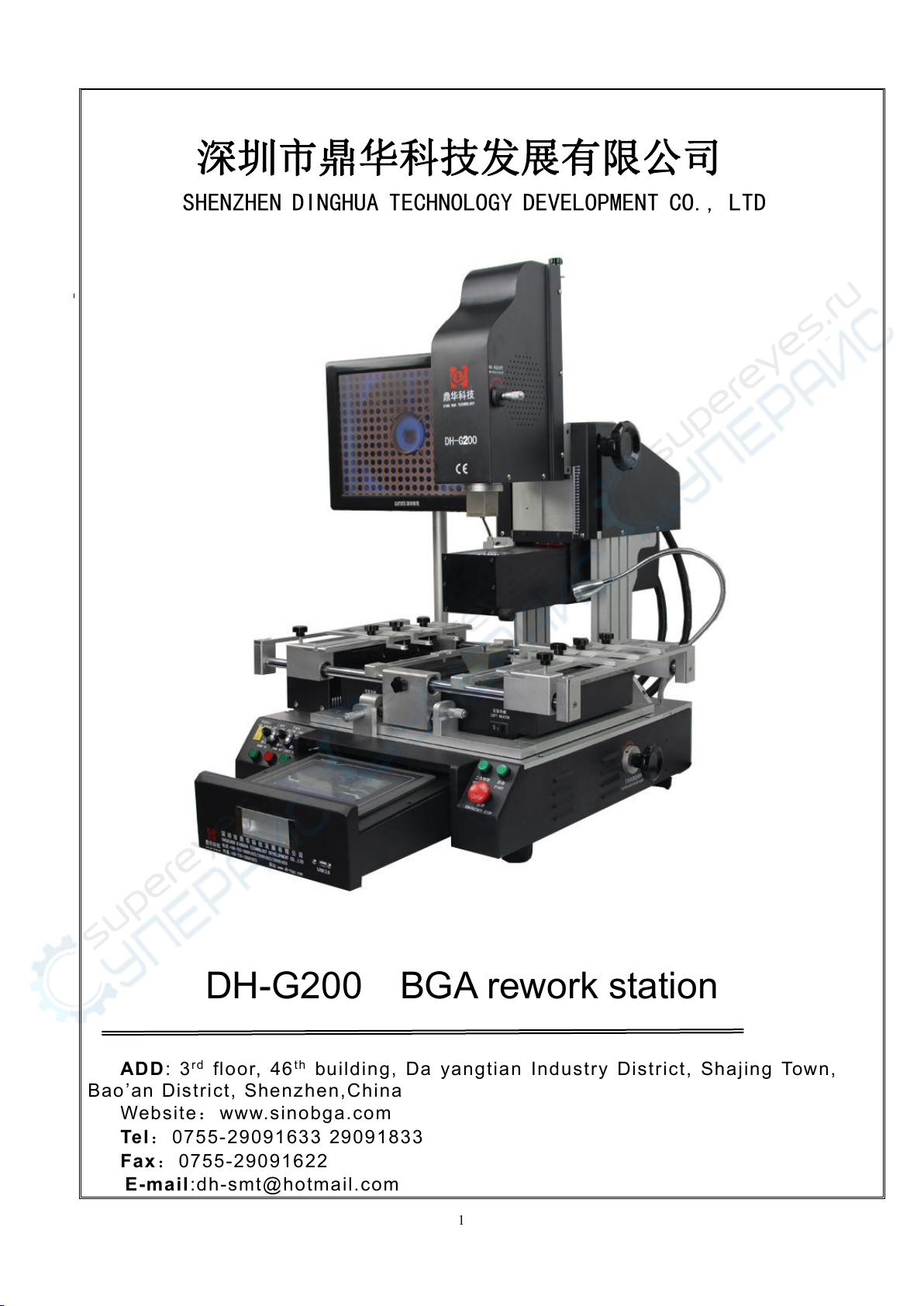

Dinghua DH-G200 User manual

1

DH-G200 BGA rework station

ADD : 3r d floor, 46th building, Da yangtian Industry District, Shajing Town,

Bao’an District, Shenzhen,China

Website:www.sinobga.com

Tel:0755-29091633 29091833

Fax :0755-29091622

E-mail:dh-smt@hotmail.com

深圳市鼎华科技发展有限公司

SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD

2

Contents

一Compang Profile……………………………………………...……….3.

