Dinel Flexi Watch FLD-32 User manual

Thru-wall level swiTch

FlD-32 "Flexi WaTch"

Before the rst use of the level sensor, read the instructions in this manual and keep it carefully.

The manufacturer reserves the right to do alteration without prior notice.

INSTRUCTION MANUAL

1. Basic description ........................................................................................................................... 4

2. Technical specications ................................................................................................................ 4

3. Dimensional drawings .................................................................................................................. 4

4. Recommended range of application .......................................................................................... 5

5. Unsuitable range of application .................................................................................................. 5

6. Installation and setup of the sensor ........................................................................................... 5

7. Electrical connection ..................................................................................................................... 6

8. Sensor setup .................................................................................................................................. 7

9. Fault indication .............................................................................................................................. 8

10. Connecting the FLD-32 to the analytical units ......................................................................... 9

11. Order code .................................................................................................................................13

12. Correct specication examples ...............................................................................................13

13. Accessories ................................................................................................................................13

14. Protection, safety, compatibility .............................................................................................13

CONTENTS

FLD-32 © Dinel, s.r.o.

4

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

Used symbols

Thru-wall level switch FLD–32 "Flexi Watch" is designed for indication of the presence of

(conductive or non-conductive) liquids through the wall of glass or plastic vessels. The sensitivity

and switching mode can be simply set up using "programming" wire or magnetic pen, depending

on the type of sensor used. The sensor housing is made of a exible polyurethane material with

a self-adhesive layer and holes for fastening bands.

