Dinel CPS-24 User manual

Read carefully the instructions published in this manual before the rst use of the level meter. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

průmyslová elektronika

1 . Basic description ........................................................................................................................4

2 . Dimensional drawing ...................................................................................................................5

3 . Installation and putting into operation .........................................................................................5

4 . Installation instructions ................................................................................................................6

5 . Electrical connection ...................................................................................................................7

6 . Settings .......................................................................................................................................8

7 . Function and status indication .....................................................................................................9

8 . Order code ..................................................................................................................................9

9 . Correct specication examples ...................................................................................................9

10 . Accessories .............................................................................................................................10

11. Safety, protections, compatibility a explosion proof.................................................................10

12 . Use, manipulation and maintenance .......................................................................................10

13 . General, conditions and warranty ...........................................................................................11

14 . Marking of labels .....................................................................................................................11

15. Specications ..........................................................................................................................13

16 . Packings, shipping and storage ..............................................................................................14

CPS–24 © Dinel, s.r.o.

3

Capacitive proximity switch CPS–24 is intended for detection of proximity or motion of solid

objects. It is suitable for indication of the liquid level through non-conductive walls of vessels or on

non-conductive gauge-pipes. It is excellent for liquid leakage detection in collection pits or directly

on oors. The sensor state is indicated by LED. The sensitivity is adjustable by a trimmer located

under a cover screw on the rear side. The design and housing materials of CPS allow the use in

complicated environments (harsh, dusty, explosive, aggressive) as well as in clean environments

(medical technology).

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

This symbol indicates particularly important characteristics of the device.

This symbol indicates helpful additional information.

Alloperations described inthis instruction manualhave to becarried out bytrained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.

4

© Dinel, s.r.o. CPS–24

Variant "A" with

short cable outlet

Please follow next 3 steps:

Variant "B" with

long cable outlet

Variant "C" with

connector

Inthecaseoftheuseforanaggressivemediumis necessary to prove the chemical compatibility

of used materials of the sensor (Tab. Used materials on page 13). This guarantee ceases

when the product is chemically damaged.

CPS–24 © Dinel, s.r.o.

5

Sensing of bulky-solid materials in metal con-

tainers or tanks. The position of the sensor is

set so that it is approximately 10 mm from the

inner wall of a storage tank.

Sensor is used for sensing leakages in an

interception tank. Leakage indication in de-

tention pits and boxes with “Plate holder

PD–24–1”.

PD–24–1

Fixing plastic strap

PD–24–1

Sensor application for level gauges and eye

sights. The maximum wall thickness in both

cases is up to 10 mm. A glass or plastic level

gauge (tube) must have an outer diameter of

at least 20 mm. The face of the sensor must

be touching the wall.

Sensing of moving objects on conveyor. The

distance of the sensor from moving objects is

set according to their size, shape and material

composition (approx. 1 to 8 mm).

Detection of liquid presence in the inter-wall space of double-walled storage tanks. The sensor is

suspended down into the inter-wall space on its own cable. For this application, we recommend

variant „B“ with an extended cable terminal with the installation variant of a PVC hose for cable

protection.

Distance crown DK–24

Intrinsically safe supply units

(NSSU, NDSU or NLCU)

Fig. 1: Sensing bulk-solid materials in storage tanks Fig. 2: Use of CPS for sensing leakages in an

interception tank

Fig. 3: Sensing objects on a conveyor Fig. 4: CPS sensor application for level gauges and

eye sights

Fig. 5: Use of CPS for indicating presence of liquid in the inter-wall space

6

© Dinel, s.r.o. CPS–24

In the case of vertical mounting in outer areas or in the

case of high mechanical exertion we recommend to in-

stall in Variant “B” protective hose on the cable (see

gure).

