Ishida OMNi-4000 Error Codes and Troubleshooting

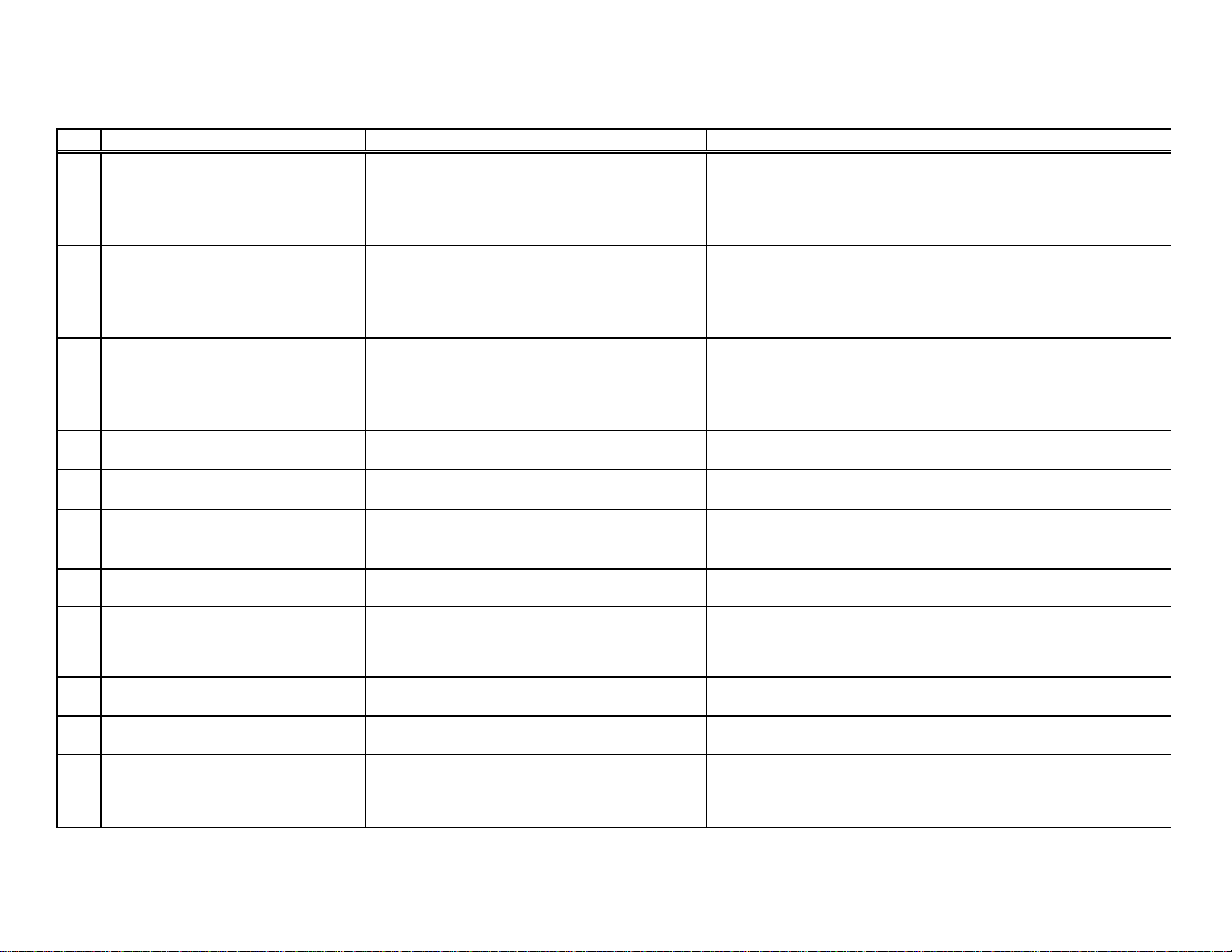

15.2 ERROR CODE (0200 - )

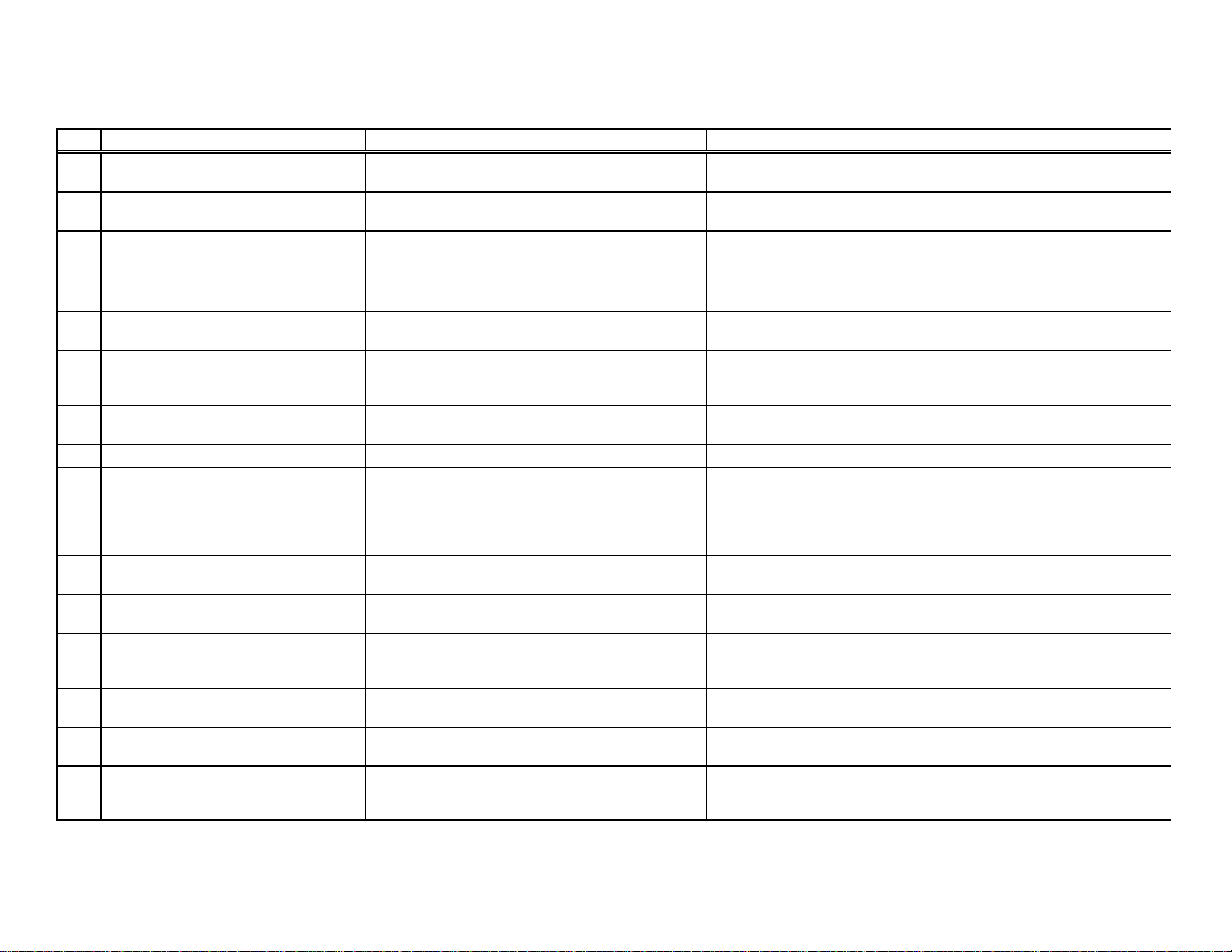

No. Message Symptom or Phenomenon Response or Check

0202 "PRODUCT MASTER IS NOT

REGISTERED"

PLU No. ** is not programmed.

Check PLU No.

Register the PLU on the REGISTRATION menu.

0203 "POP MASTER IS NOT REGISTERED" POP No. ** is not programmed. Delete ? Register POP on the REGISTRATION menu. If auto updating for POP No. is

set to "NO", it can not be deleted even if EXECUTE is pressed. Error display

"YES/NO" can be changed by LINK MASTER error setting.

0204 "ORIGIN MASTER IS NOT

REGISTERED"

Country of Origin No. is not programmed.

Delete?

Register the country of origin on REGISTRATION menu. If auto updating for

Country of Origin No. is set to "NO", it cannot be deleted even if EXECUTE is

pressed. Error display "YES/NO" can be changed by LINK MASTER error

setting.

0205 "EXTRA MSG 1 MASTER IS NOT

REGISTERED";

Ingredient No. ** is not programmed.

Delete?

Register ingredients on REGISTRATION menu. If auto updating for Ingredient

No. is set to "NO", it cannot be deleted even if EXECUTE is pressed. Error

display "YES/NO" can be changed by LINK MASTER error setting.

0206 "EXTRA MSG 3 MASTER IS NOT

REGISTERED"

Storage method No.** is not programmed.

Delete?

Register the storage method on REGISTRATION menu. If auto updating for

Storage Method No. is set to "NO", it cannot be deleted even if EXECUTE is

pressed. Error display "YES/NO" can be changed by LINK MASTER error

setting.

0207 "EXTRA MSG 2 MASTER IS NOT

REGISTERED"

Storage temperature No.** is not

programmed. Delete?

Register the storage temperature on REGISTRATION menu. If auto updating

for Storage Temp. No. is set to "NO", it cannot be deleted even if EXECUTE is

pressed. Error display "YES/NO" can be changed by LINK MASTER error

setting.

0208 "IMAGE NO. 1 MASTER IS NOT

REGISTERED"

Image No.1** is not programmed.

Check Image No.1**.

If auto updating for Image No.1 is set to "NO", it cannot be deleted

even if EXECUTE is pressed.

