5.

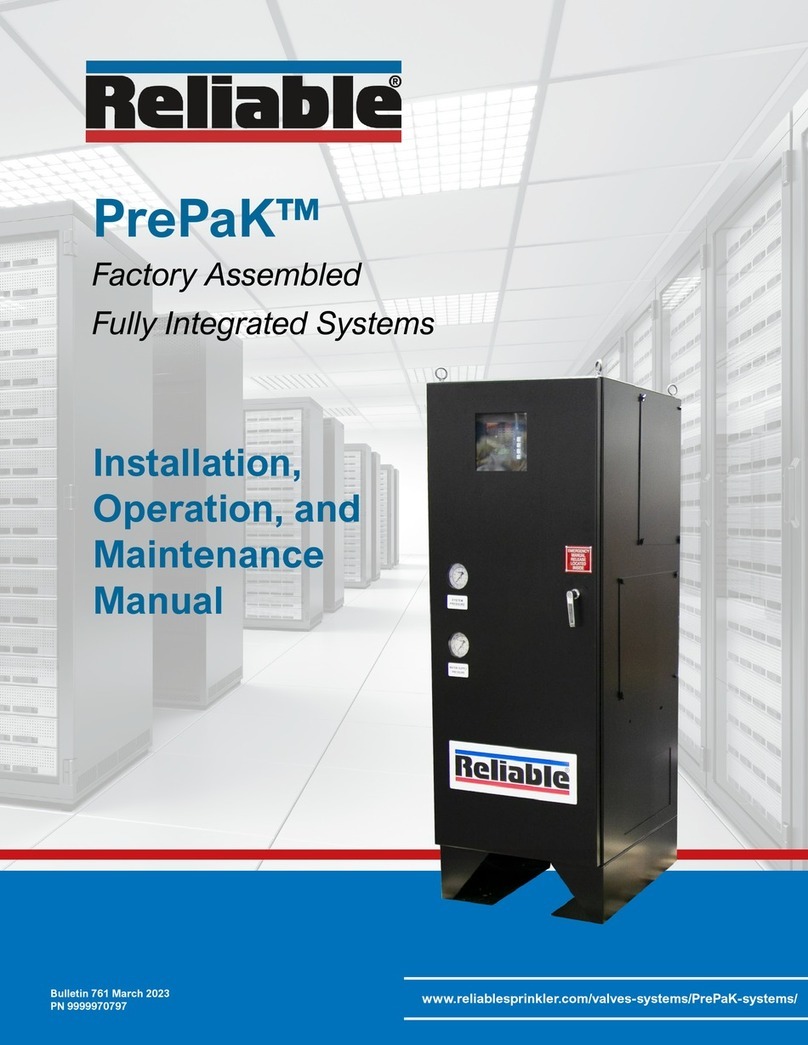

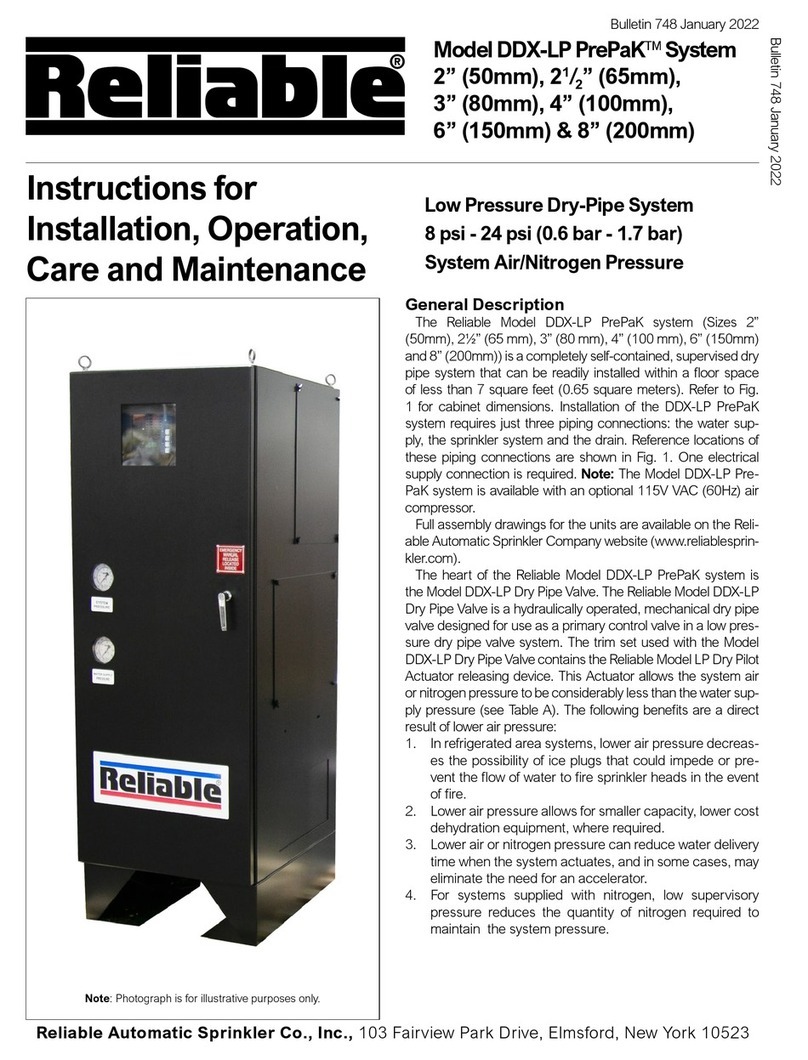

When the air compressor in the Model DDX Type F PrePaK

system is used to initially fill the sprinkler system with air, the

steel enclosure door should remain open to provide maxi-

mum intake air flow to the air compressor. The air compressor

is connected to a storage tank. This tank functions as a res-

ervoir, providing make-up air to compensate for small, inter-

mittent leaks in the sprinkler system. It should be noted that

significant leaks may overburden this storage tank, thereby

causing the air compressor to continuously cycle on and off.

The factory-installed system air pressure switch may need

on-site adjustment to correspond with the air pressure val-

ues found in Table A. Adjustment, if required, should be

made according to Potter Bulletin 5401564 included with

the switch.

