DIEGON AP80 User manual

Manual AP80

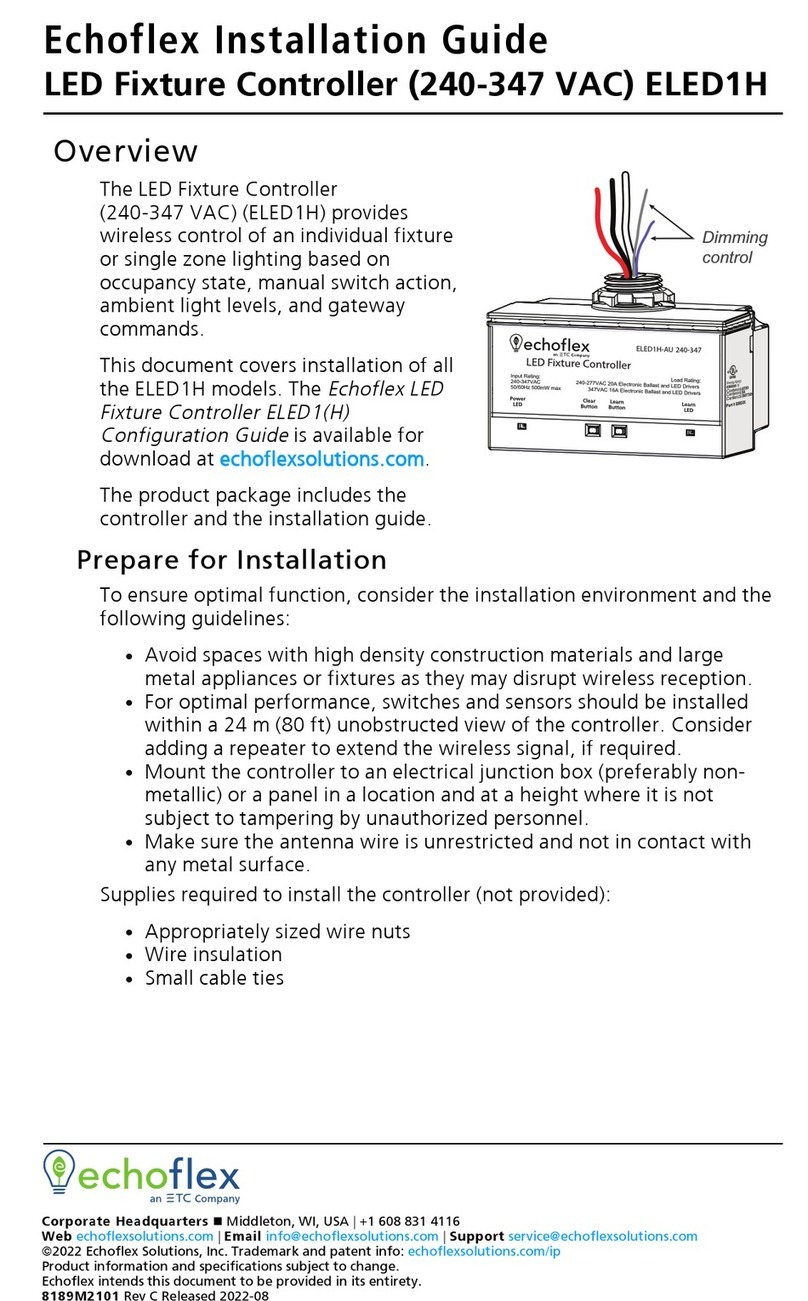

Display Controller

•8 Digit display in DIN-enclosure 144 X 72 mm

•Supply voltage 10 – 35V DC

•All in- and outputs optically isolated

•Input for absolute SSI encoders, incremental en-

coders, parallel encoders and Start/Stop sensors

•CAN-bus, RS232, RS422/RS485

•6 Digital inputs and 9 digital outputs

•24 Programmable cams / 9 outputs

•48 Programmable nominal values

•Dynamic cam-adjustment (cycletime 250µ

µµ

µS)

•Programmable analog output (16 bit)

•Linearization function

•Datamodule for 24 in- and 24 outputs

•Datamodule for 32 (tri-state) outputs

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

2

Table of contents

1

Introduction................................................................................................6