1 . BaSiC dESCripTiON

TEChNiCal SpECifiCaTiONS

Supply voltage 6 ... 30 V DC

Current consumption (idle-circuit condition) max. 0.6 mA

Switched current (min. / max.) 3.3 / 40 mA

Residual voltage in the closed state max. 6 V

Max. switching frequency 1 Hz

Ambient temperature range -20 ... +70 °C

Diameter of the vessel for the attachment of the sensor min. 300 mm

maximum thickness

of the vessel wall

conductive liquids

non-conductive liquids with Ɛr< 10*

8 mm

3 mm

Protection class IP 67

Housing material polyurethane

Type of connection cable PUR 3 x 0.14 mm2

Weight (including 2 m cable) about 40 g

Weight (without cable) 10 g

2 . TEChNiCal SpECifiCaTiONS

5

© Dinel, s.r.o. FLD-32

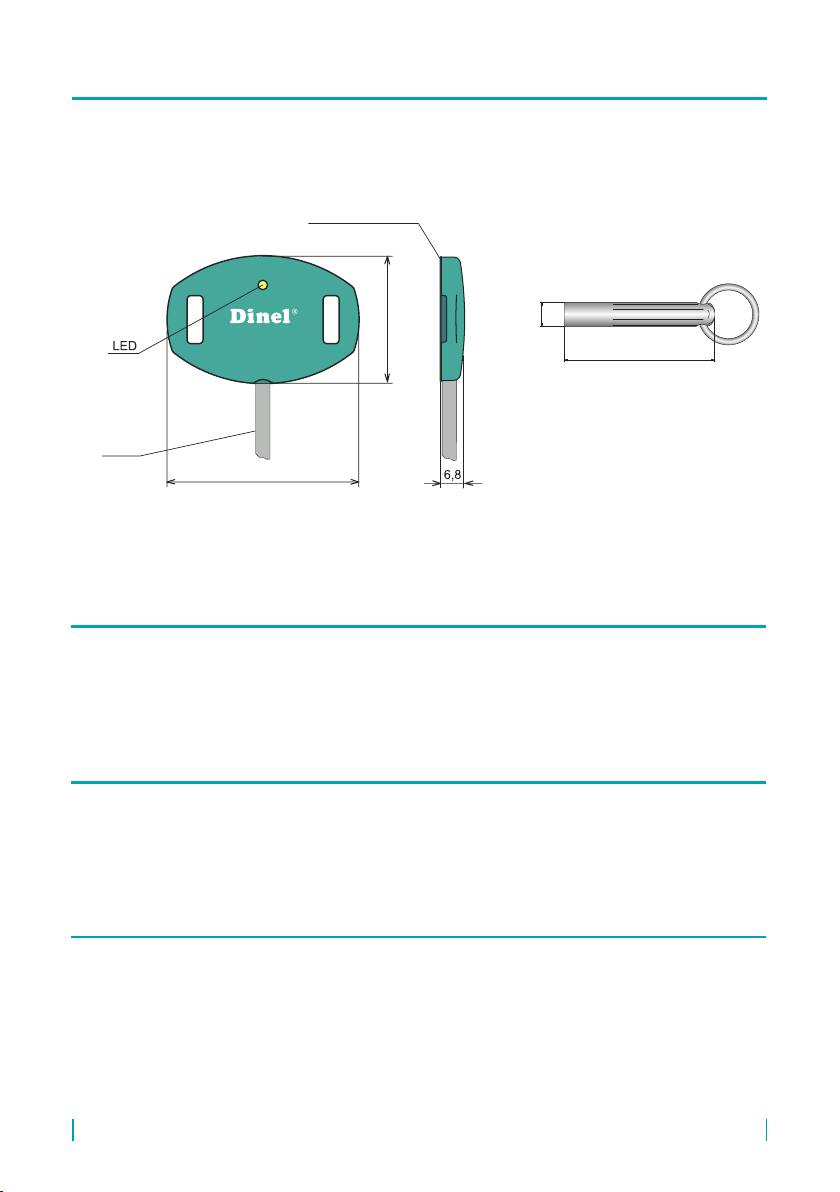

3 . dimENSiONal drawiNgS

32

48

min. ø 300

sensor

tank wall

self-adhesive layer

cable

50

8

magnetic pen MP-8

6 . iNSTallaTiON aNd SETup Of ThE SENSOr

Detection of various types of liquids - water, diesel fuel, oil, cooling uids, water solutions,

certain types of solvents. Suitable for plastic container tanks, plastic tubs, pools, canisters, etc.

The sensor is not intended for measurement of levels on level gauges and on the walls of

vessels with antistatic coating (partially conductive).

The sensor can be attached using self-adhesive layer or using special fastening bands.

Individual sensors may be arranged next to each other without any eect on their function.

4 . rECOmmENdEd raNgE Of appliCaTiON

5 . uNSuiTaBlE raNgE Of appliCaTiON

FLD-32 © Dinel, s.r.o.

6

FASTENING USING SELF-ADHESIVE LAYER

This technique may be used for at or slightly curved surfaces with a diameter larger than 300 mm.

1. One protective lm is removed from the adhesive layer and attached to the bottom of

the sensor.

2. The target area should be cleaned and degreased.

3. Remove the second protective lm and apply slight pressure to the sensor to attach it to

the desired location.

When replacing or removing the sensor, the sensor should be detached from the wall of the

tank carefully. If the original self-adhesive layer is destroyed, it needs to be removed from the

sensor and a new one should be used (delivered as accessories).

32

48

min. ø 300

sensor

tank wall

self-adhesive layer

cable

Fastening the FLD-32 using self-adhesive layer

fastening bands

with ø 180 - 300 mm

FASTENING USING ATTACHMENT BANDS

This technique is recommended for curved surfaces with a diameter of 180 - 300 mm. Use two

bands for fastening (each has one end modied).

1. The modied end of the band is threaded from the inside through the fastening eyelet

and glued over.

2. The same technique is used to attach the band at the second fastening eyelet.

3. The sensor is placed at the desired location on the tank, wrapping the bands around the

tank, tightening them and gluing over.

The sensor must be fastened well otherwise the function of the sensor may be unstable.

Fastening FLD-32 using attachment bands

7

© Dinel, s.r.o. FLD-32

7 . ElECTriCal CONNECTiON

BN

GN

WH

The positive pole of the power supply (+U) is connected to the brown wire, the negative (0V)

to the white wire. The output from the sensor is tted with short-circuit protection. Capacitive

loads and those with low resting resistance (light bulb) are evaluated by the sensor as a short-

circuit.

