Diener femto User manual

- 1 -

OPERATING

INSTRUCTIONS

Type: Femto

Please read this manual carefully before installing the

machine.

L

O

W

P

R

E

S

S

U

R

E

P

L

A

S

M

A

S

Y

S

T

E

M

- 2 -

S

Su

um

mm

ma

ar

ry

y

O

Of

f

D

De

el

li

iv

ve

er

re

ed

d

C

Co

om

mp

po

on

ne

en

nt

ts

s

1. Cabinet/

Basic Unit

2. Gas supply

3. Connections

4. Vacuum-

chamber

5. Carrier

6. Electrodes

7. Control

8. Generator

9. Vacuum

Pump

10. Options

Customer:

Date of delivery:

Please note, that for the handling with your machine, it is only neccesary to read the marked chapters!

1.1.1 1.1.2 1.1.3 1.1.4 1.1.5 1.1.6 1.1.7 1.1.8

1.4.1 1.4.2 1.4.3 1.4.4 1.4.5 1.4.6

1.5.1 1.5.2 1.5.3 1.5.4 1.5.5 1.5.6 1.5.7 1.5.8 1.5.9

1.6.1 1.6.2 1.6.3 1.6.4 1.6.5 1.6.6

1.7.1 1.7.2 1.7.3

1.8.1 1.8.2 1.8.3 1.8.4 1.8.5 1.8.6

1.9.1 1.9.3 1.9.4 1.9.5 1.9.6 1.9.7 1.9.8

1.10.1 1.10.2 1.10.3 1.10.4 1.10.5 1.10.6 1.10.7 1.10.8

1.10.10 1.10.11 1.10.12 1.10.13 1.10.14 1.10.15 1.10.16 1.10.17

1.10.19 1.10.20 1.10.21 1.10.22 1.10.23 1.10.24 1.10.25 1.10.26

1.10.27 1.10.28 1.10.29 1.10.30

1.2.1 1.2.2 1.2.3 1.2.4 1.2.5 1.2.6 1.2.7

obligatorisch

1.10.18

1.10.9

1.9.2

- 3 -

S

Su

um

mm

ma

ar

ry

y

O

Of

f

D

De

el

li

iv

ve

er

re

ed

d

C

Co

om

mp

po

on

ne

en

nt

ts

s

11

.

Special

Options:

12

.

Remarks:

13

.

Specify

Connections:

- 4 -

T

Ta

ab

bl

le

e

O

Of

f

C

Co

on

nt

te

en

nt

ts

s

1. Delivered components and description.................................................

2. Connecting of the machine …………………………………………………..

3. Technical features of machine ..............................................................

4. Safety warnings ....................................................................................

5. Maintenance .........................................................................................

6. Emergency maintenance ......................................................................

7. Spare part list........................................................................................

8. EG declaration of conformity.................................................................

9. Warranty................................................................................................

10. Information according plasma processes.............................................

11. Index.....................................................................................................

12. Circuit diagram .....................................................................................

Manual for

Low Pressure Plasma Systems

Of following production series: Femto

Producer: Diener electronic GmbH + Co. KG

Talstr. 5

D-72202 Nagold

Germany

Tel.: 00 49 (0) 74 52 / 8 88 07 – 0

Fax: 00 49 (0) 74 52 / 8 88 07 – 50

Internet: www.plasma.de

As of: 2008-12-31

Copyright: Diener electronic GmbH + Co. KG

All rights reserved. This publication may be reproduced or transmitted only

with permission in writing form from the publisher (Diener electronic GmbH +

Co. KG)

Technical modifications are subject to change.

© Diener electronic GmbH + Co. KG

- 5 -

Checkliste

1. Schaltplan geprüft

2. Baratron Datenblatt dabei

3. MFC Datenblatt dabei

4. Generatordoku dabei

5. Pumpendoku dabei

6.

7.

8.

9.

10.

Dies wird dem Kunden nicht ausgeliefert.

Datenblätter in jedes Kapitel gleich dazuheften.