1.1

G

ENERAL

.................................................................................................................................6

1.2

I

MPORTANT INFORMATION

......................................................................................................7

1.3

EMC .......................................................................................................................................7

1.4

D

EFINITIONS

............................................................................................................................7

1.4.1

Display units AWE ..........................................................................................................7

1.4.2

Parameter number ..........................................................................................................7

1.4.3

Notation...........................................................................................................................8

1.4.4

Edges...............................................................................................................................8

2

Operation...................................................................................................9

2.1

K

EY FUNCTIONS

......................................................................................................................9

2.2

K

EY FUNCTIONS IN PROGRAMMING MODE

.............................................................................10

2.3

D

ISPLAY FUNCTIONS

..............................................................................................................11

2.3.1

Status functions .............................................................................................................11

2.3.2

Error messages .............................................................................................................11

2.3.3

Survey of error messages ..............................................................................................12

3

Programming ...........................................................................................14

3.1

A

UTOMATIC MODE

................................................................................................................14

3.1.1

Monitor function ...........................................................................................................15

3.1.2

Displaying the type number ..........................................................................................16

3.1.3

Displaying the software-version ...................................................................................16

3.1.4

Status in- and outputs....................................................................................................17

3.2

C

HANGING NOMINAL VALUES

................................................................................................18

3.3

C

HANGING PARAMETERS

.......................................................................................................19

3.3.1

Menus ............................................................................................................................19

3.3.2

Input parameters ...........................................................................................................20

4

Functions.................................................................................................21

4.1

B

ASIC FUNCTION

...................................................................................................................21

4.2

A

CTUAL POSITION

.................................................................................................................24

4.3

A

CTUAL VELOCITY

................................................................................................................24

4.4

M

ULTIPLICATOR

....................................................................................................................25

4.5

P

OWER FAILURE PROTECTION

................................................................................................25

4.6

E

DGE MULTIPLICATION

(

COUNTER INPUT

) .............................................................................26

4.7

P

RESET

(

COUNTER INPUT AND INTERNAL FREQUENCY

)..........................................................26

4.7.1

Preset using input K0....................................................................................................27

4.7.2

Preset using service parameter P[207] ........................................................................27

4.7.3

Preset using front keys ..................................................................................................27

4.7.4

Preset using input 1…6 .................................................................................................27

4.8

C

OUNTING RANGE

(

COUNTER INPUT AND INTERNAL FREQUENCY

).........................................28

4.8.1

Set counting range by parameter “Counting range” P[004]......................................28

4.8.2

Set counting range by nominal value ............................................................................29

4.9

N

UMBER OF BITS

SSI.............................................................................................................29

4.10

SSI

MONITORING

..................................................................................................................30

4.10.1

Output "SSI error" ........................................................................................................31

4.10.2

Reset "SSI error"...........................................................................................................31

4.11

J

USTAGE

SSI

EN

S

TART

S

TOP SENSORS

..................................................................................31

4.11.1

Juatage using the parameter "Adjustment absolute value" ..........................................31

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

3

4.11.2

Justage Using the input K0 ...........................................................................................32

4.11.3

Justage using service parameter P[207] ......................................................................32

4.11.4

Justage using front keys ................................................................................................33

4.11.5

Justage using input 1…6 ...............................................................................................33

4.12

CAN-

BUS

..............................................................................................................................34

4.12.1

AP-Link .........................................................................................................................34

4.12.2

Start/Stop sensor ...........................................................................................................36

4.13

ASCII

PROTOCOL

..................................................................................................................37

4.13.1

Overview functions........................................................................................................37

4.13.2

General..........................................................................................................................38

4.13.3

Functions.......................................................................................................................39

4.13.4

Error messages .............................................................................................................46

4.14

A

NALOG OUTPUT

...................................................................................................................47

4.15

V

OLTAGE OUTPUT

.................................................................................................................47

4.16

C

URRENT OUTPUT

.................................................................................................................48

4.17

E

XAMPLE PROGRAMMING VOLTAGE OUTPUT

.........................................................................49

4.18

C

AMS

.....................................................................................................................................50

4.18.1

General..........................................................................................................................50