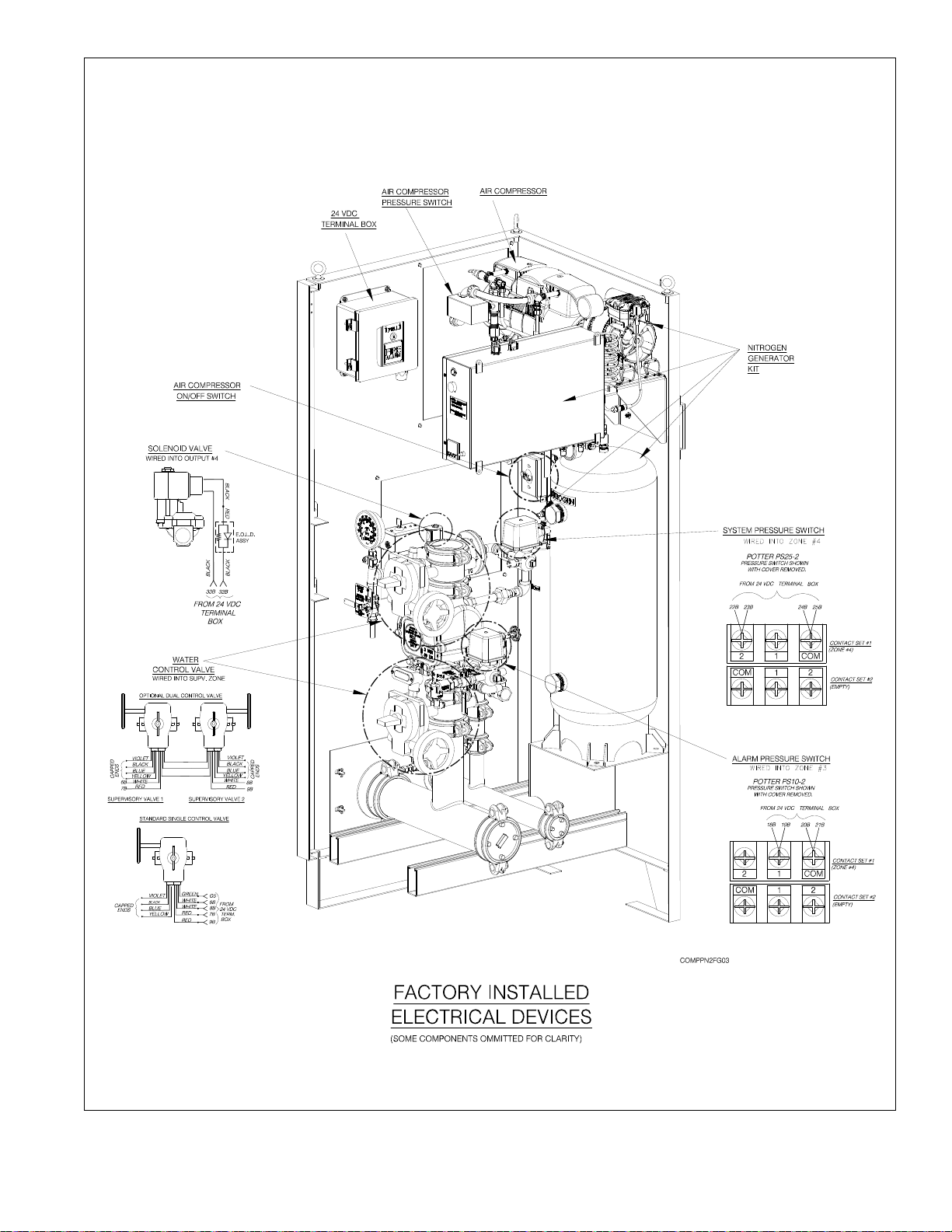

System Electrical Requirements

All releasing, alarm, and detection devices in the Reli-

able Model DDX Type F PrePaK system are supervised by

a Potter Model PFC-4410-RC Releasing Control Panel. All

of the terminals are translated to a water-tight terminal box

mounted on the interior of the enclosure. All field wiring is

connected to this terminal box. Note: The EOL (End of Line)

resistors have also been relocated.

The Reliable Model DDX PrePaK system is delivered

with six factory-installed electrical devices. They consist of

the following:

1. A system air pressure switch, which is used to monitor

sprinkler piping.

2. An alarm pressure switch, which indicates an actuation

of the deluge valve.

3. A normally-closed, releasing solenoid valve, which is

used to actuate the deluge valve.

4. A 1/2 HP (2”, 2-1/2”, & 3” valve) or 1 HP (4” valve) air

compressor with tank.

5. A supervised butterfly (main control) valve (Note: A sys-

tem side butterfly valve is available as an option).

6. A release control disable switch (RCDS) which is used

to disable the solenoid valve for test purposes.

The factory electrical connections of these devices,

along with information on the connection of detection devic-

es (initiating zones 1 and 2), signaling devices, and super-

visory outputs to the Potter PFC4410-RC Releasing Control

Panel are included in this bulletin. The power supply, stand-

by emergency power supply, battery charger and rectifier

circuitry are all contained within the PFC4410 panel. Bat-

teries that provide 90 hours of standby power are provided

with the panel. For additional information and detailed wiring

diagrams, please refer to Potter Manual #5403550 (Instal-

lation, Operation and Instruction of PFC4410-RC Releasing

Control Panel).

Note: In order for the solenoid valve to maintain a warranty it

must remain sealed as it came from the factory. If there are

concerns about the valve’s internal components, immediate re-

placement is recommended.