- 6 -

1.1 Delivered Components and Description

1.1 Cabinet / Basic Unit

1.1.1 BASIC UNIT TYPE A

•Dimensions: Width approx. 345 mm

Depth approx. 420 mm (570 mm incl. plugs)

Height approx. 211 mm

1.1.2 BASIC UNIT TYPE B

•Dimensions: Width approx. 560 mm

Depth approx. 600 mm (750 mm incl. plugs)

Height approx. 310 mm

1.1.3 BASIC UNIT TYPE C

•Dimensions: Width approx. 562 mm

Depth approx. 420 mm (570 mm incl. plugs)

Height approx. 211 mm

1.1.4 BASIC UNIT TYPE D

•Dimensions: Width approx. 211 mm

Depth approx. 420 mm (570 mm incl. plugs)

Height approx. 570 mm

1.1.5 BASIC UNIT TYPE E

•Dimensions: Width approx. 500 mm

Depth approx. 550 mm (700 mm incl. plugs)

Height approx. 460 mm

- 7 -

1.1.6 BASIC UNIT TYPE F

•Dimensions: Width approx. 500 mm

Depth approx. 550 mm (700 mm incl. plugs)

Height approx. 600 mm

1.1.7 BASIC UNIT TYPE G

•Dimensions: Width approx. 350 mm

Depth approx. 600 mm (750 mm incl. plugs)

Height approx. 860 mm

1.1.8 BASIC UNIT TYPE H

•Dimensions: Width approx. 600 mm (850 mm incl. plugs)

Depth approx. 800 mm

Height approx.1700 mm

- 8 -

1

1.

.2

2G

Ga

as

s

S

Su

up

pp

pl

ly

y

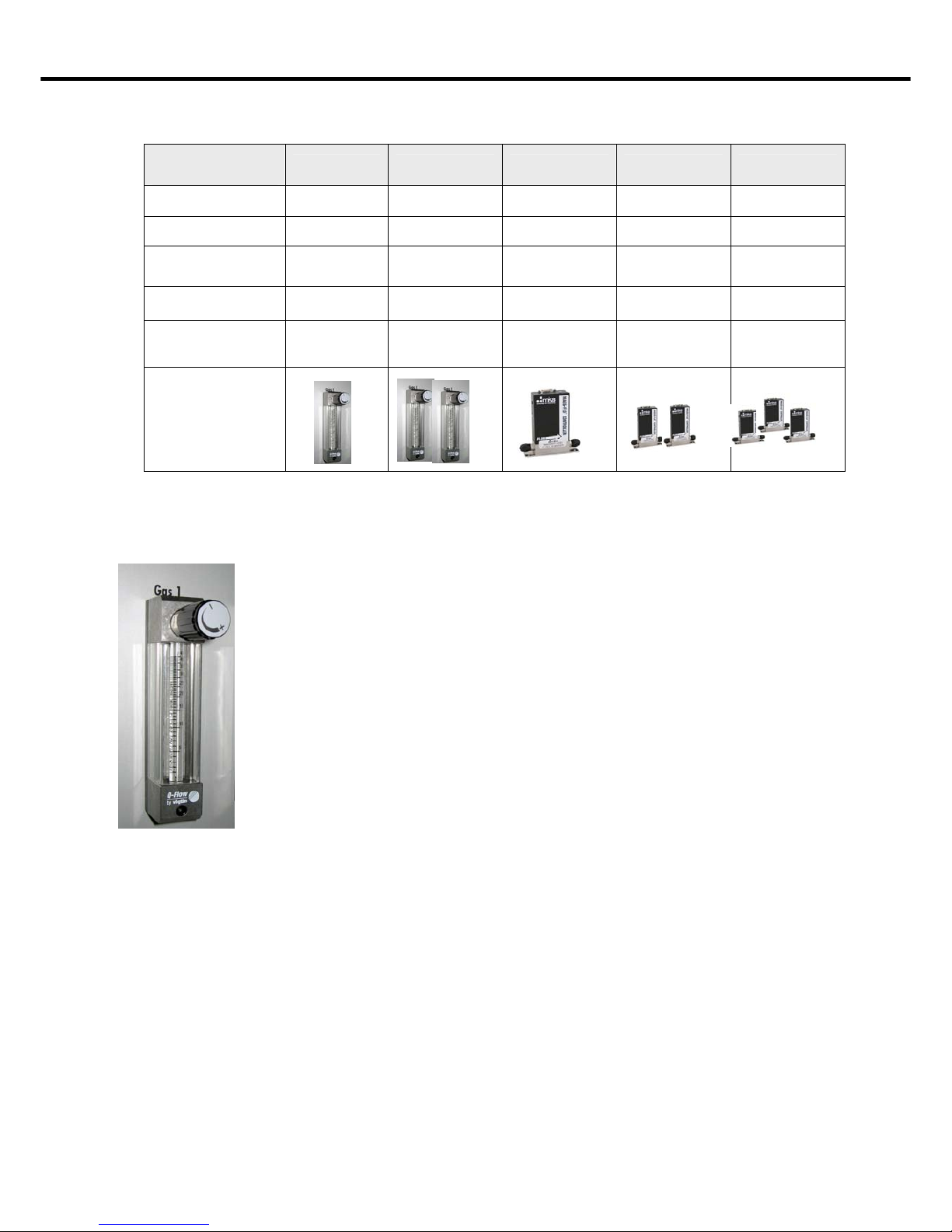

SELECTION

GAS SUPPLY 2.1 TYPE A2.2 TYPE B2.3 TYPE C2.4 TYPE D2.5 TYPE E

Qty. of gas

channels 1 2 1 2 3

Material stainless steel stainless steel stainless steel stainless steel stainless steel

