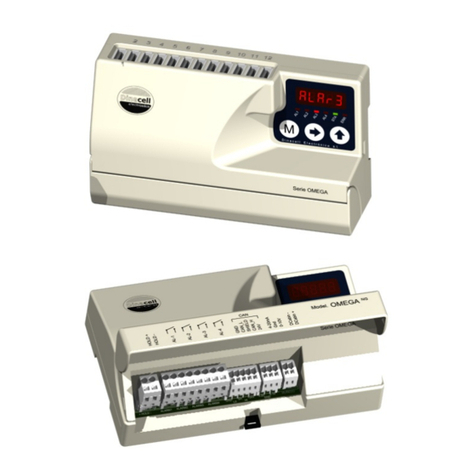

dinacell OMEGA Series User manual

OMEGA ng

LOAD WEIGHING DEVICE

User manual

OMEGA

ng

2

OMEGA

ng

3

Index

1. DESCRIPTION AND MAIN FEATURES ............................................................. 4

2. DISPLAY AND CONTROL BUTTONS ................................................................ 4

3. DIMENSIONS INSTALLATION AND CONNECTIONS ...................................... 5

4. MENU STRUCTURE .......................................................................................... 6

5. HOW TO VISUALIZE OR CHANGE PARAMETERS ......................................... 7

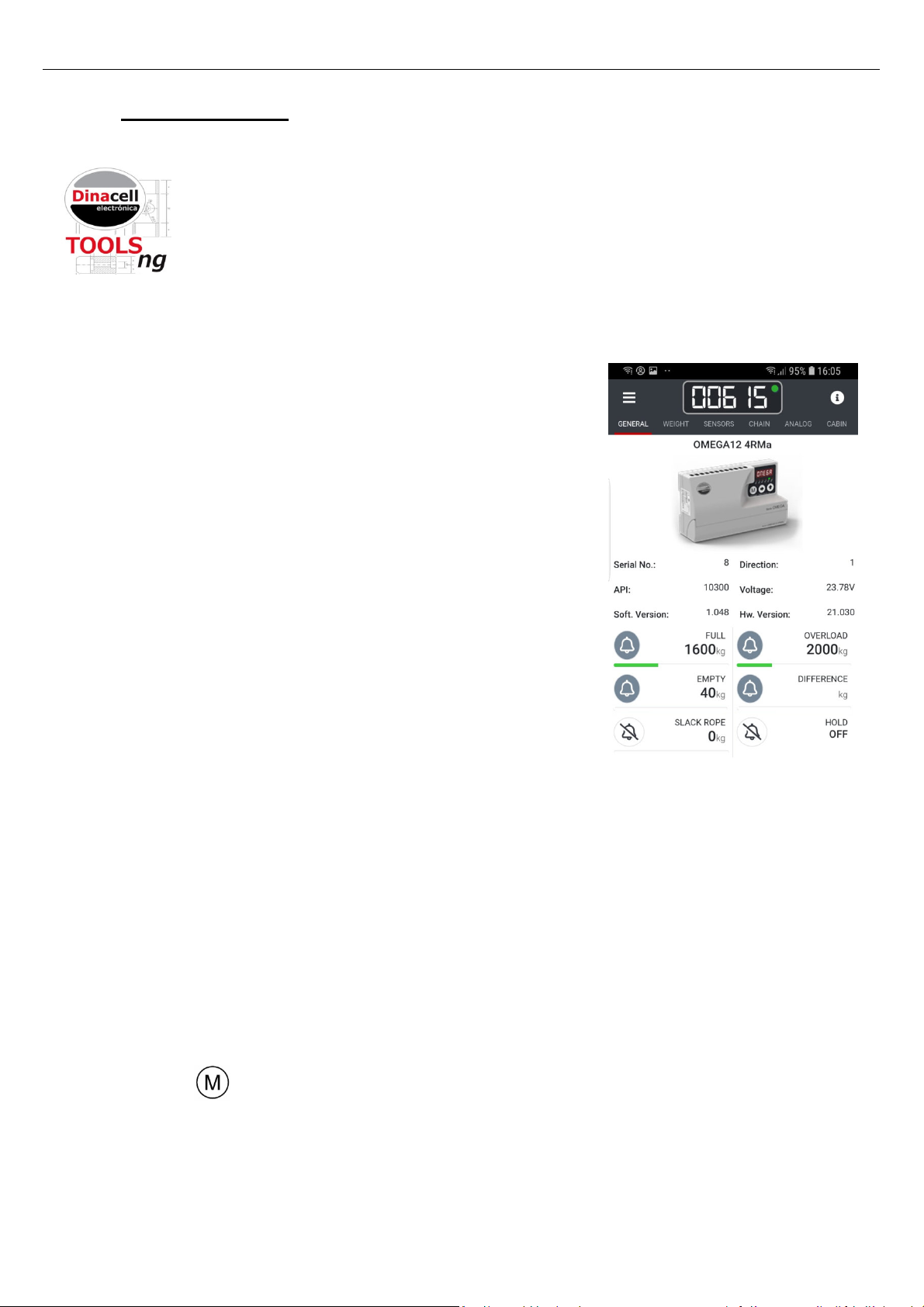

6. DEVICE INFO ..................................................................................................... 7

7. SYSTEM CONFIGURATION .............................................................................. 8

8. ALARMS CONFIGURATION ............................................................................ 10

9. CHAIN COMPENSATION ................................................................................. 12

9.1. New advanced Chain Compensation ........................................ 12

9.2. Submenu Chain ......................................................................... 12

9.3. Chain Compensation Adjust ...................................................... 13

9.3.1. Software Compensation ................................................ 13

9.3.2. Hardware Compensation .............................................. 14

10. AUTO-ZEROING COMPENSATION................................................................. 14

11. ADDITIONAL FUNCTIONS .............................................................................. 15

11.1. Hold function.............................................................................. 15

11.2. Cabin Display (Optional) ............................................................ 15

12. ANALOG OUTPUT ........................................................................................... 16

13. CANOPEN-LIFT CIA 417 .................................................................................. 17

14. ERROR CODES AND TROUBLESHOOTING .................................................. 18

15. ELECTRICAL SPECIFICATIONS ..................................................................... 18

16. NG CONECTION .............................................................................................. 19

16.1 Wifi NG Connection ................................................................... 19

16.2 Firmware Update ....................................................................... 19

17. WIRE ROPE TENSION ADJUSTMENT ............................................................ 20

17.1 Wire Rope Tension checking Tool ............................................. 20

17.2 Assistance to the wire rope tension adjustment......................... 21

18. QUICK CONFIGURATION GUIDE ................................................................... 23

OMEGA

ng

4

1. DESCRIPTION AND MAIN FEATURES

OMEGA

/NG

Unit control is a Load Weighing device of the (NG) New Generation units from

Dinacell Electronic with CanOpen-Lift CIA 417 Integrated.

The Main features of this unit depending on the model are:

- Measu es, monito s and Indicates Ove loads in elevato s.

- Up to 12 Individual Rope Tension monito ing.

- Wi e Rope Tension adjustment.

- 5 Digits display with 4 LEDs fo ala m indication and 2 LEDs fo Can Status

- Hold Input (inhibit Ala ms activations while lift is t avelling).

- 5 Ala ms Th esholds (Full Load, Ove Load, Ze o Cabin, Slack Rope, Diffe ent ope Tension)

- 4 Relays output

- 0-10v Analog Output

- 4-20ma o 0-20ma Analog Output

- Inve ted Analog Output Selection

- Cabin Display Output

- CanOpen-Lift CiA 417

(Optional).

