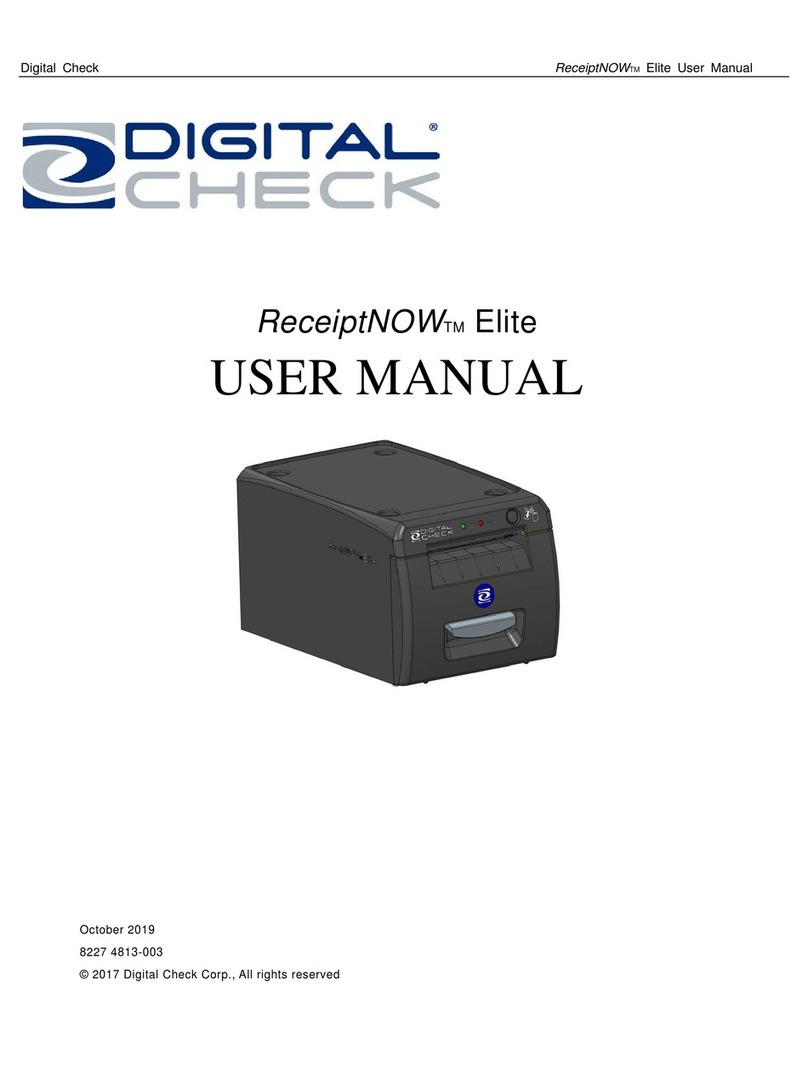

Digital Check ReceiptNOW User manual

Digital Check ReceiptNOWTM User Manual

ReceiptNOWTM

USER MANUAL

January2020

82273540-006

© 2011-2017 Digital Check Corp. All rights reserved

Digital Check ReceiptNOWTM User Manual

NO WARRANTIES OF ANY NATURE ARE EXTENDED BY THIS DOCUMENT. Any product or related information

described herein is only furnished pursuant and subject to the terms and conditions of a duly executed agreement

to purchase or lease equipment or to license software. The only warranties made by Digital Check Corp., if any,

with respect to the products described in this document are set forth in such agreement. Digital Check cannot

accept any financial or other responsibility that may be the result of your use of the information in this document

or software material, including direct, special, or consequential damages.

You should be very careful to ensure that the use of this information and/or software material complies with the

laws, rules, and regulations of the jurisdictions with respect to which it is used. The information contained herein

is subject to change without notice. Revisions may be issued to advice of such changes and/or additions.

Notice to U.S. Government End Users: This is commercial computer software or hardware documentation

developed at private expense. Use, reproduction, or disclosure by the Government is subject to the terms of

Digital Check standard commercial license for the products, and where applicable, the restricted/limited rights

provisions of the contract data rights clauses.

FCC Statement

The statement below is included in this document to comply with a Federal Communications Commission (FCC)

regulation. The FCC is an agency of the United States government; thus, the statement below applies to

computing equipment installed in the United States of America. Digital Check is taking appropriate steps to be in

compliance with FCC regulations and similar regulations of other countries.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Caution

Changes or modifications not expressly approved by Digital Check could void your authority to operate this

equipment.

Digital Check ReceiptNOWTM User Manual

Canadian Regulatory Statement

CAN ICES-3 (B)/NMB-3(B)

VCCI Regulatory Statement

Trademarks

Digital Check is a registered trademark licensed to Digital Check Corp. in the United States and other countries.

SmartSource is a registered trademark of Digital Check Corp. ReceiptNOW is a trademark of Digital Check Corp.

All other brands and products referenced in this document are acknowledged to be the trademarks or registered

trademarks of their respective holders.

