Digital Check ReceiptNOW Elite User manual

Digital Check ReceiptNOWTM Elite User Manual

ReceiptNOWTM Elite

USER MANUAL

Janua ry 2 017

8227 4813 -001

© 2017 Di git al Chec k Corp. , All rights r eser ved

Digital Check ReceiptNOWTM Elite User Manual

NO WARRANTIES OF ANY NATURE ARE EXTENDED BY THIS DOCUMENT. Any product or related

information described herein is only furnished pursuant and subject to the terms and conditions of a duly

executed agreement to purchase or lease equipment or to license soft ware. The only warranties made by Digital

Check Corp., if any, with respect to the products described in this document are set forth in such agreement.

Digital Check cannot accept any financial or other responsibility that may be the result of your use of the

information in this document or software material, including direct, special, or consequential damages.

You should be very careful to ensure that the use of this information and/or software material complies with the

laws, rules, and regulations of the jurisdictions with respect to which it is used. The information contained herein

is subject to change without notice. Revisions may be issued to advice of such changes and/or additions.

Notice to U.S. Government End Users: This is commercial computer so ftware or hardware documentation

developed at private expense. Use, reproduction, or disclosure by the Government is subject to the terms of

Digital Check standard commercial license for the products, and where applicable, the restricted/limited rights

provisions of the contract data rights clauses.

FCC Statement

The statement below is included in this document to comply with a Federal Communications Commission (FCC)

regulation. The FCC is an agency of the United States government; thus, the statement below applies to

computing equipment installed in the United States of America. Digital Check is taking appropriate steps to be

in compliance with FCC regulations and similar regulations of other countries .

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates uses and can radiate r adio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Caution

Changes or modifications not expressly approved by Digital Check could void your authority to operate this

equipment.

Canadian Regulatory Statement

This class B apparatus meets all requirements of the Canadian Interference -Causing Equipment Regulations.

Cet appareil de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

Trademarks

Digital Check is a registered trademark licensed to Digital Check Corp. in the United States and other countries.

SmartSource is a registered trademark of Digital Check Corp. ReceiptNOW is a trademark of Digital Check Corp.

All other brands and products referenced in this document are acknowledged to be the trademarks or registered

trademarks of their respective holders.

