Dinel GPLS-25 Series User manual

Read carefully the instructions published in this manual before the rst use of the level meter. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

INSTRUCTION MANUAL

Thru-wall level switches GPLS-25

GPLS-25 © Dinel, s.r.o.

2

1. Basic description .......................................................................................................................3

2. Range of application ................................................................................................................3

3. Variants of sensors ...................................................................................................................4

4. Dimensional drawings .............................................................................................................4

5. Installation and putting into operation ............................................................................... 5

6. Mechanical mounting...............................................................................................................5

7. Electrical connection ................................................................................................................ 7

8. Setting ..........................................................................................................................................7

9. Status signalization .................................................................................................................. 8

10. Order code................................................................................................................................... 9

11. Correctspecicationexamples..............................................................................................9

12. Accessories .................................................................................................................................9

13. Safety, protection and compatibility ...................................................................................9

14. Use, operation and maintenance ........................................................................................10

15. General warranty conditions................................................................................................10

16. Marking of labels .....................................................................................................................11

17. Technicalspecications ........................................................................................................12

18. Packing, shipping and storage..............................................................................................12

Contents

3

© Dinel, s.r.o. GPLS-25

Through wall level switches GPLS-25 are intended for liquid (conductive and non-conductive)

level detection on glass or plastic gauge-pipes, tubes and tanks. The sensor is equipped with high

frequency technology,which allows reliable operation even for sensing of the adherent electrically

conductive medium. The sensitivity and modes (O - normally open or C - normally closed) of the

switches can be easily set by placing magnetic pen on sensitive spot. Output performance - transistor

output with open collector (PNP) or two wire electronic switch (S). This connection is done by means

of two wires directly into a circuit with relay or to binary input of control system.

1. Basic description

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

Used symbols

Safety

All operations described in this instruction manual have to be carried out by trained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.

2. Range of application

Detection of various types of liquids - water, disel, oil, cooling liquids, water solutions, some types

of solvents. It is suitable for glass or plastic gauge-pipes, vessels, plastic container tanks, plastic

tubs, pools, canisters, etc.

GPLS-25 © Dinel, s.r.o.

4

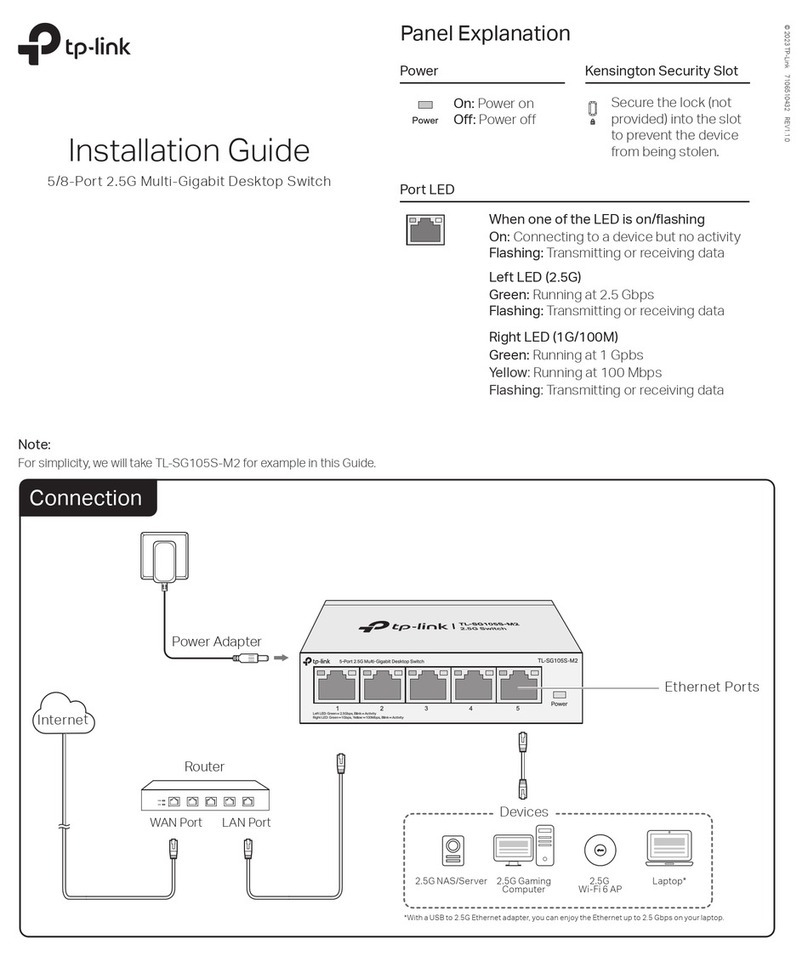

3. Variants of sensors

VARIANTS

code electrode description

GPLS–25N–0

Prismatic

(refracted)

electrode

Shape-adapted to be attached to the gauging pipe or other tube. The

xing of the sensor onto a pipe is provided by plastic straps.