- Softwa e Chain compensation.

- Ha dwa e Chain compensation.

(Requires additional Load Cell).

- Auto Ze o Co ection Function.

And the new features of Our NG devices

- Remote WIFI P og amming ( NG ) (Requi es additional device).

- USB connection fo fi mwa e upg ading.

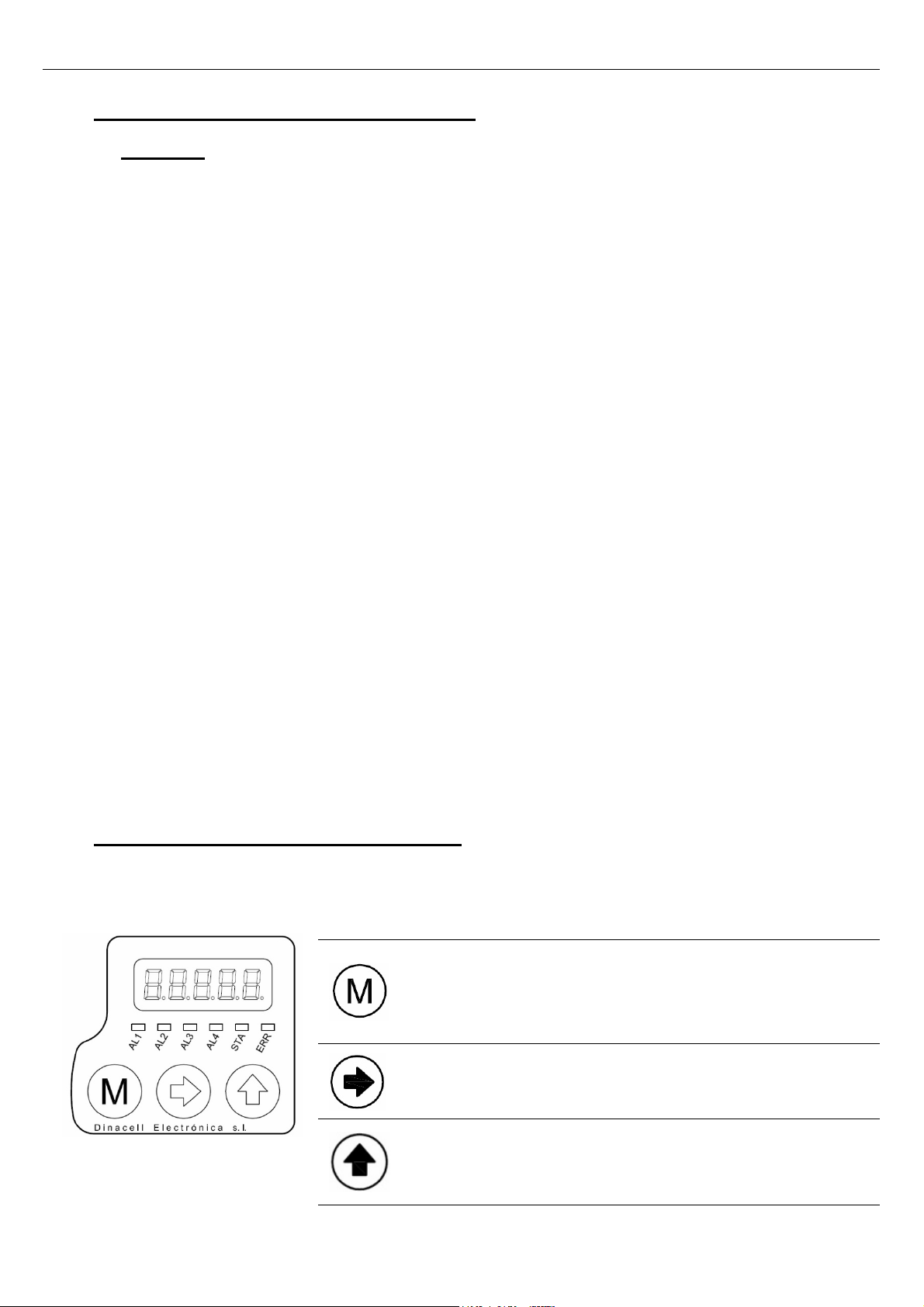

2. DISPLAY AND CONTROL BUTTONS

Functions of control buttons:

The unit is equipped with a menu by which the individual setting

parameters can be displayed or modified.

a. By Pressing this key for 2 Seconds Enter/exit the menu

b. By Pressing this key inside the menus will navigate through

parameters.

c.

Accept and save modified values when modifications are on

progress.

a. During menu navigation: Enter to modify a parameter.

b. While modifying a parameter: Chose digit to change.

a. During menu navigation: Show the stored value of the selected

parameter.

b.

While modifying a parameter: Change the blinking digit

incrementally from 0 to 9.

OMEGA

ng

5

Note: After two minutes without any operation the unit automatically returns to the total weight measure

display independent of the menu item previously selected.

Led Functions

AL1 Full Load Alarm Indicator

AL2 Over Load Alarm Indicator

AL3 Zero Load Level Indicator (Empty Cabin)

AL4 Difference and Slack Rope tension indicator

STA Led status

( For CanOpen: Status Led )

ERR Error

( For CanOpen: Error Led)

