Dill Retrofit TPMS User manual

Thank you for purchasing a Dill Retrofit TPMS Kit. Properly inflat-

ed tires increase fuel economy, reduce tire wear and improve han-

dling. A warning system that notifies you of an underinflated tire

will provide you time to respond prior to potentially damaging your

tire, vehicle, or trailer.

For more information visit our website at http://www.trailertpms.com or

http://www.dillvalves.com

Alerts when tire pressure is too low

Alerts when tire pressure is too high

Alerts when tire temperature is too high

1500 -

BAND

Retrofit

TPMS Kit

Key Features:

Visual and audible warnings

Set desired PSI level

Mounts to windshield or

dashboard

Table of Content Page

1. Setting Up the System 2

1.1 Transmitter Installation 2

1.2 Install the Display 2

1.3 Setting the Baseline (Cold Inflation) Pressure 2

1.4 Using the External Antenna—RF Interference 3

2. Transmitter Installation: 5

3. System Overview 6

3.1 System Components 6

3.2 How the System Works 6

3.3 Normal Monitoring 7

3.4 Warnings 8

3.5 Display Indicator and Controls 10

3.6 Transmitter Components 10

3.7 Tire Rotation 11

3.8 Changing Number Of Wheel Positions 12

4. Frequently Ask Questions 13

5. Specifications 15

5.1 Transmitter (Part Number = 9300) 15

5.2 Display (Part Number = 1900) 15

5.3 Alternate Valve Part Numbers 15

2

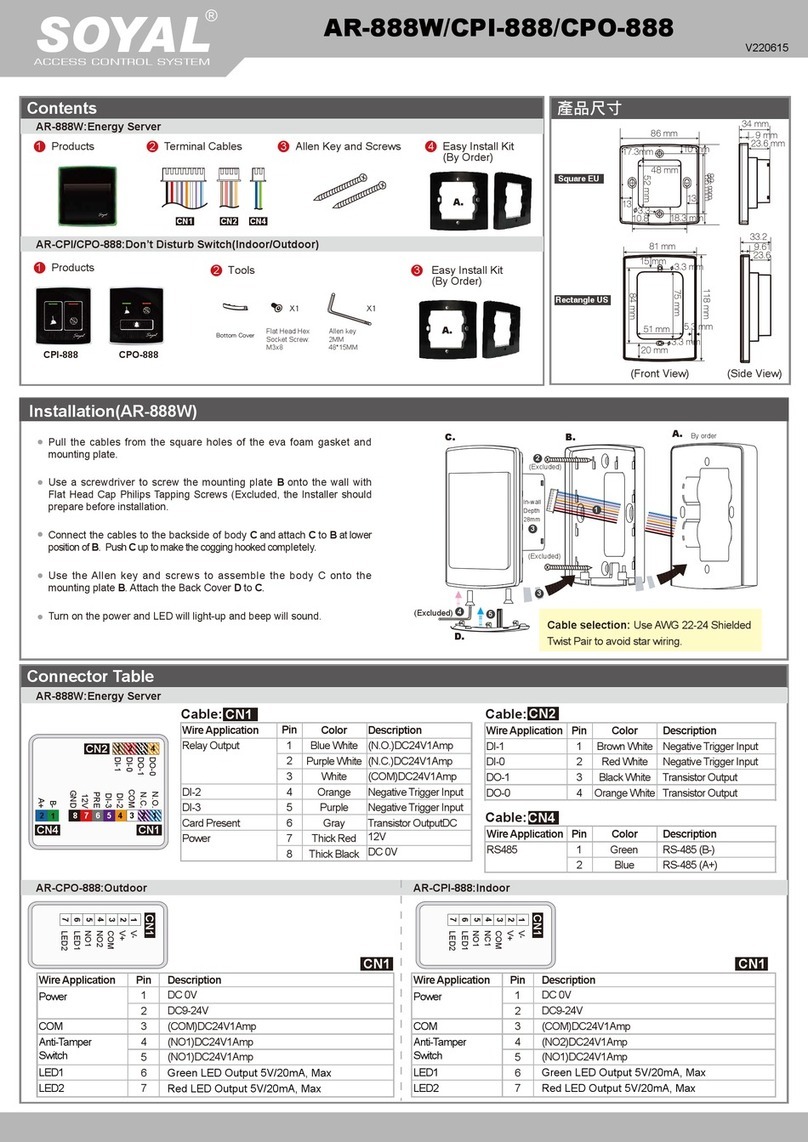

1.0 Setting Up the System

1.1 Transmitter Installation

Have a professional tire retailer install the bands with transmitters in the

wheels. See section 2 for details. Each transmitter has a unique ID and

needs to be installed in the same corresponding position as noted in

Figure on page 11.