GPLS–25N–1 Plannar

electrode

Suitable for installation on at surfaces (e.g. plastic or glass tanks). The

sensor can be xed with plastic straps or by double sided adhesive layer.

4. Dimensional drawings

GPLS–25N–0

GPLS–25N–1

Magnetic pen MP–8

Variant“A“

with cable outlet

Variant „C“

with connector

cable

LED

Electrode

Sensitive spot

for setting

5

© Dinel, s.r.o. GPLS-25

4

5. Installation and putting into operation

Please follow next 4 steps:

• Mechanical mounting - see chapter 5

• Electrical connection - see chapter 7

• Settings - see chapter 8

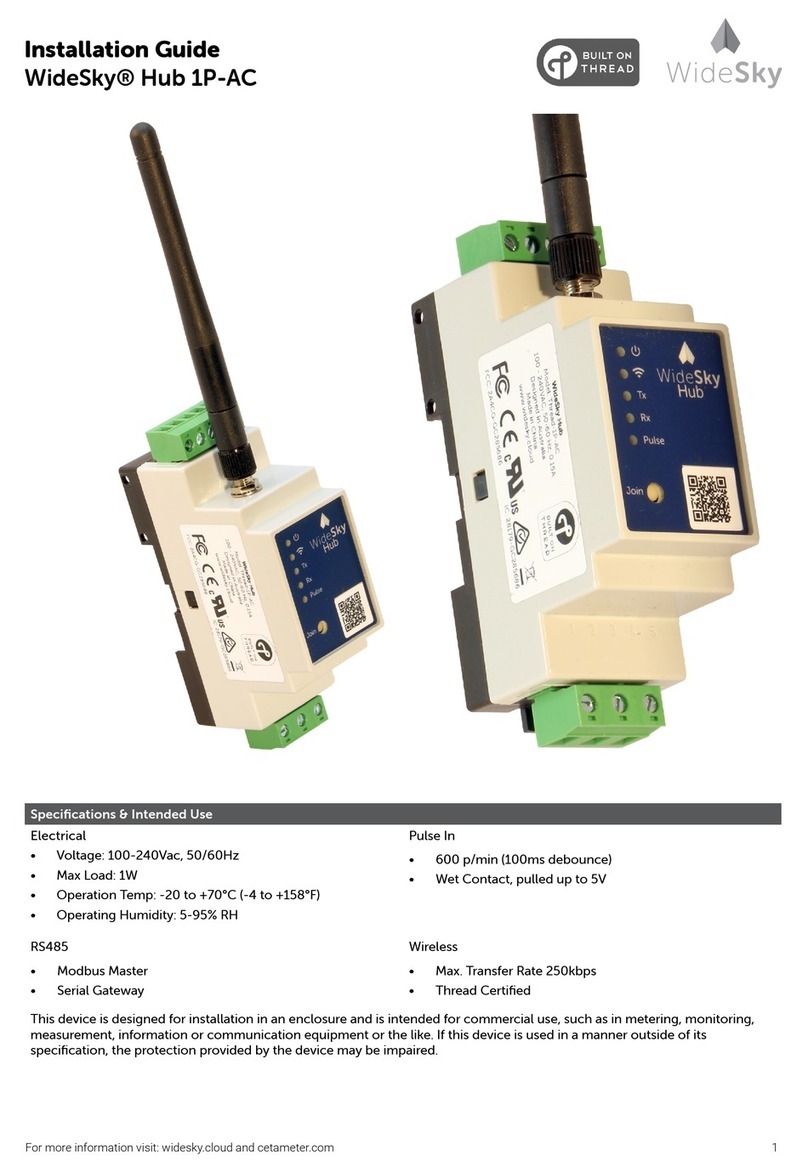

6. Mechanical mounting

THE SENSOR TYPE GPLS–25N–0

• is intended to point level detection on plastic or

glass and gauge-tubes.