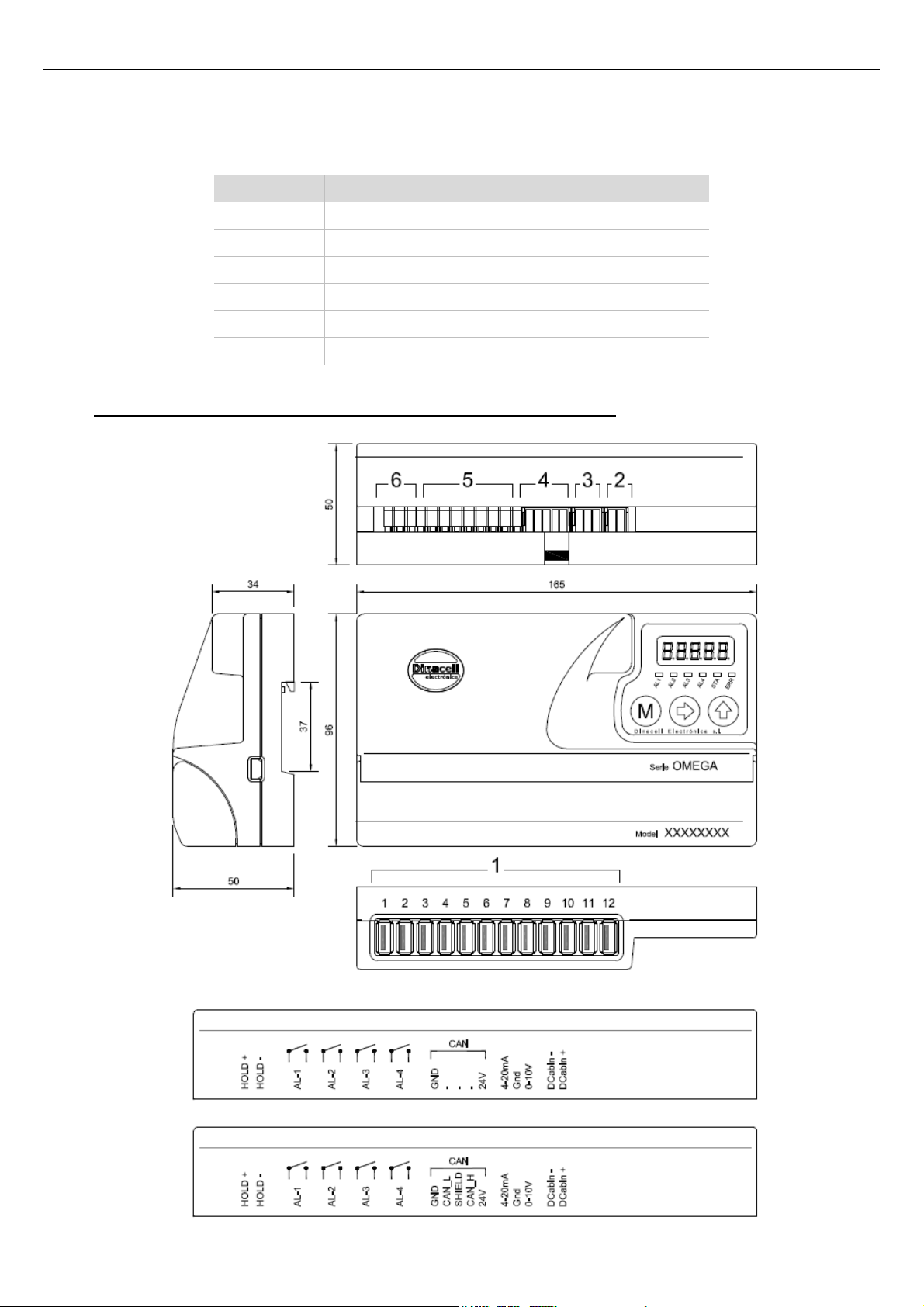

3. DIMENSIONS, INSTALLATION AND CONNECTIONS

OMEGA

ng

6

1

Senso inputs Up to 12 USB Connectors for easy plugging

2

Cabin display

output

Output there are two types of output:

INC: Progressive display MB-D (two wire connection without polarity).

LED: If overload it will be an intermittent voltage of 5V (max. 30mA) with the

polarity shown in the figure.

3

Analog outputs These outputs reflect the sensors signal over the range 0-10V for Voltage and 4-20mA or 0-

20mA for current. Common signal is GND. (See the ADDITIONAL FUNCTIONS chapter 12).

4

Can Open Input 24 VDC power supply and Can Bus in an Open Style connector

5

Relay

connections fo

ala ms

Terminals for the alarm relays.

(See the alarms section in chapter 8)

6

HOLD input This function will be activated if an input voltage from 24 to 125V (DC or AC) is applied. (See

the ADDITIONAL F NCTIONS chapter 11).