4.18.2

Cam with start- and end-value......................................................................................50

4.18.3

Greater than or equal to limit value .............................................................................51

4.18.4

Smaller than or equal to limit value..............................................................................51

4.18.5

Dynamic cams ...............................................................................................................52

4.18.6

Start/stop cam ...............................................................................................................53

4.18.7

Output "Cams active"....................................................................................................53

4.18.8

Relative cams ................................................................................................................54

4.19

D

ATA INPUT

...........................................................................................................................56

4.20

D

ATA OUTPUT

.......................................................................................................................56

4.20.1

General..........................................................................................................................56

4.20.2

Output data ready .........................................................................................................56

4.20.3

Input enable...................................................................................................................57

4.21

E

XTERNAL THUMBWHEEL SETS

.............................................................................................58

4.21.1

General..........................................................................................................................58

4.21.2

Connecting thumbwheel sets.........................................................................................58

4.21.3

Parameter settings ........................................................................................................59

4.22

L

INEARIZATION

.....................................................................................................................60

4.22.1

mode 0 “4-Quadrant”..................................................................................................61

4.22.2

mode 1 “Mirror Y-axis” ..............................................................................................62

4.22.3

mode 2 “Mirror XY-axis” ............................................................................................62

5

Parameters..............................................................................................63

5.1

M

ENU

1

C

ONFIG

...................................................................................................................63

5.2

M

ENU

2

A

CTUAL

..................................................................................................................65

5.2.1

Submenu 2.1 Counter...................................................................................................65

5.2.2

Submenu 2.2 SSI...........................................................................................................66

5.2.3

Submenu 2.3 Internal frequency ..................................................................................69

5.2.4

Submenu 2.4 Parallel ...................................................................................................70

5.2.5

Submenu 2.5 CAN AP-Link ..........................................................................................71

5.2.6

Submenu 2.6 Start/Stop ................................................................................................72

5.3

M

ENU

3

CAN-

BUS

................................................................................................................73

5.4

S

UBMENU

3.1

C

ONFIG

..........................................................................................................73

5.5

S

UBMENU

3.2

O

BJ

1/PDO1

I

N

...............................................................................................74

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

4

5.6

S

UBMENU

3.3

O

BJ

1/PDO1

O

UT

...........................................................................................74

5.7

M

ENU

4

S

ERIAL

....................................................................................................................75

5.7.1

Submenu 4.1 Config .....................................................................................................75

5.7.2

Submenu 4.2 Ser-1 (RS232) ........................................................................................75

5.7.3

Submenu 4.3 Ser-2 (RS422/485) ..................................................................................76

5.8

M

ENU

5

I

NPUT

......................................................................................................................77

5.9

M

ENU

6

O

UTPUT

...................................................................................................................79

5.9.1

Submenu 6.1 – 6.9 Op1…9...........................................................................................79

5.10

M

ENU

7

D

ATA

......................................................................................................................80

5.10.1

Submenu 7.1 Data in....................................................................................................80

5.10.2

Submenu 7.2 Data out..................................................................................................81

5.11

M

ENU

8

A

NALOG

..................................................................................................................82

5.11.1

Submenu 8.1 Config .....................................................................................................82

5.11.2

Submenu 8.2 DA-U (voltage) .......................................................................................82

5.11.3

Submenu 8.3 DA-I (current).........................................................................................83

5.12

M

ENU

9

C

AM

........................................................................................................................84

5.12.1

Submenu 9.1 … 9.24 CA1…24.....................................................................................84

5.13

E

XTERNAL THUMBWHEEL SETS

.............................................................................................85

5.13.1

Submenu 10.1 Config ...................................................................................................85

5.13.2

Submenu 10.2 …10.4 Set-1...4 .....................................................................................86

5.14

M

ENU

11

L

INEARIZATION

.....................................................................................................87

5.14.1

Submenu 11.1 Config ...................................................................................................87

5.14.2

Submenu 11.2 … 11.31 P1…P30 ..................................................................................87

5.15

O

VERVIEW PARAMETERS

.......................................................................................................88

6

Connections.............................................................................................91

6.1

O

VERVIEW CLAMP CONNECTIONS

..........................................................................................93