• The sensor is xed to the gauge pipe or tube by

means of two plastic straps (2.5 mm width). The

cable should be vertically downwards oriented.

The maximum wall thickness of the tube depends

on the detected medium (see technical data), the

maximum is 8 mm.

Plastic straps

THE SENSOR TYPE GPLS–25N–1

• is intended to thru-wall level sensing of liquids in

plastic or glass vessels with at walls.

• The sensor is installed on a clean and degreased

surface of the vessel wall. The attachment is done

by doublesides adhesive layer. Orientation of the

sensor can be arbitrary. Maximum thickness of

the vessel wall depends on the detected medium

(see technical data), the maximum is 8 mm.

GPLS-25 © Dinel, s.r.o.

6

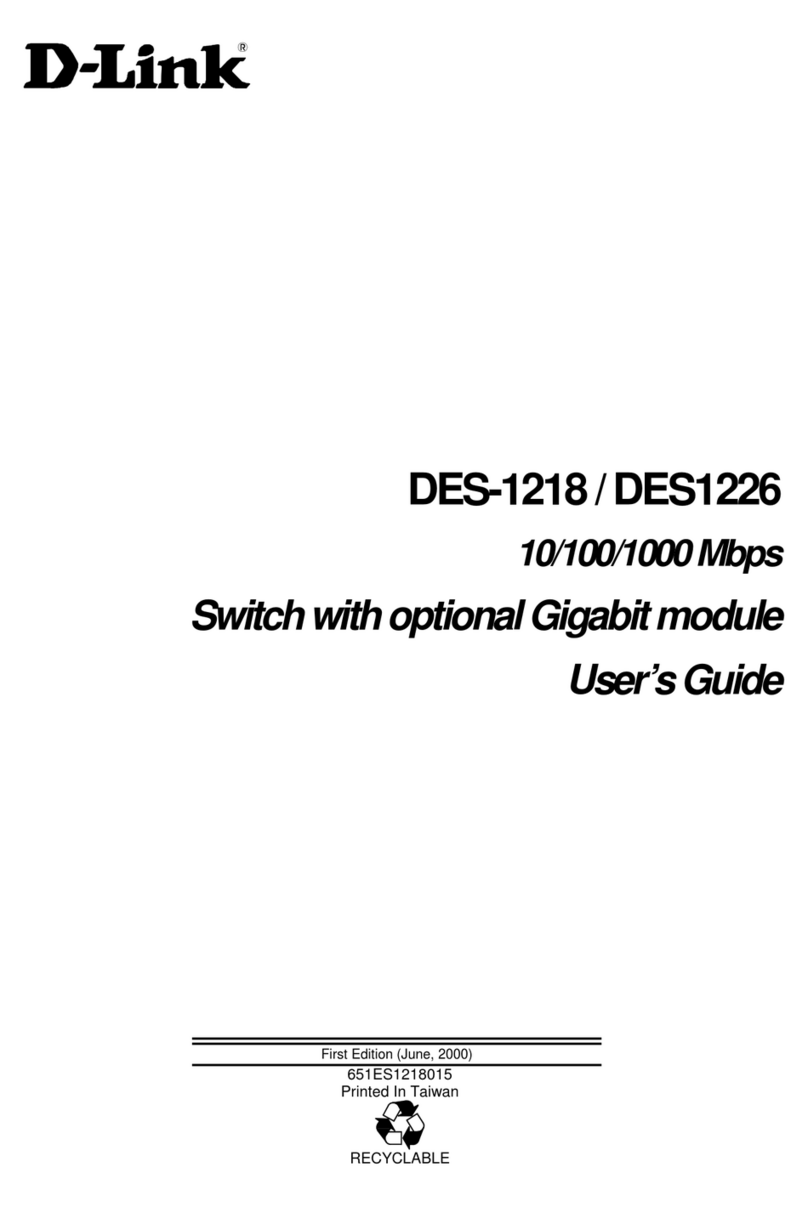

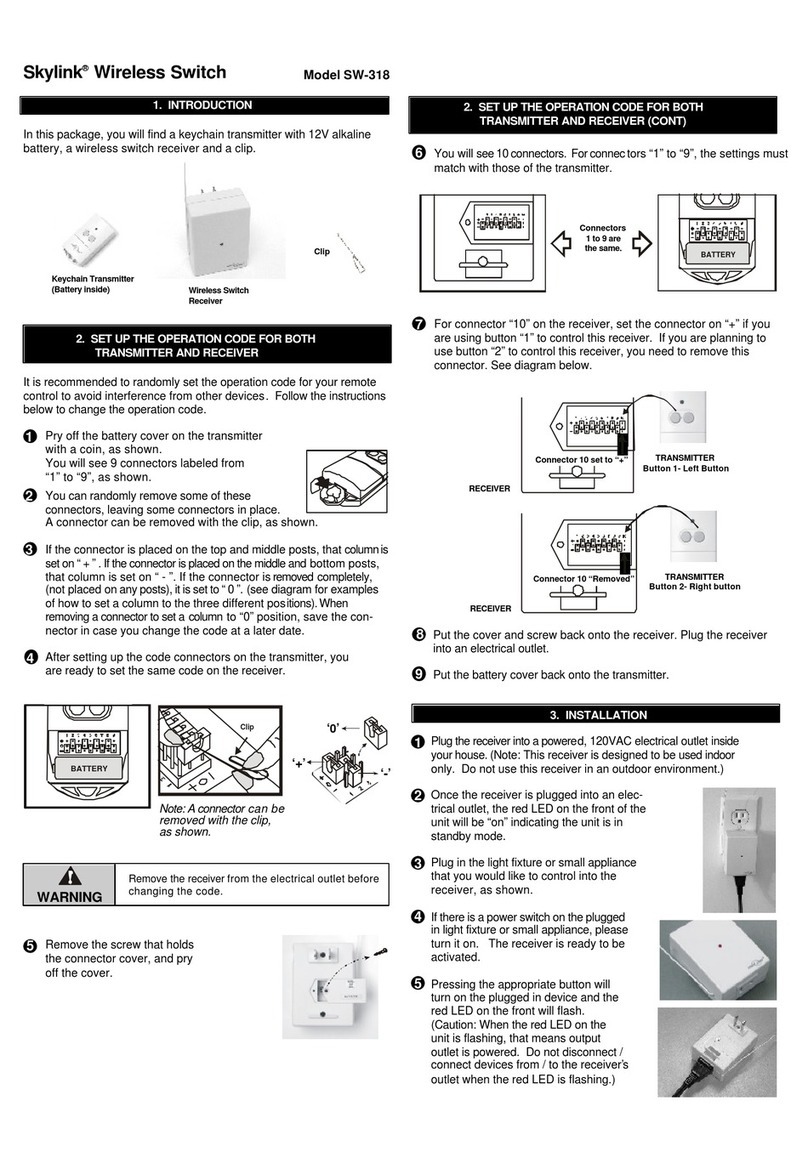

7 . Electrical connection

THE TYPE OF SENSOR GPLS–25N–_-S

Positive pole (+U) of power supply is connected through a load (relay) to brown wire or pin

connector No. 1, negative pole is connected to while wire or pin connector No.3.

THE TYPE OF SENSOR GPLS–25N–_-P

Positive pole (+U) of power supply is connected to brown wire or pin connector No.1, negative

pole is connected to blue wire or pin connector No.3. Load (relay) is connected to black wire or

pin connector No.2.

Connection scheme of sensor

with “S“ type output

Connection scheme of sensor

with “PNP“ type output

Legend:

(1) – Terminals number for variants with connector

BN – Brown

WH – White

BU – Blue

The sensor GPLS-28 output is protected againts short circuits. Capacity loads and loads with

low sleep resistance (bulb) the sensor evaluation as a short circuit. In case of high ambient

electromagnetic interference, parallel conductors with power lines, or lines at distances greater than

30 m, we recommend to use shielded cable.

Electrical connection must be done in de-energized state!

For switching supply sources, it is necessary to check that the input is galvanically separated

from the network side and that they are tted with a lter suppressing the conforming

interference (terminals + and – oscillate together towards the ground potential), or the

interference is removed in another manner.

7

© Dinel, s.r.o. GPLS-25

8 . Setting

a) Mode O (normally open)

1. Put the level of the measured medium in the state below the lower edge of the sensor in the

tank or in the gauge-pipe.

2. Attach the magnetic pen MP-8 to the sensitive spot Mfor maximum 2 seconds. When the

LED goes out, the sensor is in the state open.

3. After removal of the magnetic pen check the status of orange lights:

- f the LED doesn´t light or is ashing rapidly (0.2 s), go to step 4.