Digital Check ReceiptNOWTM Elite User Manual

Contents

F C C S TAT EM E N T ............................................. 1

CA U T I ON .......................................................... 1

C A NA D I A N R E G UL ATO RY S TAT E M E N T ......... 1

T R AD E M A R K S .................................................. 1

1 S U M M AR Y ...................................................... 3

1.1 BR IE F INTROD UCT ION .................................. 3

1.2 MA IN FE ATUR ES .......................................... 3

2 T E CH N I C A L S P E C I F IC AT I ON S ..................... 4

2.1 PR IN TE R TECHN ICAL SP EC IF IC AT IO NS ............ 4

2.2 CU T TER TECHN ICA L SP EC IF IC AT IO N S ............. 5

2.3 PR IN TIN G CO NSUM AB LE MATE R IA L TECHN IC AL

SPEC IFIC ATIONS ................................................ 5

2.4 PR IN T PO SIT IO N ........................................... 6

3 A P P E A R AN C E A N D C O M P O N E N TS .............. 7

4 P R I N T ER I N S TA L L AT I ON ............................. 8

4.1 UN PAC KIN G THE PR INTER ............................. 8

4.2 PR IN TE R INS TALLATIO N ................................ 9

4.3 PR IN TE R POW E R CON NEC TIO N ....................... 9

ATTEN TION :.................................................... 9

4.4 CON NE CT ING IN TERFACE CAB LE .................... 9

4.5 PAP ER ROLL INS TA L LATION AND PR I NT CHE C K10

4.6 PR I NT ER P O WE R O N A ND S E LF T ES T ...............11

4.7 ETH ERNE T IP ADDR ESS CON FIGUR ATION .......11

5 P R I N T ER R O U T I N E M A I N T E N AN C E ...........12

5.1 CL EA R IN G JAMME D PAPER ...........................13

5.2 CLEAN PR I NT HEAD A ND RO LLER .................14

5.3 CLEAN PAP ER SENS OR .................................14

6 I N T E RFAC E S I GN AL S ..................................15

6.1 USB INTER FAC E .........................................15

6.2 ETHER NET IN TE RFAC E .............................15

6.3 PO W ER INTER FAC E DEF IN IT ION ....................16

7 R E C O V ER I N G F R O M E R R O R S ....................17

7.1 PR IN TE R D OE S N O T W OR K ............................17

7.2 ERR OR INDIC ATOR LIGH T AND BUZZ ER ALARM –

SEE SEC TION 7.3 FOR DE SCR IPT IO NS ..................17

7.3 IND ICATOR LIGH T AN D BU Z ZER INFOR MATION 17

7.4 TR OU B LE SH OO T IN G PR IN T IN G PR OB LEM S .......18

8 I N S TA L LAT I O N O F S M A RT S O UR C E ® E L IT E 19

9 P O W ER M A N A GE M E N T ...............................19

A P P EN D I X A : PA R AM E T E R S E T T I N G B Y F E E D

B U T TO N ...........................................................20

Digital Check ReceiptNOWTM Elite User Manual

- 2 -

Safety Instruction

Before operating the printer, please read following notes carefully.

Safety warnings

Warning: Do not touch the cutter on the printer

Warning: Do not touch the print head and its surrounding parts during or just after printing

as the print head is hot.

Attention

1) Printer should be placed on a flat and s table location.

2) Leave enough space for operation and maintenance around the printer.

3) Printer should be kept away from water. Avoid direct sunlight, strong lights and heat.

4) Avoid getting water or conductive material (such as metal) into the interior of the printer. If this

happens, disconnect the printer power supply immediately.

5) Do not allow condensation to form on the surface of the printer. If condensation has formed, the

printer should not be powered on until the condensation has been eliminated.

6) Do not use or store printer in conditions of high temperature , high humidity or serious pollution.

7) Avoid placing printer in a location that would subject it to vibration or impact.

8) Connect the printer power cable to a properly grounded socket. Avoid using the same socket with

large motors or other devices which could cause power supply voltage fluctuations .

9) If the printer is not to be used for an extended period, unplug the power cord..

10) Do not attempt to print without paper. This will seriously damage the print rollers and thermal

print head.

11) To ensure print quality and product life use the recommended paper or the same quality of paper.

12) Turn off the printer power switch before plugging in or unplugging power or interface cables.

Failure to do so may damage the printer.

13) To maximize the life of the printer, i t is suggested that users use the lowest level print density

that meets print quality requirements .

14) There are no user-serviceable parts inside the printer. Disassembling the printer will void the

warranty.

15) Keep this manual for reference.

Digital Check ReceiptNOWTM Elite User Manual

- 3 -

1 Summary

1.1 Brief Introduction

ReceiptNOW Elite is a high-performance thermal printer which can be integrated with the

Digital Check SmartSource®Elite check scanner to save desk space. It can be used for a wide

range of financial transactions to print receipts, notes, vouchers ,financial slips and transaction

list printing.

ReceiptNOW Elite uses front-end paper exit, drop-in paper replacement, and provides a

custom support platform for SmartSource®Elite scanners. The ReceiptNOW Elite detects

print-head-in-place, out of paper, paper low, and low supply voltage conditions. The standard

data interface is USB 2.0. It supports Standard Font A (12 × 24), Font B (9 × 17), Kanji Font A (24

× 24), Thai, Simplified Chinese, Korean and other languages, supports multiple code pages to

print, one-dimensional bar code : UPC-A, UPC-E, CODE 39, CODE 93, CODE 128, EAN8,

EAN13, ITF, CODABAR; two-dimensional bar codes: PDF417, QR-CODE; using ESC / POS

command set, automatic state return. With the user Custom Sample function, users can set print

format and fix content of printing by firmware settings. P aper width can be set in a row,

compatible with EPSON TM-88IV.

1.2 Main Features

◇Quiet, high-speed printing

◇Supports two-tone printing, watermark and gray level printing

◇Easy, drop-in paper loading

◇Easy to use and maintain

◇Paper width can be adjusted from 56-82.5mm

◇Supports full cut and partial cut

◇USB 2.0 interface/Ethernet interface (optional)

◇Compatible with ESC / POS commands or Windows Print

◇Paper-saving

◇Low power consumption design (minimum power consumption less than 1W ) . Automatically

defaults to ‘sleep’ mode after 5 minutes of inactivity.