6.2

S

UPPLY

..................................................................................................................................94

6.3

SSI

INPUT

..............................................................................................................................95

6.4

SSI

ENCODER

24V.................................................................................................................95

6.5

C

OUNTING INPUT

...................................................................................................................96

6.6

E

NCODER

5V

WITH INVERTED SIGNALS

.................................................................................96

6.7

E

NCODER

5V

WITHOUT INVERTED SIGNALS

...........................................................................97

6.8

E

NCODER

10

–

30V ...............................................................................................................97

6.9

S

TART

/S

TOP SENSOR

.............................................................................................................98

6.10

D

IGITAL INPUTS

.....................................................................................................................99

6.11

D

IGITAL OUTPUTS

..................................................................................................................99

6.12

A

NALOG OUTPUT

.................................................................................................................100

6.13

CAN-

BUS

............................................................................................................................100

6.14

RS232

S

ER

-1.......................................................................................................................101

6.15

RS422/485

S

ER

-2................................................................................................................101

6.16

D

ATA INPUT

(25P

SUB

-D

MALE

)..........................................................................................102

6.17

D

ATA OUTPUT

(25P

SUB

-D

FEMALE

) ...................................................................................103

6.18

D

ATA OUTPUT

(37P

SUB

-D

FEMALE

) ...................................................................................104

7

Technical specifications.........................................................................105

7.1

S

PECIFICATIONS

..................................................................................................................105

7.2

T

YPEKEY

.............................................................................................................................108

7.3

T

YPEKEY

T

HUMBWHEEL SETS

.............................................................................................108

7.4

D

IMENSIONS

AP80 ..............................................................................................................109

7.5

D

IMENSIONS

EMC

BRACKET TYPE

EMC-B01.....................................................................110

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

5

7.6

D

IMENSIONS THUMBWHEEL SWITCHES

APD-

XX

.................................................................111

7.7

D

IMENSIONS PROTECTIVE HOOD TYPE

CDS-B01.................................................................112

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

6

1 Introduction

1.1 General

With the microcontroller based AP80 it is possible connect the following en-

coder types:

- Incremental with quadrature (two 90°) signals

- Incremental with impulssignal and directionsignal

- Absolute with SSI (Synchron Serial Interface)

- Absolute with start/stop (MTS Sensor)

It is standard equipped with 6 digital inputs and 9 digital outputs, all free pro-

grammable. The AP80 incorporates possibilities like CAN-bus, RS232 com-

munication, RS422/485 communication, an analog output and a datamodule

with 24 inputs and 24 outputs or 32 tri-state outputs.

All in- and outputs, including the communication-ports, are electrically isolat-

ed.

With the 24 programmable cams several functions can be realized like limit

detection.

Another feature of the AP80 is the memory for the nominal values. The 48

programmable values can be used to determine the positions of the cams.

Up to 4 values can be read from external thumbwheel switches. These values

can be used as positions for the cams or as preset values.

The microcontroller reads the actual sensor value and calculates the display-

value and the actual velocity.

A programmable power failure protection makes sure that the actual value is

stored in an EEPROM.

The AP80 is configurable for numerous applications by adjusting its parame-

ters. One of the functions is an that the actual sensor value can be calculated

with a linearization table for nonlinear movements.

The AP80 can be programmed with the DST80 PC-based software.

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

7

1.2 Important information

The AP80 is a high-tech electronic product. To ensure safety and a correct

functioning of the product it is important that only qualified specialists will

install and operate the AP80.

If through a failure or fault the AP80 an endangering of persons or damage

to plant is possible, this must be prevented using additional safety

measures. These must remain operational in all possible modes of the

AP80.

Necessary repairs to the AP80 are only to be carried out by the manufac-

turer.

1.3 EMC

To ensure the best possible electromagnetic compatibility, it is recommended

to pay attention to shielding and grounding the AP80:

Shielding on both sides and with the largest possible contact area.

Keep wiring as short as possible.

Earth-connections should be short and with the highest possible wiring-

diameter.

Signal-cables and supply-cables must be separated.

The EMC-bracket type EMC-B01 should be used.