- If the LED lights, you must repeat step 2 so as not to exceed the limit of 2 seconds attaching

magnetic pen.

4. Put the level of the measured medium in the state above the upper edge of the sensor in the

tank or in the gauge-pipe.

5. Attach the magnetic pen MP-8 to the sensitive spot Mfor minimum 4 seconds. When the

LED lights up, the sensor is in the state closed.

6. After removal of the magnetic pen check the status of orange lights:

- If the LED lights, settings of the sensor is correct.

- If the LED doesn´t light, the sensor was set incorrectly and you must repeat the procedure

from step 1.

- If the LED is ashing, the sensor didn´t recognize upper and lower limits. In this case, rst

verify that at the step 1 the level of the measured medium was below the lower edge of the

sensor and at the step 3 the level of the measured medium was above the upper edge of

the sensor. Then make sure that the thickness of the gauge-pipe wall or the tank wall does

not exceed the limit specied in the Technical specications (p. 2). If not, check there isn´t

a thick layer of sediment on the inner wall of the tank or the gauge-pipe.

For security reasons, we recommend to set the mode O (normally open, sensor closes when

immersed) for minimum level detection. Any failure of the sensor or wiring is equally apparent as

the emergency level state. Analogously – for the maximum level detection is recommended to set

the mode C (normally closed, sensor opens when immersed).

Sensitive

spot

The setting is done by placing of magnetic pen MP-8 to

sensitive spot Mlocated on the front of the sensor. Short

time attaching (up to 2 sec.) of the magnetic pen to the

sensitive spot Mmakes the sensor open. Long attach (at

least 4 sec.) of the pen when the level is changed, denes

closed state of the sensor. In this way the sensitivity for

the measured medium and switching modes “O“ (normally

open) or “C“ (normally closed) is set. When changing the

uid it is necessary to make the new setting.

GPLS-25 © Dinel, s.r.o.

8

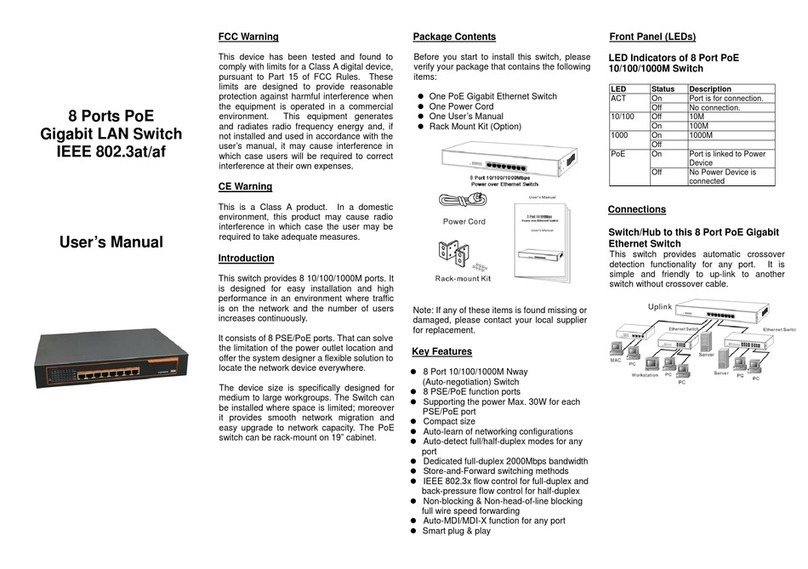

Indicator Function

Orange

LED

Continuous light – Sensor is closed (switched ON)

Dark – Sensor is open (switched OFF)

Rapid ashing (period 0,2 sec.) *

– Unrecognized upper and lower limits of setting mistake

Slow ashing (period 0,8 sec.) – Short circuit at sensor output

9 . Status signalization

* Sensor with “S“ type output, for each ash of the LED switches its output on for approx. 3 ms. This period is sufci-

ently short to avoid unwanted switching of relay contacts. For binary inputs, we recommend to set the lter so as not

to respond to pulses shorter than 3 ms.

b) Mode C (normally closed)

1. Put the level of the measured medium in the state below the lower edge of the sensor in the

tank or in the gauge-pipe.

2. Attach the magnetic pen MP-8 to the sensitive spot Mfor minimum 4 seconds. When the

LED lights up, the sensor is in the state closed.

3. After removal of the magnetic pen check the status of orange lights:

- If the LED lights or is ashing rapidly (0.2 s), go to step 4.