Description needle valve needle valve MFC MFC MFC

Manufacturer Vögtlin Vögtlin MKS MKS MKS

Available

flow values in

sccm on request on request on request on request on request

Figure

The handling of the needle valve is very easy. To control the gas flow and

therefore the process pressure, the valve will be opened or closed.

The direction (to open and close the valve) is easily to see.

Please note following things:

•If the valve is completely closed, the plasma will turn off after

consumption of tail gas in the tubes.

•The gas flow ball, in the glass gauge tube of the valve,

sometimes gets caught at the upper end of the scale. That

happens when the valve has been opened too much. To detach

the ball, knock at the security glass of the gauge tube.

•Liquids may damage the needle valve. (Agglutinating of the

valve)

•Some aggressive solutions and gases (like HNO3, HCl, NH4,

…) may destroy the sealing of the needle valve. If you want to use

such chemicals, you should order the Special Option with a Kalrez

– Sealing. To ensure a long-lasting and save operating with such

materials, the complete machine and pump has to be modified

(Corrosive – Gas – Version).

•At usage of aggressive gases and chemicals, please contact

us to clarify if your machine is suitable for this process.

- 9 -

1

1.

.2

2G

Ga

as

s

S

Su

up

pp

pl

ly

y

There are two variations of MFC’s (Mass Flow

Controller)

Variation 1: manual control,

which has to be controlled like

the needle valve

And Variation 2: PC – controlled MFC. Detailed

Information according the handling of PC – controlled

MFC’s you will find in chapter 1.7 Controls, section PC-

Control.

Control MFC

- 10 -

1

1.

.3

3C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

1.3.1 Connections for basic unit type A

•Gas: 6mm Swagelok

•Voltage / Power: 230 V / 16 A

•Exhaust Air: tube, inner diameter approx. 10 mm

1.3.2 Connection for basic unit type D

•Gas: 6mm Swagelok

•Voltage / Power: 230 V / 16 A

•Exhaust Air: tube, inner diameter approx. 10 mm

Type label

Timer

Evacuation tube for

vacuum chamber

Ventilator

Connection

pump

Main power

supply

(220 – 240 V /

50/60 Hz)

Ventilation

Fuse

Gas connection

6 mm Swagelok

Ventilator

Connection

pump

Main power

supply

(220 – 240 V /

50 Hz)

Evacuation tube for

vacuum chamber

Type label

Ventilation

1 Gas connection

6 mm Swagelock

2 Gas connection

6 mm Swagelock

Fuse

- 11 -

1

1.

.3

3C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

1.3.3 Connections for basic unit type H

•Gas: 6mm Swagelok

•Voltage / Power: 400 V / 16 A

•Exhaust Air: tube, inner diameter approx. 10 mm

Gas connection 1

Gas connection 2

Evacuation tube

f

or vacuum

c

hamber

Ventilation

Main power

switch

Power supply

Scavenging gas /

flushing gas

connection

Compressed

air

Gas connection 3

(optional)

- 12 -

1

1.