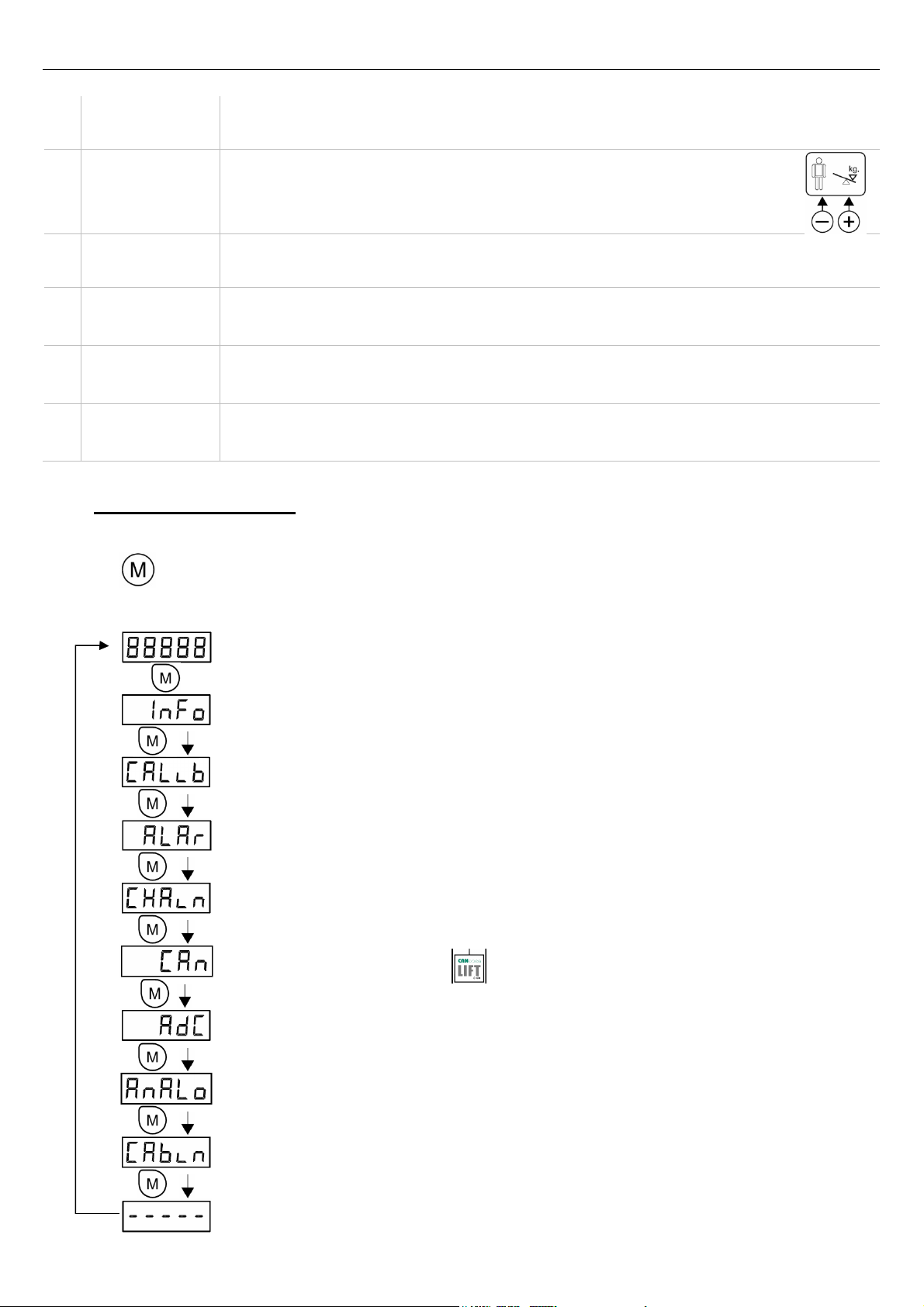

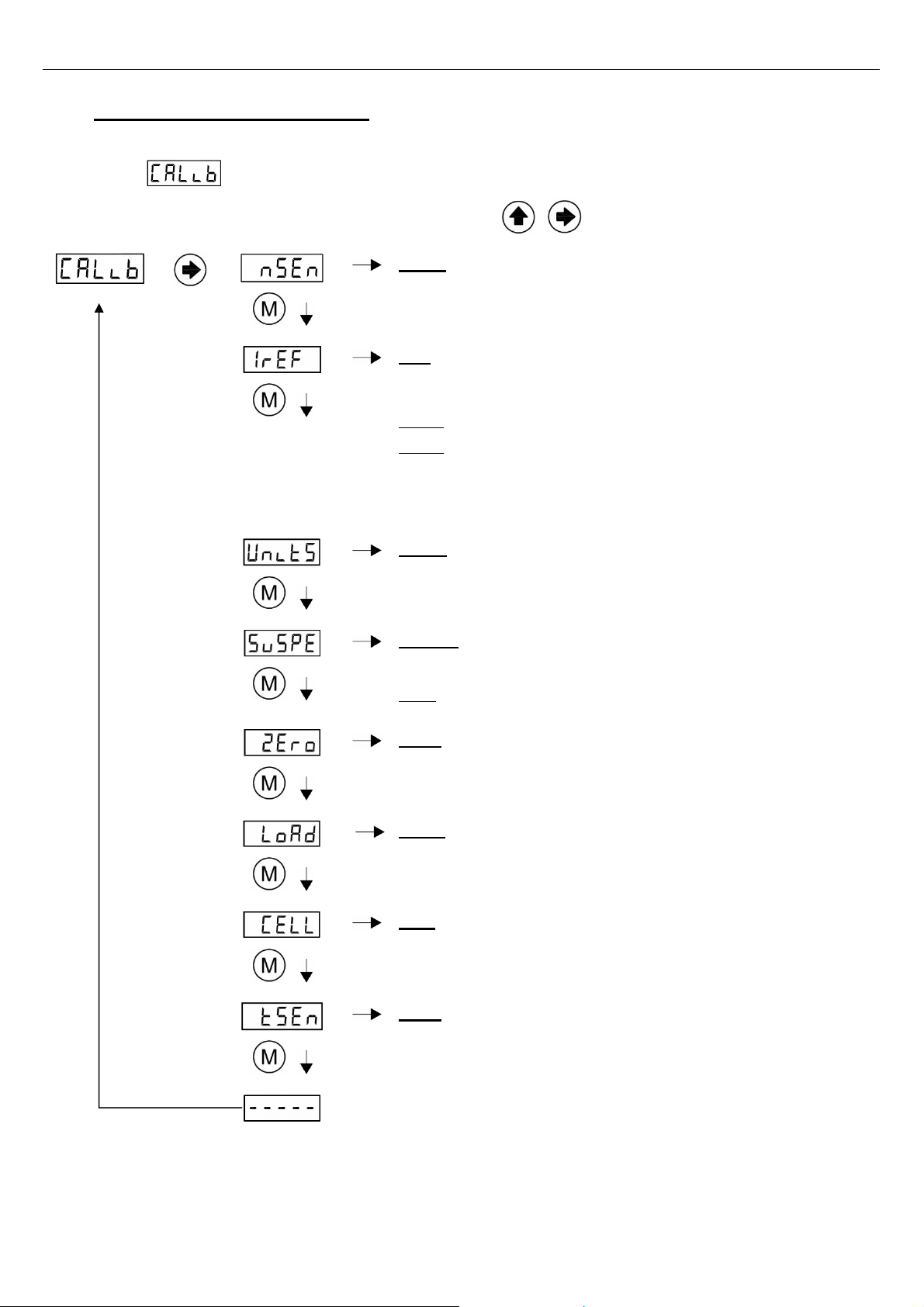

4. MENU STRUCTURE

The menu has the cyclic structure shown in the following figure.

Press button for 2 seconds to enter and then press it repeatedly to move from a parameter to

another. Press it for 2 seconds to exit.

Weight indication. Display the value of the measured load

Press Menu for 2 Seconds

Shows Identification Data of the unit

System calibration. These menus shows all parameters related with the load cell

Configuration.

Alarm Levels configuration.

Chain compensation options

CanOpen Configuration.

(Only relevant for OMEGA-C models )

Load Cell mv/v. signal value.

Analog Output

(Only relevant for OMEGA models with analog option)

Led or Cabin Display Output

(Only relevant for OMEGA-4RM models )

OMEGA

ng

7

Pressing Menu for 2 seconds inside the internal navigation menu will end the menu navigation and

return to Display the value of the measured load

5. HOW TO VISUALIZE OR CHANGE PARAMETERS

Once inside any menu and displaying the parameter to be viewed or changed:

Press to display the current value.

Press to select the parameter to be modify :

Press to choose the digit position to change ( Flashing )

Press to change the value of the Current Flashing digit position. (if there’s no flashing digit

change the value with key directly)

Press twice to save the value.

If button is not pressed twice before display Flashing ends (10 seconds) the

parameter value will not be changed.

After any of these operations the display will show the current parameter.

6. DEVICE INFO

All new NG units store some important information in this menu in order to build wireless

connections with any remote future unit developed by Dinacell Electronica. All parameters can be read in

this submenu.

Submenu

Press to enter Check value

Enter to modify

Ve : Firmware Version of Unit OMEGA

ng

Valid Values: 1.00 and above

V_Ha : Hardware Version of Unit OMEGA

ng

VOLt: Internal Power supply Voltage of unit OMEGA

ng

Valid Values: (around 24 volts )

ESE: Reset all parameters value to Factory defaults. All

calibration data will be lost.

Values: “NO”: Cancel Reset

“ALL” : Reset All Parameters

OMEGA

ng

8

7. SYSTEM CONFIGURATION

This section describes how to configure the Unit to obtain the best measure accuracy. The configuration

is done in Menu.

Press

to enter Check value

Enter to modify

nSen: Number of sensors connected to ropes or cables. If this

parameter is not set correctly the unit will show E 1 and

alarm relays will be activated.

I ef: Initial Reference for the individual Rope Tension sensors

(

SWR SWK Hitch Point Sensors

). This operation must be done

with the Sensors not installed on the ropes.

Note 1: It is mandatory to do the Iref operation for Rope Tension Equalizing

Note 2: Iref is not needed For sensors under cabin (TCA) or Beam sensors

(SV).

If rope tension equalization is not required or you forget to make this

operation, just set this option to “None” in Iref Submenu to make the

operation

with sensors

already

installed.

Units: Display Weight units. Available units are Kilos/Pounds

SusPE: Type of suspension at installation:

1:1 2:1 3:1 4:1

Note : Suspension should set to 1:1 For sensors under cabin (TCA) or

Beam sensors (SV)

Ze o: Zero point adjustment With empty elevator. Store a

Countdown value for Zero and load calibrating parameters

Load: A well known weight must be placed inside the elevator

to do the load setting of the unit. (It is recommended to set up

a

minimum of 60% of the nominal load of the elevator being

adjusted).

Cell: Nominal load cell sensibility. This value is calculated

when LOAD operation is done. Use should not modify this

value. ( If this parameter is modified the previous calibration

settings will be overwritten)

tSen: Raw Rope Tension of each individual Sensor. On the

display appears the weight in units selected (e.g. 100kg

)

alternating with the Sensor number ( SE 1, SE 2, etc.)

OMEGA

ng

9

Calib ation p ocess:

1) Install the control unit with the information of the INSTALL AND CONNECTIONS Chapter 3.

2) Connect Load Cell to the OMEGA

ng

3) Power up the unit with the correct voltage (see the ELECTRICAL SPECIFICATIONS Chapter

15).

4) Go to Submenu:

5) Detail Calibration Procedure:

Follow next steps to set a precise Load Measuring system

5.1 ) Select number of ropes.

5.2 ) Do an Iref “ALL” Operation with rope sensors NOT INSTALLED on the ropes.

and a 5” seconds countdown occurs.

Note: for hitch point sensors or if your sensors are already installed or if you don’t

need to equalize the individual rope tension just select “None” option in Iref submenu

for this operation.

I ef is not equi ed fo TCA o SV Senso s.

5.3 ) Select display measuring units. Available units are Kilograms or Pounds

5.4 ) Select Suspension. By default 1:1 is selected.