Protective hose

Cable

Hose clip

Fig. 6: protective PVC hose

Sensor with NPN or PNP output is allowed to lead only by resistive or inductive lead. Positive sup-

ply voltage (+U) is connected to the brown conductor BN (1), negative (0 V) to the blue conductor

BU (3) and the leads (only NPN or PNP type of output) to the black conductor BK (4). The capacity

loads and low resistance loads (bulb) is evaluated by the sensor as short circuit.

The line from CPS-24N to the connecting device is from a suitable three wire (min. 3x0.5 mm2)

cable, in the case of variant CPS-24Xi using a two wire (min. 2x0.5 mm2) cable. In the event that

a disassemblable socket ELWIKA or ELKA 4012 K PG7 are used, the max. outer diameter of the

cable is 6 mm. Connector socket is not part of the sensor.

Fig. 7: NPN type sensors connection

(version “N”)

Fig. 8: NAMUR type sensors connection

(version “Xi”)

Fig. 9: PNP type sensors connection

(version “P”)

Output (BK)

0V (BU)

+U (BN)

Fig. 10: Inside of the connector socket

Legend:

(*) – Numbers of terminals inside of the connector

BK – Black

BN – Brown

BU – Blue

Electrical connection can only be made when de-energized!

The source of the power voltage must comprise of a stabilised safe low power source with

galvanic separation. In the event that a switch-mode power supply is used, it is essential

that its construction effectively suppresses common mode interference on the secondary

side. In the event that the switch-mode power supply is equipped with a PE safety terminal,

it must be unconditionally grounded! Spark-safe devices (type CPS-24) must be powered

from a spark-safe power source meeting the above-mentioned requirements.

CPS–24 © Dinel, s.r.o.

7

Due to the possible occurrence of an electrostatic charge on the non-conductive parts of

the sensor, it is necessary to ground all sensors intended for use in environments with an

explosion hazard (type CPS-24Xi). This can be performed by grounding el. conductive tanks

or el. conductive tank lids, and in the case of el. non-conductive tanks using and grounding

an auxiliary plate electrode PDE-27.

In the event that the water level meter (sensor) is installed in an outdoor environment at a

distance greater than 20 m from the outdoor switchboard, or from an enclosed building, it

is necessary to supplement the electrical cable leading to the water level meter (sensor)

with suitable overvoltage protection.

In the event of strong ambient electromagnetic interference, paralleling of conductors with

power distribution, or for distribution to distances over 30 m, we recommend using a shielded

cable and grounding the shielding on the side of the power source.

The sensitivity is set by trimmer located under cover screw on the rear side. Clockwise turning

makes the sensitivity lower, reverse direction turning makes the sensitivity higher.

LED

Sensitivity

Cable outlet

or connector

Fig. 11: Top view of level sensor

SETTING THE BASE SENSITIVITY:

a) Type CPS-24_-_-_O:

Turn the trimmer to the left until the LED is lit. Then turn slightly to the right until the LED just

turns o. From this point, turn 180° to the right.

b) Type CPS-24_-_-_C:

Turn the trimmer to the left until the LED turns o. Then turn slightly to the right until the LED is

lit. From this point, turn 180° to the right.

After setting the sensitivity, do not forget to properly tighten the trimmer cover screw.

The base sensitivity of the sensor is factory set (sensing distance on the metal surface) 8 mm. The

actual sensitivity (sensing distance) depends on the dielectric properties or where appropriate the

conductivity of the sensed material.

For sensing of materials with a low relative permittivity (plastics), we recommend to individually set

a higher sensitivity, or consult with the manufacturer if necessary.

8

© Dinel, s.r.o. CPS–24

Level state Type of output Output state LED indication

Minimum level sensing

CPS–24N– _ –NO

CPS–24N– _ –PO CLOSED

(Shine)

CPS–24Xi –_ –RO HIGHER

CURRENT

CPS–24N– _ –NO

CPS–24N– _ –PO OPEN

(Dark)

CPS–24Xi –_ –RO LOWER

CURRENT

Maximum level sensing

CPS–24N– _ –NC

CPS–24N– _ –PC CLOSED

(Shine)

CPS–24Xi –_ –RC HIGHER

CURRENT

CPS–24N– _ –NC

CPS–24N– _ –PC OPEN

(Dark)

CPS–24Xi –_ –RC LOWER

CURRENT

For minimum level sens-

ing we recommend sen-

sor with normally open

output (NO, PO, RO). It is

for failure safety reasons

– eventual failure of sen-

sor behaves similarly as

an exceeding of the limit

state.