.4

4V

Va

ac

cu

uu

um

m

C

Ch

ha

am

mb

be

er

r

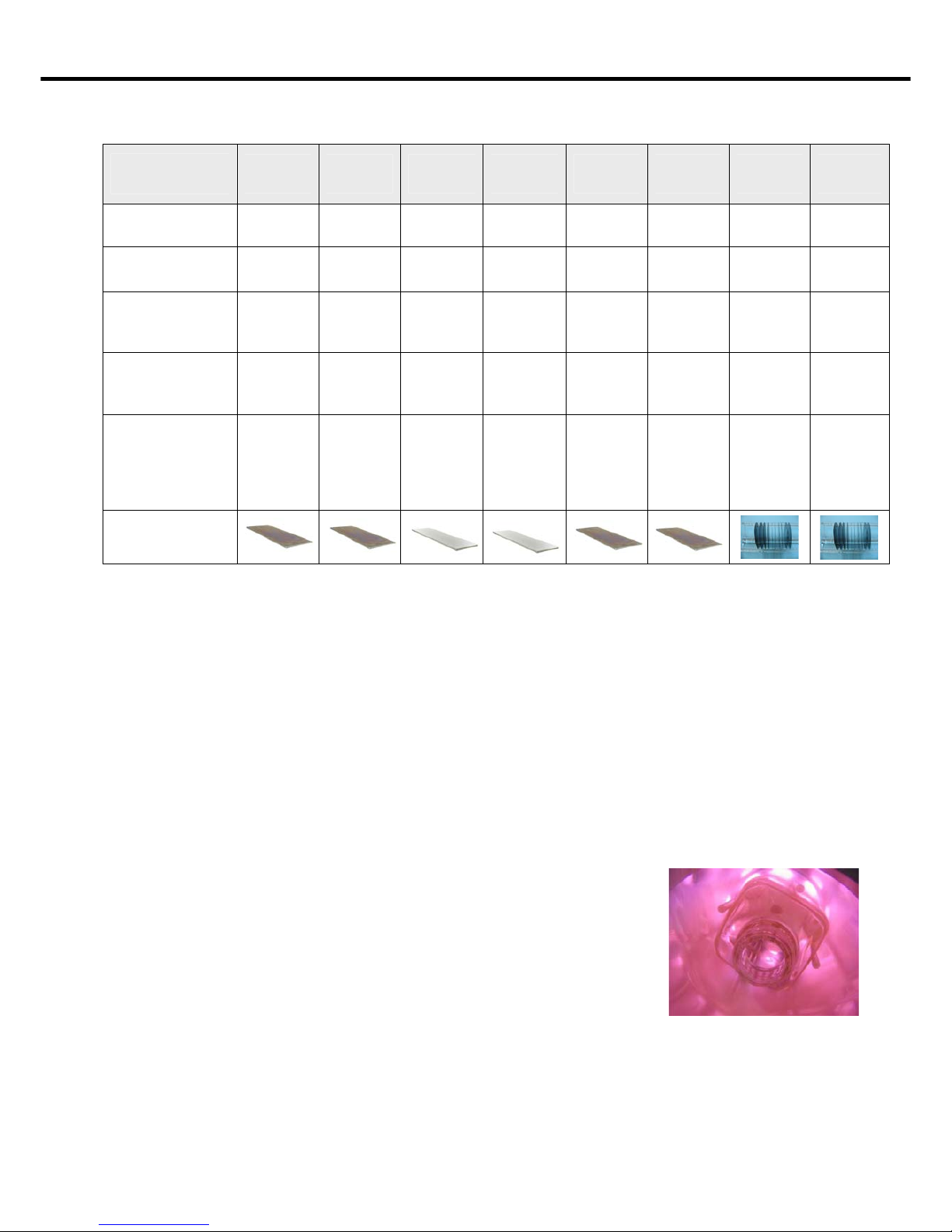

SELECTION

VACUUM

CHAMBER 1.4.1

TYPE A1.4.2

TYPE B1.4.3

TYPE C1.4.4

TYPE D1.4.5

TYPE E1.4.6

TYPE F

Chamber

configuration round round round round round rectangular

Material:

vacuum chamber stainless

steel

borosilicate

glass

borosilicate

glass quartz glass quartz glass stainless steel

Chamber cover cap cap hinged door cap hinged door hinged door

Covering material aluminium,

glass pane

aluminium,

glass pane

aluminium,

glass pane

aluminium,

glass pane

aluminium,

glass pane

aluminium,

glass pane

Inner diameter Dia. 100 mm

D 278 mm

Dia. 95 mm

D 320 mm

Dia. 95 mm

D 320 mm

Dia. 95 mm

D 320 mm

Dia. 95 mm

D 320 mm

W 103 mm

D 285 mm

H 103 mm

Opening diameter of

recipient Dia. 100 mm Dia. 90 mm Dia. 90 mm Dia. 90 mm Dia. 90 mm W 103 mm

H 103 mm

Chamber volume approx.

2 litres

approx.

2 litres

approx.

2 litres

approx.

2 litres

approx.

2 litres

approx.

3 litres

Application areas

standard

plasma

processes,

small batch-

and

laboratory

equipment

for pure

plasma

processes,

small batch-

and laboratory

equipment

for pure

plasma

processes,

bulk

production and

manufacturing

for ultra pure

plasma

processes,

small batch-

and laboratory

equipment

for ultra pure

plasma

processes,

bulk

production and

manufacturing

standard

plasma

processes,

bulk

production

and

manufacturing

Figure

Cleaning of the chamber:

To clean the chamber a simple oxygen gas process is enough. The process duration should be

one hour with an empty chamber (the trays are loaded into the chamber, but no sample parts).

