Digga HH-6K User manual

Operator’s Manual

PM-000127-C

LIGHTWEIGHT DRIVES

MY.DIGGA.COM

S

C

A

N

T

H

I

S

Q

R

C

O

D

E

ACCESS OPERATOR MANUALS

RISK ASSESMENTS AND MORE

2PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

MY.DIGGA.COM

S

C

A

N

T

H

I

S

Q

R

C

O

D

E

ACCESS OPERATOR MANUALS

RISK ASSESMENTS AND MORE

DECAL IS APPLIED TO THE ATTACHMENT

3

1 Table of Contents

1Table of Contents............................................................................................................................ 3

2Critical Information - Service Intervals......................................................................................... 4

3 To the Purchaser............................................................................................................................. 5

4Service and Preparation for Use................................................................................................... 6

5Safety Precautions - General Information.................................................................................... 8

6Safety - Working with the Attachment.......................................................................................... 14

7Safety - Decal Labels..................................................................................................................... 17

8Safety - Decal Label Location....................................................................................................... 18

9Before Use....................................................................................................................................... 20

10 Commissioning Procedure............................................................................................................ 22

11 Operating Instructions.................................................................................................................... 28

12 Maintenance.................................................................................................................................... 34

13 Spare Parts..................................................................................................................................... 39

14 Troubleshooting.............................................................................................................................. 41

15 Notes: Operator’s Manual.............................................................................................................. 43

Warranty Statement....................................................................................................................... 44

4PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

Your Digga Lightweight Planetary drive unit is a high performance attachment that is designed for screw

anchoring (Pier) installation, drilling and other extreme applications where it is seeing high levels of torque. To

avoid premature wear and failure, and to full your terms of warranty please read this statement.

All Digga Planetary drive units must have a rst oil change within the rst 30 hours (extreme use) or 50

hours (moderate use) or 3 months of use, which ever comes rst to ensure the bed in of the drive unit.

For more detailed information please read the maintenance section of this manual.

If the rst oil change is not performed within this period, excessive wear within the gearbox will occur

that will cause premature failure and all Warranty will be voided.

Oil must then be changed thereafter every 300 hours (extreme use) or 500 hours (moderate use) and

a full service every 12 months must be performed by an authorised service agent to ensure Warranty

requirements are met.

In the event of a failure under the warranty period:

• Contact Digga immediately, do not disassemble your drive without rst obtaining written permission and

instructions from Digga.

• Proof of service must be provided in hard copy form of both operational and service history records

(including serial number of gearbox and hydraulic motor). Service must be performed by an authorised

Digga service agent.

2 Critical Information - Service Intervals

Do not connect or operate your Planetary drive unit without rst having read and understood the following statement.

NOTE

5

Thank you and Congratulations on the purchase of your new Digga Planetary drive unit.

This product was carefully designed and manufactured to give you years of dependable service. It is mandatory

that oil changes are performed at the specied interval to keep it in top working condition (for details see the

maintenance section of this manual).

Before Operation

Inspect the attachment for shipping damage and if any damage does exist, do not operate until the damaged parts

have been replaced or repaired. The primary responsibility for safety with this equipment falls to the operator.

Make sure the equipment is operated only by trained individuals that have read and understood this manual.

If there is any portion of this manual or function you do not understand, contact your local authorized Digga dealer

or the manufacturer to obtain further assistance. Keep this manual available for reference. Provide the manual to

any new owners and/or operators.

About This Manual

This manual has been designed to help you do a better and safer job. Read this manual carefully and become

familiar with its contents before connecting and operating this unit.

Service

Use only manufacturer replacement parts. Substitute parts may not meet the required standards.

3 To The Purchaser

Never allow anyone operate this attachment without reading the “Safety precautions” and “Operating instructions” sections

of this manual. Always choose hard and level ground to park the vehicle on and set the brake, so the unit cannot roll.

CAUTION

!!

6PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

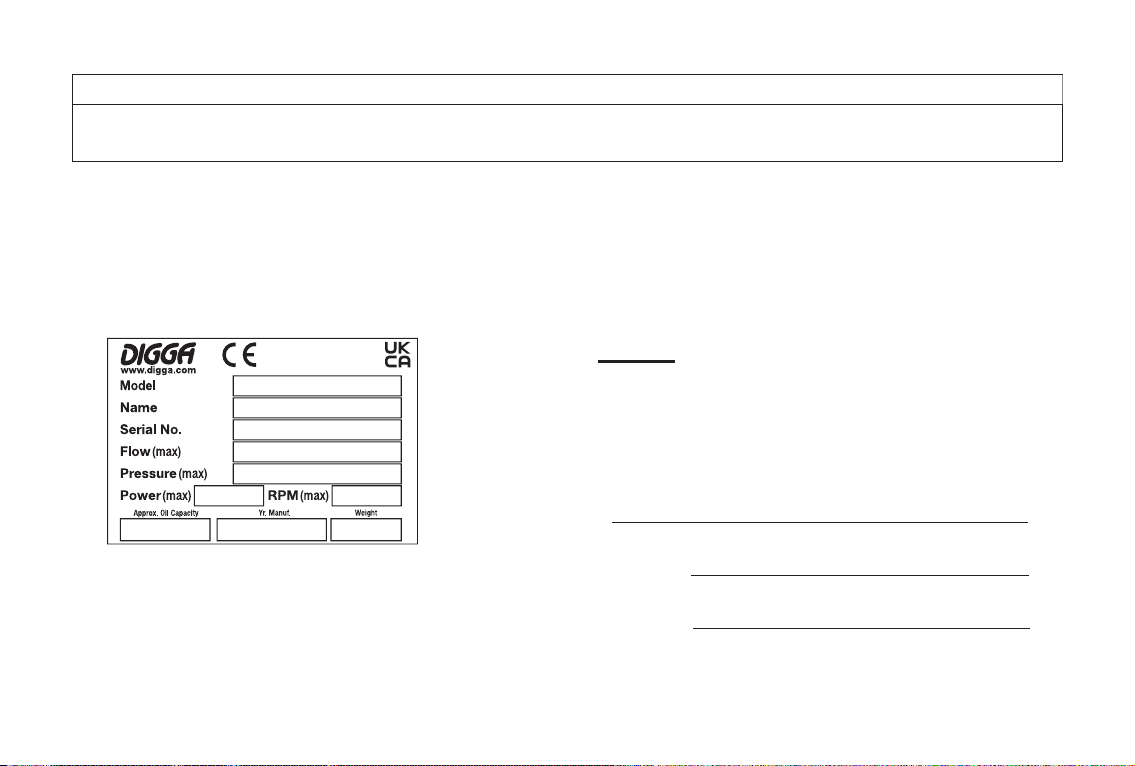

During the specied warranty period, your Digga Planetary drive unit is a user non serviceable part and

unauthorised disassembly will void warranty. All service and warranty must be performed by an authorised

Digga service agent. Contact your local Digga dealer for details. To facilitate warranty or service, record the

model and serial number of your unit in the space provided on this page. This information may be obtained from

the identication decal located on the product. HH units have their serial number and year of manufacture directy

engraved onto the gearbox ange (see page 18).

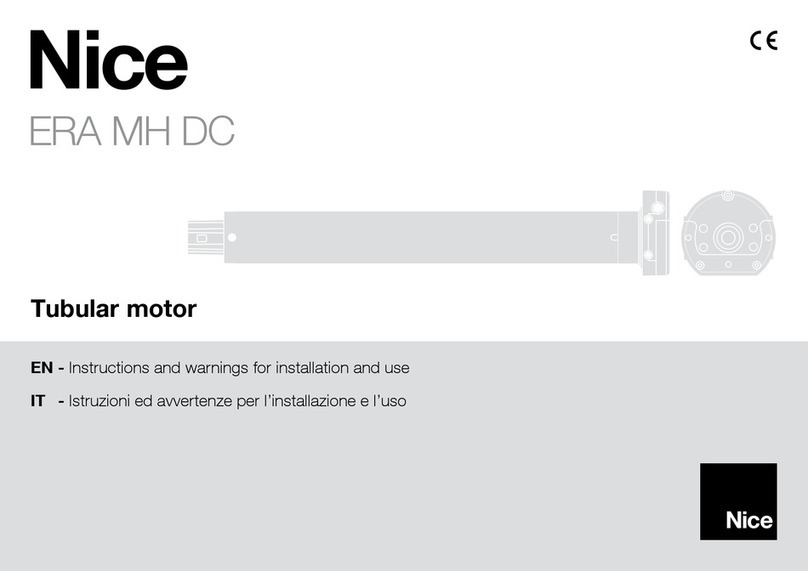

MODELS COVERED IN THIS MANUAL

HH-6K

HH-8K

4 Service and Preparation for Use

Model:

Serial Number:

Purchase Date:

The parts department needs this information

to ensure accurate parts can be sent to the

authorised service agent.