Digital Check ReceiptNOWTM User Manual

Contents

FCC STATEMENT ..................................................... 1

CAUTION ................................................................... 1

CANADIAN REGULATORY STATEMENT ............... 2

VCCI REGULATORY STATEMENT .......................... 2

TRADEMARKS .......................................................... 2

1 SUMMARY .............................................................. 3

1.1 BRIEF INTRODUCTION ......................................3

1.2 MAIN FEATURES ..............................................3

2 TECHNICAL SPECIFICATIONS ........................... 4

2.1 PRINTER TECHNICAL SPECIFICATIONS ...............4

2.2 CUTTER TECHNICAL SPECIFICATIONS ................5

2.3 PRINTING CONSUMABLE MATERIAL TECHNICAL

SPECIFICATIONS ...................................................5

2.4 PRINT POSITION..............................................5

3 APPEARANCE AND COMPONENTS ................... 7

4 PRINTER INSTALLATION ..................................... 8

4.1 UNPACKING THE PRINTER.................................8

4.2 PRINTER INSTALLATION ....................................9

4.3 PRINTER POWER CONNECTION .........................9

ATTENTION:.......................................................9

PLEASE UNPLUG THE POWER SUPPLY BRICK FROM THE

AC OUTLET,IF NOT USING THE PRINTER FOR A LONG

TIME. ...................................................................9

4.4 CONNECTING INTERFACE CABLE .......................9

4.5 PAPER ROLL INSTALLATION AND PRINT CHECK....9

4.6 PAPER LOW ADJUSTMENT SETTING .................10

4.7 PRINTER POWER ON AND SELF TEST ................12

4.8 ETHERNET IP ADDRESS CONFIGURATION .........12

5 JK-W03 MODULE HTTP WEB .............................13

5.1 OVERVIEW.................................................... 13

5.2 INTERFACE STATUS ....................................... 14

5.3 PRINTER STATUS .......................................... 14

5.4 FIRMWARE UPDATE........................................ 15

5.5 WIRED TCP/IP ............................................. 19

6 PRINTER ROUTINE MAINTENANCE..................21

6.1 CLEARING JAMMED PAPER ............................. 21

6.2 CLEAN PRINT HEAD AND ROLLER –ONCE PER

MONTH.............................................................. 21

6.3 CLEAN PAPER SENSOR.................................. 22

7 INTERFACE SIGNALS .........................................24

7.1 USB INTERFACE ........................................... 24

7.2 ETHERNET INTERFACE ................................... 25

7.3 POWER INTERFACE DEFINITION ...................... 26

8 RECOVERING FROM ERRORS...........................27

8.1 PRINTER DOES NOT WORK.............................. 27

8.2 ERROR INDICATOR LIGHT AND BUZZER ALARM –

SEE SECTION 7.3 FOR DESCRIPTIONS .................. 27

8.3 INDICATOR LIGHT AND BUZZER INFORMATION ... 27

8.4 ISSUES EMERGING DURING PRINT PROCESS ..... 28

9 INSTALLATION METHOD FOR SUPPORTING

VARIOUS SCANNERS.............................................29

9.1 SMARTSOURCE OPEN INSTALLATION ............... 29

9.2 SMARTSOURCE INSTALLATION ........................ 30

9.3 TS240 INSTALLATION .................................... 30

9.4 CR-55 SCANNER INSTALLATION ...................... 31

9.5 LS150 SCANNER INSTALLATION ...................... 31

9.6 VISION XSCANNER INSTALLATION ................. 32

10. POWER MANAGEMENT ...................................33

APPENDIX A: PARAMETER SETTING BY FEED

BUTTON....................................................................34

Digital Check ReceiptNOWTM User Manual

- 2 -

Safety Instruction

Before operating the printer, please read following notes carefully.

Safety warnings

Warning: Do not touch the cutter on the printer

Warning: Do not touch the print head and its surrounding parts during or just after printing as the

print head is hot.

Attention

1) Printer should be placed on a flat and stable location.

2) Leave enough space for operation and maintenance around the printer.

3) Printer should be kept away from water. Avoid direct sunlight, strong lights and heat.

4) Avoid getting water or conductive material (such as metal) into the interior of the printer. If this happens,

disconnect the printer power supply immediately.

5) Do not allow condensation to form on the surface of the printer. If condensation has formed, the printer

should not be powered on until the condensation has been eliminated.

6) Do not use or store printer in conditions of high temperature, high humidity or serious pollution.

7) Avoid placing printer in a location that would subject it to vibration or impact.

8) Connect the printer power cable to a properly grounded socket. Avoid using the same socket with large

motors or other devices which could cause power supply voltage fluctuations.

9) If the printer is not to be used for an extended period, unplug the power cord.

10) Do not attempt to print without paper. This will seriously damage the print rollers and thermal print head.

11) To ensure print quality and product life, use the recommended paper or the same quality of paper.

12) Turn off the printer power switch before plugging in or unplugging power or interface cables. Failure to

do so may damage the printer.

13) To maximize the life of the printer, it is suggested that users use the lowest level print density that

meets print quality requirements.

14) There are no user-serviceable parts inside the printer. Disassembling the printer will void the warranty.

15) Keep this manual for reference.

16) The DHCP function of network interface printer is enabled by default. The default timeout time of DHCP

is 20 seconds (customers can set the time as required). If no IP address is obtained within 20 seconds,

the default IP address is 192.168.1.251.

17) The network interface does not support disconnection detection.

18) Plugging and unplugging the network cable will not start DHCP to obtain an IP address.

