECIFICATIONS

Voltage

Power

Accessory power output

Automatic closing time

Operating time

Slowing time

Courtesy light time

Number of codes

Transmitters

Frequency

Operating temperature

Sensibility

Homologation

220 VAC +/- 10%

550 W

24 VAC 250mA

5 to 120 sec

3 to 120 sec

2 to 120 sec

2 to 180 sec

254 codes

Fix\Rolling code

433.92 / 868 Mhz

0 to 70°C

–100dBm

Conf ETS 300-220/ETS 300

-683

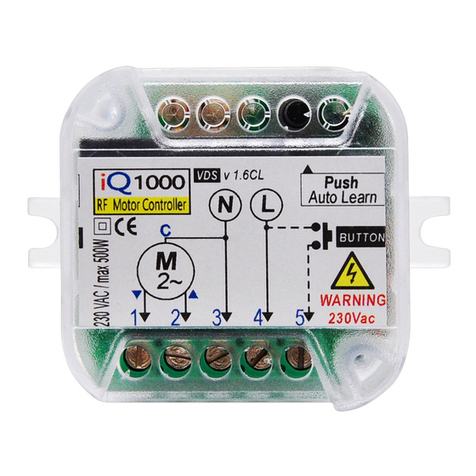

Terminals Type Description

1 - 2com NO START contact (Alternate Pulse OPEN/STOP/CLOSE/STOP)

3 - 2com NO PEDESTRIAN contact

4 - 6com NC BAND/PHOTOCELL OPENING contact (If you do not use it, please close the contact)

5 - 6com NC PHOTOCELL CLOSING contact (If you do not use it, please close the contact)

7 - 6com NC STOP contact (If you do not use it, please close the contact)

9 - 8com NC LIMIT SWITCH OPENING contact

10 - 8com NC LIMIT SWITCH CLOSING contact

11 - 12 24V ~ Photocells + accessories 24VAC 250mA power

13-14-15 220V ~ MOTOR input (13-14 electrical phases with a capacitor in parallel) (15 neutral/common)

16 - 18 220V ~ FLASHING LIGHT input

17 - 18 220V ~ COURTESY LIGHT input

19 - 20 220V ~ LINE input 220VAC

21 - 22 ANTENNA input (21 joiner / 22 signal)

L1 STATUS Led On when the control panel is powered

L2 RADIO Led On when you log in the radio memory

L3 PROGRAMMING TIME

Led

The led flashes during the programming

L4 START Led On when you give a pulse

L5 PEDESTRIAN Led On when you give a pedestrian pulse

L6 PHOTOCELL Led On when the potocells are aligned

L7 L. S. OPENING Led On when the limit switch is in N.C.

L8 L. S. CLOSING Led On when the limit switch is in N.C.

L7+L8 STOP Led Both on when the stop is in N.C.

LED READING

JUMPER J1

Radio memory opening by transmitter.(Possibility of storing from the ou-

tside the transmitters without operating on the control panel).

Insert jumper: ON OFF

TRIMMER T1

The Power Trimmer regulates the pair and the sensitivity in normal operation.

TRIMMER T2

The Power Slow Trimmer regulates the pair and the sensitivity in slowing.

-+The pair increases turning the trimmer in clockwise.

BUTTON P1

RADIO PROG button for the storage of the transmitters

BUTTON P2

TIME PROG button for the storage of the operating time

P1

P2

J1

T1 T2

L4 L5 L6 L7 L8

L2

L3

COM

N.C.

N.C.

N.C.

N.O. N.O.

1234

5678

L1

N.C.

COM N.C.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

COM

21 22

SELECTION

OPTIONS 1-8

P2

v M 01022012

OPTION 1 GARAGE / SLIDING SECTION

ON Garage (2 sec pressure in more after the L.S. closing)

OFF Sliding

OPTION 2 AUTOMATIC CLOSING

ON Inserted automatic closing

OFF Not inserted automatic closing

OPTION 3 RESIDENTIAL MODE / STEP BY STEP

ON The automation always stops the operation to the limit switch: in

the opening movement it does not accept pulses; in the closing move-

ment it causes the inversion of the direction.