Digital Check ReceiptNOWTM Elite User Manual

- 4 -

2 Technical Specifications

2.1 Printer Technical Specifications

Items

Parameter

Print method

Thermal print by line

Print resolution

203*180DPI

Print speed

Maximum print speed is 250mm/sec, two-color printing speed

100mm/sec, gray print speed 100mm/sec. Depending on print

content, the printer will autom atically adjust print speed

Print Span

Maximum is 80mm; paper width is from 56-82.5mm.

Paper type

Paper thick ness is 0.06~0.10mm, Maximum paper roll OD is

83mm

Continuous thermal paper or thermal paper tags

Support Bar code type

Barcode 1D: UPC-A, UPC-E, CODE 39, CODE 93, CODE 128,

EAN8, EAN13, ITF, CODABAR

Barcode 2D sym bols: PDF417, QR-CODE

Character support

U.S.A., France, Germany, U.K., Denmark I, Denmark II, Italy

Sweden, Spain I, Spain II, Japan, Norway, Latin America,

Korean etc. optional

Enlarge character

All characters can be enlarged from level 1-6 both in the

horizontal and vertical direction.

Character rotation

Four selectable print orientations(0°, 90°, 180°, 270°)

Paper detection

Photoelectric sensors (out of paper, paper low)

Front cover position

detection

Micro switch

Print head temperature

detection

Thermistor

Graphics processing

Download bitmap

Print bitmap directly

Download buffer size:

RAM:128KB

FLASH:512KB

Support bitmap mode, fast graphic

printing

Communication interface

USB 2.0 interface/ Ethernet interface (optional)

Memory

FLASH Memory Capacity: Maximum 4MB;

SDRAM memory total capacity: Maximum 2MB;

Data receive buffer size: 64K, 4KB, 45 bytes selectable;

RAM bit map area: 128KB;

Area available to the user FLASH: 512KB;

Power

AC 110-240V 50/60 Hz, ~1.5A (Power supply)

DC 24V ± 5% average current 2.0A

Maximum instantaneous current 8A

Print head lifetime

Print head lifetime, thermal single color print : 100 Kilometers

Print head lifetime, thermal two color print: 50 Kilometers

Print duty `cycle: 12.5%

Operating tem perature and

humidity

5°C-40°C (41°F-113°F). When used with a scanner,

specification of scanner may be different. Specification of

scanner does not modify specification of this product and

vice-versa.

Relative humidity 20% -90% (40°C/104°F)

Storage temperature and

humidity

-40°C - 60°C (-40°F - 140°F) , 10%~93% (40°C/104°F )

Dimensions

241mm × 146mm ×135mm (9.5in ×5.7in × 5.3in)(L×W ×H)

Digital Check ReceiptNOWTM Elite User Manual

- 5 -

2.2 Cutter Technical Specifications

Item

Parameter

Note

Cutting m ethod

Sliding blade

Cutting time

500ms

Cutter cuts for one time.

Cutting interval

2s

30 cuts / min (maximum)

Type of paper

0.06~0.1mm

thermal paper or equivalent thickness

paper

Operating voltage

24VDC

Maximum operating current

1.2A

24VDC

Cutter lifetime

1.5 million times (0.06mm

thick paper)

*Includes full-cut, partial cut

Full cut: Completely severs paper

Partial cut: Partially severs paper, leaves cut end attached with tear-off tab

2.3 Printing Consumable Material Technical Specifications

2.3.1 Thermal Paper Parameter s

Type ofPaper: Continuous thermal paper

Paper Feeding Method: Paper Roll

Paper Width: Maximum 80mm, width can be adjusted between 56-82.5mm

Paper Thickness: 0.06mm-0.1mm

Thermal Layer: External

Paper Roll Size: OD (Max):83 mm

Inside Diameter (Min) 12.5mm

Recommended Paper:

Part Number

Manufacturer

401095994

Digital Check

F240AC,F220-VP,FV230A1,

PA220AG,HP220A

Mitsubishi Paper Mill CO., LTD

FD210,PD150R,PD160R

OJI Paper CO., LTD.

F70NA

FUJI PHOTO FILM CO., LTD

Attention:

Please use recommended paper or equivalent quality paper. The use of other types of paper

may affect print quality and print head life.

If the paper is contaminated by chemicals or oil, the paper may become discolored or printing

result may not be clear.

Do not scratch the thermal paper with any sharp or hard object. This may cause the printing

to be obscured or unclear.

