Diesse Chorus Trio User manual

SERVICE MANUAL

FOR CHORUS TRIO (REF. 81200) AND CHORUS TRIO RAS (REF. 81220)

REVISION 1 Issued in April 2021

Software version 7.xx

THIS MANUAL IS TO BE USED FOR CHORUS TRIO INSTRUMENTS STARTING

FROM S/N 4000 OR UPDATED WITH CHORUS EXPANDER UPGRADE KIT

(REF 83600)

FOR IN VITRO DIAGNOSTIC USE ONLY

This page is intentionally left blank

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

1

CHORUS TRIO models:

The present manual refers to the following CHORUS TRIO models with the 7.xx family

of software installed:

Catalog number

Description

81200

CHORUS TRIO

81220

CHORUS TRIO RAS

Manual revisions list:

Manual revision

Description of changes

0 of 03/2021

First issue relative to Chorus TRIO with Expander

1 of 04/2021

Correction of paragraph 2.2 following the replacement of the

internal barcode reader

2

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

Manufacturer

DIESSE DIAGNOSTICA SENESE SpA

Strada dei Laghi 39, 53035 Monteriggioni (SI) Italy

Tel. +39 0577 307109, Fax. + 39 0577 307106

www.diesse.it

TECHNICAL SUPPORT

Strada dei Laghi 39, 53035 Monteriggioni (SI) Italy

Tel. +39 0577 307109, Fax. + 39 0577 307106

Numero Verde: 800 606932

e-mail: technicalsupport@diesse.it

No page in this manual may be reproduced in any form or by any means, electronic,

mechanical or otherwise, for any use whatsoever without prior written permission

from DIESSE Diagnostica Senese S.p.A.

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

3

Symbols:

Key of graphic symbols

Instrument meeting the requirements of the European Directive

98/79/EC on in vitro diagnostic medical devices (98/79/CE).

In vitro

diagnostic medical device

Manufacturing date

Serial number

Manufacturer

Key of electric and safety symbols

Protective conductor

WEEE: Waste electrical and electronic equipment –Separate

Collection is required pursuant to Legislative Decree No. 49 of

March 14. 2014 (Italy), on “implementation of Directive 2012/19/EC.”

Attention: please read this manual carefully and comply with the

safety symbols.

Caution: risk of electrical shock

Caution: laser beam

BIOHAZARD: potential risk of contamination handling infectious

substances

Crush hazard: moving parts can crush and cut; keep hands away

Risk of thermal shock due to the warming of the tray for samples

Risk of puncture to hands and fingers due to the presence of

needles for collection and dispensing

4

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

LIMITATIONS AND WARNINGS

Version 7.00, revision 0 of this manual corresponds to the CHORUS TRIO model of the

instrument with the 7.xx family of software installed.

It was drafted and carefully reviewed and this version is closely related to the

instrument model

(data can be obtained from the instrument’s ID plate)

and the

version of the software that controls it

(data can be obtained through a procedure on

the instrument itself)

.

It must be read carefully before using the instrument, especially the parts relating to

safety.

ATTENTION

Do not use this manual except in its complete form.

If this manual is used in an incomplete form, DIESSE Diagnostica Senese S.p.A.

declines any responsibility for adverse results.

ATTENTION

Any instrument updating done with the customer’s authorization requires that the

user manual be updated in a corresponding manner.

DIESSE Diagnostica Senese SpA accepts no responsibility for damage caused

directly or indirectly by errors, defects, or incidents due to any use of this manual that

does not correspond with the version of the supplied instrument.

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

5

Index:

SOMMARIO

1MOVING THE STRIPS................................................................................................................................................................... 9

1.1 THE WORKSTATIONS............................................................................................................................................................. 9

1.2 THE TRAY.......................................................................................................................................................................................10

1.3 TRAY ROTATION .......................................................................................................................................................................10

1.3.1 ABSOLUTE SENSOR .............................................................................................................................................................12

1.3.2 STEP CHECK................................................................................................................................................................................12

1.3.3 SYNCHRONIZATION.............................................................................................................................................................13

1.4 STRIP HOUSING........................................................................................................................................................................14

1.5 TRAY LOCK...................................................................................................................................................................................15

1.6 CALIBRATIONS AND CONTROL PARAMETERS..................................................................................................15

1.6.1 ALIGNMENT AND CENTERING OF THE PLATE..............................................................................................15

2Strip recognition unit..................................................................................................................................................................17

2.1 Strip presence sensor (SPS)...............................................................................................................................................17

2.1.1 Check SPS sensor (Strip Presence Sensor).........................................................................................................17

2.2 Internal barcode reader.......................................................................................................................................................18

2.2.1 Internal barcode reader check and calibration ............................................................................................. 18

3Transfer unit.....................................................................................................................................................................................20

3.1 Dispensing hydraulic circuit............................................................................................................................................20

3.2 The strip, needles and the well........................................................................................................................................21

3.3 Dispenser.......................................................................................................................................................................................21