If the machine is heavier contaminated (dusty, thick Polymerization layers), we advise to clean the

chamber manual with metal (chrome) polish or a standard trade oven cleaning spray. For harder

contaminations you can use steel wool (only in metal chambers).

Never use acetone to clean the chamber!

If you want to clean your machine after a coating process with HMDSO (Hexamethyldisiloxane), a

plasma process with CF4(Tetra fluorine methane) and O2(Oxygen) is the most effective process.

Use CF4only if your machine and pump are made for corrosive gases!

Check regularly the door seal and the chamber seal of the machine. Dust on the seals may cause

leakage, which may disturb / irritates some sensitive coating processes. Remove those pollutions

before starting the process.

Also check regularly the metal filters at the back of the chamber. Are the filters dark discoloured, it

is possible that their pores might be clogged. In this case clean the filters or replace them. The

consequences of clogged metal filters are the reduction of the suction power and the pirani sensor

might be disturbed in his measurement results (the results might be weighted).

Clean regularly the chamber window. Remains of coatings may disturb other processes and

you keep a better process control if you see the colour and spreading of the plasma.

- 13 -

1

1.

.5

5C

Ca

ar

rr

ri

ie

er

r

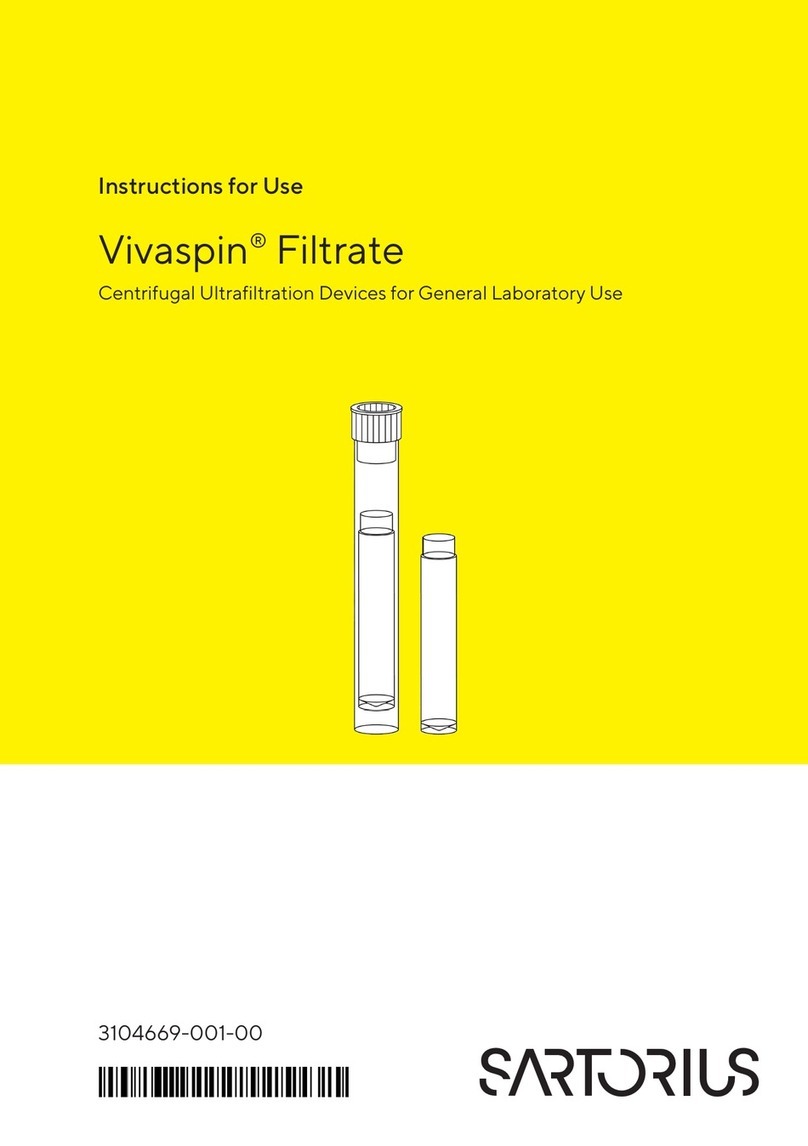

SELECTION

TRAYS 1.5.1

TYPE A1.5.2

TYPE B1.5.3

TYPE C1.5.4

TYPE D1.5.5

TYPE E1.5.6

TYPE F1.5.7

TYPE G1.5.8

TYPE H

Description flat tray flat tray flat tray flat tray flat tray flat tray quartz glass

boat

quartz

glass boat

Material: Tray aluminium stainless

steel

borosilicate

glass quartz glass aluminium stainless

steel quartz glass quartz

glass

Dimensions W 90 mm

D 255 mm

H 3 mm

W 90 mm

D 255 mm

H 3 mm

W 83 mm

D 265 mm

H 5 mm

W 83 mm

D 265 mm

H 5 mm

W 100 mm

D 270 mm

H 3 mm

W 100 mm

D 270 mm

H 3 mm

2 “

L 200 mm

for 15 pcs.