NOTE

Digga Australia PTY LTD

4 Octal St, Yatala

QLD 4207 Australia

ENGRAVED ON THE

GEARBOX FLANGE

ENGRAVED ON THE

GEARBOX FLANGE

HH-6K

LIGHTWEIGHT

57 LPM (15 GPM)

145 BAR (2100 PSI)

15 kW (18HP)

31kg (69 lbs)

DE-000634

15 RPM

1.05l (0.28 US gal)

MADE IN AUSTRALIA

DE-000624 (Decal)

Serial number and year of manufacture

engraved on the gearbox ange.

7

DE-000850

To avoid any inconvenience before operation, please check that you have received the following items which you

may have ordered. Items may dier depending on type of machine on which the drive units are to be tted to.

4 Service and Preparation for Use

A

TORQUE

CHART

BC

D

F

GH

REF DESCRIPTION

A QR Code Decal my.digga.com (see page 2)

B Operator's manual PM-000127

C Torque Chart

DHH Lightweight Planetary Drive Unit

FPressure Dierential Gauge (see manual PM-000081) (optional kit)

G In-line Pressure Relief Valve (optional kit)

HFoot-operated control (optional kit)

IHose kit

I

8PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

5 Safety Precautions - General Information

The DANGER designation indicates an imminently hazardous situation that, if not avoided, will result in death.

DANGER

The WARNING designation indicates a potentially hazardous situation that, if not avoided, could result in death or

serious injury.

WARNING

You will also see information called out with the NOTE designation. This additional safety or general information is important

to the maintenance and operation of your loader.

NOTE

The CAUTION designation indicates a potentially hazardous situation that, if not avoided, could result in minor or moderate

injury or property damage.

CAUTION

You must understand all safety statements shown on your attachment and in this manual. Especially note the

information called out by the designations shown below. Follow these safety precautions, when operating or

maintaining the attachment.

During day-to-day operation of your attachment, you will encounter a variety of situations beyond those listed in

this manual. We encourage you to assess the risk present at any job site and in every work task before beginning

work. Apply appropriate risk mitigation strategies to make safety a rst priority at all times, and if these are not

sucient, stop the job and immediately seek the help of a qualied safety consultant.

!

!!

!!

9

5 Safety Precautions - General Information

Before You Dig

• Service provided in Australia through the website www.byda.com.au.

• Never begin work at a new location until the work area has been fully marked for underground

utilities. Buried electrical, telephone, cable wires, gas, water and sewer lines are likely to be present.

Unintentionally disrupting these hidden hazards while working with your loader can result in dangerous

situations and property damage.

• Many countries oer a “dial before you dig” or similar service which advises the location of underground

services in your area. If available also use this service prior to digging, drilling, trenching or any form of

excavating and earthmoving.

You must ensure that underground utilities have been ofcially marked before working in the area. Markings must be valid

according to state law or practice.

CAUTION

Exposure to Respirable Crystalline Silica Dust Along with Other Hazardous Dusts

• It is recommended to use dust suppression, dust collection, and if necessary personal protective

equipment during the operation of this or any other machine attachment that may cause high levels of

dust.

Remove Paint Before Welding or Heating

• Hazardous fumes/dust can be generated when paint is heated by welding, soldering, or using a torch.

Do all work outside or in a well ventilated area and dispose of paint and solvent properly.

• Remove paint before welding or heating. When sanding or grinding paint, avoid breathing the dust. Wear

an approved respirator. If you use solvent or paint stripper, remove stripper with soap and water before

welding. Remove solvent or paint stripper containers and other ammable material from area. Allow

fumes to disperse at least 15 minutes before welding or heating.

!!

10 PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

5 Safety Precautions - General Information

Operating the Planetary Drive

• The primary responsibility for safety with this equipment falls to the operator. Make sure that the

equipment is operated only by trained individuals, who have read and understood this manual.

• A risk assessment is required before commencing any job. Consider the site and terrain conditions,

space available, the movement of personnel and equipment and any other factor relevant to this specic

job.