1.4 Definitions

1.4.1 Display units AWE

The display units, referred to as AWE, is the value shown on the display

without regarding the decimal point. The decimal point is only used for

the comfort of the operator, but has no functional meaning.

(display = 347.4 >> AWE = 3474)

1.4.2 Parameter number

A parameter number is always shown in the format P[xxx]. It is possible

that a parameter number appears in more than one menu.

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

8

1.4.3 Notation

Values can be displayed in different notations like binary or

hexadecimal. The character behind the value shows in which notation

the value is represented:

100D Decimal

238H Hexadecimal

244G Gray

10010011B Binary

for example 220D = DCH = 11011100B

1.4.4 Edges

LH : rising edge (low to high)

H L : falling edge (high to low)

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

9

P

+1

2 Operation

2.1 Key functions

[P] key

-Cycle through monitoring displays

-Activate programming mode (in combination with other keys)

[+1] key

-View type number

[Cursor] key

-View software version

-View custom software version (in combination with the [Enter] key)

[Enter] key

-View status of inputs and outputs

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

10

P

2.2 Key functions in programming mode

[P] key

-one step back in menu

-discontinue programming mode

-discontinue changing nominal values/parameters (edit mode)

-LED is on when programming mode is active

[+1] key

-cycle through menu

-increase nominal value- / parameter number

-increase digit (in edit mode)

[Cursor] key

-activate edit mode

-move one digit to the left (in edit mode)

[Enter] key

-enter a submenu or parameter

-increase nominal value-/parameter number

-store a changed value

-clear value, hold down [Cursor] button (edit mode)

+1

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

11

2.3 Display functions

2.3.1 Status functions

2.3.2 Error messages

There are two groups of errors:

Parameter errors (error numbers 0…499, preceeded by a “P”)

General error (error numbers from 500 and up)

Example:

General error 700

Error parameter 203

(Parameter out of min/max value)

General error number

Parameter error number

Operating (normal) mode

Power on

Appr. 1sec.

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

12

2.3.3 Survey of error messages

Error messages:

000...499 Parameter error is displayed as PXXX on the display.

700 = Reference value P[003] >= Counting range P[004]

701 = Adjustment value SSI P[005] >= Counting range

or Adjustment SSI P[005] < Offset P[002] (only if adjustment

type = 1,2, or 4)

702 = Adjustment value parallel P[005] >= Counting range

703 = Number of active SSI databits > number of SSI Clock pulses

704 = Transmitting and receiving with AP-Link not possible with the

same adress

705 = Offset SSI P[002] > Counting range

708 = No Hold-Reset possible (only possible with incremental and

internal frequency)

710 = Minus-sign and data ready on the same output on the data IO module

711 = Data input not possible together with parallel actual value

(absolute encoder)

712 = Minus-sign and data valid on the same input on data IO module

713 = Number of active bits on the data IO module too large

(minus-sign and or data valid are active)

716 = Umin >= Umax

717 = Imin >= Imax

720 = Changelock nominal values active

721 = Changelock parameters active

725 = Serial RS232 and RS485 both with ASCII at the same time not possible

732 = Function input-2 not valid (equal to input-1)

733 = Function input-3 not valid (equal to input-1...input-2)

734 = Function input-4 not valid (equal to input-1...input-3)

735 = Function input-5 not valid (equal to input-1...input-4)

736 = Function input-6 not valid (equal to input-1...input-5)

800 = SSI error delta-s

801 = SSI error cable failure

810 = Start/Stop error no magnet detected

811 = Start/Stop error time-out no stop signal detected

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

13

Error meldingen linearisatie (xx = P1 …P30)

9xx = Linearisatie Xn <= Xn-1

940 = Linearisatie (modus 1 of 2) X1 <> 0

941 = Linearisatie modus 1) Y1 <> 0

Error messages for cams (latst 2 digits = cam number)

1001…1024 length cam = 0 (cam begin = cam end) or

cam begin <= cam end (with no counting range active)

1101…1124 length cam <= Hysteresis

1201…1224 (2 * hysteresis) + cam length >= counting range

1301…1324 cam begin and/or cam end outside counting range

(incl. hysteresis)

Error messages ASCII

er 1 = parity error

er 2 = frame error

er 3 = overflow error

er 4 = buffer overrun

er 5 = number invalid

er 6 = data invalid (outside min/max value)

er 7 = programming mode parameters/nominal values active

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

14

3 Programming

There are three different modes of operation:

Automatic mode

Programming mode for nominal values

Programming mode for parameters

3.1 Automatic mode

In the automatic mode, depending on the type of sensor, the increments are

counted or the absolute position is read and the result is shown on the display

as the actual value. The velocity is calculated and can be visualized as well.