All thermal printer paper will degrade and produce poor quality printing if exposed to

temperatures greater than 70°C (158°F), high humidity or strong light. Store thermal printer

paper in a cool, dry place and in its original wrappin g until ready for use.

Digital Check ReceiptNOWTM Elite User Manual

- 6 -

2.4 Print Position

2.4.1 Print Location On The Paper

L1 Maximum Paper Width:82.5±0.5mm

L2 Maximum Effective Print W idth :80mm

L3 Distance from print head to left side of paper pocket (fixed width): 1.75±1mm

L4 Distance from print head to right side of paper pocket (fixed width): 1.75±1mm

L5 Left margin: Set by command (see Programming Manual), the printer default is 8mm

L6 Width of print area: Set by command (see Programming Manual), the printer default is 64mm

L7 Right margin: Set by command (see Programming Manual), the printer default is 8mm

Digital Check ReceiptNOWTM Elite User Manual

- 7 -

3 Appearance and Components

1—Top Cover

2—Power Indicator Light - Indicates power status.

3—Error Indicator Light - Reports warning or error

status (such as out of paper, etc.). Indicator

light flashes. Under normal conditions, the light

remains off.

4—Paper Feed Button

Paper Feeder:If there are no errors or

warnings, pressing this button will

feed paper.

Print Configuration Function: To review

printer configuration settings - Hold

down this button at the same time

while turning on power. Printer will

print the configuration settings (such

as print length and width, print speed

and other settings).

5—Paper Pocket

6—Paper pocket width adjustment - Roll

thumbwheel to adjust the paper

pocket width. The range of

adjustment is 56 ~ 82.5mm

7—Out of paper sensor - continuously

detects presence of paper roll.

8—Roller

9—Cutter

10—Handle

11—Paper low sensor (inside the printer) -

Detects how much paper remains.

Error indicator flashing rapidly

means paper roll is low and needs to

be replaced soon. The printer will

continue to work until out of paper.

12—Ethernet Interface (optional)

13—USB Interface

14—Power Interface

15—Power Switch - Press “O” to turn off the

power, press“-”to turn on the power

Digital Check ReceiptNOWTM Elite User Manual

- 8 -

4 Printer Installation

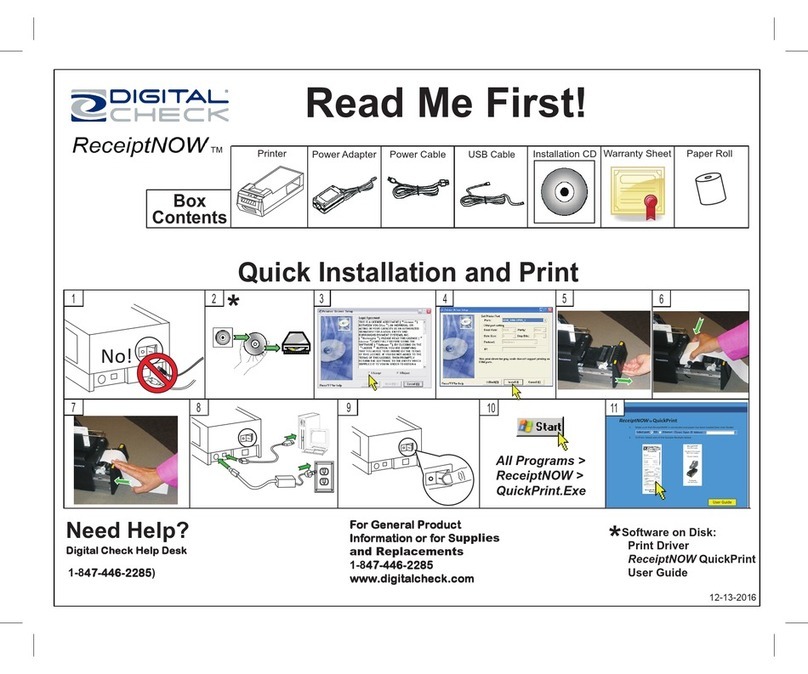

4.1 Unpacking the Printer

Please check the package contents when unpacking the printer. If something is missing or damaged,

please contact Digital Check at 847-446-2285.

Digital Check ReceiptNOWTM Elite User Manual

- 9 -

4.2 Printer Installation

1) Printer should be installed on a flat surface.