• An operator must not use drugs or alcohol, which can change his or her alertness or coordination. An

operator taking prescription or over-the-counter drugs should seek medical advice on whether or not he

or she can safely operate the equipment.

• Don’t hurry the learning process or take the unit for granted.

• It is the skill, care, common sense, and good judgement of the operator that will determine how eciently

and safely the job is performed.

• Visually inspect your equipment, ensure correct assembly and installation is done and never operate the

equipment that is not in proper working order.

• Know the capabilities of your equipment and practice its operation to become familiar with the controls,

emergency shut down procedures, and the way it handles on your machine.

• Two persons are required to lift and position the HH lightweight unit in place.

• Lift using your back and not your legs. Keep the unit close to your body and avoid twisting your trunk.

Apply the same technique when lowering the unit.

• Follow all safety decals and keep them clean. Replace them, If they become worn, damaged or illegible.

• Do not paint over, remove or deface any safety signs or warning decals on your equipment.

• Operate only from the operator’s station and operate only in daylight or with sucient articial light.

• Establish and maintain a minimum 6 meters (20 feet) exclusion zone around the working area. No person

other than the operators should enter the work zone, while the hydraulic power supply is running.

11

Operating the Planetary Drive (Continued)

• Drill stem rotation must be stopped before adding or removing sections, or marking adjustments to the

drill stem or sampling equipment.

• Ensure adequate ventilation and exhaust of air contaminants when operating in conned spaces or

indoors. Consider the exhaust of hydraulic power packs.

• Flow and pressure gauges, ttings, and hoses must have a continuous operating pressure rating of at

least 25% higher than the highest pressures of the system.

• All screw pilling operations must be stopped in the event of local thunderstorm or lightning activity.

During operation, weather conditions shall be monitored, operations shall cease during electrical storms

or when electrical storms are imminent.

5 Safety Precautions - General Information

12 PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

5 Safety Precautions - General Information

During screw pilling operation, maintain a minimum “no-work zone” buffer of 3 meters (10 feet) from any overhead

electrical service and 2 meters (6 feet) from any underground service .

DANGER

Ground Personnel and Bystanders

• Be alert to others in the work area. Be sure others know when and where you will be working.

• Loose tting clothing, long hair, jewellery and equipment which might become entangled in moving

equipment are prohibited while working near the Auger Drive.

• Operators, helpers, and other personnel working near the attachment must wear steel-toe safety shoes,

safety glasses, and hard hats as a minimum. Hearing protection, respirators, and personal protective

clothing will be specied in the site-specic Health and Safety Plan.

Storing Your Planetary Drive Unit

• Seal hydraulic couplers from contaminants and secure all hydraulic hoses o the ground to help prevent

damage.

• Clean the unit thoroughly by removing all mud, dirt, and grease etc..

• Inspect for visible signs of wear, breakage, or damage. If required, order any damage parts and perform

the necessary repairs to avoid delays upon removal from storage.

• Check that drive unit motor and hoses are full of clean oil and planetary gearbox is full.

• Coat liberally with grease the output shaft and collar, extension shaft and collar, and all connecting pins

to prevent rust and reduce wear.

• Tighten loose nuts, cap screws, and hydraulic connections.

• Replace safety decals that are damaged or in an unreadable condition.

• Store unit in a dry and protected place, as leaving the unit outside will materially shorten its life.

!

13

5 Safety Precautions - General Information

End of Life Disposal

• At the completion of the useful life of the Planetary Drive unit, drain all uids and dismantle by separating

the dierent materials (rubber,steel, and plastic etc.). Follow all federal, state and local regulations for

recycling and disposal of the uid and components.

Maintaining the Planetary Drive

• All maintenance should be performed with the hydraulic power supply engine turned o and hydraulic

pressure relieved.

• Never adjust a relief valve for pressure higher than recommended by the machine’s manufacturer.

Transporting the Planetary Drive

• When transporting your attachment, follow all local government regulations that may apply along with

any equipment safety precautions provided in this manual.

• It is the responsibility of the operator that safe systems of work are employed while handling this

attachment.

• No tie down points are provided on the attachment and its the responsibility of the operator to ensure

that the attachment is rmly fastened without causing any damage to it.

• Attachment should be well secured, when being moved or in transit and furthermore prior to moving,

storing, loading/unloading,or parking.