Note: In case of strong envi-

ronmental electromagnetic

interference, routing of wires

next to high-voltage lines or

when the total distance is

more than 30 m, the use of

a shielded cable is recom-

mended.

connecting the sensor with programming wire (version W)

BN

WH

Cable core

identication:

BN - brown

GN - green

WH - white

connecting the sensor without programming wire (version M)

The setup is made by using green wire (so-called programming) at version FLD-32N-W-S or

by touching the magnetic pen MP-8 at version FLD-32N-M-S to the sensitive spot on the body

of the sensor. This can be used to setup the upper and lower limits of liquid level, SO modes

(open contact when the level decreases) and SC (closed contact when the level decreases).

8 . SENSOr SETup

Attachment bands are recommended for applications where frequent removal of the sensor

from the vessel surface is expected.

FLD-32 © Dinel, s.r.o.

8

Setup using programming wire at version FLD-32N-W-S

SO mode: open when level decreases - For empty or partially lled vessel (level under the

lower edge of the sensor), the programming wire (P) is placed for about 2 seconds

on terminal 0V. Once the level reaches the upper edge of the sensor or when the

tank is full, the wire (P) is placed to +U terminal for the same time period (2 s).

SC mode: closed when level decreases - For empty or partially lled vessel (level under the

lower edge of the sensor), the programming wire (P) is placed for about 2 seconds

on terminal +U. Once the level reaches the upper edge of the sensor or when the

tank is full, the wire (P) is placed to 0V terminal for the same time period (2 s).

Note: The wire (P) is used only for programming the sensor. In all other situations it is

unconnected.

For comfortable setup of the FLD-32N-W-S sensor we recommend using of wall-mounted

evaluation unit Dinel, type SDSU-1222-W with setup buttons, power supply, optical status

indication and relay output.

Set up using magnetic pen MP-8 at version FLD-32N-M-S

The setup is made by using the magnetic pen MP-8 touching on a sensitive spot Mon the

front side of the sensor. Short touch (for 2 s max.) of the magnetic pen on the spot Mis used

to open the sensor, longer touch of the magnetic pen (for 4 s min.) closes the sensor. This is

used to set up the sensitivity to the measured medium and switching modes (SO, SC).

SO mode: open when the level decreases - For empty or partially lled vessel (level below

the lower edge of the sensor), touch the magnetic pen on the sensitive spot for 2 s

max. M (sensor opens). Once the tank is lled above the upper edge of the sensor,

touch the magnetic pen on the sensitive spot for 4 s at least M(sensor closes).

SC mode: closed when the level decreases - For empty or partially lled vessel (level below

the lower edge of the sensor, touch the magnetic pen on the sensitive spot for

4 s at least M (sensor closes). Once the tank is lled above the upper edge of

the sensor, touch the magnetic pen on the sensitive spot for 2 s max. M(sensor

opens).

9 . faulT iNdiCaTiON

* Thesensorwith"S"typeofoutput,witheachashofLED,closesforapprox.3ms.Thisisasucientlyshort

period to avoid unwanted contact making of the connected relay. For binary inputs, we recommend setting up the

ltrationsothatpulsesshorterthan3msarenotdetected.

**Setting of the close (open) limits to the same level or erroneous resolution between the "close" and "open" levels

(low medium permittivity).

control lamp function

orange LED

permanent shine – the sensor is closed

dark – the sensor is open

fast ashing (0.2 s interval) *– setup error **

slow ashing (0.8 s interval) – short-circuit at the output of the sensor.