- If the LED doesn´t light, you must repeat step 2 so as to observe the limit of 4 seconds

attaching magnetic pen.

4. Put the level of the measured medium in the state above the upper edge of the sensor in the

tank or in the gauge-pipe.

5. Attach the magnetic pen MP-8 to the sensitive spot Mfor maximum 2 seconds. When the

LED goes out, the sensor is in the state open.

6. After removal of the magnetic pen check the status of orange lights:

- If the LED doesn´t light, settings of the sensor is correct.

- If the LED lights, the sensor was set incorrectly and you must repeat the procedure from

step 1.

- If the LED is ashing, the sensor didn´t recognize upper and lower limits. In this case, rst

verify that at the step 1 the level of the measured medium was below the lower edge of the

sensor and at the step 3 the level of the measured medium was above the upper edge of

the sensor. Then make sure that the thickness of the gauge-pipe wall or the tank wall does

not exceed the limit specied in the Technical specications (p. 2). If not, check there isn´t

a thick layer of sediment on the inner wall of the tank or the gauge-pipe.

After this settings the sensor responds to the level immersion and emersion in the upper half of

the sensing area and the hysteresis size 5 mm (1/8 of the distance between the bottom and the

top of the sensor).

9

© Dinel, s.r.o. GPLS-25

GPLS–25N–1–A–P cable 5 m

(1) planar electrode, (A) cable outlet with 5 m length xed cable; (P) output type PNP.

GPLS–25N–0–C–S

(0) prismatic electrode, (C) electric connection with connector; (S) output type S (electronic switch).

10 . Order code

11 . Correct specification examples

GPLS – 25N – – – cable Length of cable in meters (variant “A“)

A– cable outlet (+ Spec. the length of the cable)

C– connector (socket not included in the sensor,

see accessories for recommended type)

Electrode

type:

0– Prismatic (refracted)

1– Planar

Electric

connection:

P– PNP (open collector)

S– 2-wire electronic switch

Type of

output:

12 . Accessories

13 . Safety, protection and compatibility

The level sensor is equipped with a protection against electric shock on electrode, polarity, over-

voltage and short-term current overload on the output.

Protection against dangerous contact is ensured by supplying safe voltage according to ČSN 33

2000-4-41 (SELV).

Electromagnetic compatibility is provided by conformity with standards EN 55011(B), EN 61326-1,

EN 61000-4-2 (A, 8 kV), EN 61000-4-3 (A, 10 V), EN 61000-4-4 (A, 2 kV), EN 61000-4-5 (B, 1

kV), EN 61000-4-6 (A, 3 V) and EN 61000-4-8 (A, 30 A).

This equipment has been issued a declaration of conformity in accordance with Act 90/2016 Coll.

and subsequent amendments. The delivered electrical equipment meets the requirements of the

applicable government regulations on safety and electromagnetic compatibility.

Standard - included in the level sensors price Optional - for extra charge

• 2 pcs of Plastic straps 2,5 x 200 mm

• 1 pc of Double-side self adhesive tape

(GPLS–25N–1)

• 1 pc of Magnetic pen MP–8

• Connector ELKA KV 3308

GPLS-25 © Dinel, s.r.o.

10

14 . Use, operation and maintenance

15 . General warranty conditions

The manufacturer warrants from the date of delivery that this product will have the specied char-

acteristics as stated in the technical specications for a period of 3 years.

The manufacturer is liable for defects found during the warranty period and claimed in writing.

The warranty does not cover defects caused by improper handling or failure to comply with the

technical specications.

The warranty is void if the customer or a third party makes changes or modications to the product,

if the product is mechanically or chemically damaged, or if the serial number is illegible.

To make a claim, the warranty certicate must be presented.

In the event of a legitimate claim, we will repair or replace the defective product. In both cases, the

warranty period will be extended by the repair period.

The sensor requires no operator to operate. During operation,the operator of the technological unit is

informed about the level of the measured substance in the status gauge by an LED signalling diode.

The maintenance of the device consists in regular checking of the cable integrity and removal of

dirt from the back side of the sensor. It is forbidden to make any changes to the device without the

manufacturer‘s consent. Any repairs must be carried out only by the manufacturer of the device

or by a service organisation authorised by him.

Installation, operation and maintenance of the equipment must be carried out in accordance with

these technical conditions and the provisions of the applicable standards must be observed.