3.4 X-axis movement....................................................................................................................................................................23

3.5 The syringe unit........................................................................................................................................................................24

3.6 The transfer function ............................................................................................................................................................25

3.6.1 Transfer function parameters......................................................................................................................................25

3.6.2 The double dispensing needle....................................................................................................................................25

3.6.3 Priming of the dispensing and wash circuit................................................................................................... 26

3.6.4 Withdrawal................................................................................................................................................................................. 26

3.6.5 Drying of the tip...................................................................................................................................................................... 28

3.6.6 Perforation of the cuvette membrane ................................................................................................................ 28

3.6.7 Level detection........................................................................................................................................................................ 29

3.6.8 Mixing............................................................................................................................................................................................. 30

3.6.9 Simple transfer..........................................................................................................................................................................31

3.7 CALIBRATIONS AND CONTROL PARAMETERS.................................................................................................33

3.7.1 Circuit transfer..........................................................................................................................................................................33

3.7.2 Dispensers ...................................................................................................................................................................................33

3.7.3 X-axis movement .................................................................................................................................................................. 34

3.7.4 Level sensor test......................................................................................................................................................................35

3.7.5 Transfer test................................................................................................................................................................................35

3.7.6 Strip perforation......................................................................................................................................................................37

4Optical unit .......................................................................................................................................................................................38

4.1 Light source................................................................................................................................................................................38

6

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

4.2 The optical device...................................................................................................................................................................38

4.3 The optical channel ...............................................................................................................................................................39

4.4 Positioning of filters.............................................................................................................................................................. 40

4.5 Optical calibration .................................................................................................................................................................40

4.5.1 Transmittance and absorbance................................................................................................................................40

4.5.2 Alignment of the optical fibres................................................................................................................................... 42

4.5.3 Calibration of the optical channels.........................................................................................................................44

4.5.4 Calibration of the dark electronic offset..............................................................................................................44

4.5.5 Calibration of light emission.........................................................................................................................................44

4.5.6 The control ramp................................................................................................................................................................... 45

4.5.7 Report of the virtual ramp..............................................................................................................................................46

4.5.8 Control window......................................................................................................................................................................48

4.6 Optical unit testing procedure ..................................................................................................................................... 49

4.6.1 Setting of the optical filter offset...............................................................................................................................49

4.6.2 Calibrating the offset (dark reading).....................................................................................................................49

4.6.3 Calibrating the light............................................................................................................................................................49

4.6.4 Check of absorbance at 650 nm with control solutions.................................................................. 50

4.6.5 check of absorbance at 450 nm with control solutions...........................................................................51

5WASHING unit................................................................................................................................................................................53

5.1 Hydraulic wash circuit..........................................................................................................................................................53

5.2 Tank probes ................................................................................................................................................................................54

5.3 The washer ..................................................................................................................................................................................55

5.4 The drying station...................................................................................................................................................................56

5.5 Collection wells.........................................................................................................................................................................56

5.6 Washing procedure ..............................................................................................................................................................58

5.7 Washing circuit testing procedure.............................................................................................................................59

5.7.1 Supplying of buffer from washer #1....................................................................................................................... 59

5.7.2 Supplying of buffer from washer #2...................................................................................................................... 59

5.7.3 Washing of the piping for washer #1..................................................................................................................... 59

5.7.4 Washing of the piping for washer #2 ................................................................................................................... 59

5.7.5 Aspiration at drying station #3...................................................................................................................................60

5.8 CONTROL PARAMETERS.................................................................................................................................................. 60

5.8.1 Filling level of washer #1 (step 21) .............................................................................................................................60

5.8.2 Filling level of washer #2 (step 25)...........................................................................................................................60

6The drain circuit.............................................................................................................................................................................62

6.1 The main waste well..............................................................................................................................................................62

6.1.1 Normal operation.................................................................................................................................................................. 63

6.1.2 Obstructed drain...................................................................................................................................................................64

6.1.3 Full waste tank........................................................................................................................................................................64

6.1.4 Faulty drain pump................................................................................................................................................................ 65

6.2 Waste circuit testing procedure...................................................................................................................................65

6.2.1 Checking of waste level warning sensor (WS)............................................................................................... 65

6.2.2 Checking of waste level error sensor (ES).......................................................................................................... 66

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

7

7Temperature control..................................................................................................................................................................67

7.1 Temperature control of the instrument..................................................................................................................67

7.2 Measuring chamber..............................................................................................................................................................67

7.3 Heater ............................................................................................................................................................................................ 68

7.3.1 Electrical properties of the heater...........................................................................................................................68

7.4 Cycle temperature .................................................................................................................................................................69

7.5 Stand-by temperature.........................................................................................................................................................69

7.6 Procedure for testing the temperature control system...............................................................................69

7.6.1 Checking of the instrument temperature sensor...................................................................................... 69

7.6.2 Chamber temperature control.................................................................................................................................. 69

7.6.3 Strip temperature correction ...................................................................................................................................... 69