( Select 1:1 for TCA and SV Sensors)

5.5 ) Zero adjustment:

a) Install sensors on ropes when using SWK SWR or LCA.

b) Select Submenu Ze o by pressing

c) Change countdown value if desire.

d) Press menu and display will start flashing

e) Make sure elevator is empty and confirm operation by pressing again.

f) The countdown will start. During this time the car weight must not change.

5.6 ) Load Point adjustment: This function ensures the accuracy of the control.

Put a well known weight into the cabin. It is recommended to place into the cab a minimum

weight of 60% of the elevator duty load. (100% is preferred.)

To make the Load point adjustment:

a) Select Submenu Load by pressing

b) Set the value with the total Load added into the elevator.

c) Press menu and display will start flashing

d) Confirm operation by pressing again.

e) The countdown will start. During this period of time the car weight must not change

5.5) This parameter stores the Sensor Sensibility. Cell value is automatically calculated

after a Load Point adjustment.

This parameter can be Set when using Calibrated Sensors

with known Cell

value. If Cell Value is changed the previous calibrating process will be

OMEGA

ng

10

overwritten.

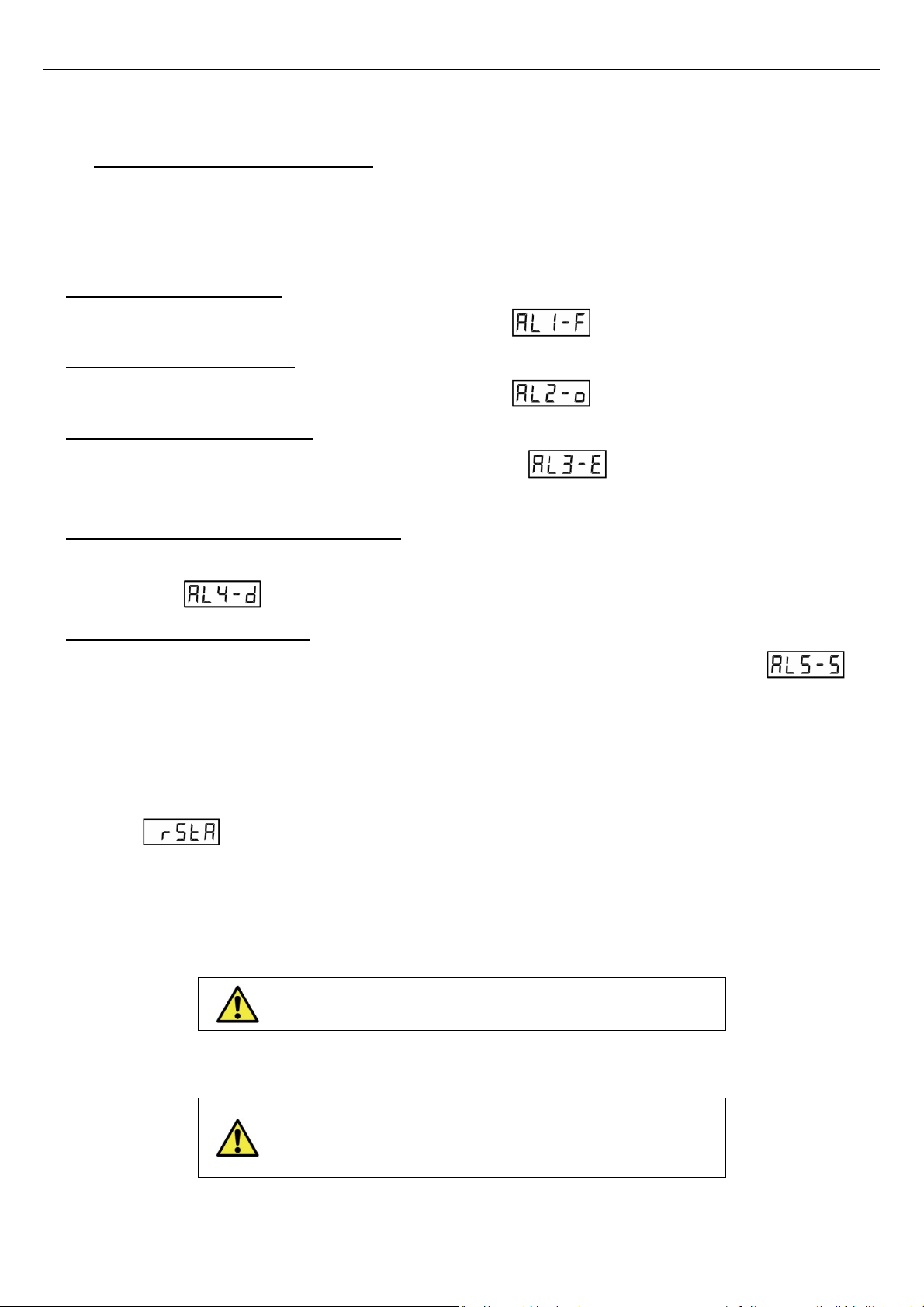

8. ALARMS CONFIGURATION

The alarms values correspond to the load threshold at which each relay change its state.

The relays allows to be configured individually as make or break contact

Alarms are activated when their threshold is exceeded. The Unit OMEGA

ng

has 5 different alarms:

AL1-F (Full Load Relay #1):

Change of state when exceeding the load programmed in

AL2-O (Over Load Relay #2):

Change of state when exceeding the load programmed in

AL3-E (Empty Load Relay #3):

Change of state when falling below the load programmed in

Note: This alarm is active below Alarm3 Threshold.

AL4-d (Rope Tension Difference Relay #4):

Change of state if any ope deviates f om the ave age of all othe opes at least by the pe centage

programmed in .

AL5-S ( Slack Rope Relay #4):

Change of state if any rope has a slack rope tension ( A value below alarm level threshold)

When Slack Rope Alarm is activated the word “Slack” will flash on the display.

The working procedure of the relays as a make or break contact can be changed for each alarm output

using the parameter. Valid values a e (Close) fo the ope ating mode MAKE and (Open)

fo the ope ating mode BREAK. Close is a no mally closed elay and OPEn is a no mally open

elay. Alarm LEDs indicators will be activated when the display measured value overload corresponding

alarm level

Note: LEDs are not related to relay state but alarms levels.

Note: AL4-d and AL5-S share the same relay Output. When

there is a sla k rope, the Display will show the word “Sla k”

on it.