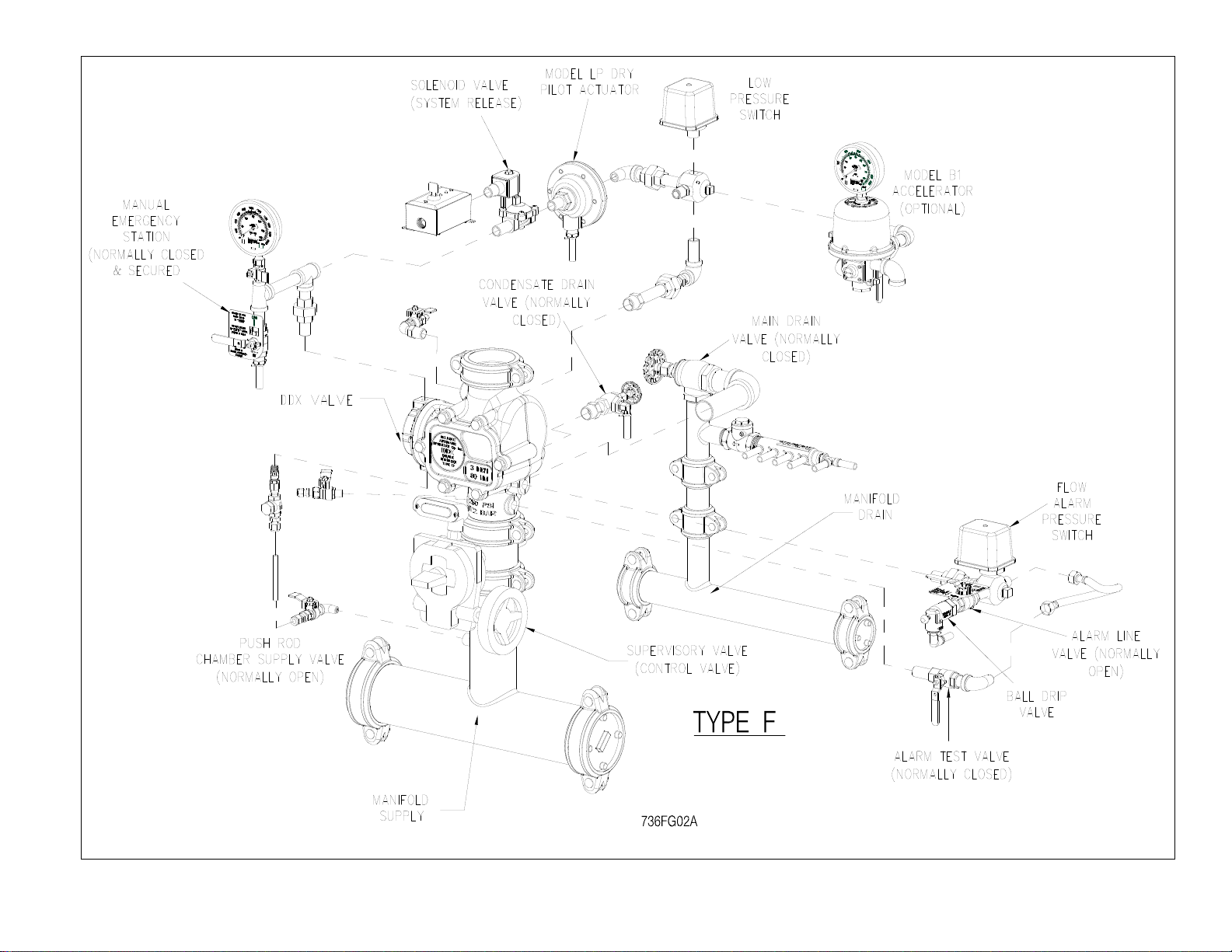

System Operation (Double Interlock)

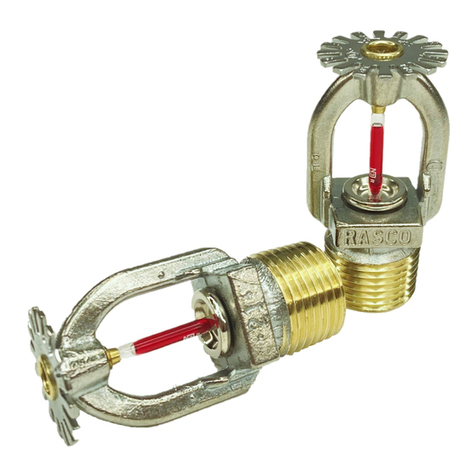

To fully activate (discharge water from) the Reliable Model

DDX Type F PrePaK system, a fire detection device must ac-

tivate and pneumatic pressure must be lost from the sprin-

kler system piping (normally from the activation of one or

more fire sprinklers).

When the system is properly set for service, the water sup-

ply pressure simultaneously acts on both the underside of

the deluge valve’s clapper and on the valve’s push rod by

means of the pressurized push rod chamber. The resultant

pressure force acting on the push rod, in unison with the me-

chanical advantage of the deluge valve lever, is more than

sufficient to hold the valve clapper in the closed position

against the water supply pressure.

Energizing the releasing solenoid valve is only one of the

events required towards opening the deluge valve. Air pres-

sure in the sprinkler system must also be reduced to a level

low enough to activate the Model LP Dry Pilot Actuator. Both

of these events allows the deluge valve’s push-rod chamber

to be vented to drain through its outlet. Since the push-rod

chamber pressure cannot be replenished through the inlet

restriction as rapidly as it is vented, the pressure falls rapidly.

When the push-rod chamber pressure drops below one-

third of the water supply pressure, the force acting beneath

the valve clapper becomes greater than the push-rod force