0209 "IMAGE NO. 2 MASTER IS NOT

REGISTERED"

Image No.2** is not programmed.

Check Image No.2**.

If auto updating for Image No.2 is set to "NO", it cannot be deleted

even if EXECUTE is pressed.

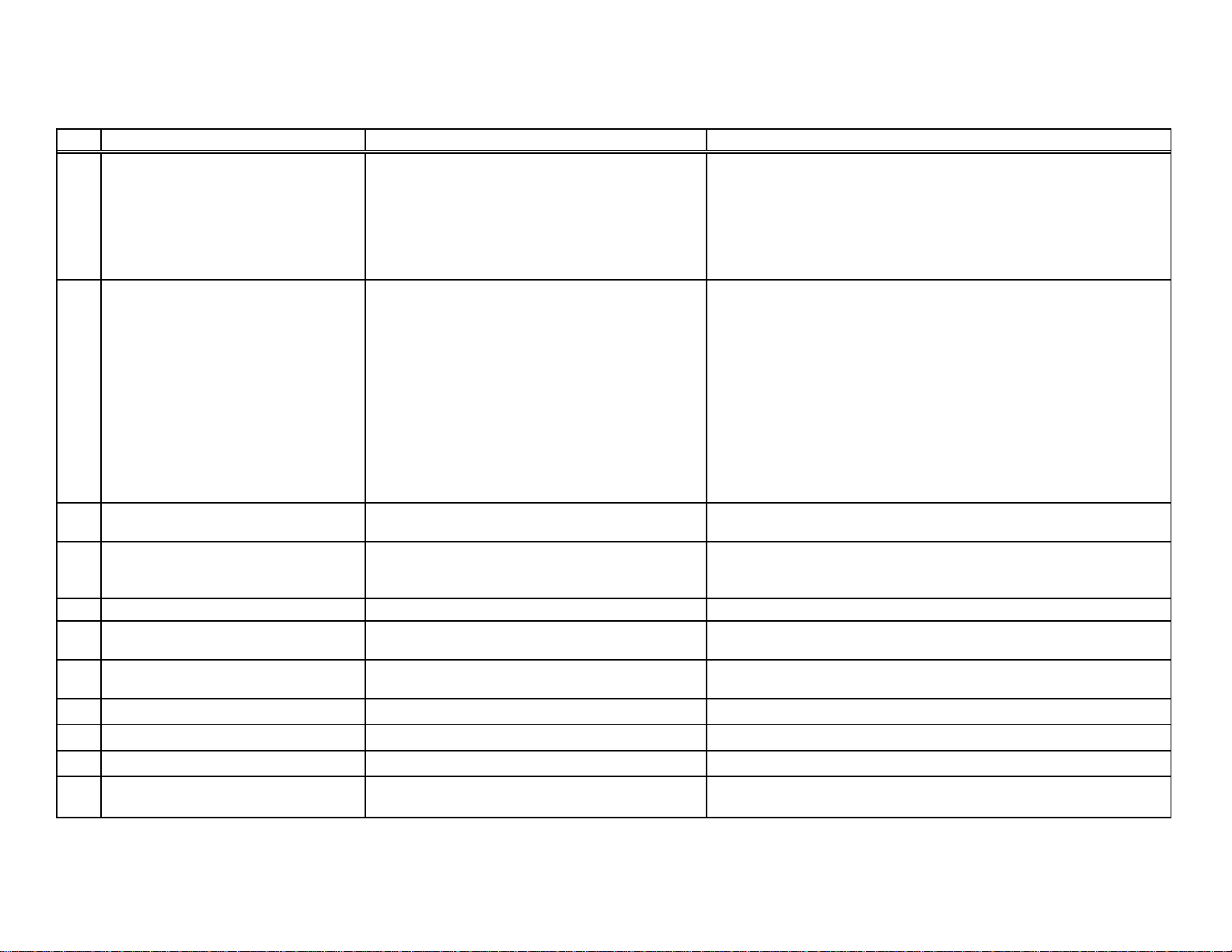

0210 "TRAY MASTER IS NOT Tray No.** is not programmed. Check Tray No.

0212 " IS NOT REGISTERED" ** is not programmed. Delete? Register FREE MASTER 1 on REGISTRATION menu. If auto updating

for Free Master 1 is set to "NO", it cannot be deleted even if EXECUTE

is pressed. Error display "YES/NO" can be changed by LINK MASTER

error setting. Free Master name must be careful as it can be changed

at “FREE MASTER NAME SETTING” in system mode.

0213 " IS NOT REGISTERED" ** is not programmed. Delete? Register Free Master 2 on REGISTRATION menu. If auto updating for

Free Master 2 is set to "NO", it cannot be deleted even if EXECUTE is

pressed. Error display "YES/NO" can be changed by LINK MASTER

error setting. Free Master name must be careful as it can be changed

at “FREE MASTER NAME SETTING” in system mode.

Rev. Feb 2015 3/40 Yellow highlights indicate updates