OMEGA

ng

11

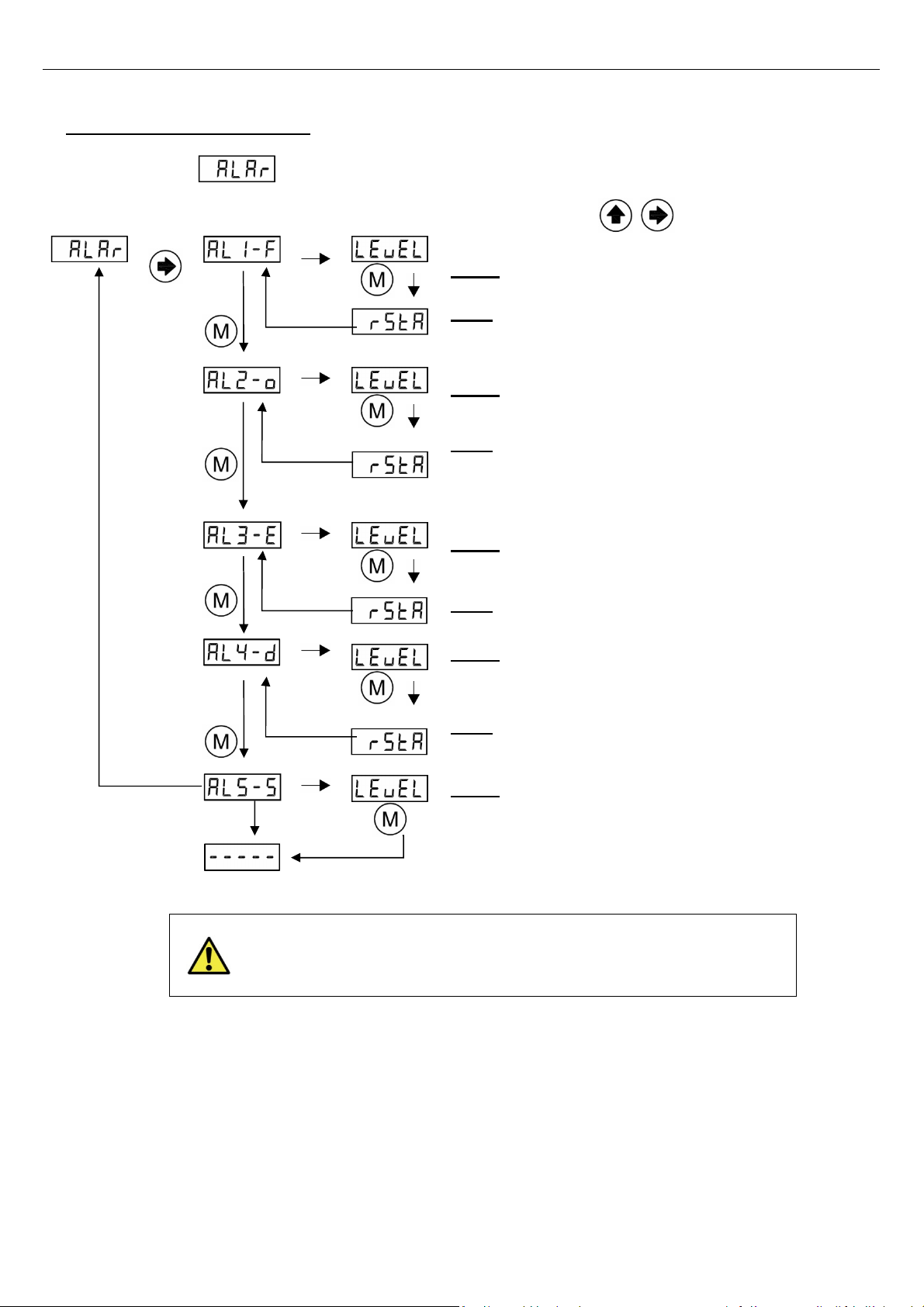

How to configure alarm settings:

Go to Submenu

Press

to enter

Check value

Enter to modify

Level: Alarm 1 Level Threshold for Full load ala m.

StA: Relay Status. When alarm 1 is deactivated (Idle

Mode)

(Only relevant models with relay outputs )

Level: Alarm 2 Level Threshold for Ove load ala m.

StA: Relay Status. When alarm 2 is deactivated (Idle

Mode)

(Only relevant models with relay outputs )

Level: Alarm 3 Level Threshold for Ze o Load ala m.

StA: Relay Status. When alarm 3 is deactivated (Idle

Mode)

(Only relevant models with relay outputs )

Level: Alarm 4 Level percentage Threshold for

Rope tension diffe ence ala m.

StA: Relay Status. When alarm 4 is deactivated (Idle

Mode)

(Only relevant models with relay outputs )

Level: Alarm 5 slack ope ala m.

(Activates Relay #4

output).

All Displayed weights and alarm thresholds are shown in

selected units. All internal calculations are made in kg

therefore rounding errors are possible

OMEGA

ng

12

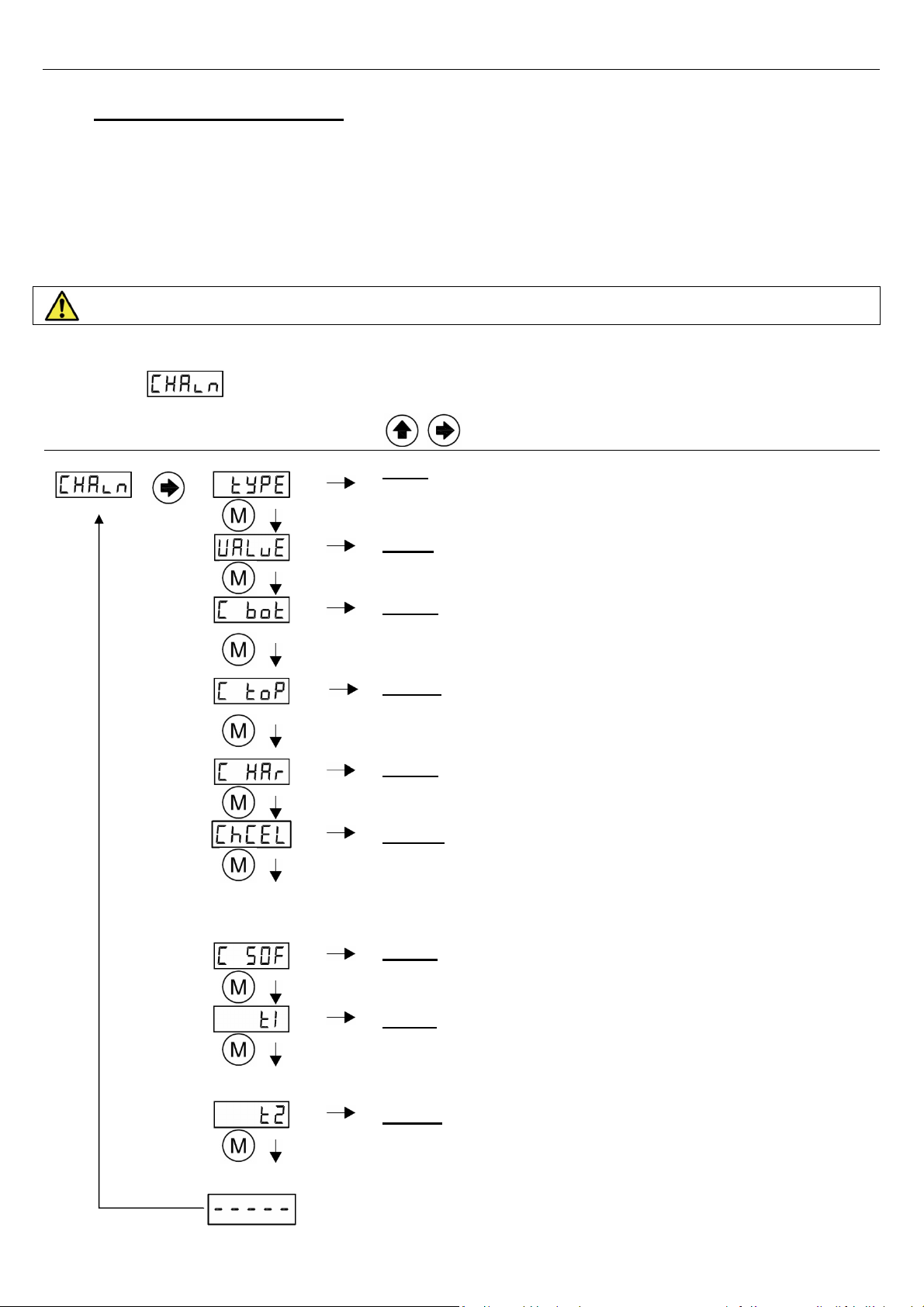

9. CHAIN COMPENSATION

9.1. New advanced Chain Compensation

The New Generation (NG) of Load Weighing Devices has the newest software for chain

compensation. It offers several options to improve the accuracy to compensate for the weight of the

chain. In this Submenu the user can choose between three options no compensation software

compensation and hardware compensation.