Digital Check ReceiptNOWTM User Manual

- 3 -

1 Summary

1.1 Brief Introduction

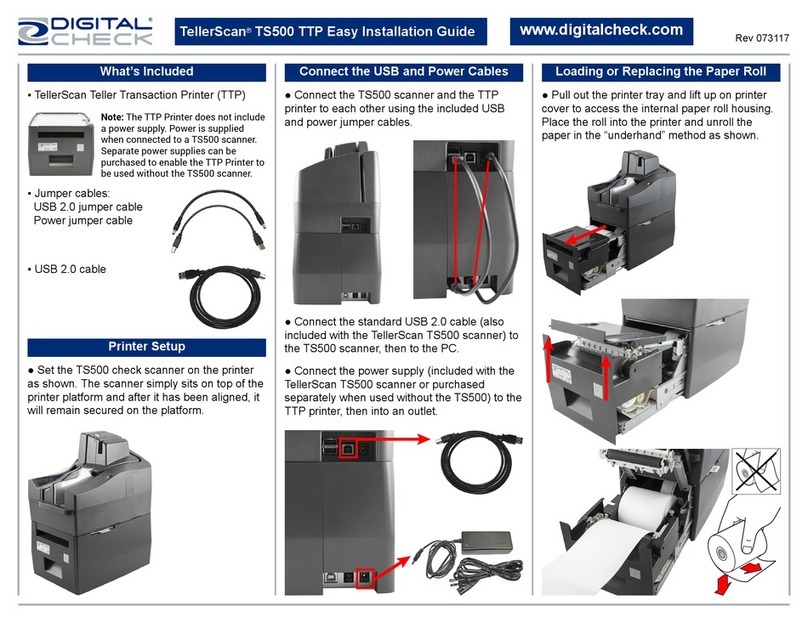

ReceiptNOW is a high-performance thermal printer which can be integrated with a check scanner to

save desk space effectively. It can be widely used in the financial industry to print receipts, notes and

provide vouchers such as financial slip printing or transactions list printing.

ReceiptNOW uses front-end paper exit, drop-in paper replacement, as well as providing a support

platform for Smart Source® Series scanners. By adding a Digital Check ‘Printegrate’ Adapter,

ReceiptNOW can support Digital Check TS240, Panini Vision X, CTS LS150, Cannon CR 55scanners and

other scanner brands. The ReceiptNOW printer detects print head in place, out of paper, paper low, and

voltage detection. It also supports USB2.0 or Ethernet 10/100 self-adapting. The USB version can be

easily upgraded to add an Ethernet interface. It supports Standard Font A (12 × 24), Font B (9 × 17), Kanji

Font A (24 × 24),Thai, Simplified Chinese, Korean and other languages, supports multiple code pages to

print, one-dimensional bar code: UPC-A, UPC-E, CODE 39, CODE 93, CODE 128, EAN8, EAN13, ITF,

CODABAR; two-dimensional bar codes: PDF417, QR-CODE; using ESC / POS command set, automatic

state return. With the user Custom Sample function, users can set print format and fix content of printing

by firmware settings. Paper width can be set in a row, compatible with EPSON TM-88IV.

1.2 Main Features

◇Quiet, high-speed printing

◇Supports of two-tone printing, watermark, gray level printing

◇Adapts to fit multiple check scanners

◇Easy paper loading(Drop-in paper)

◇Easy to use and maintain

◇Paper width can be adjusted from 56-82.5mm

◇Supports full cut and partial cut

◇Optional communication interfaces (USB or Ethernet)

◇Compatible with ESC / POS commands or Windows Print

◇Paper-saving

◇Storage Compartment

◇Low power consumption design (minimum power consumption less than 1W): Enters sleep mode in 5

minutes.

Digital Check ReceiptNOWTM User Manual

- 4 -

2 Technical Specifications

2.1 Printer Technical Specifications

Items

Parameter

Print method

Thermal print by line

Print resolution

203*180DPI

Print speed

Maximum print speed is 200mm/sec, two-color printing speed

100mm/sec, gray print speed 100mm/sec. Depending on the

different print content, the printer will automatically adjust print

speed

Print Span

Maximum is 80mm; paper width is from 56-82.5mm.

Paper type

Paper thickness is 0.06~0.10mm, Maximum paper roll OD is

83mm

Continuous thermal paper or thermal paper tags

Support Bar code type

Barcode 1D: UPC-A, UPC-E, CODE 39, CODE 93, CODE 128,

EAN8, EAN13, ITF, CODABAR

Barcode 2D symbols: PDF417, QR-CODE,MAXICODE,GS1

Character support

U.S.A., France, Germany, U.K., Denmark I, Denmark II, Italy,

Sweden, Spain I, Spain II, Japan, Norway, Latin America, Korean

etc. optional

Enlarge character

All characters can be enlarged from in level 1-6 both in the

horizontal and vertical direction.