• Verify that all tie down accessories (chains, slings, ropes, and shackles etc.) are capable of maintaining

attachment stability during transporting and are attached in such a way to prevent unintended

disengagement or shifting of the unit.

• Use extra care when loading or unloading the attachment on to a trailer or truck and disconnect hydraulic

couplers during the transportation. No responsibility for loss or damage to persons or property in any

regard can be attributed to Digga.

14 PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

6 Safety - Working with the Attachment

Complete a Risk Assessment

Your Digga Planetary Drive is a versatile earthmoving machinery attachment, capable of performing its tasks in

a safe and eective manner. To ensure the safety of operators and others, it is important to document the work

at hand for hazard and risk. Before beginning work, complete a risk assessment. The following steps provide a

framework for this activity:

1

DOCUMENT THE ACTIVITY

Assemble those involved in the activity. Write down the tasks required for the activity in step-by-step

form.

2

IDENTIFY THE HAZARDS

Next to each task, identify what part of the task may cause injury to those engaged in the task or

others in the vicinity. Rate the consequences and likelihood of the hazard using the risk assessment

matrix.

3

DOCUMENT THE CONTROL MEASURES

Using the results from the risk assessment matrix, determine which hazards require attention. List all

mitigation measures that are required to eliminate or minimize those hazards.

4IDENTIFY THE RESPONSIBLE PERSON

Document the name of the person responsible for implementation of the mitigation measure.

5MONITOR AND REVIEW

Ensure that the activity is supervised and that the documented process is being followed.

All bystanders should be kept at a minimum of 6 meters (20 feet) away from the working area of the planetary drive.

DANGER

!

15

6 Safety - Working with the Attachment

Take Extreme Care When Dealing with Hydraulics - Whilst Assembling, Operating, Maintaining or

Performing any work on or near this product.

• Hydraulic uid under pressure can penetrate the skin and may develop gangrene or other permanent

disabilities. Hydraulic leaks under pressure may not be visible!

• If any uid penetrates the skin, get immediate medical attention!

• Wear safety glasses, protective clothing, and use a sound piece of cardboard or wood when searching

for hydraulic leaks. Do not use your hands!

• Before connecting or disconnecting hydraulic hoses, read your machine or power unit’s operator manual

for detailed instructions on connecting and disconnecting hydraulic attachments.

• Ensure that all parts meet the specications for this product when installing or replacing hydraulic hoses

or ttings.

• All hoses located within 1m (3 ft) of the operator during normal operation must be guarded with a exible

burst protection sleeve (Eaton® Guardian, or equivalent).

• After connecting hydraulic lines:

□Operate the hydraulics on this product to ascertain forward and reverse.

□Ensure that the hoses cannot interfere with or actuate the quick-attach mechanism.

□Ensure that hoses will not be pinched, or get tangled, in any equipment.

• Do not lock the hydraulics of your power unit or foot control in the “ON” position.

• Refer to host machine operator’s manual and this manual for procedures and service intervals, then

inspect and maintain the entire hydraulic system to ensure that the uid remains clean, that all devices

function properly, and that there are no uid leaks.

Remember, Personal Protection Equipment (PPE) provides a level of protection during work, but PPE is the last level of

harzard control and prevention. Always refer to the hierarcy of hazard control, when planning a safety process.

NOTE

16 PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

When Connecting this Product to a Hydraulic Power Unit

• Refer to the operator’s manual of your power unit for any special or detailed mounting instructions

regarding quick-attach mechanism.

• Be familiar with the emergency shutdown procedure of the hydraulic power unit and ensure quick and

unobstructed access to any emergency stop device.

• Where enabler (‘Dead Man’) switches are installed connections are connected or installed it is illegal to

disengage, tamper with, or remove them.

When Adjusting Servicing or Repairing this Product

• Do not make any modications to your Digga Planetary drive unit.

• When making repairs use only authorised Digga service agents and use only genuine Digga parts for the

gearbox. For fasteners, hydraulic hoses, or hydraulic ttings, use only properly rated parts.

• Replacement parts must also have safety signs attached.

6 Safety - Working with the Attachment

For any additional safety information please see “Risk Management Booklet”. To obtain a copy of this document please

contact Digga Head Ofce.