Hold Input must be wi ed to use the Softwa e Chain compensation Function.

(See Hold Function Section 11.1)

9.2.

Submenu Chain

Submenu

Press

to enter

Check

value

Enter to modify

Type: Type of chain compensation applied. User can choose

between ha dwa e compensation softwa e compensation or

none compensation

Value: Max Chain value to compensate. At installation.

Valid Values : 0-600

( Set Value to 0 to deactivate software compensation )

.

C_Bot: Chain zero operation at the ground floor

(only applies to Hardware compensation)

.

C_Top: Chain load operation at the top floor

(only applies to Hardware compensation)

.

C_Ha : Real chain load value compensated by hardware

measure in selected units

(only applies to Hardware compensation)

.

ChCEL: Nominal Chain load cell sensibility. This value is

calculated when C_Bot or C_top operation is done. Use

shouldn´t modify this value. ( If this parameter is modified the

previous calibration settings will be overwritten)

( only applies to

Hardware compensation)

.

C_Sof: Chain load value compensated by software estimation in

selected units

Time 1:

Starting Time to hold the weight before Hold input is

activated. It is an optional correction on installations where the Hold

Input is activated too fast. (Units are tenths of seconds).

(Default

Recommended Value: 2 (0.2secs)).

(only applies when hold input is connected)

.

Time 2:

Delay time to release hold weight after Hold input is

deactivated. It is an optional correction on installations where the Hold

Input is deactivated too fast. (Units are tenths of seconds).

(Default

Recommended Value: 4 (0.4secs)).

(only applies when

hold input is connected)

OMEGA

ng

13

T1 and T2 options are only shown if is set to SOFT compensation. See Section

10 Hold Function to adjust these parameters.

9.3. Chain Compensation Adjust

The NG Series has new advanced chain compensation. To use all the features of new

compensation is necessary to adjust some parameters in Menu.

There are two types of compensation.

oftware chain compensation: When selected the unit compensates the chain with hold signal

activations/ deactivations.

Note:

and parameters must be set to use the Software Chain compensation.

Hardware chain compensation: When selected the unit compensates the chain with the on

real time weight of the chain. This can be done using the auxiliary Load Cell input for chain

compensation and adjusting the parameters for hardware compensation.

Note: To deactivate all chain compensations just set Type parameter to none.

Set Type to value.

9.3.1. Softwa e Compensation

This function compensates the weighting difference between floors produced by the extra

weight of the chain and the travelling cables. The unit needs the HOLD signal to be active when

the doors closed to compensate the weight during the elevator movement.

To configure the software compensation:

Set Type to SoFT value.

Set the estimated weight of the chain. This parameter will be the maximum value compensated

by software compensation

In this parameter you can check the value the OMEGA

ng

is compensating by software each

time the HOLD signal is deactivated

When using software compensation Auto_Zero compensation will be activated automatically.

OMEGA

ng

14

9.3.2. Ha dwa e Compensation

In some installations with many landings software chain compensations does not work

well due to friction in the rails between floors weight changes during long elevator travels or

auto_zero does not occur because elevator never stops.

These problems can be solved with Hardware compensation.

It is mandatory to plug an auxiliary Sensor when hardware compensation is selected.

A dedicated Load Cell for chain compensation is needed. Otherwise Err11 will flash in the

display.

A system Configuration (Section 7) must be done previous to set the Hardware

compensation parameters.

Set Type to Hard value

Take the elevator to the ground floor and set C_Bot To Yes. A Countdown will start.

Take the elevator to the Top floor and set C_TOP To Yes. A Countdown will start

In this parameter you can check the value the OMEGA

ng

is compensating by hardware with

the chain load cell

10. Auto-Ze oing Compensation

The Auto_Zero compensation is designed to automatically remove small measurement errors

lower than parameter

The Auto-Zero function will happen whenever the OMEGA

ng

detects a total unload of the

elevator and measures a static offset of ± for a period of at least 60 seconds. During this

time the measured load must not change by more than ±20kg.

To eliminate the Auto_Zero compensation a Zero operation should be done.

If is set to “00000” Auto_Zero compensation will

be automatically disabled.

OMEGA

ng

15

11. ADDITIONAL FUNCTIONS

11.1. Hold function

During the elevator travel the measured loads can greatly fluctuate due to friction in the rails

cab and load movements etc. The Hold Input prevents the control from measuring the load

while the elevator is travelling This ensures that the movement of the cabin will not affect the

weighing process and therefore no alarms or relay will be activated during elevator travel.

How Hold Input Function works:

When a voltage in the range 24-125V (DC or AC) is applied in this input the unit holds the

last stable measurement of weight acquired.

The voltage must be applied when the doors close and it must be removed as the doors

open.

This ensures that the movement of the cabin will not affect the weighing process and therefore

no alarms or relay will be activated during elevator travel.

The OMEGA

ng

unit has an internal register that stores all previous weighting measures of the last

3 seconds. As some installations sets the HOLD input at the same time the doors closes it may happen

that the last measure obtained could not be as stable as desired. The same issue might happen when

removing the HOLD input as the doors Open

To improve the hold of a stable measure two parameters have been added at CHAIN menu

and .

As some installations sets the HOLD input at the same time it closes the doors sometimes the

last measure obtained is not as stable as desire. The same issue can happen when removing the HOLD

input and the doors Open.

Time in tenth of seconds to take the measure before the HOLD signal is active.

Time in tenth of seconds to update the measure after the HOLD signal is released.

Note: For example; With T_1 set at 10 and T2 set at 15:

When the hold signal is activated then the OMEGA

ng

will take as a valid load measurement the

value that was stored 1 second before HOLD signal was activated. Then when HOLD input is released

the first stable load value will be taken 1.5 seconds after the hold signal is deactivated.

This option offers great flexibility to resolve problems in some critical installations.

11.2. Cabin Display

(Optional)

It provides two types of output depending on the Cabin Display (CDISP)

parameter:

OMEGA

ng

16

LED Indicato : Under overload it will be an intermittent

voltage of 5V (max. 75mA) with the polarity shown in the

figure.

LED Inc emental Progressive display MB-D is used (two wire

connection with polarity)

(Requires an external MB-D unit).

12. ANALOG OUTPUT

The unit is provided with two analog outputs (Voltage and current output). Both Outputs are

active and operative at same time.

Analog_High: Set the Load value desired (kg or Lb) To

deliver the maximum analog output ( 10v or 20 ma)

Analog_Low: Set the Load value desired (kg or Lb) to deliver

the minimum analog output ( 0v 0ma or 4 ma)

Type of cu ent output: Set the desired current output range.

It can be configured as 4-20 or 0-20 ma.

This function reflects the Display measure over the range between analog Low and analog High

values.