8Speaker-printer display.............................................................................................................................................................71

8.1 Display .............................................................................................................................................................................................71

8.2 The speaker..................................................................................................................................................................................71

8.3 The printer ....................................................................................................................................................................................71

8.3.1 Printer testing...........................................................................................................................................................................72

9Electronic Parts..............................................................................................................................................................................73

9.1 General Map...............................................................................................................................................................................73

9.2 Carrier+IMX8 Board ...............................................................................................................................................................75

9.2.1 Power supply and connections..................................................................................................................................75

9.3 CPU 2010 Board and Driver 2010 Board...................................................................................................................76

9.3.1 Power supply............................................................................................................................................................................ 77

9.3.2 Description of the Test Points and CPU 2010 board jumpers...........................................................86

9.3.3 DESCRIPTION OF THE TEST POINTS AND THE DRIVER 2010 BOARD JUMPERS ...........87

9.3.4 Troubleshooting.....................................................................................................................................................................87

9.4 Low Power...................................................................................................................................................................................87

9.4.1 Description................................................................................................................................................................................. 87

9.4.2 Power supply and connections.................................................................................................................................87

9.4.3 Troubleshooting.....................................................................................................................................................................94

9.5 Power Supply............................................................................................................................................................................ 94

9.6 DESCRIPTION............................................................................................................................................................................95

9.6.1 Troubleshooting...................................................................................................................................................................100

9.7 Connectors board................................................................................................................................................................ 100

9.7.1 Description...............................................................................................................................................................................100

9.7.2 Troubleshooting................................................................................................................................................................... 103

10 Service Procedures................................................................................................................................................................... 104

10.1 Programming firmware CPU 2010........................................................................................................................... 104

10.1.1 Service application.............................................................................................................................................................104

10.1.2 Successful connection with CPU 2010 board.........................................................................................104

10.1.3 Unsuccessful Connection with CPU 2010 board.................................................................................. 105

10.1.4 Firmware upload on the CPU 2010 board.................................................................................................106

10.1.5 Replacement of the Carrier+IMX8 board...................................................................................................108

10.1.6 Methods saving...............................................................................................................................................................108

10.1.7 Calibrations saving....................................................................................................................................................... 109

8

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

10.1.8 Software upgrade on the Carrier+IMX8 board...................................................................................... 109

10.1.9 Methods and Calibrations upload on the Carrier+IMX8 board ...................................................111

10.2 Programming BarCode reader Zebex Z 3080................................................................................................... 112

10.2.1 Connect the reader to the instrument through the RS232 cable............................................112

10.2.2 Disconnect the RS232 cable...................................................................................................................................112

10.2.3 PROGRAMMING PARAMETERS..........................................................................................................................113

10.3 Maintenance.............................................................................................................................................................................118

10.3.1 Routine maintenance..................................................................................................................................................118

10.3.2 Periodic maintenance.................................................................................................................................................118

10.3.3 Wash well for the dispenser needles...............................................................................................................119

10.3.4 Dispensers #1 and #2....................................................................................................................................................121

10.3.5 X-axis guide..........................................................................................................................................................................121

10.3.6 Washers 21 –25 –28......................................................................................................................................................122

10.3.7 Optical unit..........................................................................................................................................................................123

10.3.8 Washer wells......................................................................................................................................................................125

10.3.9 Upper plate..........................................................................................................................................................................126

10.3.10 Carousel .................................................................................................................................................................................126

10.3.11 Peristaltic pumps ...........................................................................................................................................................126

10.3.12 Diaphragm pump .........................................................................................................................................................127

10.3.13 Hydraulic waste and syringe unit......................................................................................................................127

10.3.14 Hydraulic unit....................................................................................................................................................................128

10.3.15 Syringe Unit ........................................................................................................................................................................128

10.3.16 Rotation..................................................................................................................................................................................129

10.3.17 Tray synchronization device ..................................................................................................................................129

10.3.18 Led box and filter handler .......................................................................................................................................129

10.3.19 Tank probes ........................................................................................................................................................................129

10.3.20 Tubing .................................................................................................................................................................................... 130