+1

Automatic

mode

Programming mode

Nominal values

Programming mode

Parameters

+1

1)

2)

1)

5x

2)

1) hold

2) press once

P

P

P

P

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

15

3.1.1 Monitor function

In automatic mode different variables can be displayed. By using the [P] key

one can cycle through the different pages:

Actual position

Actual velocity

Actual linearization

Voltage or current of the D/A-converter

Data input from the I/O module

CANbus error

Actual values thumbwheel sets

Parameter P[208] determines which option is visible after start-up.

P

After 2sec.

Actual value

Variable

Thumb 1 ..4

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

16

3.1.2 Displaying the type number

3.1.3 Displaying the software-version

Automatic mode

+1

Type

Automatic mode

Standard software

Custom software

(

Keep

pressed

)

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

17

3.1.4 Status in- and outputs

Inputs Outputs Outputs

1 = input-1 7 = output-1 17 = Hold/Reset active

2 = input-2 8 = output -2 18 = Cams active

3 = input-3 9 = output -3

4 = input-4 10 = output -4

5 = input-5 11 = output -5

6 = input-6 12 = output -6

A = input K1 13 = output -7

B = input K2 14 = output -8

C = input K0 15 = output -9

Automatic mode

1

4

7

10

13

16

2

5

8

11

14

17

3

6

9

12

15

18

A

B

C

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

18

3.2 Changing nominal values

Automatic mode

+1

P

Nominal value number

Nominal value

After 2 s

P

+1

P

+1

Nominal value number +1

Activate edit

mode

Nominal value number +1

Exit edit mode

Increase digit

Move one digit left

Confirm change

Exit programming mode

Clear inputThen

Then

*)

*) keep pressed

Edit mode

*)

blinking

Select nominal values

Changing values

Access to nominal va

lues

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

19

3.3 Changing parameters

3.3.1 Menus

The parameters are displayed in different menus and submenus:

1 ConFiG 10 D-SEt

2 ActuAL 10.1 ConF.

2.1 Cnt. 10.2 SEt-1

2.2 SSI 10.3 SEt-2

2.3 FrEG. 10.4 SEt-3

2.4 Par. 10.5 SEt-4

2.5 CanAP 11 Lin

2.6 StStP 11.1 Conf

3 Canbus 11.2 P 1

3.1 ConFG. ... ...

3.2 Obj/PDO in ... ...

3.3 Obj/PDO out 11.31 P30

4 SEriAL

4.1 ConFG.

4.2 SEr-1

4.3 SEr-2

5 InPut

6 OutPut

6.1 OP1

... ...

... ...

6.9 OP9

7 DAtA

7.1 DAtA in

7.2 DAtA out

8 AnALoG

8.1 ConFG.

8.2 dA-U

8.3 dA-I

9 Cam Example:

9.1 CA1 PAr. 6.1.1 means

... ... menu 6, submenu 1, parameter 1

... ...

9.24 CA24

Manual AP80

2016 V02. For software version V6.03. Subject to change without notice.

20

3.3.2 Input parameters

Automatic mode

P

+1

P

Menu

Submenu

+1

P

+1

Parameter number

Parameter value

After 2s

P

+1

P

+1

Menu item +1

To submenu/parameter number

Back to menu

Submenu item +1

To parameter number

Parameter number +1

Activat

e edit mode

Parameter number +1

Exit edit mode

Increase digit-value

Move 1 digit to the left

Confirm input

Back to menu/submenu

Clear inputThen

Then

*)

*) keep pressed down

Exit programming mode

Edit mode

5x

*)

submenu

Menu

Menu

subm

enu

Par.

Menu

blinking

Menu selection

Submenu selection

Selecting parameters

Changing parameters

Access parameters

Table of contents