Character rotation

Four direction printing rotation (0°, 90°, 180°, 270°)

Paper detection

Photoelectric sensors (out of paper, paper low)

Front cover position

detection

Micro switch

Print head temperature

detection

Thermistor

Graphics processing

Download bitmap

Print bitmap directly

Download buffer size:

RAM:128KB

FLASH:512KB

Support bitmap mode, fast graphic

printing

Communication interface

USB interface, Ethernet interface optional

Memory

FLASH Memory Capacity: Maximum 4MB;

SDRAM memory total capacity: Maximum 2MB;

Data receive buffer size: 64K, 4KB, 45 bytes selectable;

RAM bit map area: 128KB;

Area available to the user FLASH: 512KB;

Power

AC 110-240V 50/60 Hz, ~1.5A (Power supply)

DC 24V ± 5% average current 2.0A

Maximum instantaneous current 8A

Print head lifetime

Print head lifetime, thermal single color print: 100Kilometers

Print head lifetime, thermal two color print: 50 Kilometers

Print duty ratio: 12.5%

Operating temperature and

humidity

5~40°C (41 ~ 104°F), 20%~90% (40°C, 104°F)

Storage temperature and

humidity

-40~60°C (-40 ~ 140°F), 10%~93% (40°C, 104°F)

Dimensions

388mm×155mm×109mm (15.3in × 6.1in × 4.3in)

(

L×W×H

)

Digital Check ReceiptNOWTM User Manual

- 5 -

2.2 Cutter Technical Specifications

Item

Parameter

Note

Cutting method

Slide the blade

Cutting time

500ms

Cutter cuts for one time.

Cutting interval

2s

30cuts / min (maximum)

Type of paper 0.06~0.1mm

Thermal paper or equivalent thickness

paper

Operating voltage

24VDC

Maximum operating current

1.2A

24VDC

Cutter lifetime

1.5 million times

(0.06mmthickpaper)

*Includes full-cut, partial cut

Full cut: cut off all the paper

Partial cut: keep a little connection among the paper, not completely cut off.

2.3 Printing Consumable Material Technical Specifications

2.3.1 Thermal Paper Parameters

Type ofPaper: Continuous thermal paper

Paper Feeding Method: Paper Roll

Paper Width: Maximum 82.5±0.5mm, width can be adjusted between 56-82.5mm

Paper Thickness: 0.06mm-0.1mm

Thermal Layer: External

Paper Roll Size: OD (Max):83 mm

Inside Diameter (Min) 12.5mm

RecommendedPaper:

Type of Paper Manufacturer

F240AC,F220-VP,FV230A1,

PA220AG,HP220A Mitsubishi Paper Mill CO., LTD

FD210,PD150R,PD160R OJI Paper CO., LTD.

F70NA FUJI PHOTO FILM CO., LTD

Attention:

Please use recommended paper or equivalent quality paper. The use of other types of paper may

affect print quality and print head life.

If the paper is contaminated by chemicals or oil, the contaminated parts of paper may become

discolored or printing result may not be clear.

Do not scratch hard layer of thermal paper by using sharp or hard object, which may cause the

printing to not be clear.

When the temperature exceeds 70°C (158°F), the thermal layers of paper will fade. Therefore, it’s

necessary to avoid heat, high humidity, and high light when using or storing paper.

Digital Check ReceiptNOWTM User Manual

- 6 -

2.4 Print Position

2.4.1 Print Location On The Paper

L1 Maximum Paper Pocket Width:82.5±0.5mm

L2 Maximum Effective Print Width:80mm

L3 Distance from print head to left side of paper pocket (fixed width): 1.75±1mm

L4 Distance from print head to right side of paper pocket (fixed width): 1.75±1mm

L5 Left margin: Set by the command (see Programming Manual), the printer default is 8mm

L6 Width of print area: Set by the command (see Programming Manual), the printer default is 64mm

L7 Right margin: Set by the command (see Programming Manual), the printer default is 8mm

Digital Check ReceiptNOWTM User Manual

- 7 -

3 Appearance and Components

1—Top Cover

2—Power Indicator Light - Indicates power status.

3—Error Indicator Light - Reports warning or error status

(such as out of paper, etc.). Indicator light flashes.

Under normal conditions, the light remains off.

4—Paper Feed Button

Paper Feeder:If there are no errors

or warnings, pressing this button will

feed paper.

Print Configuration Function: Hold

down this button at the same time

while turning on power. Printer will

print the configuration settings (such

as print length and width, print speed

and other settings).

5—Paper Pocket

6—Paper pocket width adjustment - Slide

wheel towards the front or back to

adjust the paper pocket width. The

range of adjustment is 56 ~ 82.5mm

7—Out of paper sensor - Continuous paper

status, for the detection of paper or

paperless

8—Roller

9—Paper Exit

10—Handle

11—Paper low sensor (inside the printer) –

Detects how much paper remains.

Error indicator flashing rapidly means

paper is near end and needs to be

replaced soon. The printer will continue

to work until out of paper.