OFF For each pulse the automation stops. With the dip 2 ON during the

closing movement a pulse causes the inversion of direction.

OPTION 4 INVERSION OF DIRECTION

ON Inverts the direction of movement of the motor with its L.S.

OFF Inverts the direction of movement of the motor with its L.S.

OPTION 5 SETUP OF THE SAFETY CONTACT IN OPENING

ON Opening safety operation: the control panel stops the movement and

inverts it for 2 sec

OFF Opening safety operation: the control panel stops the movement

OPTION 6 FLASHING LIGHT FUNCTION

ON Intermittent light

OFF Fixed light

OPTION 7 SLOWING

ON Inserted slowing

OFF Not inserted slowing

OPTION 8 ENCODER

ON Active Encoder input

OFF Not active Encoder input

GENERAL

The panel EKOS M1 230 is a control unit for sliding door, garage door and road barrier systems at 230Vac. This control panel

can manage motors with or without limit switch, with encoder and encoder + limit switch. The peculiarity of the EKOS M1 230 is the

regulation of separated pair, using the T1 and T2 trimmers (T1 regulates the pair during the opening time in normal speed

and T2 regulates the pair in the slowing). Interacting on these control panels you can optimize the operation of the automatism

within the parameters of the existing regulations. The self-learnig programming of the operating time and the transmitters simplifies the

procedure of installation.

In case of management by ENCODER (OPTION 8 ON) the security is guaranteed by mechanical photocells / bands and enco-

der system: in presence of obstacles the opening operation is inverted or blocked.

With the not active ENCODER (OPTION 8 OFF) you do not have the inversion of direction but only the control of the pair using

the trimmer T1 and T2.

TRANSMITTER PROGRAMMING

The control panel can manage fixed and rolling code transmitters. The two systems can not be manged simultaneously; the

first programmed transmitter encodes the radio software.

The EKOS M1 230 can manage 254 transmitters.

Press the button P1 for 2 sec, the led L2 flashes, then press the button of the transmitter: the led L2 will flash twice to indicate that the

transmitter has been stored. After 6 sec the control panel will automatically exit from the programming function.

PEDESTRIAN PASSAGE PROGRAMMING (by transmitter)

Press the button P1 for 2 sec, release it and press it again for 1 sec, the led L2 starts to flash and for each pressure of the button of

a transmitter there is a quick double flash of the led L2. After 6 sec the control panel will automatically exit from the programming fun-

ction. The operating time of the pedestrian passage is 8 sec.

STORED CODES DELETING

Press the button P1 for 6 sec: when you release it, there is a quick flash of the led L2; after 6 sec it will be off.

OPENING TIME PROGRAMMING

The programming starts when the automation system is closed: the first operation is the opening; if not, invert the direction

of movement using the dip 4.

PROGRAMMING WITHOUT SLOWING (OPTION 7 OFF)

Set the option 7 to OFF for the exclusion of the slowing. Follow the above-mentioned instructions (programming with slowing) without

sending the second pulse for the elimination of the slowing in the opening operation and the fourth pulse for the elimination of the slo-

wing in the closing operation. Then the pulses transmitted for the start of the operations will stop to the limit switch.