Analogically for maximum

level sensing we recom-

mend normally closed out-

puts (NC, PC, RC).

For leakage indication

we recommend the NC,

PC, RC version too. It is

maximum level sensing

as well, despite the sen-

sor is at the lowest place

in the room.

CPS – 24 – –

Mech. performace:

N – non-explosive areas

Xi – for explosive environmentsr

Output state at non-activated electrode: O – Open (NAMUR – Lower current)

C – Closed (NAMUR – Higher current)

Type of output: N – NPN (Open collector)

P – PNP (Open collector)

R – NAMUR

Electric connection:

A – Short cable outlet (+ Spec. the length of the cable)

B – Long cable outlet (+ Spec. the length of the cable)

C – Connector (+ Spec. type of the socket)

CPS–24N–A–PC cable 4 m

(N) Performance for non-explosive areas; (A) Short cable outlet with 4 m cable length; (PC) Output type PNP with

closed state at non-activated electrode

CPS–24Xi–B–RO cable 7 m

(Xi) Explosion-proof performance; (B) Long cable outlet with 7 m cable length; (RO) Output type NAMUR with

lower current at non-activated electrode

CPS–24N–C–NO cable 7 m

(N) Performance for non-explosive areas; (C) Connector; (NO) Output type NPN with open state at non-activated

electrode

CPS–24 © Dinel, s.r.o.

9

optional – for a surcharge

(see catalogue sheet of accessories)

• Extra cables over the standard length 2 m

(for electric connection type “A” or “B”)

• Connector plug (type ELWIKA or ELKA)

• Plate holder PD–24–1

• Distance crown DK–24

standard – included in the level sensor price

• 2 pcs. of stainless steel xing nuts

• 1 pcs. Screwdriver for adjustment (each

5 pcs.)

The level sensor is equipped with protection against electric shock on the electrode, reverse polar-

ity, output current overload, short circuit and against current overload on output.

Protection against dangerous contact is provided by low safety voltage according to EN 33 2000-4-

41. Electromagnetic compatibility is provided by conformity with standards EN 55 022/B, EN 61326-

1/Z1, EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-6.

Explosion proof CPS-24Xi is provided by conformity with standards EN 60079-0:2013, EN 60079-

11:2012.

Explosion proof CPS-24Xi is veried FTZÚ – AO 210 Ostrava – Radvanice: FTZÚ 02 ATEX 0233X

A declaration of conformity was issued for this device in the wording of Act No. 90/2016 Coll., as

amended. Supplied electrical equipment matches the requirements of valid European directives for

safety and electromagnetic compatibility.

The level sensor is designed to be connected with supply unit type NSSU, NDSU and NLCU.

If some other approved apparatus is used, its output parameters comply with above mentioned

parameters, then it is necessary to include galvanic separation and/or in case of application of ap-

paratus without galvanic separation (Zener safety barriers) it is necessary to provide equipotential

equalisation between sensor and point of barrier earthing.

For zone 0 application the present potentially explosive atmosphere of air mixture with gases, mists

or vapours shall comply the following:

Tamb = -20 to +60°C, p = 0.8 bar to 1.1 bar.

Maximum input parameters:

Ui = 12 V; Ii = 15 mA; Pi = 45 mW; Ci = 15 nF; Li = 10 µH

10

© Dinel, s.r.o. CPS–24

Detection of approach or assessment of the movement of solid objects, level indication in electri-

cally non-conductive storage tanks (plastic, glass) and level gauges. Limit sensing of non-abrasive

bulk-solid materials (cereals, grains, granulates, sand, etc.) in metal storage tanks. Detection of the

presence of liquids in the inter-wall area of double-walled storage tanks, liquid leakage detection in

interception traps, concrete sumps or directly on the oor.