12—Adjustment for paper low sensor

13—Scanner installation location

14—Power Switch - Press “O” to turn off the

power, press “-” to turn on the power

15—Ethernet Interface

16—USB Interface

17—Power Interface

18—Storage compartment

Digital Check ReceiptNOWTM User Manual

- 8 -

4 Printer Installation

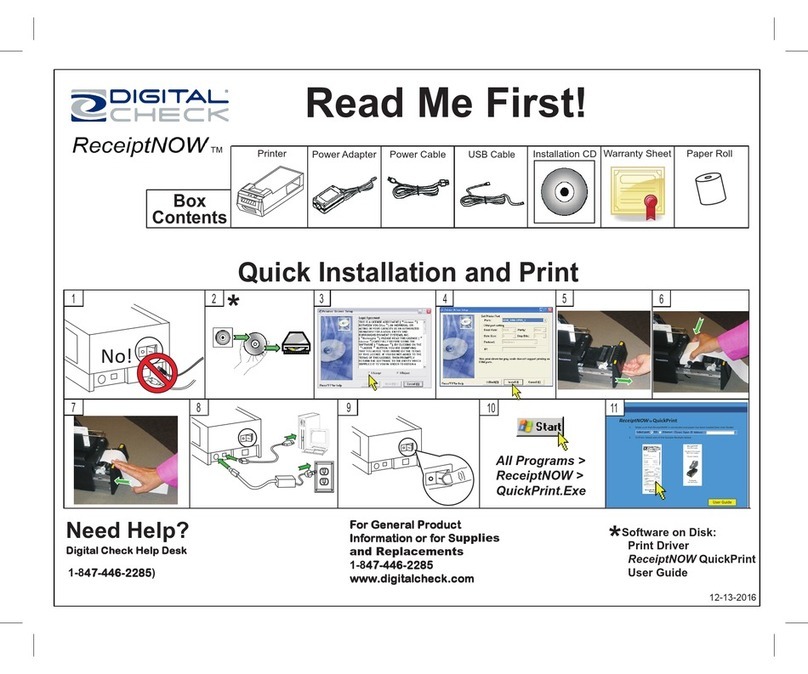

4.1 Unpacking the Printer

Please check the packing list when unpacking the printer. If something is missing or damaged, please

contact Digital Check at 1-847-446-2285.

Digital Check ReceiptNOWTM User Manual

- 9 -

4.2 Printer Installation

1) Printer should be installed on a flat surface.

2) Printer should be kept away from water.

3) Avoid placing printer in a location that would subject it to vibration or impact.

4) The printer should only be plugged into an electrical outlet that has a safety ground.

5) Allow the proper space for printer operation and maintenance. Please see picture below showing the

printer open and reserve enough operating space.

6) Follow the Instructions on the ReadMe First! document to complete the installation and to print

sample receipts. For more detailed installation instructions and to print a test configuration printout,

proceed with the next Installation section.

4.3 Printer Power Connection

1) Make sure that the printer’s power switch is turned off.

2) Connect power plug into power socket behind the printer.

Attention:

Please unplug the power supply brick from the AC outlet, if not using the

printer for a long time.

4.4 Connecting Interface Cable

1) Make sure printer’s power switch is turned off.

2) Plug connecting USB or Ethernet interface cable into appropriate socket.

3) Connect the other end of cable to the computer.

4.5 Paper Roll Installation and Print Check

4.5.1 Check Printing Paper

Paper may be installed while the power and interface cables are connected. Please check paper type

before printing.

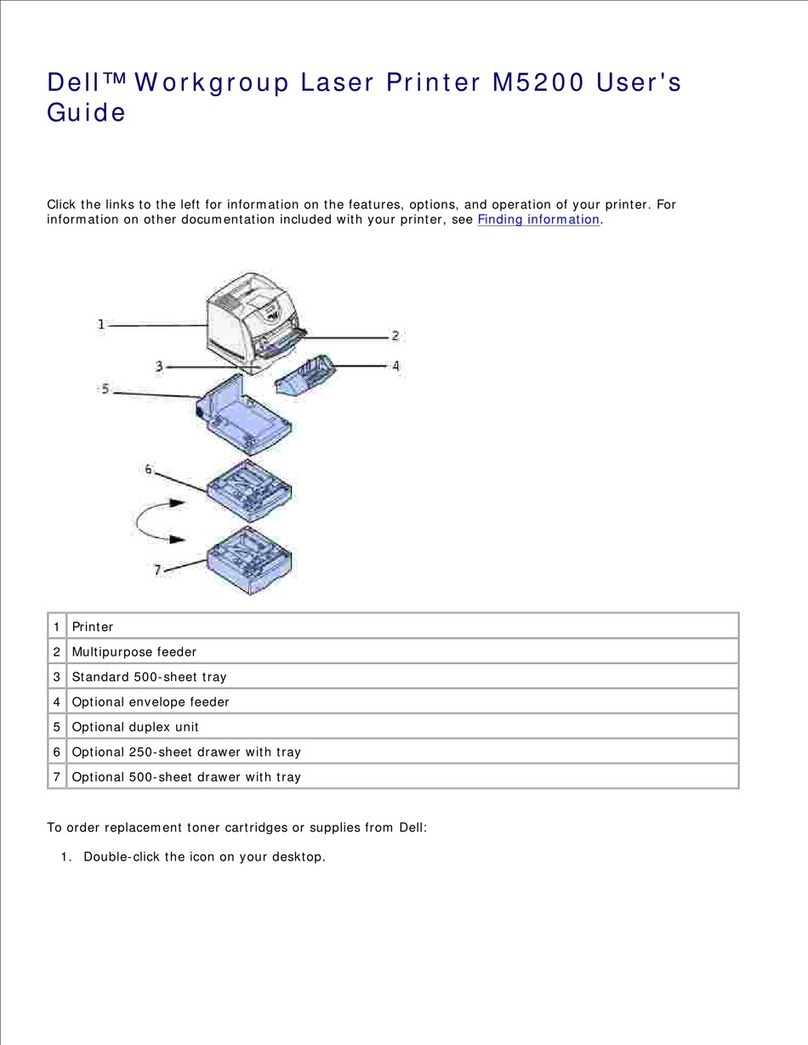

4.5.2 Install/Change Paper Roll

1) Turn off power.