2) Printer should be kept away from water.

3) Avoid placing printer in a location that would subject it to vibration or impact.

4) The printer should only be plugged into an electrical outlet that has a safety ground .

5) Allow the proper clearance for printer operation and maintenance . Please see picture below

showing the printer open, and ensure adequate clearance .

6) Follow the Instructions on the Read Me First! document to complete the installation and to

print sample receipts. For more detailed installation instructions and to print a test

configuration printout , proceed with the next Installation

section.

4.3 Printer Power Connection

1) Make sure that the printer power switch is turned off.

2) Connect power plug into power socket behind the printer.

Attention:

If the printer is not to be used for an extended period, unplug the power cord. .

4.4 Connecting Interface Cable

1) Make sure printer power switch is turned off.

2) Plug USB cable into the USB socket on the printer.

3) Connect the other end of cable to the computer.

Digital Check ReceiptNOWTM Elite User Manual

- 10 -

4.5 Paper Roll Installation and Print Check

4.5.1 Check Printing Paper

Paper may be installed while the power and interface cables are connected. Please check paper

type before printing.

4.5.2 Install/Change Paper Roll

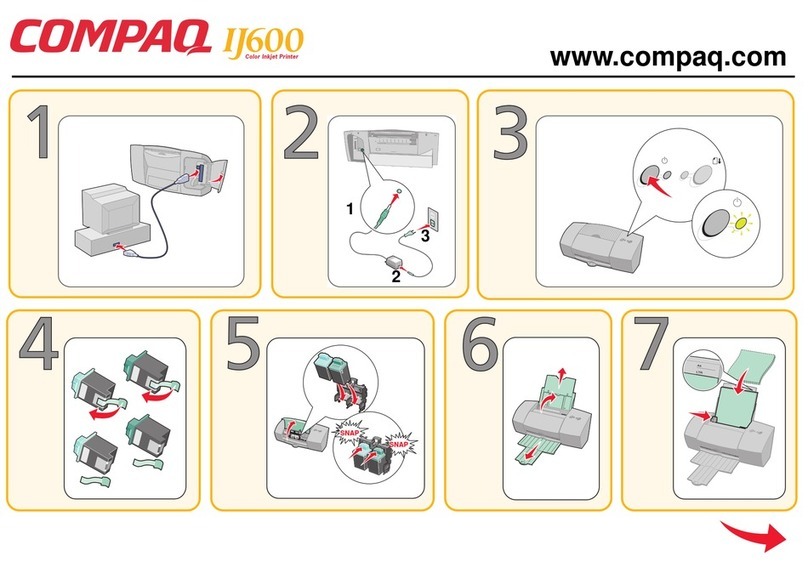

1) Pull the handle and open front cover.

2) Using the paper width adjustment wheel, adjust to fit the width of the paper being installed , as

shown below. Roll the adjustment wheel towards the rear of the unit to adjust for wider rolls. Roll

the adjustment wheel towards the front of the unit to adjust for narrower rolls. After the paper roll

is installed, it should rotate freely.

3) Put paper roll into printer according to direction s shown on the label.

4) Pull out paper end and close front cover.

Digital Check ReceiptNOWTM Elite User Manual

- 11 -

4.6 Printer power on and self test

1) Make sure power cable is connected to the printer and the paper roll is loaded.

2) Make sure POWER INDICATOR LIGHT is off and printer is powered off.

3) Hold down the paper feed button while turning the printer on . The printer will perform a self-test

and then print ‘Press and Release FEED key to print characters ’and ‘Press and Hold FEED key

to configure the printer’. The printer will change to holding state and PAPER INDICATOR LIGHT

blinks.

4) When the self-test page is finished, press the paper feed button briefly to print test characters or

hold the paper feed button down to configure the printer. For specific function and operational

approach for using the paper feed button to configure the printer , please refer to Appendix A

“Parameter Setting by FEED Button ”.

4.7 Ethernet IP Address Configuration

ReceiptNow printers that have an Ethernet interface are factory configured for a default IP address

of 192.168.1.251. Changes to the unit’s default IP address or to set the unit for DHCP mode can be

done by communicating with the unit via a web browser set to the d efault IP address as shown in the

screen shot below. The web browser utility can also provide printer and interface status.

The current IP address of the printer can be determined by powering on the printer while holding the

feed button down which will ca use the printer to print out a test form which lists various hardware and

communication interface parameters.