Wafer

3 “

L 200 mm

for 15 pcs.

Wafer

Qty. of possible

trays on request on request 1 piece 1 piece on request on request 1 piece 1 piece

Application areas standard

plasma

processes

standard

plasma

processes

pure plasma

processes

standard

plasma

processes

standard

plasma

processes

standard

plasma

processes

ultra pure

plasma

processes,

Wafer

treatment

ultra pure

plasma

processes,

Wafer

treatment

Figure

5.9 Device for powder treatment

•Powder is treated in a rotating glass bottle

•To fill the bottle, it can be removed from the mounting support

•Please note, that the bottle can only be filled to a third of the volume, according

to the size to the grain size / product fineness we advise an even smaller

amount, because fine powders have bigger surfaces.

•A suction filter is necessary at operating with abrasive chemicals

•More information can be found in chapter 10 Plasma Processes

•Only available with glass chambers

- 14 -

1

1.

.6

6

E

El

le

ec

ct

tr

ro

od

de

es

s

Selection Of

Electrodes 1.6.1 Type A1.6.2 Type B1.6.3 Type C1.6.4 Type D1.6.5 Type E1.6.6 Type F

Title standard

electrode

standard

electrode

multi level

electrode

multi level

electrode RIE-electrode

RIE-electrode

with gas

shower

Suitable For

Following Vacuum

Chambers round square round square round / square square

Material stainless steel /

aluminium-plate

stainless steel /

aluminium-plate

stainless steel /

aluminium-plate

stainless steel /

aluminium-plate stainless steel stainless steel

Area Of Application standard

plasma

processes

standard

plasma

processes

standard

plasma

processes

standard

plasma

processes

anisotropic and

isotropic etching

anisotropic

etching

Miscellaneous scope of delivery

scope of delivery to treat more

parts at once

to treat more

parts at once

to achieve

higher etching

rates

to achieve

higher etching

rates through

homogeneous

gas spread

Picture

Information concerning electrodes

1. Avoid short circuits. Short circuits may occur, when the Electrode gets in Contact with

the chamber wall or when electric conductive sample parts produce a contact between the

chamber wall and the electrode.

2. Metals, like stainless steel or aluminium, may start to sputter in little doses caused by

constant ion bombardment during the plasma process. Usually that does not bother /

disturbs the process in any kind. At very high expectations regarding the cleanness of

a product, it is advisable to use a glass chamber instead of a metal chamber.

3. The electrode has to be cleaned in regular intervals. At coating processes in the

machine, the interval should be shorter than at cleaning or activation processes. The

cleaning intervals are set by user.

4. The closer the carrier is placed to the electrode, the more intense the plasma will work on

the surface, whereas a distance of 20 mm to the electrode has to be kept.

- 15 -

1

1.

.7

7.

.

C

Co

on

nt

tr

ro

ol

ls

s

At all machines, without reference to the type of control, there are 5 process steps:

1. Pumping down: Recipient is evacuating to lower pumping down

pressure

2. Gas stabilization time: Gas is feeding in and pressure stabilize automatic

3. Process time: HF-Generator is turned on

4. Flushing time: Pump is running while purge gas (f.e. Air) rushes

into the chamber.

The chamber is flushed from eventually harmful

process gases.

5. Venting time: Chamber is filling with Air. The pump has to be

off.

For more Information see chapter 10 ‘Information According Plasma Processes’ and

the brochure ‘Plasma Technology’

- 16 -

1

1.

.7

7.

.

C

Co

on

nt

tr

ro

ol

ls

s

1.7.1 Control type A: semi - automatic

•The controlling of the process happens semi automatic

•Pump, gas flow, plasma process and venting have to be started manual.

•Selectable parameters: process time, power, kind of gas, gas flow

The single process steps are selected manual by user:

1. turn on pump

2. turn on process gas

3. set time

4. set power

5. start generator

6. flush

7.vent

main power switch

pump

gas

generator

c

ca

ar

rr

ri

ie

er

r

Set timer

a) Version with manual timer (at the back of the machine, see 1.3.1)

scale

1

1.

.7

7.

.