9

© Dinel, s.r.o. FLD-32

10 . CONNECTiNg TO ThE aNalyTiCal uNiTS fld-32

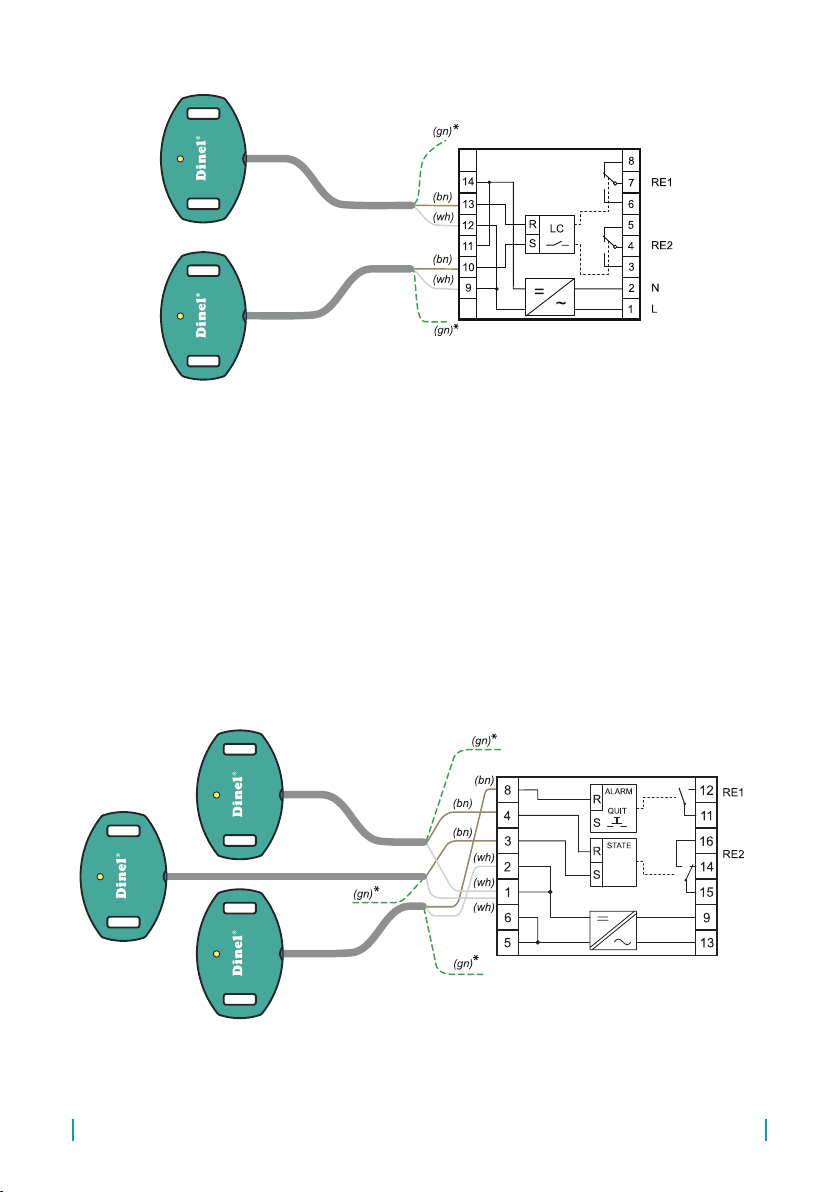

Connecting of the sensor FLD-32 to the evaluation unit SDSU-1222-W

wh – white

bn –brown

gn – green

Legend:

Connecting of the sensor FLD-32

to the PLC logical unit

Connecting of the sensor FLD-32

to the relay coil

power

supply unit

power

supply unit

The thru-wall level switch FLD-32 "Flexi Watch" can be connected to various analytical units. See

below for connection examples of this setup. This provides general connection of the sensor

to the relay coil and to logical unit. Connection to specic analytical units is also described.

Connecting of the sensor FLD-32 to the evaluation units SDSU-1222-W and DSU-1222-W

This unit is intended for evaluation of sensors programmable using third wire (FLD-32 "Flexi

Watch"). It contains the programming buttons for setup of sensors and stabilized 12 V DC

power supply. It enables the level control (sensing of the amount of liquid in tanks, wells, etc.)

This unit is suitable for the FLD-32 variant with programming wire setup. DSU-1222-W unit is

suitable for the type with magnetic pen setup.

FLD-32 © Dinel, s.r.o.