NOTE

17

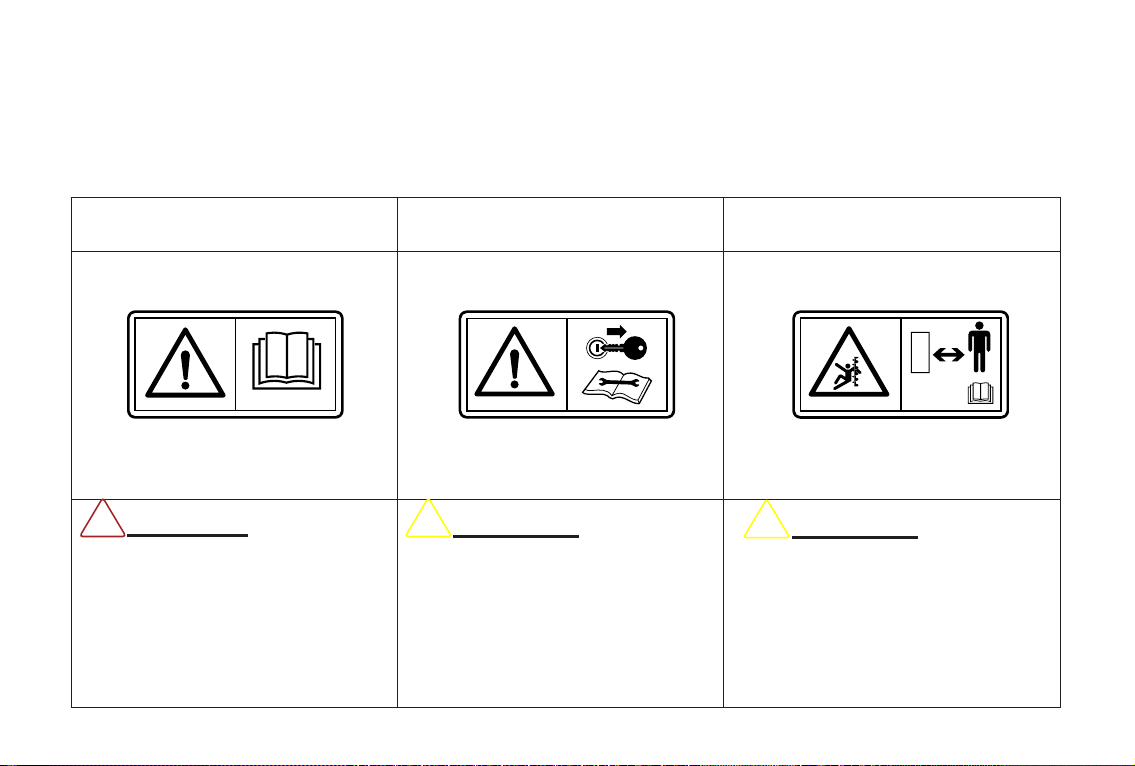

The following section provides a glossary of safety labels found on your Digga Planetary drive unit. These labels

are important! Become familiar with both their meaning and location prior to operating your drive unit. They must

be maintained and ensure that each label is clean, visible, and legible. To clean the decal, use a soft cloth, water,

and soap. Avoid the use of solvents, gasoline, or other harsh chemicals, as these may damage the decal. If a

label has been damaged or removed, it must be replaced.

READ OPERATOR’S MANUAL REMOVE IGNITION KEY ENTANGLEMENT / CRUSH

HAZARD

Completely read and understand

this operator’s manual before

using your attachment. Keep the

manual with the attachment at

all times.

DANGER

Before performing any

maintenance on the Planetary

drive or attachment, switch engine

o and remove the key. Never

leave the key in an unattended

machine.

CAUTION

Keep hands and body parts clear

of auger drive. Keep all bystanders

at a safe distance (6 meters/20

feet) from operating auger drive

and work zone. Refer to this

operator’s manual for more

information.

CAUTION

7 Safety - Decal Labels

!!

!!

!