S

St

te

eu

ue

er

ru

un

ng

ge

en

n

1

1.

.7

7.

.

C

Co

on

nt

tr

ro

ol

ls

s

0,5 – 10 min

3 – 60 min

0,15 – 3 h

0,5- 10 h

3

–

30 h

0,15 – 3 min

3 – 60 sec

0,5 – 10 sec

0,15 – 3 sec

0,05 - 1 sec

door

electrode

power

HF-generator

timer

needle valve

Timer

venting

- 17 -

Choose the time range accordingly the process:

Example: Process duration 5 minutes

Pre chosen time range ½ - 10 minutes:

At the potentiometer on the front of the machine the time can be varied between ½ und 10

minutes via the scale division parts 0 – 10.

b) Version with digital timer: control timer settings

For more Information see chapter 10 ‘Information According Plasma Processes’ and the

brochure ‘Plasma Technology’.

•Connect 230 V (16 A)

•Turn on main power switch

•Turn off venting valve

•Load machine

•Take the door and push it against the chamber opening (while pump is on)

(Version with hinged door: close door)

This type of control is very comfortable to handle by operating with just one switch.

The single process steps are shown via analog measurement instruments.

1.7.2 Control type B: automatic

•The control of procedures happens automatic

•By pushing of the start button the pump, gas flow, plasma

process (timer, generator) and venting starts automatically.

•Selectable parameters: process time, power, kind of gas, pressure

Operating with automatic control:

1. Activate main power switch to start up machine

2. Push ‚start’ button

3. Activate and select the process gas (gas channel 1 or gas channel 2), the generator and the

venting button (‚flood’)

4. As soon as a pressure of 0.4 mbar is reached the timer, the gas and the generator will enable

to start. To install a new program it is advisable to start the process without parts inside. After

setting the parameters, a continuous process is possible.

5. Set the timer (see chapter 10.15)

6. Setting of wanted generator power via turning of button (potentiometer). The upper number

shows the ten’s, the lower number shows the unit place. The real power is shown in the analog

display.

7. Setting of the pressure via needle valve (Regulating the gas flow via opening and closing of

the needle valve).

8. Process ends up automatic after expiration of time. Also venting is automatic.

9. The ‚stop’ button exists only to interrupt a running process.

- 18 -

1

1.

.7

7.

.

C

Co

on

nt

tr

ro

ol

ls

s

Documentation for the control-software of the plasma machine (PRS)

Femto-Nano-Pico-Tetra V 4.0

- 19 -

1

1.

.7

7.

.

C

Co

on

nt

tr

ro

ol

ls

s

1. General___________________________________________________________________21

2. System requirements, installation_____________________________________________21

3. Operating modes___________________________________________________________22

3.1.1 Login / Logout_________________________________________________________________ 22

3.2 Operating Modes ________________________________________________________________ 24

3.2.1 Manual Mode ___________________________________________________________________________25

3.2.1.1 Generators____________________________________________________________________________26

3.2.1.1.1 LF-Generator ________________________________________________________________________26

3.2.1.1.2 RF-Generator ________________________________________________________________________26

3.2.1.1.3 RF-Generator with DC-Bias _____________________________________________________________27

3.2.1.1.4 RF-Generator with pulse width modulation__________________________________________________28

3.2.1.2 Matching _____________________________________________________________________________30

3.2.1.2.1 Diener eletronic Auto Matching___________________________________________________________30

3.2.1.2.2 Hüttinger Matching ____________________________________________________________________31

3.2.1.3 Pressure______________________________________________________________________________32

3.2.1.3.1 Pressure control with gases _____________________________________________________________32

3.2.1.3.2 Pressure control with gases or vapor ______________________________________________________32

3.2.1.4 Recipient _____________________________________________________________________________33

3.2.1.5 Pump stand ___________________________________________________________________________34

3.2.1.5.1 Pump stand with rotary vane pump _______________________________________________________34

3.2.1.5.2 Pump stand with rotary vane pump and roots pump___________________________________________34

3.2.1.6 Rotary drive ___________________________________________________________________________35

3.2.1.7 Vaporizer _____________________________________________________________________________36

3.2.1.7.1 Vaporizer with Cycle time and On time_____________________________________________________36

3.2.1.7.2 Vaporizer with two valves _______________________________________________________________36

3.2.1.8 Temperature __________________________________________________________________________37

3.2.1.9 Gas supply____________________________________________________________________________38

3.2. Automatic mode ________________________________________________________________ 39

3.2.1. Pumping down __________________________________________________________________________40

3.2.2. Gas supply time _________________________________________________________________________40

3.2.2.1 Gas supply time without vaporizer _________________________________________________________40

3.2.2.2 Gas supply time with vaporizer with Cycle time and On time _____________________________________41

3.2.2. 3 Gas supply time with vaporizer with two valves_______________________________________________42