11

© Dinel, s.r.o. GPLS-25

Data on the plate of the unit of

16 . Marking of labels

GPLS-25

Dinel

STATE

SENSE

U = 6 ... 30 V

t = -20 ... +80°C

a

I = 100 mA

o max

IP67

GPLS-25N-0-A-P

No:170001

M

Cable: 2 m

www.dinel.cz

BN

BU

BK

+U

0V

ŠtítekproGPLS-25N-x-x-P

BN

WH (BU)

+U

0V

GPLS-25

Dinel

STATE

SENSE

U = 6 ... 30 V

t = -20 ... +80°C

a

I = 40 mA

max

IP67

M

www.dinel.cz

ŠtítekproGPLS-25N-x-x-S

GPLS-25N-0-A-S

No:170001

Cable: 2 m

rf

rf

GPLS-25N-x-x-P GPLS-25N-x-x-S

GPLS-25

Dinel

STATE

SENSE

U = 6 ... 30 V

t = -20 ... +80°C

a

I = 100 mA

o max

IP67

GPLS-25N-0-A-P

No:170001

M

Cable: 2 m

www.dinel.cz

BN

BU

BK

+U

0V

ŠtítekproGPLS-25N-x-x-P

BN

WH (BU)

+U

0V

GPLS-25

Dinel

STATE

SENSE

U = 6 ... 30 V

t = -20 ... +80°C

a

I = 40 mA

max

IP67

M

www.dinel.cz

ŠtítekproGPLS-25N-x-x-S

GPLS-25N-0-A-S

No:170001

Cable: 2 m

rf

rf

Symbol of producer: logo Dinel®

Internet address: www.dinel.cz

Type of level meter: GPLS–25N-_-_-_

Cable length: (only for GPLS-25N-_-A-_)

Product serial number: Ser. No.: xxxxx – (from left: year of manufacture, serial production No.)

Supply voltage range: U=6...30 VDC

Output current range: IMAX , nebo IOMAX

Ambient temperature range: ta= -20 ...+80 °C

protection: IP67

mark of conformity:

mark for take-back of electrical waste:

GPLS-25 © Dinel, s.r.o.

12

17. Technical specifications

Technical specifications

Supply voltage 6 ... 30 V DC

Supply current – Output type P

– Output type S

max. 0,6 / 7 mA

max. 0,6 mA

Switched current (Min. / Max.) – Output type P

– Output type S

100 mA

3,3 / 40 mA

Remanent voltage – ON state – Output type P

– Output type S

1,8 V

6,0 V

Switching frequency 1 Hz

Ambient temperature range –20 ... +80°C

Temperature range at the tube or vessel surface / with double-side self adhesive tape –20 ... +90°C/+60°C

Max. thickness of the vessel wall – Conductive liquids

– Non-conductive liquids with ɛr< 10*

8 mm

3 mm

Protection class IP 67

Housing material plastic (PP)

Connection cable type (Variants “A”) – Output type P

– Output type S

PVC 3 x 0,34 mm2

PVC 2 x 0,34 mm2

Weight (including 2 m cable) Approx 60 g

*) ɛrsee “Table of dielectric constants”

18 . Packing, shipping and storage

The GPLS-25 is packed in a polythene bag and the entire shipment is placed in a cardboard box.

Suitable padding is used in the cardboard box to prevent mechanical damage in transit.

Remove the equipment from the packaging before using it to prevent possible damage.

Transportation to the customer is carried out by a freight forwarding company. By prior arrange-

ment, personal collection of the ordered goods at the company‘s headquarters is also possible.

Upon receipt, please check whether the shipment is complete and corresponds to the scope of

the order, or whether the packaging and equipment have been damaged during transport. Do not

use equipment obviously damaged in transit, but contact the manufacturer to resolve the situation.

If the equipment is to be transported, it must be packed in its original packaging and protected

against shocks and weathering.

Store the equipment in its original packaging in a dry area, sheltered from the weather, with humidity

up to 85% without the eects of chemically active substances. The storage temperature range is

-10 °C to +50 °C.

13

© Dinel, s.r.o. GPLS-25

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

phone: +420 577 002 003

email: sale@dinel.cz

www.dinel.cz

The current version of the manual can be found on www.dinel.cz

Version: 04/2021

industrial electronics

Other manuals for GPLS-25 Series

1

This manual suits for next models

2

Table of contents

Other Dinel Switch manuals