2) Pull the handle and open front cover.

Digital Check ReceiptNOWTM User Manual

- 10 -

3) Using the paper width adjustment wheel, adjust to fit the width of the paper being installed, as shown

below. Roll the adjustment wheel towards the rear of the unit to adjust for wider rolls. Roll the adjustment

wheel towards the front of the unit to adjust for narrower rolls. After the paper roll is installed, it should be

loose so that it rotates easily.

4) Put paper roll into printer according to directions shown on the label.

5) Pull out paper end and close front cover.

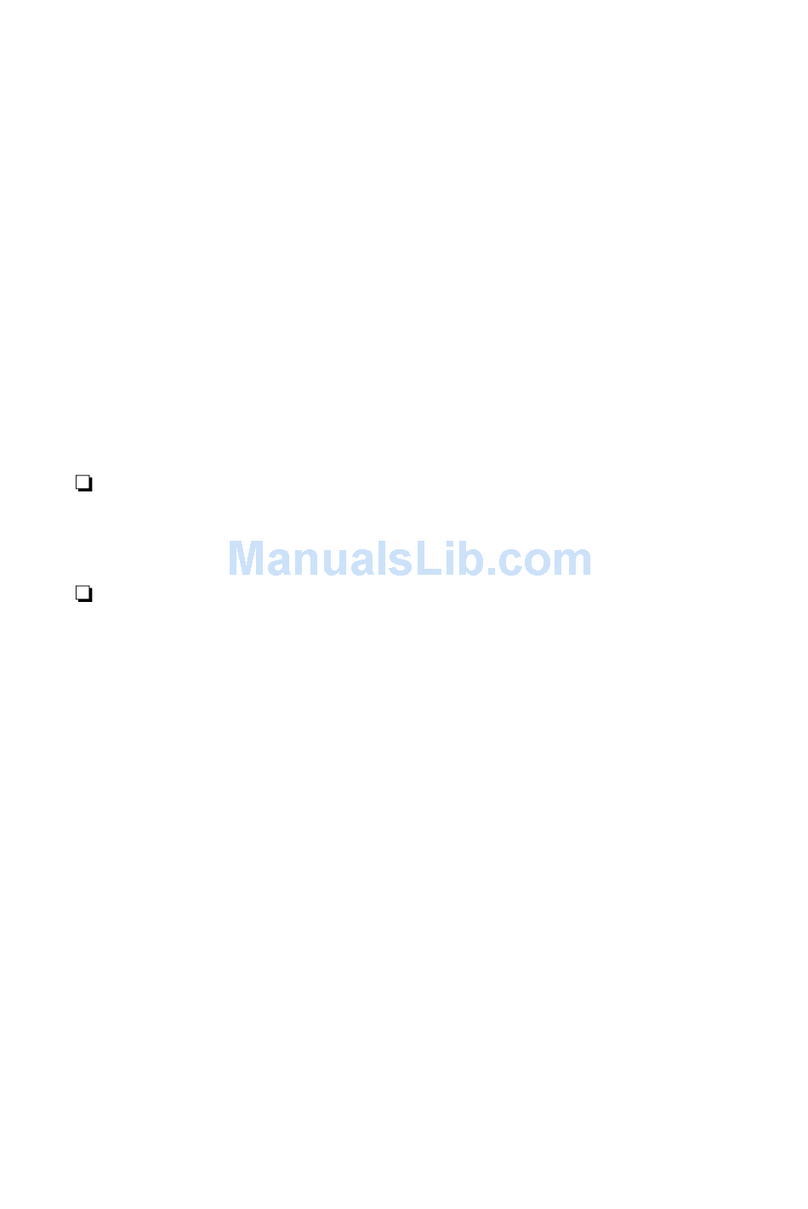

4.6 Paper Low Adjustment Setting

4.6.1 Paper Low Sensor

ReceiptNOW paper low detect is adjusted at the factory. If necessary, it can be adjusted by changing

the paper low sensor’s position. The paper low sensor location is shown in red below.