Dinel, s.r.o. guarantees for the period of three (3) years that the product has the characteristics as

mentioned in the technical specication.

Dinel, s.r.o. is liable for defects ascertained within the warranty period and were claimed in writing.

This guarantee does not cover the damages resulting from misuse, improper installation or incorrect

maintenance.

This guarantee ceases when the user or the other person makes any changes on the product or the

product is mechanically or chemically damaged, or the serial number is not readable.

The warranty certicate must be presented to exercise a claim.

In the case of a rightful complaint, we will replace the product or its defective part. In both cases, the

warranty period is extended by the period of repair.

We do not recommend using for the measurement of el. conductive liquids that leave a

continuous lm on the inner wall of an el. non-conductive storage tank or level gauge and

liquids that exude el. conductive particles that deposit themselves on the wall of a storage

tank or level gauge (e.g. heavily mineralised water, chemically treated waste water). Likewise,

the sensor is also not intended for measuring levels on level gauges and walls of storage

tanks with antistatic treatment (partially electrically conductive).

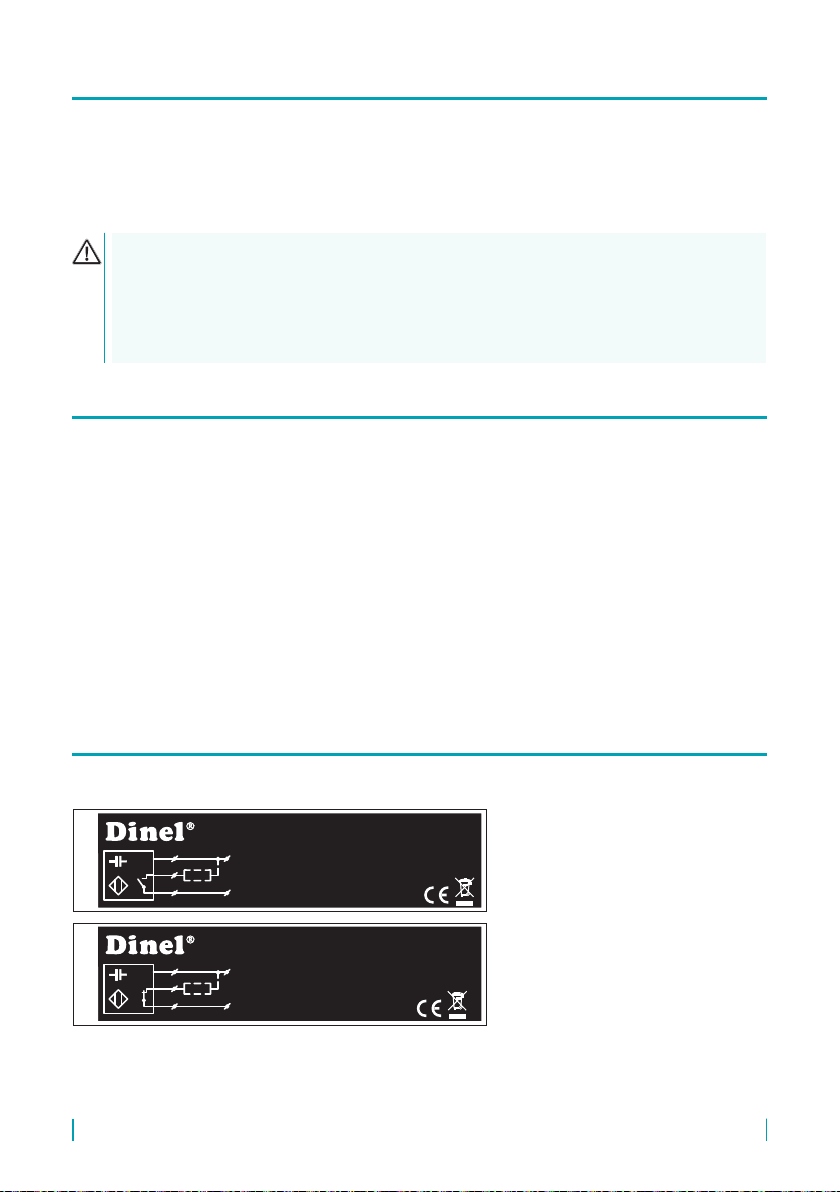

Labels for device of the type CPS-24N-_-NO, CPS-24N-_-NC, CPS-24N-_-PO, CPS-24N-_-PC:

ŠtítkyprovariantuCPS-24N-_-__

s

U

I

Iomax

n

s

U

I

Iomax

n

s

U

I

Iomax

n

0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

Dinel

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

s

U

I

Iomax

n0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

CPS-24N-_-NO No.: ______Cable: __ m

CPS-24N-_-NC No.: ______Cable: __ m

CPS-24N-_-PO No.: ______Cable: __ m

CPS-24N-_-PC No.: ______Cable: __ m