DE-000636

DE-000637

DE-000638

18 PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

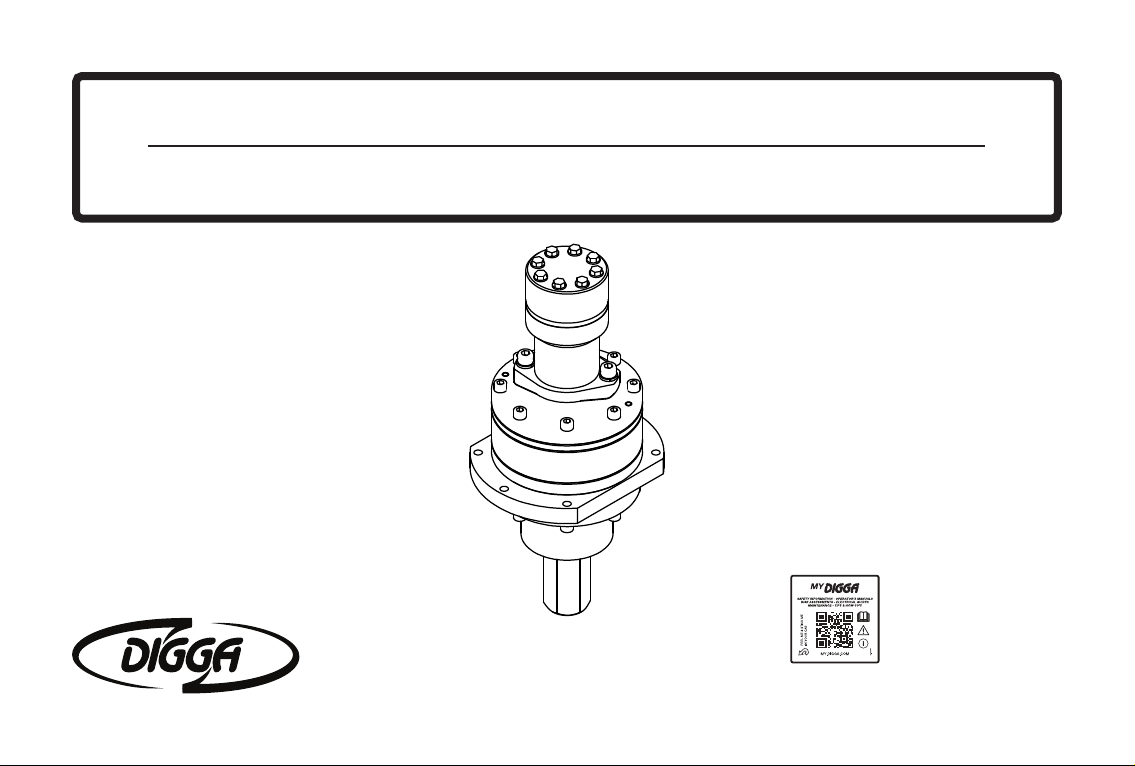

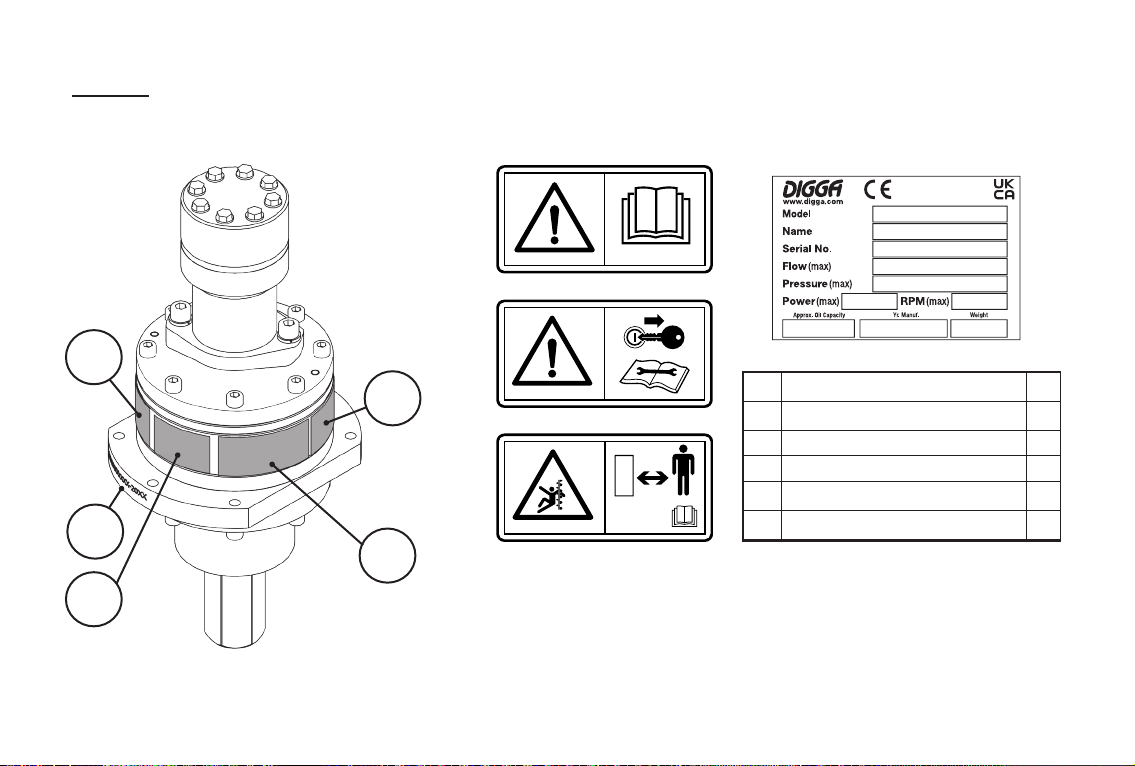

8 Safety - Decal Label Location

3

4

2

6

The following gure and table show typical safety decal labels location. The actual position and quantity of the labels on

your product may differ.

NOTE

ITEM RE-ORDER CODE - HH Units QTY

1DE-000638 1

2DE-000637 1

3DE-000636 1

4DE-000634 1

5DE-002063 1

ITEM 4

Digga Australia PTY LTD

4 Octal St, Yatala

QLD 4207 Australia

ENGRAVED ON THE

GEARBOX FLANGE

ENGRAVED ON THE

GEARBOX FLANGE

HH-6K

LIGHTWEIGHT

57 LPM (15 GPM)

145 BAR (2100 PSI)

15 kW (18HP)

31kg (69 lbs)

DE-000634

15 RPM

1.05l (0.28 US gal)

MADE IN AUSTRALIA

1

DE-000636

DE-000637

DE-000638

ITEM 1

ITEM 2

ITEM 3

ITEM 6: Serial number and Year of Manufacture engraved on the

gearbox ange.

19

Notes

20 PM-000127-C - Operator’s Manual - Lightweight Drives - Jun 2023

The key feature of your Digga Planetary drive is low maintenance, regular oil changes only are required. It

contains no user serviceable parts, unauthorised disassembly will void warranty. Written permission from Digga

must be obtained before performing any disassembly.

Before First Use

Inspect the drive unit for shipping damage. If damage does exist, do not operate until the damaged parts have

been replaced or repaired.

Before Each Use

• Make sure that all nuts and bolts are in place and properly tightened.

• Make sure that all other fasteners are in place and are performing their specied function.