1.2.4 If your tire cold inflation pressure is 35 psi, you are done. If it is

something besides 35 psi, complete section 1.3.

1.3 Setting the Baseline (Cold Inflation) Pressure

1.3.1 Set the pressure in all tires to the recommended cold inflation

pressure.

1.3.2 Plug in the display using either provided power cord.

1.3.3 Hold down the “R/D” button until

you hear a beep then release.

1.3.4 Press and release the “SET” button.

The display will show “dd” in place

of the pressure readings.

NOTE:

For hardwired connection, black wire is ground and red is positive.

1.2 Install the Display

1.2.1 Install the supplied antenna to your display unit located at the back of

the unit.

1.2.2 Use the display mount to affix the display unit on the windshield or

dashboard. Do not block the driver’s view. If necessary, adjust the

viewing angle of the display.

1.2.3 Plug the power cord into the display unit and plug the adapter into

auxiliary power supply or hardwire to vehicle electrical system.

FIGURE 1

FIGURE 2

3

The display is now in LEARN MODE and will store the cold inflation

pressure of each tire once it receives a signal from the transmitter. The

process may take up to 8 minutes. If all pressures are not received in 8

minutes, the display will shift back to the monitoring mode. The tire

positions that did not register will display 00. You will need to repeat

section 1.3.2 until a signal is received from all tire positions. Driving the

vehicle will speed up the process. When rotating, the transmitters send

a signal more frequently than when the vehicle is stationary.

If any or all tires positions do not register after performing the

Baseline Pressure setting process at least twice, or if transmitter

signals are intermittent, experimentation with an external antenna

and/or signal booster will be necessary to get the unit to function.

1.4 Using the External Antenna - RF Interference

The system has been tested to work 40 feet, along line-of-sight path

ways. However, tire construction, vehicle construction, electronic

interference and low temperatures all reduce this distance. RF signals

are subject to interference from many types of signals and products,

which can cause errors in the operation of the product. As with cell

phones and other types of electronics using RF signals, signal

interruption can occur and cause lost signal transmission.

19’ COAXIAL

WIRE

DISPLAY/RECEIVER

CONNECTOR

MAGNET NOTE: THE MAGNET’S

STRENGTH IS VERY

STRONG AND WILL ADHERE

QUICKLY TO ANY STEEL OR

IRON OBJECT. KEEP FIN-

GERS AWAY FROM THE

BOTTOM OF THE MAGNET.