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

9

1MOVING THE STRIPS

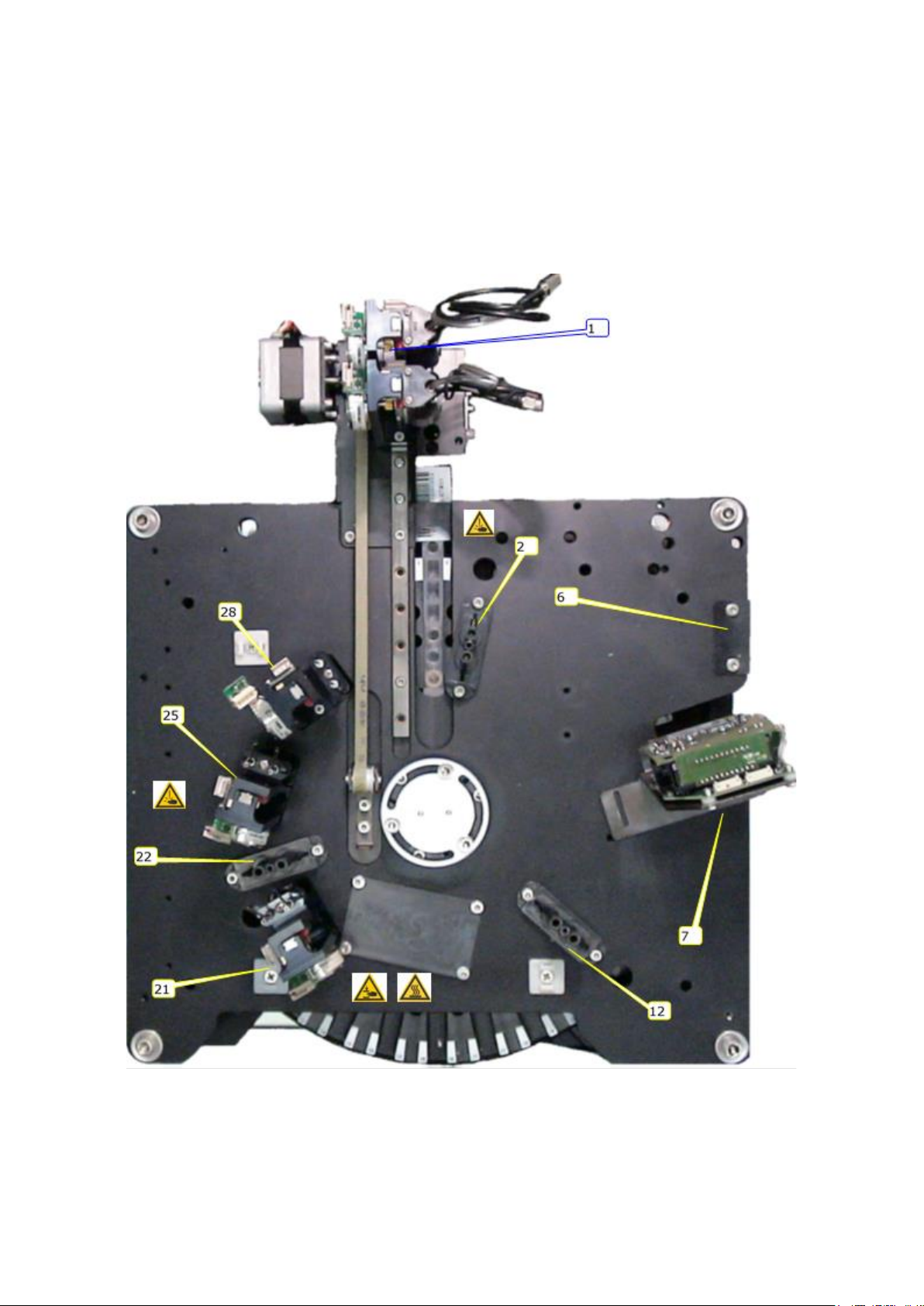

1.1 THE WORKSTATIONS

The functioning of the system is based on the carrying out of hydraulic, optical and

mechanical operations in certain positions called workstations. The workstations are

mounted on a base located above the tray called the upper level, shown in the figure

below:

Fig. 1-1

10

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

Pos.

Function

1

fluid transfer station, where liquids are transferred from one well to another. The

positioning unit is able to move from one well to another and to transfer the

liquids.

2

1st reading station

6

station where the presence of the strip is checked

7

station for the reading of the strip’s barcode

12

2nd reading station

22

3rd reading station

21

1st well washer for the strip

25

2nd washer

28

3rd washer (drying)

Since the strip has two reaction cuvettes, wash and reading stations are created so

that the operations can be performed on both cuvettes simultaneously.