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

IP67

IP67

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

IP67

IP67

IP67

IP67

IP67

IP67

CPS–24 © Dinel, s.r.o.

11

Symbol of producer: logo Dinel®

Contact: Dinel, s.r.o., U Tescomy 249, 760 01 Zlín, Czech Republic, www.dinel.cz

Connection scheme and labelling of wires: +U, 0 V

Type of level meter: CPS-24N-_-NO, CPS-24N-_-NC, CPS-24N-_-PO, CPS-24N-_-PC

Cable length: Cable: _ _ m

Serial number: Ser. No.: ______ – (from the left: production year, serial production number)

sensitivity range of sensor Sn: 0-10 mm

Supply voltage range U: 7-36 V DC, Supply current I: 3 / 7 mA

Maximum output current Iomax: 200 mA

Coverage: IP6_

(Protection class according to electrical connection)

Compliance mark:

Electro-waste take-back system mark:

Labels for device of the type CPS-24Xi-_-R_:

Symbol of producer: logo Dinel®

Contact: Dinel, s.r.o., U Tescomy 249, 760 01 Zlín, Czech Republic, www.dinel.cz

Connection scheme and labelling of wires: +U, 0 V

Type of level meter: CPS-24Xi-_-R_

Cable length: Cable: _ _ m

Serial number: Ser. No.: ______ – (from the left: production year, serial production number)

Mark of non-explosive device: II 1 G Ex ia IIC T6 Ga

Limit parameters: Ui=12VDC, Ii=15mA, Pi=45mW, Ci=15nF, Li=10μH

Ambient temperature range : ta= -20 ... +70 °C , ta= -20 ... +60 °C (zone 0)

Number of certicate of intrinsic safety: FTZÚ 02 ATEX 0233X

Coverage: IP6_

(Protection class according to electrical connection)

Compliance mark: , No. of authorized person examining control of system quality: 1026

Electro-waste take-back system mark:

Size of labels 70 x 20 mm, the size shown does not correspond to reality.

ŠtítekprovariantuCPS-24Xi-_-__

II1GExiaIICT6Ga

U =12VDC I =15mA P=45mW

C =15nF t =-20...+70°C

t (zone 0)