PROGRAMMING WITH SLOWING (OPTION 7 ON)

Pulse = Wired start or Channel 1 of the transmitter

To enter in programming mode, press the P2 button for 2 seconds; the LED 3 will flash, then:

1. Give a first pulse: the gate starts the opening operation.

2. Give a second pulse where you want to start the slowing operation.

3. The gate stops the operation to the limit switch. (If you use an automation without FC, give a pulse to stop the operation)

4. After stopping the opening operation, it will start the PAUSE storage in sec.

5. After your desired time interval, give a third pulse: the gate starts the closing operation.

6. Give a fourth pulse where you want to start the slowing operation.

7. The gate stops the operation to the limit switch. (If you use an automation without FC, give a pulse to stop the operation)

8. When the led 3 is off you have finished the programming.

ENCODER OPERATION

The encoder input is programmed using the OPTION 8,

CHANGE OF SENSITIVITY ACCORDING TO THE PAIR

More pair = Less sensitivity

Less pair = More sensitivity

The parameters are regulated using the T1 and T2 TRIMMER.

OPTIONS SELECTION USING THE DIP-SWICHT

Other Dieffematic Control Unit manuals

Popular Control Unit manuals by other brands

Siemens

Siemens HOTEL SOLUTION HTC3.1/A manual

Agilent Technologies

Agilent Technologies 54751A manual

Captron

Captron CANEO 41 Series Original operating instructions

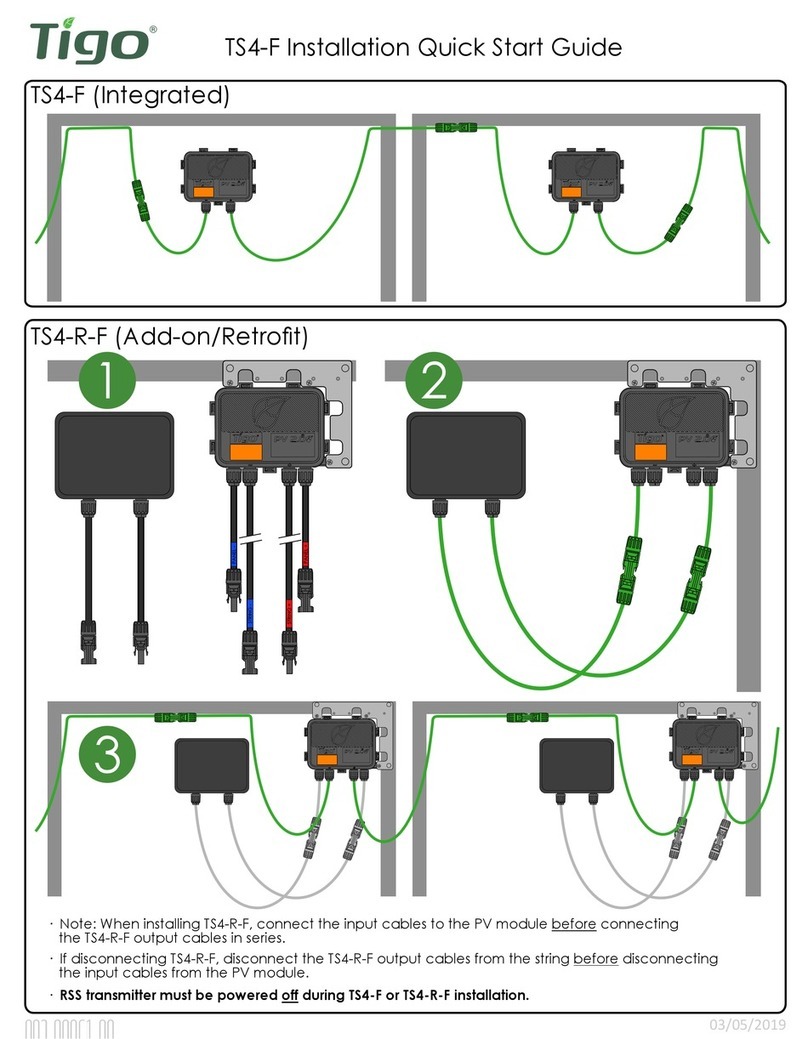

Tigo

Tigo TS4-F Installation & quick start guide

Becker

Becker Centronic UnitControl UC52 Assembly and operating instructions

CLA-VAL

CLA-VAL 34AR Series installation manual