ANTENNA

FIGURE 3

4

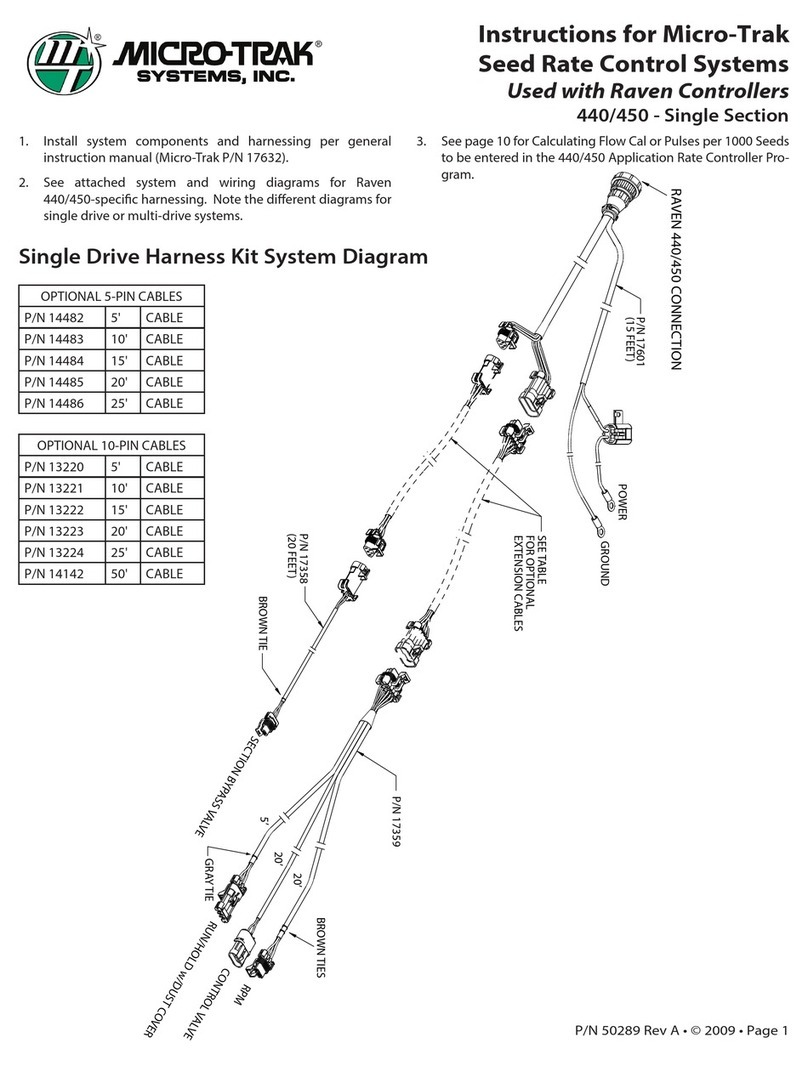

External Antenna Installation

Remove the original antenna from the back of the display unit and replace it

with the coaxial wire antenna via display connector.

Install the magnet/antenna underneath the rear of the vehicle, which will give

it the nearest proximity to the transmitters. Thus, increasing signal reception

between the display/receiver and transmitters.

Do not install the magnet/antenna directly on the trailer.

It is the installer/end user’s discretion how to install the antenna and coaxial

wire from the exterior and interior of the vehicle cabin.

Installing the external antenna involves a small degree of experimentation

for maximum signal reception. Temporarily connect the antenna cable to the

display, passing the cable through the vehicle’s door or window. This

temporary connection allows you to test the antenna’s location. If the

location you have selected for the antenna has difficulty in picking up signals

from all tire locations, change the antenna’s location slightly and continue to

test. When signals from all tire locations report, install the antenna

permanently in the vehicle.

Caution: Stay away from transmission, oil and exhaust lines avoiding the

inherent heat from those locations which can melt the coaxial cable.

If proper reception is not achieved with the external antenna, a signal boost

will be required.

A signal booster (part number = 1905) is an optional part for RV’s, fifth

wheels and tow-vehicles and trailers. It enhances the signal from the

transmitters. A signal booster is recommended to effectively receive the

signals from each transmitter, when there may be interference from

electronics, RV construction, length, etc.

5

2.0 Transmitter Installation

The transmitter comes pre-installed in the mounting cradle. No adjustments

need to be made to the transmitter or its mounting nut.

It is recommended to install the transmitter/cradle at the location of the

wheel’s valve hole so its location is always known during tire mounting, tire

dismounting, and if the need arises, to scan the transmitter.

2.1 Peel off the adhesive paper from the bottom of the transmitter’s cradle.

The adhesive on the cradle prevents the assembly from rotating around

the wheel barrel.

2.2 Adhere the transmitter’s cradle to the left or right of the wheel’s valve

stem. The transmitter can point inward or outward.

2.3 Insert the band through the lowest slot of the cradle.

2.4 Cut off excess band with tin-snips before tightening the worm-drive clamp.

2.5 Tighten the band’s screw to 40 inch pounds using a 7mm ratchet or

Phillips-head driver.

2.6 Lock the wheel on the tire changer. Apply lubricant on both tire beads .

Mount the lower tire bead on the rim. Ensure that the tire bead does not

touch the electronic module during mounting.

2.7 Mount the upper tire bead the same way and inflate the tire to standard

cold inflation pressure. Avoid damaging the transmitter’s antenna.