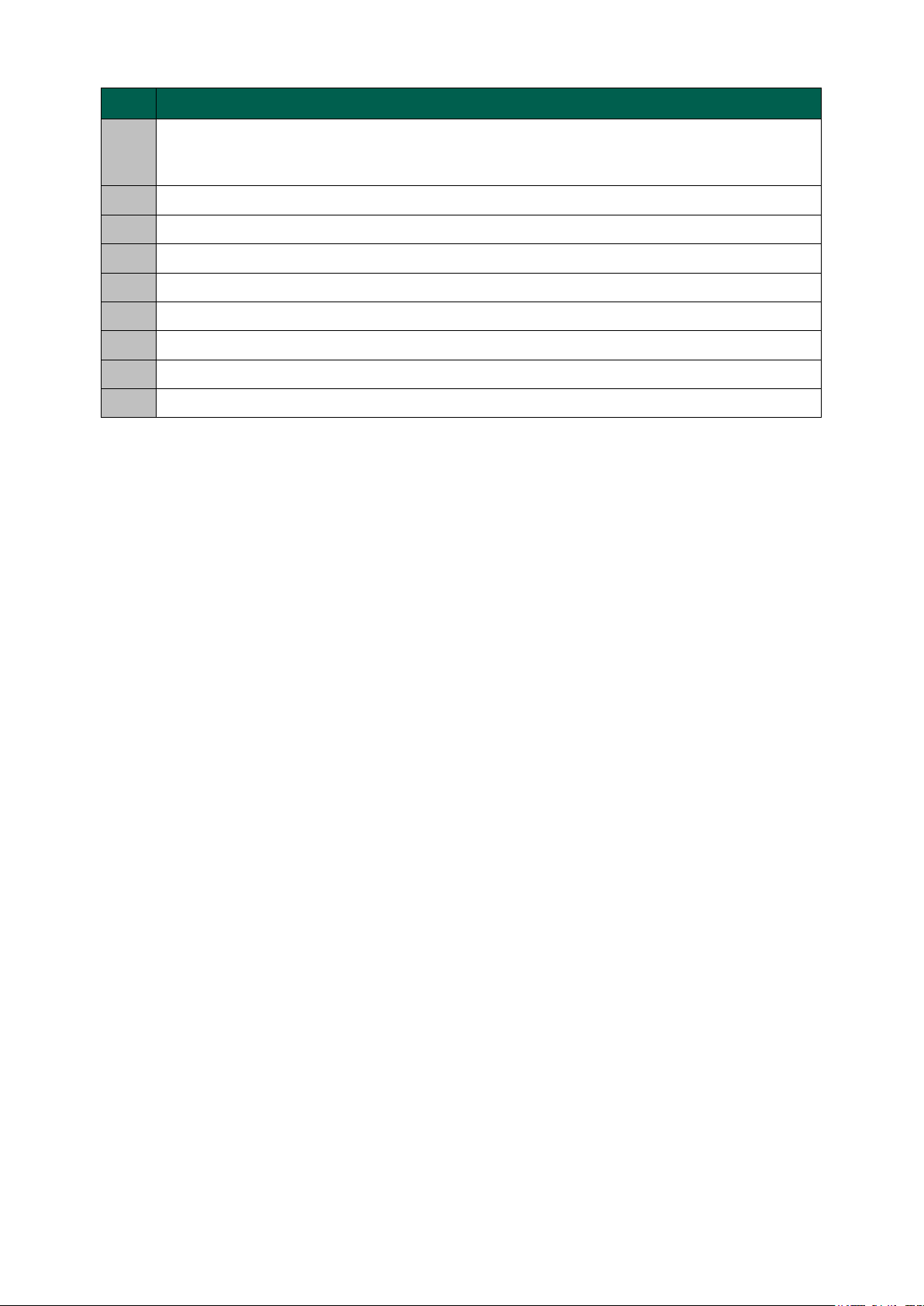

1.2 THE TRAY

The device in which the strips are inserted. Composed of a circular plate, mounted on

a pin ending with a pulley at the bottom, is able to rotate between two levels (one

upper and one lower) strengthened by four columns. The support surfaces also

border the upper and lower part of the measuring chamber, which is completed with

the special circular plastic crown fastened around the tray.

The tray is locked in place by tightening the locking ring-nut (see Fig. 1-2).

1.3 TRAY ROTATION

The rotation direction of the tray is determined by a motor whose shaft is joined to a

pulley which drives the rotor by means of a rotational belt.

The motor is mounted on a tensioning bracket so that the belt can be tightened to

one’s liking. Tensioning is done by turning the adjustment screw so that the bracket

moves closer or farther from the tray’s axis. A temporary fastening screw locks the

tensioning bracket in place so that the belt tightness can be checked. Locking the

fastening screws on the bracket holds the motor in position and maintains the belt

tension.

Tray positioning is checked by:

1. absolute positioning sensor (7) which sets the mechanical zero position

2. relative hole sensor (13) that check the movement of the tray (step check)

3. synchronization device abbreviated TSD (6) that allows the tray to be locked in

each of the work positions.

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

11

Fig. 1-2

No.

Description

1

Locking ring-nut

2

Upper surface

3

Column

4

Lower surface

5

Strip tray

6

Tray synchronization device (TSD)

7

Absolute tray sensor

8

Tray shaft with pulley

9

Drive belt

10

Drive shaft with pulley

11

Temporary lock nut

12

Tensioning bracket

13

Hole sensor (relative)