Voltage

Output

An_Low

Value

An_High

Value

Range Voltage

Output Value

0-10 volts

( 0-5 Optional )

0Kg 100Kg

When weight ≤ 0kg

(empty elevator) 0 V

When weight ≥ 100kg 10 V

(5VOptional )

100Kg 0Kg

When weight ≤ 0kg

(empty elevator)

10 V

(5VOptional )

When weight ≥ 100kg 0 V

Cu ent

Output

An_Low

An _High

Range Cu ent

Output value

0-20 ma

4-20ma

0Kg 100Kg

When weight ≤ 0kg

(empty elevator) 0 or 4 ma

When weight ≥ 100kg 20 ma

100Kg 0Kg

When weight ≤ 0kg

(empty elevator) 20 ma

When weight ≥ 100kg 0 or 4 ma

When hold (inhibit) input is activated the analog output will not

change during elevator travel until hold input deactivation.

OMEGA

ng

17

13. CanOpen-Lift CiA 417

(Only relevant for OMEGA-C and OMEGA- CA models )

Dinacell electronic is member of the CiA ( Can In Automation )

Vendo -ID 00000361

OMEGA

ng

-C accomplish with the CanOpen-Lift CiA 417 profile.

Some important CanOpen Parameters can be modified from this Submenu as Baud rate and

Node ID. Weigh change detection is a threshold that will send a PDO message when the weight

change overpasses the value.

Node Id: Node Id of the CanOpen Load Weighing Device

Baud Rate: Baud Rate of the CanOpen Device.

125kb or 250kb Supported for the 417 Profile.

Detection of weight change: Units required for detecting a

change of weight in the cabin and send a Can Message by

load changed. (1 2 5 10 20 25 50 100 250) Kg

Contact: The OMEGA

ng

-C Can detect the movement of the

car and the Car Door state if Door Control Unit is present at the

installation. Both information is used to simulate the Hardware

Hold Input. ( Move parameter is always recommended).

ContA Parameters:

: Use standard hardware Hold Input.

: Read Lift Movement information as hold input

(

Recommended value

).

: Read Door Status from Door unit as hold input.

: Read Door Status from controller as hold input.

CanOpen Ve sion suppo ted: Actual version supported 2.0.0

Bus Connection must be according application profile CiA-417 CAN high speed standard (ISO99-2) .

If the Load Weighing unit is set at the end of the installation end a 120 Ohm

resistor must be placed on the connector between Can High and Can Low lines.

OMEGA

ng

18

14. ERROR CODES AND TROUBLESHOOTING

When the unit detects some anomaly it will show an error code from the following table:

E o desc iption Action

Load cell is not properly connected or its cable is

damaged.

E 1 is shown alternating with the

number of faulty Sensors(Se-1 Se-2 etc..)

Check the indicated sensor

connection.

Negative overflow. The load cell is giving a too

high negative signal.

Check the load cell connection. It

should be no negative charge.

(

Recalibrate per Section 7).

Positive overflow. Load cell is holding a higher

load than its nominal value.

Change the load cell by another with

higher nominal load.

(Recalibrate per Section 7).

Loss of data in memory.

Notice: When this error appears relays will

change to OPEN state.

The unit must be reset to its default

values

Load cell with very low sensibility. The unit was

not properly adjusted or load cell has a low

nominal value.

Adjust the zero and Load again.

Change the load cell by another with

lower nominal load.

Chain Load cell is not properly connected or its

cable is damaged or wrong number of sensors

set in parameter nSens.

Check the chain load cell connection.

If no Hardware chain compensation

desired change Type parameter at

menu chain to None or soft

Impo tant: When an error appears all alarms are activated and the elevator remains blocked.

RESTORING THE FACTORY SETTINGS (Only in case of configuration problems)

Just go to menu and set option to yes:

15. ELECTRICAL SPECIFICATIONS

Power supply characteristics Short-circuitable.

It is not necessary to replace any fuse.

Nominal voltage 12-40 VDC

Maximum current <200mA

Relays Contacts

(Nominal Switching Capacity)

4 Relays: 250VAC / 3A - N.O.

HOLD Input 24V-125V AC/DC

Box IP-50 V0 fireproof plastic.

OMEGA

ng

19

16. NG CONECTION

All New Dinacell Units have a special feature called NG Connection (New Generation

connections)

The main function of the NG connection is to connect to android Smart phones for Unit

calibration and reading Pen Drives for software updating.

To use all advanced features of NG Connection user needs to connect the WRCT

NG

adapter.

16.1 Wifi NG Connection

Connect the WRCT

NG

adapter to the unit OMEGA

ng

. Dinacell

TOOLS Application softwa e must be installed in a smart

Phone or Laptop.

Users can download the Dinacell Application “Weighing NG”

from Google Play Store market or from Apple Store.

With the New WRCT

NG

adapter connected to the NG

Connection located on the side of the OMEGA

ng

Control, users

can:

a) Get all parameter values of the unit in real time.

b) Calibrated the unit without using the key board.

c) Test the installation performance.

d) Check and review measurements to adjust rope tensions

guides detect friction problems during travels etcetera.

e) Save all Calibrating parameters data in a Pdf report.

f) Send reports by email.

g) Stores all installation calibrations in a single phone.

h) And more as the software is in continuous development.

16.2 Fi mwa e Update

It is possible to update the firmware of any NG Device using the NG connection

located on the side

of the OMEGA

ng

Control and a Flash Pen drive. You need a standard Mini USB-B to USB-A plug

adapter to connect the Flash drive to the Unit.

Follow next steps to enter in Boot loader mode for firmware updating:

a) Copy new firmware (.CYP file) in the Flash Pen drive.

b) Plug the Pen drive in the auxiliary USB cable adapter from USB to Mini USB.

c) Switch off the unit OMEGA

ng

by removing the power supply.

d) Press key and apply powe to the unit with the key p essed. ERR LED will flash each

second and 5 Digits display will be switched off.

e) Plug the Mini USB cable on the NG connector. STA LED Will be ON and ERR LED will Flash

Faster (each 0.5 second)

f) Be patient and Wait until unit reboots. The process can take up to a minute.

OMEGA

ng

20

g) When programming ends the Unit Will reboot automatically. Then Go to Info Sub-menu and

Reset the unit.

17. WIRE ROPE TENSION ADJUSTMENT

This section explains how to check the tension of all wire ropes of the installation. All ropes

should carry the same tension. Equally tensioned ropes improve ride quality and extend life of ropes and

sheaves.

Nowadays most elevator systems have multiple wire ropes attached to the cabin and

counterweight. This ropes normally run over a traction sheave or pulley just to move the cabin up and

down the hoistway.

When some ropes have more tension than other the ropes with lower tension will slide over the

pulley and can produce a crown groove wear at the sheave. It is possible to detect this wear by rope

slapping vibrations on the cables or metal dust on the pulley.

Normally the system works better if all the ropes have similar tension (about ± 5%) of the

nominal load of the installation.

Although some installers manage to adjust the rope tension manually just touching the ropes or

Just tuning the installation plucking each rope as a harp string the best way to do this operation is

measuring the load on all the ropes and displaying it in real time.

Usually Load weighing devices manufactures have dedicated and expensive tools to do this

operations.

But the OMEGA

ng

, can be used not only as a good Load Weighing device but as an additional

low cost rope tension balancing tool also.

And as the unit will be installed for life you will have a permanent tool to adjust wire rope tension

and detect slack ropes at the installation in real time.

17.1 Wi e Rope Tension checking Tool

The only tool needed to adjust the wire rope tension is the WRCT

NG

dongle and a Smartphone a

tablet or a laptop. Then from the rope tension screen you will visualize the load of each rope in real time

Now it is possible to adjust the tension of each rope to make then equal.

This manual suits for next models

1

Table of contents

Other dinacell Accessories manuals