acting on the lever which causes the clapper to open. Refer

to Reliable Technical Bulletin 751 for further details.

Once the clapper has opened, the lever acts as a latch,

preventing the clapper from returning to the closed position.

Water from the supply flows through the deluge valve into

the system piping and also through the alarm outlet to acti-

vate water flow alarm devices. Note that the solenoid valve

will be maintained open by the Potter Model PFC-4410-RC

Releasing/Control Panel latching feature until it is reset for

operation.

After system shutdown and draining, the Model DDX Del-

uge Valve clapper is easily reset without special tools us-

ing the external reset feature. Restore detection devices by

resetting or replacing any operated device. Once detection

devices are restored the system can be reset (see Resetting

Model DDX Type F Double Interlock Preaction System).

Resetting Model DDX Type F Double Interlock

Preaction System

1. Close the valve controlling water supply to the Del-

uge Valve and close the air or nitrogen supply to the

sprinkler system.

2. Close the pushrod chamber supply valve.

3. Open main drain valve and drain system.

4. Open all drain valves and vents at low points through-

out the system, closing them when flow of water has

stopped. Open the Model B Manual Emergency Station

to relieve pressure in the pushrod chamber of the Deluge

Valve.

5. With the alarm line valve open, push in the plunger of

ball drip valve, forcing the ball from its seat, and drain the

alarm line.