12

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

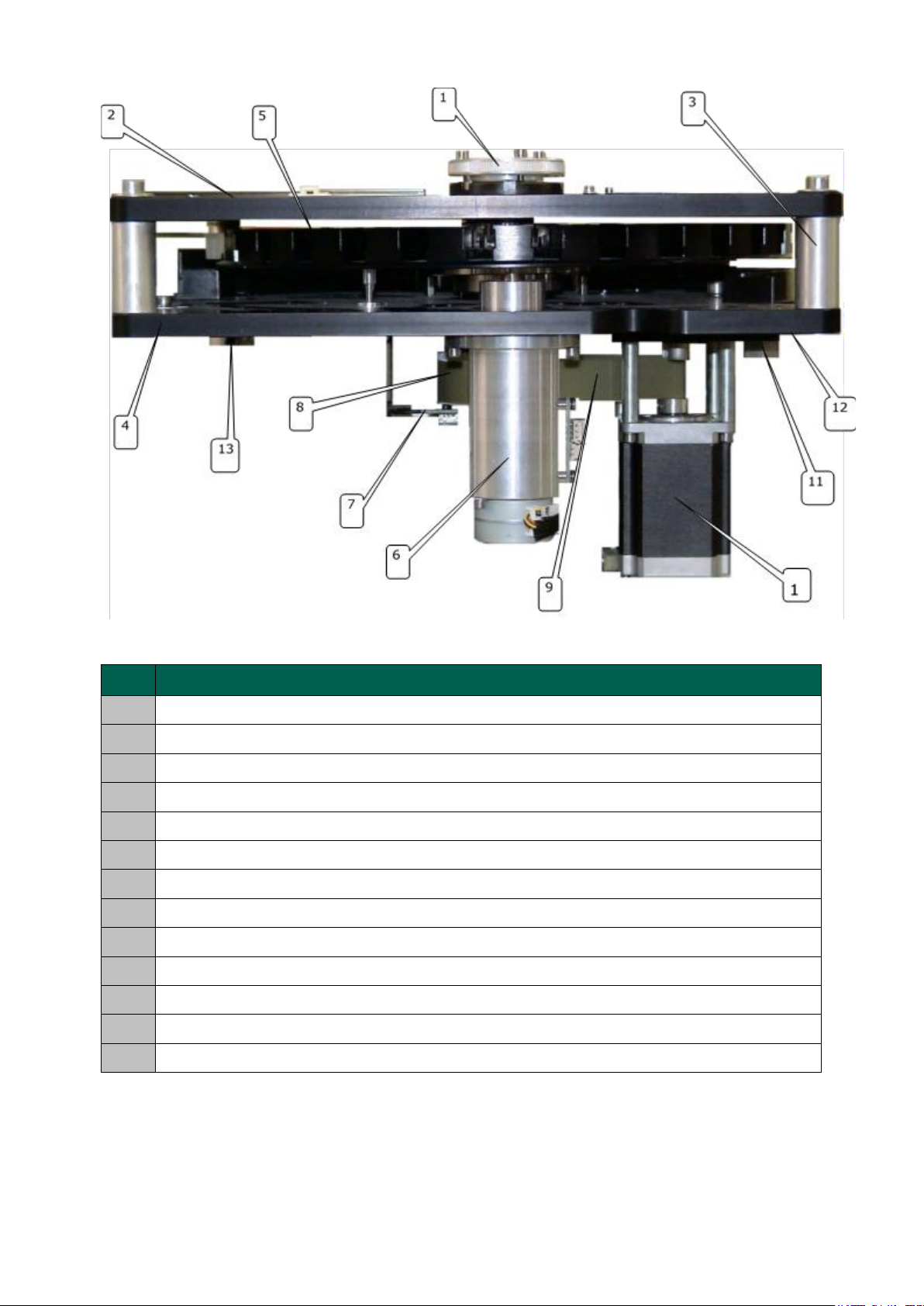

Fig. 1-3

No.

Description

1

Motor

2

Temporary fastening nut

3

Motor unit movement slide

4

Belt tensioning screw

2

7

4

3

5

6

1

8

9

13

11

12

10

1. locking ring-nut

2. upper surface

3. column

4. lower surface

5. strip tray

6. Tray Synchronization

Device (TSD)

7. absolute tray sensor

8. drive shaft with pulley

9. drive belt

10. motor with pulley

11. temporary fastening

nut

12. tensioning bracket

13. hole sensor

14. (relative)

Fig. 1-4

1.3.1 ABSOLUTE SENSOR

A small magnet is mounted on the rotational pulley of the drive shaft which is

detected by a Hall sensor located on a small plate fastened by an angular bracket.

The magnet ensures an absolute mechanical zero position and therefore alignment

of the tray.