10

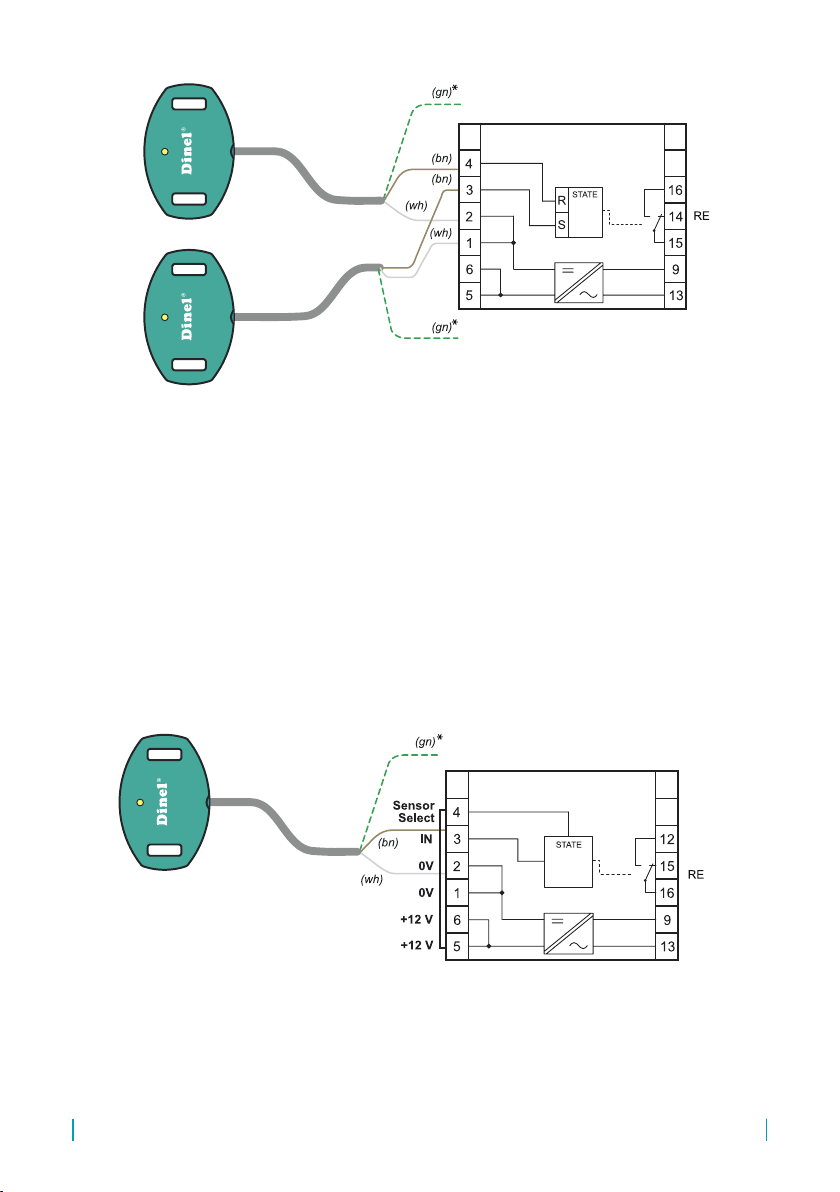

Connecting of the sensor FLD-32 to the evaluation unit LCU-1232

Connecting of the sensor FLD-32 to the evaluation unit DSU-1222-W

230 AC

230 AC

Connecting of the sensor FLD-32 to the evaluation units LCU-1232 and LCU-1221

These units have two inputs to connect two operating sensors (MIN, MAX) and one input for

connection of an emergency sensor (ALARM - only LCU-1232). The operating sensors enable

the control of the operating relay (terminals 14, 15, 16). The emergency sensor controls the

emergency relay (terminals 11, 12).