3.2.3. Plasma process time _____________________________________________________________________43

3.2.3.1 Plasma process time with LF-Generator without heating_________________________________________43

3.2.3.2 Plasma process time mit LF-Generator or RF-Generator mit Puls width modulation and heating__________44

3.2.3.3 Plasma process time with LF-Generator and rotary drive ________________________________________45

3.2. 3.4 Plasma process time with RF-Generator with matching and with heating ___________________________47

3.2.4. Flushing period _________________________________________________________________________48

3.2.5. Venting period __________________________________________________________________________48

3.2.6. Saving of programs ______________________________________________________________________48

4. Operating _________________________________________________________________49

4.1. Start of the automatic mode ______________________________________________________ 49

4.2. Error messages/Alarmlist ________________________________________________________ 53

4.2.1 New list ________________________________________________________________________________54

4.2.2 Old list_________________________________________________________________________________56

4.2.3 Chronicle_______________________________________________________________________________57

- 20 -

1

1.

.7

7.

.

C

Co

on

nt

tr

ro

ol

ls

s

5. Settings __________________________________________________________________58

5.1.1 Gas types ______________________________________________________________________________59

5.1.2 Mass-Flow-Controller _____________________________________________________________________59

5.1.3 Pressure Controller _______________________________________________________________________60

5.1.4 RF generator____________________________________________________________________________60

5.1.5 Rotary drive_____________________________________________________________________________60

5.1.6 Heating ________________________________________________________________________________60

5.1.7 Vaporizer with two valves __________________________________________________________________61

5.1.8 Controller ______________________________________________________________________________61

5.1.9 System ________________________________________________________________________________62

5.1.10 Password _____________________________________________________________________________64

5.1.11 Save _________________________________________________________________________________64

5.1.12 Load factory settings_____________________________________________________________________64

6. Diagram __________________________________________________________________65

6.1. Settings _______________________________________________________________________ 65

6.1 Channel dialogue__________________________________________________________________________66

6.2 Y-axis dialogue ___________________________________________________________________________68

6.3 Y-axes dialogue ___________________________________________________________________________68

6.3.1 Axes alignment: _________________________________________________________________________70

6.3.2 Axes __________________________________________________________________________________70

6.3.3 Minimum/Maximum value __________________________________________________________________70

6.3.4 Scaling ________________________________________________________________________________70

6.3.5 Format ________________________________________________________________________________70

6.3.6 Precision _______________________________________________________________________________71

6.3.7 Colour _________________________________________________________________________________71

6.3.8 Y-Axis _________________________________________________________________________________71

6.3.9 Grid ___________________________________________________________________________________71

6.3.10 Zero line ______________________________________________________________________________71

6.3.11 Context menu __________________________________________________________________________71

6.3.12 Function of the diagram __________________________________________________________________72

6.3.13 Functions of the diagram in the manual mode _________________________________________________75

7. Archive___________________________________________________________________76

7. 1 Load... ________________________________________________________________________ 77

7.2. Print __________________________________________________________________________ 77

7.3 Export Process data _____________________________________________________________ 78

8. Maintenance ______________________________________________________________79

8.1. General _______________________________________________________________________ 80

8.2. Oil change _____________________________________________________________________ 80

8.3 Backup ________________________________________________________________________ 80

8.4 Leakage rate measuring __________________________________________________________ 82

8.5 Information_____________________________________________________________________ 82

9. Quitting the software _______________________________________________________82

Table of contents

Popular Laboratory Equipment manuals by other brands

Sartorius

Sartorius Vivaspin Filtrate Instructions for use

Agilent Technologies

Agilent Technologies 1260 Infinity II user manual

Dynamica

Dynamica Velocity 15HR instruction manual

Agilent Technologies

Agilent Technologies 55 AA instruction sheet

Thermo Scientific

Thermo Scientific Finnpipette FOCUS Instructions for use

Rice Lake

Rice Lake Ishida OMNi-4000 troubleshooting guide

diagenode

diagenode Bioruptor Pico manual

INOXPA

INOXPA MCR Series Installation, service and maintenance instructions

GREINER

GREINER Bio-One Sapphire MaxiPette Operation manual

Diagnosys

Diagnosys 95930 Quick reference guide

Ametek

Ametek mocon OX-TRAN 2/48 Operator's manual

Sakura

Sakura Tissue-Tek DRS 2000 Quick reference guide