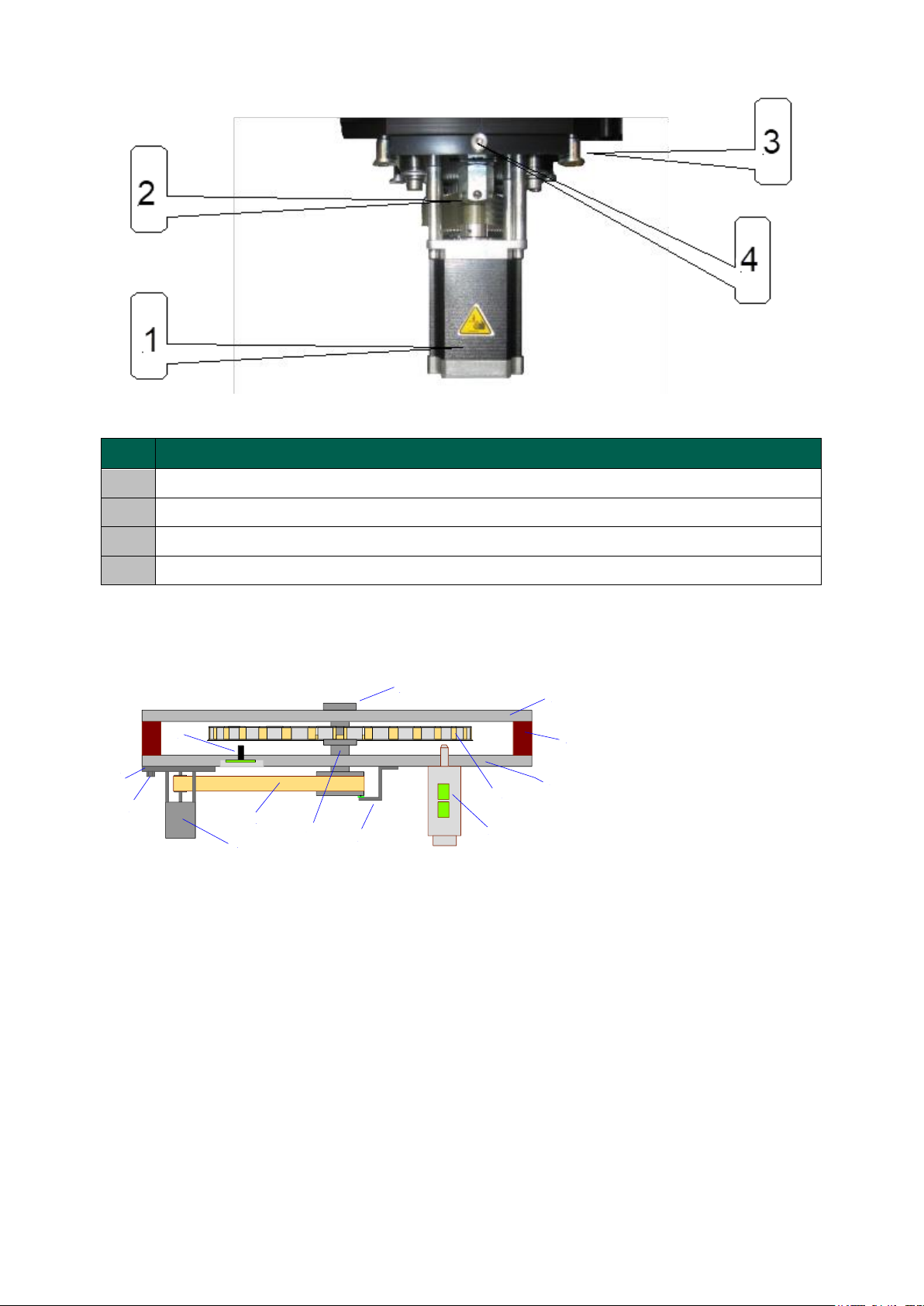

1.3.2 STEP CHECK

Every step that the tray makes during the cycle needs to be checked to ensure that

it was done correctly.

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

13

The check is done using an infra-red reflection sensor that “detects” the passage

between the plate full area (illuminated sensor) and the area with the hole (dark

sensor).

The rotation control software analyses the time intervals of the passages between the

dark zones and the illuminated zones and checks that the rotor is turning correctly.

Fig. 1-5

1.3.3 SYNCHRONIZATION

Once the rotation is finished, or after the shaking of the plate has ended, the tray is

correctly positioned by a mechanical unit made up of a special device called the Tray

Synchronization Device (TSD) or simply the tray synchronizer, which inserts a cone-

headed cylinder in one of the holes beneath the tray that correspond to each of the

30 strip insertion positions.

The wedge-shaped pin is quickly moved by a motor on which a worm screw is

mounted. Two sensors check the positioning. The first (limit switch) checks the

starting mechanical position (detail A in the Fig. 1-6). The other is used to check the

alignment of the plate before carrying out the complete insertion of the pin (detail B

in the Fig. 1-6). At the end of the operation the pin completely enters the hole and

locks the tray in the desired position. (detail C in the Fig. 1-6).

2

1

1. hole sensor (relative)

2. reference hole

14

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

1

A

B

C

3

4

2

1. conical pin of the TSD

2. positioning hole

3. relative position sensor

4. absolute sensor (at rest)

Fig. 1-6

1.4 STRIP HOUSING

The 30 strips housing is made of radial slots situated 12° from each other, which were

specially shaped in order to assure easy insertion and to prevent the strip from

moving during the movement of the plate (rotation and mixing). Above all, the seat

allows the strip to maintain the same positioning under the three optical reading

stations.

The strip is inserted in the slot and is kept in position by the spring located at the end

of the slot, which keeps the strip locked in position by holding the last well.

Upon insertion the strip must be pushed to the bottom of the seat so it can be held

by the spring.