11

© Dinel, s.r.o. FLD-32

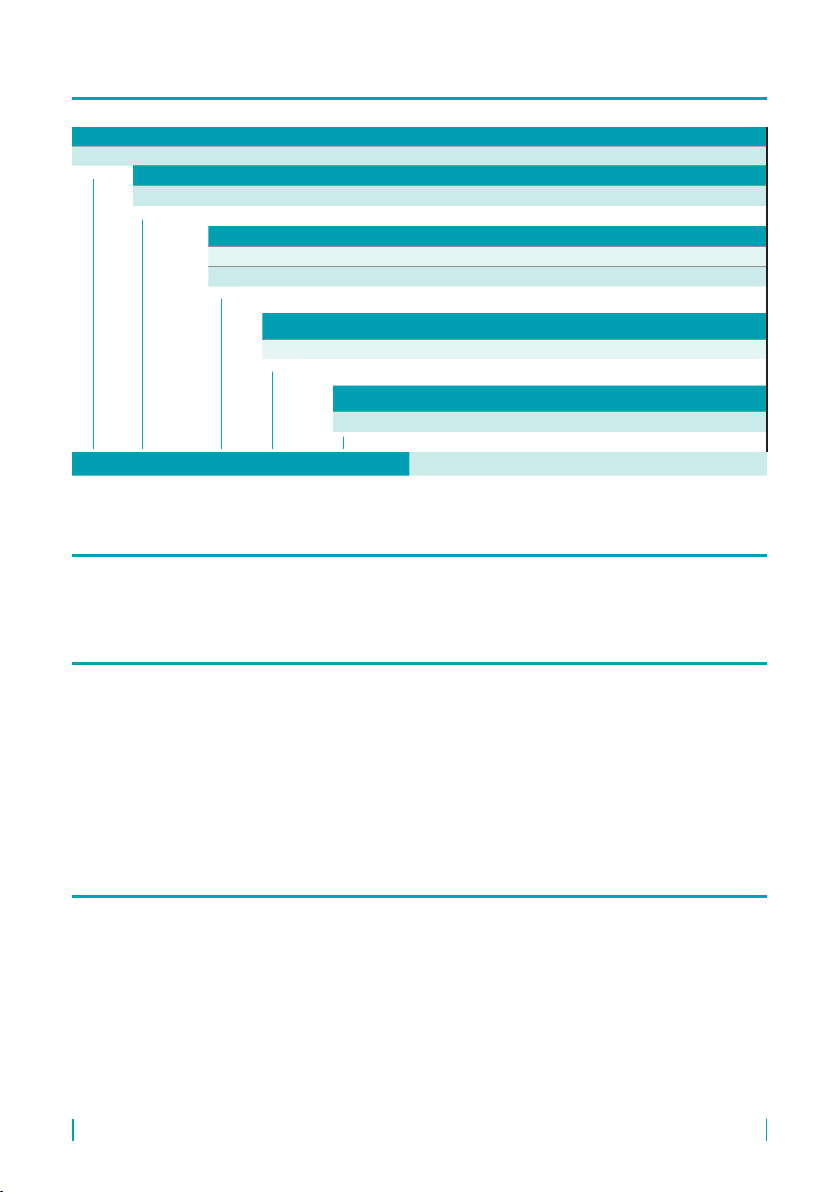

Connecting of the sensor FLD-32 to the evaluation units SSU-1211-W and DSU-1222-W

The unit SSU-1211 is used to connect a single sensor. It has one contact for the input signal

(terminal 3) and relay contact (12, 15, 16). To use the unit in combination with FLD-32, terminal

4 must be connected to terminal 5. The unit DSU-1222 is used to connect two sensors. It has

two contacts for the input signals (terminals 3 and 4) and relay contact (11, 12 and 15, 16).

Connecting of the sensor FLD-32 to the evaluation unit LCU-1221

Connecting of the sensor FLD-32 to the evaluation unit SSU-1211

230 AC

230 AC

230 AC

230 AC

FLD-32 © Dinel, s.r.o.

12

230 AC

Connecting of the sensor FLD-32 to the evaluation unit DSU-1222

position

of sensors

230 AC

230 AC

Connecting of the sensor FLD-32 to the evaluation unit TDU-1211

* Only for version FLD-32N-W-S.

Connecting of the sensor FLD-32 to the evaluation units TDU-1211

This unit has one input for connection of one limit sensor. The dened change of status on unit

input (terminal No.3 - IN) starts the timer in the range from 1 s to 100 min. While the timer is

running, the condition of the output relay changes (relay with switching contact) and contact is

made between terminals 12 and 16 (disconnected contact 15-16).