If the printer does not appear to respond to the proper IP address, the most likely cause is that the

printer is not currently configured in a ma nner that is compatible with the network to which it is

connected. Check with your network system administrator to insure that the settings for ‘DHCP’,

‘Gate Way’ and ‘IP Address’ are compatible with the network

Digital Check ReceiptNOWTM Elite User Manual

- 12 -

5 Printer Routine Maintenance

Attention:

Use only Thermal Printer Cleaning Swabs (Digital Check part number 757300999 or 751920912),

isopropyl alcohol or ethanol for cleaning print head, rollers and sensors. Do not use solvents

such as gasoline, acetone, or any abrasive cleanser.

When cleaning sensors, do not turn on printer until cleanser has totally evaporated.

The printer should be cleaned as needed , indicated by degraded print quality. The cleaning

interval depends on the environment in which the printer is operated, print usage, paper quality

and other factors. A typical cleaning interval is one month.

Digital Check ReceiptNOWTM Elite User Manual

- 13 -

5.1 Clearing Jammed Paper

Steps for clearing paper jam are as follow s:

1. Open front cover.

2. Clear jammed paper and close front cover.

Digital Check ReceiptNOWTM Elite User Manual

- 14 -

5.2 Clean Print Head and Roller

The printer should be cleaned as needed , indicated by degraded print quality. The cleaning

interval depends on the environment in which the printer is operated, print usage, paper quality

and other factors. A typical cleaning interval is one month. Steps for cleaning print head and

rubber covered roller are as follow s:

1) Turn off power. Open front cover.

2) Wait approximately 5 minutes until the print head is totally cooled down after printing.

3) Wipe out stains and dust on print head and rubber covered roller with Thermal Printer Cleaning

Swab (Digital Check part number 757300999 or 751920912) or a soft cotton cloth moistened

with isopropyl alcohol or ethanol.

4) Do not close front cover until alcohol evaporates.

5.3 Clean Paper Sensor

If ‘out of paper ’ errors are reported when there is still paper on the roll, the paper sensors may

need to be cleaned. Cleaning steps are as follows:

1) Turn off power.

2) Open front cover. Remove transparent cover plate over sensors (shown in bright yellow

below).

Digital Check ReceiptNOWTM Elite User Manual

- 15 -

3) Use Themal Printer Cleaning Swab (Digital Check part number 757300999 or 751920912) or

a soft cotton cloth moistened with isopropyl alcohol or ethanol to wipe away dust and stains on

the sensor surface ;

4) Do not install transparent cover plate until cleanser has evaporated. Close front cover.

6 Interface Signals

6.1 USB Interface

1) Parameter

Data transmission: Supports USB2.0 high-speed protocol.

Connector (Printer End): USB B serial socket, support USB HUB

2) Interface signal definition and function description

Pin No.

Signal

Name

Description

1

VBUS

+5V

2

DATA-

Printer data transmission negative phase side

3

DATA+

Printer data transmission normal phase side

4

GND

Ground

3) Interface Connector

6.2 Ethernet Interface

1) Parameter

Support of 10/100M BASE-T communication

Compatible with Ethernet II standard frame type

Indicator shows network connecting status and data transmission status

Digital Check ReceiptNOWTM Elite User Manual

- 16 -

Supports 9100 port print

Supports status back

Supports parameter configuration

Supports firmware update on-line

Supports printer status query and interface module maintenance based on HTTP(only JK-E02

interface supports)

2) Interface signal definition and function description

Interface adopts 10/100M BASE-T standard in accordance with IEEE802.3. The interface signal is defined as

below:

PIN

Signal Name

Instruction

1

TX+

Data transmission +

2

TX-

Data transmission -

3

RX+

Data receiving +

4

NC

Reserve

5

NC

Reserve

6

RX-

Data receiving -

7

NC

Reserve

8

NC

Reserve

3) Interface Connector

Socket figure of Interface module

6.3 Power Interface Definition

Power interface signal definition

24V power supply interface definition

Pin

Signal Name

1

+24V

2

GND

3

NC

Attention:

Pin

Signal Name

1

E

2

L

3

N

Digital Check ReceiptNOWTM Elite User Manual

- 17 -

The USB cable should not be plugged or unplugged with power on .

Avoid running the USB cable with other electrical supply wiring .