The insertion of the strip into the slot is aided by the bevelling of the lower edge of

the plate.

There are two holes at the bottom of every slot that allow the optical ray to pass

through. The diagram below shows the top view of a plate with 28 strips fully inserted,

one strip partially inserted and one position empty.

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

15

1

2

3

5

4

6

7

Fig. 1-7

1.

spring locking sector

2.

spring

3.

holes for optical reading

4.

strip slot

5.

strip

6.

strip slot (front view)

7.

bevel for strip insertion

1.5 TRAY LOCK

When the instrument is switched off, or there is a power outage, the manual or

random rotation of the tray needs to be blocked in order to prevent damage to the

dispenser needles and to the workers. This function is carried out by the Tray Lock

Device (TLD). It is composed of an electro-magnet which is released and

mechanically locks the tray when the power is cut off. Vice versa, when the system is

powered up, the mechanical lock is removed and the tray may be moved by the

control system.

13

2

Fig. 1-8

1.

lock pin

2.

centering hole

3.

solenoid

1.6 CALIBRATIONS AND CONTROL PARAMETERS

1.6.1 ALIGNMENT AND CENTERING OF THE PLATE.

Plate alignment is one of the operations for setting the instrument.

The aligning of the plate is designed to position the plate in the exact work point

where the following conditions have to be checked:

16

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

▪Plate position no. 1 must be centered with the dispenser slit; in particular, the

direction of the dispensing needles must be centered with the strip cuvettes.

▪Cuvettes no. 5 and 6 of the strips must be perfectly centered with the two

optical channels of the interleavers.

▪

The plate is aligned when the TSD enters the tray cavity without generating any

visible movement of the tray.

The operations to align the tray must be done using the service program present on

The Chorus Trio equipped with the Expander (IMX8) module.

To access the service program, proceed as follow:

Chorus / Utility / Service

The login Password is “diesse”

The plate alignment is obtained acting on the Tray offset parameter. This parameter

represents the number of steps that the tray must carry out, starting from the

absolute position (which is determined by the absolute sensor Fig. 1.4), to reach the

correct alignment. The following operations can be performed to check the

calibration:

1. Open the Motor window:

Chorus / Utility / Service / Diagnostics / Motors

2. Run the Reset Tray with TSD command.

3. Check that the tray doesn’t move when the TSD enters in the tray cavity.

4. If the TSD drag the tray counterclockwise, decrease the Tray offset parameter

until the desired result is obtained.

If the TSD drag the tray clockwise, increase the Tray offset parameter.

To change the parameter, open the Mechanical Calibration window:

Chorus / Utility / Service / Settings / Parameters / Mechanical Calibration

Double click on the row Tray offset and enter the number of correction steps, then

confirm with OK.

Rev. 1.0 (04-2021)

CHORUS TRIO EXPANDER | SERVICE MANUAL

17

2STRIP RECOGNITION UNIT

2.1 STRIP PRESENCE SENSOR (SPS)

The

Strip Presence Sensor

(SPS) is composed by a light emitter located on the upper

level and a corresponding receiver located on an electronic board, located in a special

housing on the lower level.

If a strip has been inserted into the tray housing, the handle stops the light beam, and

the receiver can detect the presence of the strip. An unlabelled strip cannot be

recognized.

1

A

B

2

1.

light emitter

2.

receiver

Fig. 2-1

2.1.1 Check SPS sensor (Strip Presence Sensor)

1. Insert a labelled strip in position no. 26 of the plate

2. Open the

Motors

window:

Chorus / Utility / Service / Diagnostics / Motors

3. Select the

Tray

item and press the

Reset

command.

4. Open the

Sensors

window:

Chorus / Utility / Service / Diagnostics / Sensors

5. Check at the row

Strip not present

that the sensor is off (grey colour)

6. Come back to the Motor window and select again the

Tray

item, then press

Power Off

7. Move manually the plate of one position and come back to the

Sensors

window

8. Check at the row

Strip not present

that the sensor is on (yellow colour)

18

CHORUS TRIO EXPANDER | SERVICE MANUAL

Rev. 1.0 (04-2021)

2.2 INTERNAL BARCODE READER

The internal barcode reader is an Opticon model MDC-220A linear CCD auto-scan

reader. Specifically, the barcode reading takes place under station n° 7, as

represented below:

1

2

3

4

5

1.

barcode reader

2.

reader bracket

3.

barcode reading beam

4.

tray upper surface

5.

strip being read

Fig. 2-2

Figure 2-3 shows the connections diagram of the internal barcode reader (front view).

CAB533 connects directly with the 2010 CPU while the LD2 LED represents the power

supply LED.

Fig. 2-3

2.2.1 Internal barcode reader check and calibration

1. Insert a strip with a valid code in the position n° 25 of the tray

2. Open the

Motors

window:

Other manuals for Chorus Trio

1

This manual suits for next models

3

Table of contents

Other Diesse Measuring Instrument manuals