iii

ia

ia

L =10uH =-20...+60°C

FTZÚ 02 ATEX 0233X

BN

BU

+U

0V

CPS-24Xi-_-R_ No.: ______Cable: __ m

1026

IP67

IP67

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

ŠtítkyprovariantuCPS-24N-_-__

s

U

I

Iomax

n

s

U

I

Iomax

n

s

U

I

Iomax

n

0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

Dinel

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

s

U

I

Iomax

n0÷10mm

7 ÷ 36 VDC

3/7mA

200 mA

CPS-24N-_-NO No.: ______Cable: __ m

CPS-24N-_-NC No.: ______Cable: __ m

CPS-24N-_-PO No.: ______Cable: __ m

CPS-24N-_-PC No.: ______Cable: __ m

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

IP67

IP67

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

IP67

IP67

IP67

IP67

IP67

IP67

12

© Dinel, s.r.o. CPS–24

Supply voltage 7 ... 36 V DC *

Current supply (state OFF / ON) 3 / 6 mA *

Switching current (NPN, PNP output) 200 mA *

Electric strength 500 V AC

Coupling capacity 2.2 nF

Max. switching frequency 5 Hz

Sensitivity – sensing distance 0 ... 10 mm (adjustable)

Hysteresis 5 ... 15 %

Ambient temperature range -20 ... +70°C

Protection class IP67

Cable (version with cable outlets) CPS – 24N

CPS –24Xi

PVC 3 x 0.5 mm2

PVC 2 x 0.75 mm2

Weight (incl. 2 m cable) Approx. 0.3 kg

* Only for variants “N”

variant Xi

Supply voltage 8 ... 9 V DC (Max. 12 V DC)

Current supply (state OFF / ON) – NAMUR ≤ 1 mA / ≥ 2.2 mA

Max. internal values Ui

= 12 V DC; Ii

= 15 mA; Pi = 45 mW; Ci = 15 nF; Li

= 10 µH

Part of the sensor Material

Housing St. steel W.Nr. 1.4301

Sensing surface PTFE

Ending St. steel W.Nr. 1.4301

Cable outlet (Variant “A”) Plastic POM

Cable outlet (Variant “B”) St. steel W.Nr. 1.4301

Output Variants

NPN (“NC”, “NO”) N

PNP (“PC”, “PO”) N

NAMUR (“RC”, “RO”) Xi

(EN 60079-0, EN 60079-10-1(2))

CPS–24N

Basic performance for non-explosive atmospheres.

CPS–24Xi

Intrinsically safe explosion-proof performance for use in hazardous areas (explosive gas

atmospheres or explosive atmospheres with dust), II 1G Ex ia IIC T6 Ga with intrinsi-

cally safe supply units, whole sensor zone 0.

CPS–24 © Dinel, s.r.o.

13

The device CPS–24 is packaged in a polyethylene bag, and the entire consignment is placed into

a cardboard box. A suitable ller material is used in the cardboard box to prevent mechanical damage

during transport. Remove the device from the packaging only just before using, thereby protecting it

from potential damage.

A forwarding company will be used to ship goods to the customer. Upon prior agreement, ordered

goods can be picked up in person at company headquarters. When receiving, please check to see

that the consignment is complete and matches the order, or to see if any damage has occurred to

the packaging and device during transport. Do not use a device clearly damaged during transport,

but rather contact the manufacturer in order to resolve the situation.

If the device is to be further shipped, it must be wrapped in its original packaging and protected

against impact and weather conditions.

Store the device in its original packaging in dry areas covered from weather conditions, with humidity

of up to 85 % without eects of chemically active substances. The storage temperature range is

-10 °C to +50 °C.

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

Phone: +420 577 002 002

Fax: +420 577 002 007

E-mail: [email protected]

www.dinel.cz

Find the updated version at www.dinel.cz

version: 08/2017

industrial electronics

10/2017

This manual suits for next models

1

Table of contents

Other Dinel Switch manuals

Popular Switch manuals by other brands

Vivotek

Vivotek AW-FGT-100C-120 Quick installation guide

Comtrend Corporation

Comtrend Corporation GS-7316 Quick installation guide

Speaka Professional

Speaka Professional SP-HSW-231 operating instructions

LevelOne

LevelOne Infinity IES-1085 Quick installation guide

LevelOne

LevelOne GES-0852 Quick installation guide

TRENDnet

TRENDnet TPE-224WS - Web Smart PoE Switch Quick installation guide