13

© Dinel, s.r.o. FLD-32

11 . OrdEr COdE

12 . COrrECT SpECifiCaTiON ExamplES

13 . aCCESSOriES

14 . prOTECTiON, SafETy, COmpaTiBiliTy

FLD – 32N-M-S K 2 FLD – 32N-W-S K 5

standard - included in the price of the sensor

• 2x two-sided adhesive layer

• 1x magnetic pen MP-8 (in case of version that uses MP-8 setup)

optional – for an extra charge

• attachment band (1 packaging - 2x 0.5 m)

• two-sided adhesive layer

The sensor is tted with the protection of supply voltage against polarity reversal, voltage

peaks and current overload.

Shock protection is provided by safe supply voltage according to HD 60364-4-41.

Electromagnetic compatibility is provided by compliance with standards EN 55022/B, EN

61326-1, EN 61000-4-2, -4-3, -4-4 and -4-6.

PRODUCT

FLD-32

PERFORMANCE

N non-explosive areas

SETUP TECHNIQUE

Mmagnetic pen

Wprogramming wire

TYPE OF OUTPUT

Selectronic switch

CABLE

Kcable length in m (2 or 5 m)

fld-32 N - w - S - K 2 availaBlE prOduCT alTErNaTivES

NOTES

Dinel, s. r. o.

U Tescomy 249

760 01 Zlín

Czech Republic

phone: +420 577 002 002

e-mail: [email protected]

www.dinel.cz

The current version of the manual can be found on www.dinel.cz

Version: 08/2017

07/2019

Table of contents

Other Dinel Switch manuals

Popular Switch manuals by other brands

Allied Telesis

Allied Telesis GS950 PS Series installation guide

Allied Telesis

Allied Telesis AT-9006T installation guide

CYP

CYP EL-8100V Operation manual

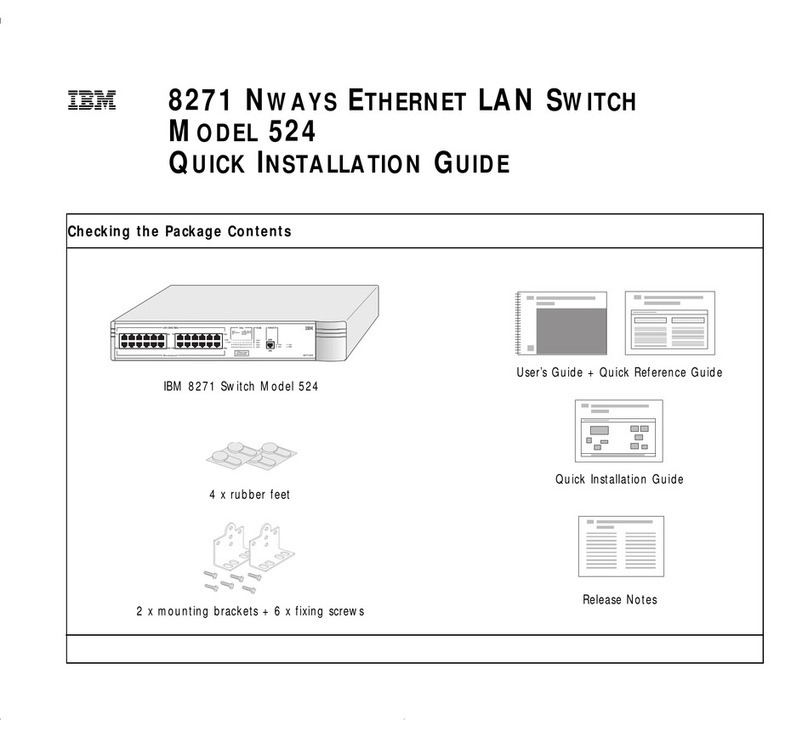

IBM

IBM 524 Quick installation guide

Guntermann & Drunck

Guntermann & Drunck TradeSwitch8-USB Installation and operation manual

Maiwe

Maiwe MIEN2016 user manual