2.8 Apply soap suds or commercial leak detection solution around the wheel’s

valve to check for leaks.

2.9 Dynamically balance the wheel before it is put back on the vehicle.

ADHESIVE

BACKING

FIGURE 4 FIGURE 5

WHEEL’S VALVE

6

3.2 How the System Works

A banded transmitter assembly is installed in each wheel, which

monitors pressure and temperature conditions inside each tire of the

vehicle. This data is wirelessly sent to the receiver that is installed on

the vehicle. The receiver displays the pressure and temperature for

each tire position. When an abnormal condition is detected, the display will

alert the driver.

3.0 System Overview

The Retrofit TPMS kit monitors tire pressure and temperature. It will pro-

vide warnings about abnormal conditions such as low pressure, high pres-

sure, and high temperature.

3.1 System Components

FIGURE 6

ANTENNA

DISPLAY MOUNT

12V DC POWER

CORD & HARD-

WIRE

CONNECTION

EXTERNAL

ANTENNA

(IF NEEDED)

DISPLAY

UNIT TRANSMITTER

WITH BAND

DISPLAY

FIGURE 7

7

The display is preprogramed to provide a warning if the pressure drops 20% below or

30% above the cold inflation pressure. It will also give a high temperature warning if

the temperature exceeds 176°F. The high temperature warning point is not adjustable.

The system is shipped with the baseline (cold inflation) pressure set at 35 psi. At this

setting, the display will provide a low pressure warning at 28 psi and a high pressure

warning at 46 psi. You can set the baseline pressure (see Setting the Baseline (Cold

Inflation) pressure in Setting up the System on page 2) up to 144 psi and the display

will automatically provide a low pressure warning at 20% below and 30% above the

baseline setting.

Examples:

Cold Inflation

Pressure

Low Pressure

Alarm

High Pres-

sure Alarm

45 psi 36 psi 59 psi

65 psi 52 psi 85 psi

90 psi 72 psi 117 psi

3.3 Normal Monitoring

3.3.1 Stationary State:

The transmitter will transmit tire pressure and temperature data to the

display at 2-minute intervals. As the data is received, the display will

refresh.

3.3.2 Moving State:

The inertial switch in the transmitter turns on when the speed ex-

ceeds 16mph.

The transmitter will transmit tire pressure and temperature data to the

display at 30-second intervals. As the data is received, the display

will refresh.

8

3.4 Warnings

3.4.1 Low Pressure Warning

If the pressure in a tire is 20% lower than the cold inflation pressure

setting, then the following will occur:

1. The display will show the pressure of the abnormal tire and the dig-

its will flash.

2. An audible alert warning sound will be heard.

3. The abnormal icon will show up.

4. The system will only display the abnormal tire. By pressing “SET”

or “R/D”, you can temporarily view other tires.

The system will not return to normal monitoring until the

problem(s) is corrected.

3.4.2 High Pressure Warning

If the pressure in a tire is 30% higher than the cold inflation pressure

setting, then the following will occur:

1. The display will show the pressure of the abnormal tire and the dig-

its will flash.

2. An audible alert warning sound will be heard.

3. The abnormal icon will show up.

4. The system will only display the abnormal tire. By pressing “SET”

or “R/D” you can temporarily view other tires.

The system will not return to normal monitoring until the

problem(s) is corrected.

3.4.3 High Temperature Warning

When the temperature in a tire exceeds 176°F, the following will oc-

cur:

1. The display will show the temperature of the abnormal tire and the

digits will flash.

2. An audible alert warning sound will be heard.

3. The abnormal icon will show up.

4. The system will only display the abnormal tire. By pressing “SET”

or “R/D” you can temporarily view other tires.

The system will not return to normal monitoring until the prob-

lem(s) is corrected.

9

3.4.4 Monitor System Malfunction will occur if the display does not receive

a signal from a transmitter(s) in the tire(s) for more than 30 minutes*,

the display screen will display as dashed lines “- - -” .

NOTE:

When the dash lines ”- - -” appears, it will not be dismissed from

the display even if you restart the unit. When the receiver

(display unit) receives an updated signal from the transmitter(s),

the dashed lines will disappear.

If you are not receiving a signal from the transmitter(s), verify the

following conditions.