Use only a standard, shielded USB cable.

7 Recovering From Errors

If there is a printer error, you can refer to this chapter for appropriate handling. If problems

persist, please contact Digital Check at 847-446-2285.

7.1 Printer does not work

Issues

Reasons

Solution

POW ER INDI CATOR

LIGHT is off and printer

does not work. (See 7.3

for description)

Printer has no power.

Connect to power supply

Power switch is off.

Turn printer power switch on .

PCBA or power supply is damaged.

Contact Digital Check at

847-446-2285

7.2 Error Indicator Light and Buzzer Alarm –See Section 7.3 for Descriptions

Issues

Reasons

Solution

Reference

ERROR INDICATOR LIGHT

blinks and buzzer beeps

Paper Out

Adjust or replace paper roll

User Manual

ERROR INDICATOR LIGHT

blinks and buzzer beeps

Front cover

open

Close front cover

User Manual

ERROR INDICATOR LIGHT

blinks and buzzer beeps

Paper Low

Replace paper roll

User Manual

ERROR INDICATOR LIGHT

blinks and buzzer beeps

Cutter Default

Contact Digital Check at

847-446-2285

ERROR INDICATOR LIGHT

blinks and buzzer beeps

Printer has a

serious fault –

4, 5 or 6 beeps

Contact Digital Check at

847-446-2285

7.3 Indicator Light and Buzzer Information

Indicator Light Name

Status

Explanation

Power Indicator Light: Green

Bright

Printer is powered on

Out

Printer is powered off

Error Indicator Red

Out

Norm al Status

Blink

Error Status or paper low status

1)Error Indicator Light and Information

Error Type

Error Indicator Light

Buzzer

Paper Low

Flash slowly

No beep

Out of Paper

Flash 2 times then

repeat

Beep 2 times

Front cover open

Flash 3 times then

repeat

Beep 3 times

Cutter Error

Flash 4 times then

Beep 4 times

Digital Check ReceiptNOWTM Elite User Manual

- 18 -

repeat

Input Voltage Abnormal

Flash 5 times then

repeat

Beep 5 times

Overheated Print Head

Flash 6 times then

repeat

Beep 6 times

Attention:

The ReceiptNOW printer detects print head temperature. If the print head is overheated, a

protection circuit will cut off print head power and stop printing. T he print head will stop printing

at 65° C (149°F). Normal operation will resume when the print head cools down.

7.4 Troubleshooting printing problems

Issues

Reasons

Solution

Referenc

e

Paper output is

crumpled or bent

Paper Jam

Open front cover.

Check paper track

and cutter. Clear

jammed paper.

Stops printing

Paper Jam

Open front cover.

Check cutter. Clear

jammed paper.

Paper is not cut

Paper Jam

Open front cover.

Check cutter. Clear

jammed paper.

No printing, light

printing or smeared

print

Incorrect

installation

of paper roll

Check if paper is

installed properly

and that thermal

coated side of

paper is ‘up’.

Wrong paper

type

Use recommended

thermal paper.

Dirty print

head or

rubber

covered

roller

Clean print head or

rubber covered

roller.

Low print

density

Increase print

density to meet

requirements

Appendix

A:

Paramete

r Setting

by Feed

Button

Lengthwise printing

missing or streaks

Dirty print

head or

rubber

covered

roller.

Clean print head or

rubber covered

roller

User

Manual

Print head

failure

Contact Digital

Check at

847-446-2285

Other manuals for ReceiptNOW Elite

1

Table of contents

Other Digital Check Printer manuals

Digital Check

Digital Check SmartSource ReceiptNOW Elite User manual

Digital Check

Digital Check ReceiptNOW User manual

Digital Check

Digital Check TellerScan TS500 TTP2 Datasheet

Digital Check

Digital Check TellerScan TS500 Datasheet

Digital Check

Digital Check ReceiptNOW Operator's manual

Digital Check

Digital Check ReceiptNOW Elite User manual

Popular Printer manuals by other brands

Canon

Canon iP6700D - PIXMA Color Inkjet Printer Specifications

Epson

Epson Expression Photo XP-750 Basic guide

Roland

Roland SOLJET Pro III XC-540 Service notes

Printekmobile

Printekmobile I-820 Operator's manual

Canon

Canon PIXMA MX340 Series Simplified service manual

DataSouth

DataSouth Documax A6300 Series user manual