• Make sure that all hydraulic ttings are tightened and that there are no leaks in any ttings or hoses.

• Make sure that all safety signs are in place, are clean, and are legible (see the safety sign section).

• Check for any oil leaks, wear and tear on pins, linkages, clips, bushes and hood.

• Ensure any damage or excessively worn parts are replaced.

• Always wear safety goggles or glasses when inspecting equipment.

9 Before Use

Escaping uid under pressure as low as 100 PSI can have sufcient force to penetrate the

skin up to 4" (100mm) away causing serious personal injury. Fluid escaping from a very

small hole can be almost invisible. Use a piece of cardboard or wood, rather than hands to

search for suspected leaks (A). Keep unprotected body parts, such as face, eyes, and arms

as far away as possible from a suspected leak and use heavy duty PVC protective gloves.

Flesh injected with hydraulic uid may develop gangrene or other permanent disabilities.

WARNING

!!

Cardboard

Hydraulic Hose

or Fitting

Magnifying

Glass

(A)

Protective

PVC Gloves

This manual suits for next models

1

Table of contents

Other Digga DC Drive manuals

Popular DC Drive manuals by other brands

PR electronics

PR electronics Hart 5107B manual

Danfoss

Danfoss VLT Automation Drive FC 300 instruction manual

Lutron Electronics

Lutron Electronics Hi-lume Premier 0.1 Installation Best Practices Guide

Emerson

Emerson Control Techniques Commander SL Series Quick Start Commissioning

KEBCO

KEBCO COMBIVERT F5 Instructions for use

M-Elec

M-Elec GD-5410 instruction manual