1. Power off the display unit and restart the system. The system will

return to normal monitoring after properly receiving signals from

the transmitter(s).

2. Check your antenna connection. Verify the center coax pin has not

become dislocated from the antenna.

If the display unit is working properly and it still does not receive

a signal from the transmitter(s), then the transmitter(s) and ID

chip(s) must be replaced simultaneously.

3. “Er” indicates there is no chip in the position, the chip is not

correctly inserted into the display or the chip is not functioning.

10

3.6 Transmitter Components

CRADLE

(P# 1025-U) ELECTRONIC

TRANSMITTER

SCREW

3.5 Display Indicator and Controls

R/D BUTTON

Used to learn tire cold inflation

pressure

SET BUTTON

Used to set number of wheel positions

Wheel

Positions

High Temp

Icon

>176°

Temperature

Pressure

FIGURE 8

FIGURE 9

BAND

(P# 1194)

MOUNTING

NUT

11

3.7 Tire Rotation

Every transmitter has a unique 8 character ID that is associated with a chip

in the display. An alpha label is also added to each transmitter and chip as

an additional identifier. As tires are rotated, the chips are moved to the

corresponding position in the display. No reprogramming is necessary. For

example if you move the right front tire (RF) to the rear (R1) you would move

the chip in the back of the display from RF to R1 and move R1 to RF.

LF

L1

L3

L4

L2

RF

R1

R3

R4

R2

B

D

H

K

F

A

C

G

E

J

ID MODULE COVER

MODULE CHIP CLIP ORIENTATION

Chip I.D.

Location

1101143

Transmitter I.D.

Location

1101134

Pressing the restore key, resets the baseline to 35 PSI

FIGURE 12

12

3.8 Changing Number Of Wheel Positions

The number of wheels in the vehicle can be set as 4, 6a, 6b, 8 or 10 as

not ed in Figure 13. Use the 4 position if monitoring a 2-wheel trailer (“Err”

or “NA” will display in the unused locations). The number of wheel position

is pre-set. However, if you add positions use the following procedure to

change it. To change the number of wheels, perform the following:

3.9.1 Press and hold the “SET” button for 5 seconds to enter the wheel

number configuration setting, a ‘beep’ will sound and the current wheel

configuration will appear on the screen.

3.9.2 Press the “R/D” button to select among 4, 6a-wheel, 6b-wheel, 8-wheel

or 10-wheel configuration. The position and the number of the wheels

will appear on the screen.

3.9.3 Press and hold the “SET” button for 5 seconds to complete the

selection. A ‘beep’ will sound when it’s complete.

6a Wheels

B

(RF)

E

(L2)

F

(R2)

C

(L1)

D

(R1)

A

(LF)

6b Wheels 8 Wheels

C

(L1)

D

(R1)

E

(L2)

F

(R2)

G

(L3)

H

(R3)

A

(LF)

B

(RF)

10 Wheels

B

(RF)

C

(L1)

D

(R1)

E

(L2)

F

(R2)

H

(R3)

J

(L4)

G

(L3)

K

(R4)

A

(LF)

B

(RF)

C

(L1)

D

(R1)

E

(L2)

F

(R2)

A

(LF)

B

(RF)

C

(L1)

D

(R1)

A

(LF)

2 or 4 Wheels

FIGURE 13

13

4.0 Frequently asked questions.

Can this system be used on a passenger car?

Yes

Can this system be used on a 6-wheel pickup?

Yes

Can this system be used on an RV?

Yes

Can this system be used on a 2-wheel motorcycle?

No

Can this system be used on an ATV or UTV?

The answer is dependent on the application's recommended tire

pressure. We do not recommend installing this system on any

application that requires a cold inflation tire pressure of less than 25 psi.

Can I install the Dill Retrofit TPMS kit myself with a basic set of

hand tools?

It is not recommended. While the Dill Retrofit TPMS tire pressure display

unit can be installed in a vehicle with no tools, the process required to

install the internally-mounted tire pressure sensors should be performed

by a trained tire technician using tire servicing equipment.

Can my trusted tire shop install your system?

Most likely, yes. If your tire shop is familiar with factory Tire Pressure

Monitoring Systems on 2008+ model year vehicles, then installing the

Dill tire pressure sensors will not be a challenge.