Digital Check ReceiptNOWTM User Manual

- 11 -

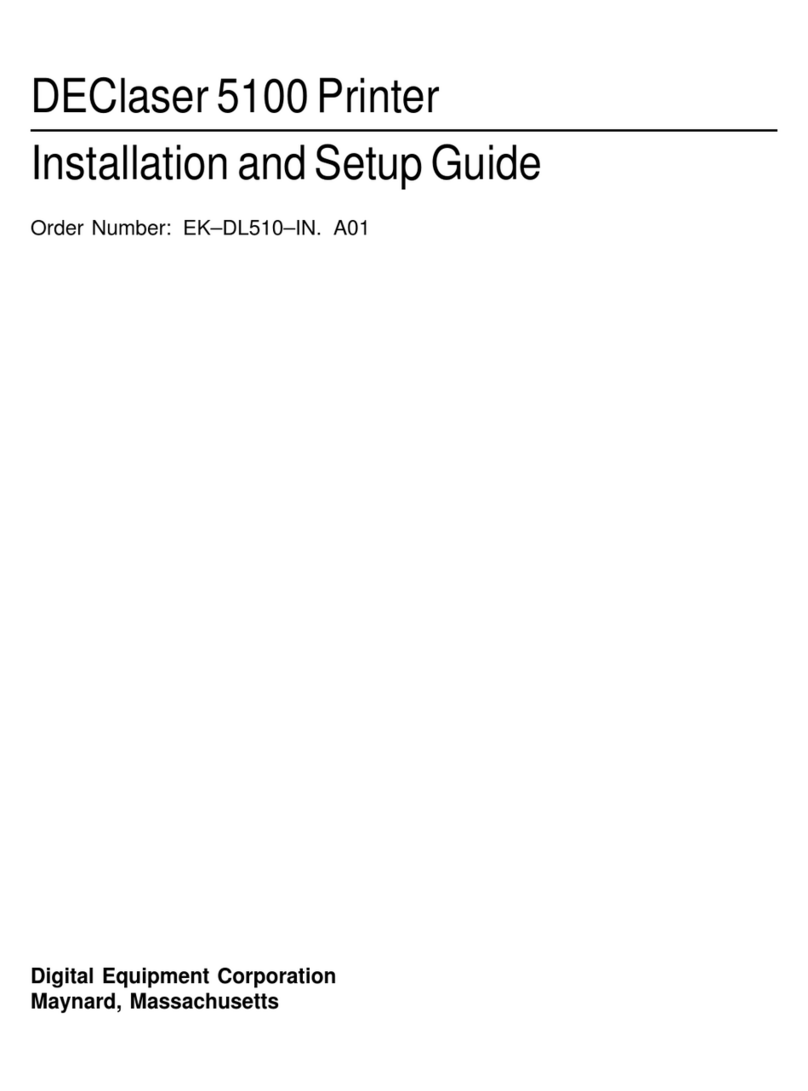

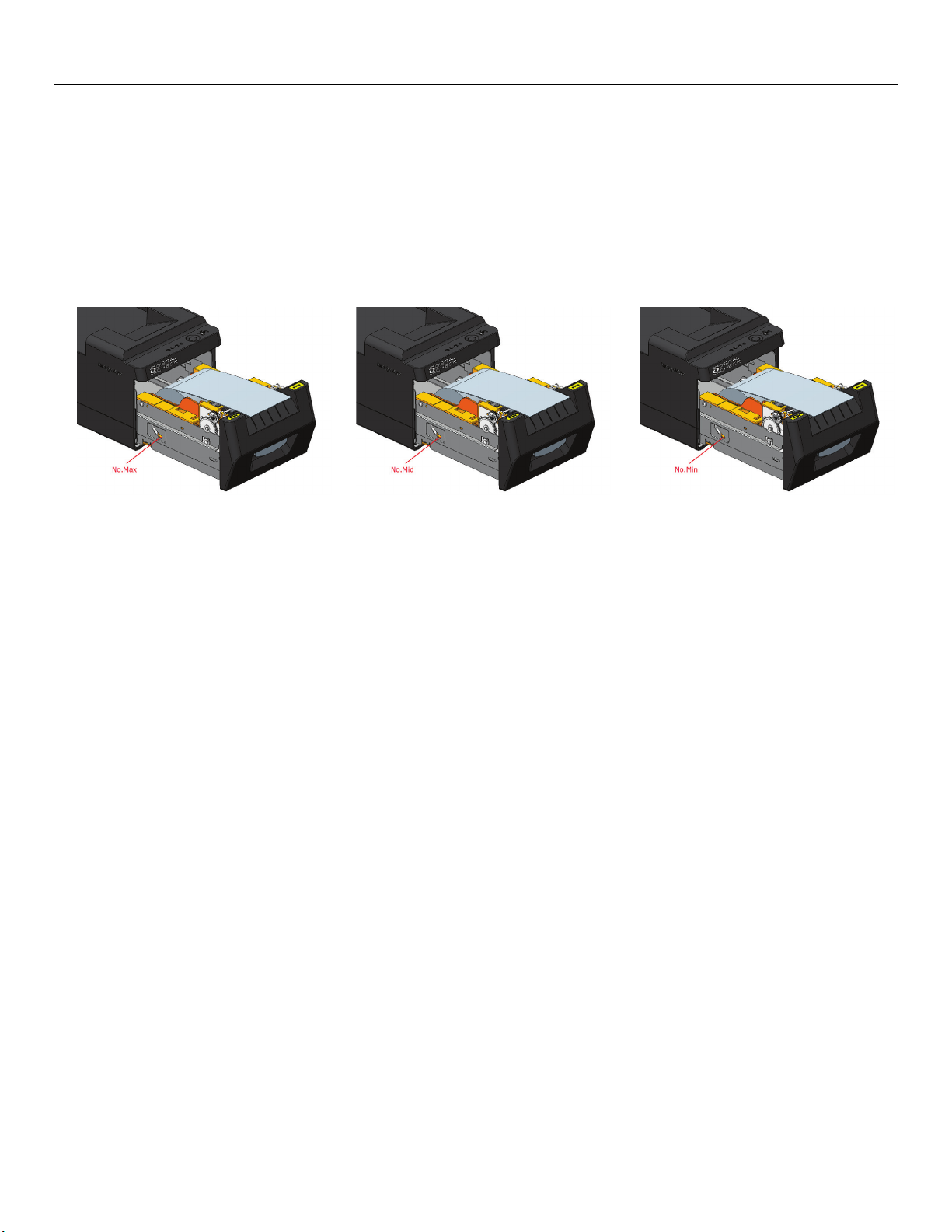

4.6.2 Adjusting the Paper Low Setting

Adjust the paper low sensor’s position to change the remaining paper quantity that will cause a low