Can the Dill Trailer TPMS monitor the original factory sensors on

my tow vehicle?

No, the tire pressure display unit can only be used to monitor the Dill

Retrofit TPMS tire pressure sensors included in the kit. However, Dill

Retrofit TPMS tire pressure sensors can be mounted in your tow

vehicle's wheel using a band if tire pressure monitoring is desired.

Please call for more info.

Will the Dill Trailer TPMS kit cause problems with my vehicle’s

factory TPMS?

No

Can my vehicle's factory TPMS read the Dill Trailer TPMS tire

pressure sensors?

No

14

Can the Dill tire pressure display monitor multiple tires that require

different recommended cold inflation pressures?

Yes. During the initial setup of the system, each Dill Retrofit TPMS tire

pressure sensor-equipped position can be programmed to monitor a

different baseline cold inflation pressure. For example, the Dill system can

accurately monitor the front and rear tires of a tow vehicle (60 psi front, 75

psi rear) and the tires on a trailer (50 psi).

Are the pressure warning levels adjustable?

No. The Low Tire Pressure Warning is preset to 20% below the user-set

baseline tire pressure. The High Tire Pressure Warning is preset to 30%

above the user-set baseline tire pressure.

Are the tire pressures monitored while the vehicle/trailer is parked?

Yes, but visual and audible warnings to the user can only happen when the

display receiver is powered on.

Can I monitor a spare tire?

Yes, but keep in mind the tire pressure display unit only shows an even

number of tire positions (2, 4, 6, 8, or 10). If you add a single spare, there

will be one position that will not be used and when the display unit cycles to

that position "Err" will display, but there will not be an audible warning.

Can the Dill Trailer TPMS detect a tire blowout?

No. Tire pressure sensors can only transmit freely when they are under

pressure.

Will I need the long magnetic antenna?

The Dill Retrofit TPMS has a radio frequency range of 40ft line-of-sight. With

various materials in between the monitored tire and dash-mounted display

unit, interference is possible. If reception is intermittent when using the short

antenna, we recommend installing the long magnetic antenna or purchasing

the Dill Retrofit TPMS Signal Booster.

Where should the long magnetic antenna be installed if my application

requires it?

We recommend attaching the magnetic antenna to the bottom of the rear

bumper hitch which would keep it in line with the sensors/tires.

Can I use the system with two different trailers?

Yes, but the process of setting up the display unit to work on multiple

trailers will depend on several factors. Please call us if this is a

requirement.

15

5. Specifications

5.1 Transmitter (Part Number = 9300)

Weight: 1.25 oz. (35g)

Dimensions: 0.59” x 2.50” x 1.11” (1.5 x 2.8 x 6.4 cm)

Operating Temperature Range: -40°F to 257°F (-40°C to 125°C)

Pressure Accuracy: ±2PSI (±.14Bar)

Temperature Accuracy: ±5.4°F (±3°C)

Battery life: 5 to 7 years

Maximum Sensing Pressure: 188PSI (12.96Bar / 1296Kpa)

Maximum Cold Inflation Pressure: 144PSI (9.93Bar / 993Kpa)

Frequency: 433.92MHz

5.2 Display (Part Number = 1900)

Power Consumption: 130mW (regular) / 230mW(Max)

Power Supply: DC12 Volt

Weight: 1.06oz. (30g)

Dimensions: 3.35” x 1.97” x 0.79” (8.5 x 5 x 2 cm)

Pressure resolution: 1PSI (.07Bar / 7Kpa)

Temperature resolution: 2°F (1°C)

5.3 Alternate Valve Part Numbers

None are compatible with OEM Sprinter van wheels

TP 416

WHEEL RIM

HOLE SIZE: .453”

TP 501

WHEEL RIM

HOLE SIZE: .625”

TP 555

WHEEL RIM

HOLE SIZE: .390”

1500 Williamsboro Street Oxford, North Carolina 27565

Dill Air Controls Products

~ Quality Automotive Products Since 1909 ~

E07357

www.dillvalves.com or www.trailertpms.com

TP 572

WHEEL RIM

HOLE SIZE: .625”

Table of contents

Other Dill Control System manuals