paper warning. The paper low setting has three levels. Below red line shows paper low setting. Push the

bar to change red line position and change paper remaining quantity that will cause the low paper warning

to be triggered. The following three pictures show the paper remaining quantity settings and the

approximate amount of paper remaining that will cause the low paper warning.

Max, ~3 meters of paper remain Mid, ~2 meters of paper remain Min, ~1 meter of paper

remains

Digital Check ReceiptNOWTM User Manual

- 12 -

4.7 Printer power on and self test

1) Make sure power cable is connected to the printer and the paper roll is loaded.

2) Make sure POWER INDICATOR LIGHT is off and printer is powered off.

3) Hold down the feed key while turning the printer on. Keep on holding the button till ‘Interface is

configuring….’is printed out, which lasts around 2 seconds. After waiting for 15 seconds (old PCBA:

JK-E02 around 10 seconds, new PCBA JK-W03 around 15 seconds), the printer will perform a self-test

and then print ‘Press and Release FEED key to print characters’ and ‘Press and Hold FEED key to

configure the printer’. The printer will change to holding state and PAPER INDICATOR LIGHT blinks.

4) When the self-test page is finished, press the FEED key briefly to print test characters or hold the

FEED key down to configure the printer. For specific function and operational approach for using the

FEED button to configure the printer, please refer to Appendix A “Parameter Setting by FEED Button”.

4.8 Ethernet IP Address Configuration

ReceiptNow printers that have an Ethernet interface are factory configured for a default turning-on DHCP

mode. To turn off the unit for DHCP mode or changes to the unit’s default IP address can be done by

communicating with the unit via a web browser set to the default IP address as shown in the screen shot

below. The web browser utility can also provide printer and interface status.

The current IP address of the printer can be determined by powering on the printer while holding the feed

button down which will cause the printer to print out a test form which lists various hardware and

communication interface parameters.

If the printer does not appear to respond to the proper IP address, the most likely cause is that the

printer is not currently configured in a manner that is compatible with the network to which it is

connected. Check with your network system administrator to insure that the settings for ‘DHCP’, ‘Gate

Way’ and ‘IP Address’ are compatible with the network.

Digital Check ReceiptNOWTM User Manual

- 13 -

5 JK-W03 Module HTTP Web

5.1 Overview

The interface module provides HTTP service. The status of printer and interface module can display based

on WEB page at the host end through browser, and can also carry out the operation of configuring the

interface module and printing the test page. This service adopts the TCP port of port 80.

When the user adopts this service:

Firstly, the user needs to get the IP address of interface module through self-test page or special

configuration tool;

Secondly, enter IP address of interface module in location bar of browser. Then you can inquire the printer

status and maintain the interface module through WEB page. The following is the detailed explanation of

WEB page.

Digital Check ReceiptNOWTM User Manual

- 14 -

5.2 Interface Status

Start Internet browser, enter IP address of printer and you can see window of interface status. Then click

“Refresh” button to refresh current status (see Figure 1):

Figure 1 Interface status

5.3 Printer Status

Click “Printer Status” link to check status of printer connected to the interface. If there is abnormal status,

the letters in the page will show in red. Click “Refresh” button to refresh current status and click “Print Test

Page” to print the self-test page through printer (see Figure 2):

Digital Check ReceiptNOWTM User Manual

- 15 -

Figure 2 Printer status

Note: When printer is busy or there is error in the printer, then the printer cannot print the self-test page.

5.4 Firmware update

Press the “Firmware update” link to load the firmware update web page. If a password has been previously

set, you must enter the password first, then you will be allowed to enter the firmware update web page (see

Figure 3). Next, press the “Browse…” button to select the firmware update and then press the “Update” to

begin updating the firmware. When the update process is completed, a message box will appear indicating

that the firmware was successfully updated, and the printer will restart automatically. (see Figure 4). If an

invalid firmware file is loaded or the update fails, a message box will appear indicating that the file format

is invalid or the update has failed.

Digital Check ReceiptNOWTM User Manual

- 16 -

Figure 3 Firmware updating page

Digital Check ReceiptNOWTM User Manual

- 17 -

Figure 4 Firmware updating successfully

After clicking Yes, the printer will remind you to “Please wait for printer to reboot”, as shown in Figure 5.

Other manuals for ReceiptNOW

1

Table of contents

Other Digital Check Printer manuals

Digital Check

Digital Check SmartSource ReceiptNOW Elite User manual

Digital Check

Digital Check ReceiptNOW Operator's manual

Digital Check

Digital Check ReceiptNOW Elite User manual

Digital Check

Digital Check TellerScan TS500 TTP2 Datasheet

Digital Check

Digital Check TellerScan TS500 Datasheet

Digital Check

Digital Check ReceiptNOW Elite User manual