二Installation……………………………………………..……………….3

1) Installation………………………………….………..……………..3

2) Power supply…………………………………………..…………..3

三Safety Precaution……………………………………..……………….4

四Structures and Specification………………………………………….5

1) Structures…………………………………………………………..5

2) Function……………………………………………...……………..6

3) Main parameters………………………………………….………..7

五Setting………………………………………………………….……….8

六OPerations………………………………………………………….…15

七Usage of external couple……………………………………………17

八Usual temperature

reference …………………………………………………………20

1) Welding of lead BGA…………………………………………….20

2) Welding of lead-free BGA……………………………………….22

九Precautions……………………………………………………………23

3

Attach: Packing list.

一、Company profile

SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO.,LTD is a professional

manufacturer of welding equipments.Our products: bga rework stations,automatic soldering

machines,automatic screwdriving machines,welding kits and SMT materials etc.Our

mission: “Research as basis, Quality as core, Service as guarantee” . Our goal:

“Professional equipment, quality and service”

To ensure the quality, Dinghua was the first to pass UL、E-MARK、CCC、FCC、CE ROHS

certificates. Meanwhile, to improve and perfect the quality system, Dinghua has passed

ISO、GMP、FCCA、C-TPAT on-site audit certification.

Science and technology are the primary productive forces, with over years of hardworking,

Dinghua has owned core technology of temperature controlled and 38 patents and finished

the development and production of manual, semi-auto and automatic series and realized

the second revolution from traditional hardware combination to integrated control.Our

products have been exported to Europe , America, Southeast Asia, Australia, Africa, the

Middle East, Taiwan and more than 80 countries and regions and established the relatively

sales network and terminal services system.We are becoming the pioneer and guide of

SMT welding industrial and our products have been applied in individual

maintenance,industrial and mining enterprises,teaching and research work,military

manufacturing industry and aerospace industry and so on, which has treed good reputation

among users.

We believe:your successes are our successes,let’s work together and build a

better future!

二、Installation

(A)Installation sites

In order to ensure that the useful life of BGA rework station, installation of repair station must meet

the following conditions:

1.Away from flammable and explosive materials

2.Do not splash water or other liquids

3.Well-ventilated , dry place

4.Stable , flat areas less susceptible to vibration

5.Place less dust

6.Prohibit Placing heavy objects on top of the touch screen

7.Without the influence of air-conditioners, heaters and fans

8.Reserved for 30cm to move and rotate around the upper for the back of rework station

(B)Power supply

INPUT :220AV±10% 50/60HZ

三、Safety precautions

Safety Precautions

4

1.Do not use fans or other devices directly to the repair station hair when it works, otherwise it will

lead to negative differential heating plate surface , burn the workpiece

2.When the machine is on working, high-temperature heating zone can not be any direct contact with

the object , it may cause fire or explosion ,and the PCB workpiece should be placed on the PCB support

shelves

3.Do not shake rework station , and move gently

4.Do not touch the high fever area , otherwise you will burned

5.When turned on, do not use the flammable spray , liquid or flammable gas near the repair station

6.Do not try to modify rework station , otherwise it will cause fire or electric shock

7.Electrical box has the high-voltage components , do not attempt to disassemble

8.If the metal objects or liquids fall into the repair station when it works , immediately disconnect the

power , unplug the power cord until the machine to cool down , then completely remove litter , dirt ; if

dirt left ,there is odor when reboot

9.When abnormal heating or smoking, immediately disconnect the power , and inform the technical

service to repair It needs to disconnect the wires between the electrical boxes and machine parts, and

have to hold the plug, otherwise it leads to poor contact, and does not work

10.Note that the repair station not to press or run over other electrical equipment or power lines or

communication cable , and it may cause device malfunction or cause fire or electric shock

11.Before use the rework station, you must read this manual carefully

四、 Structure and Parameter:

(一) structure:

5

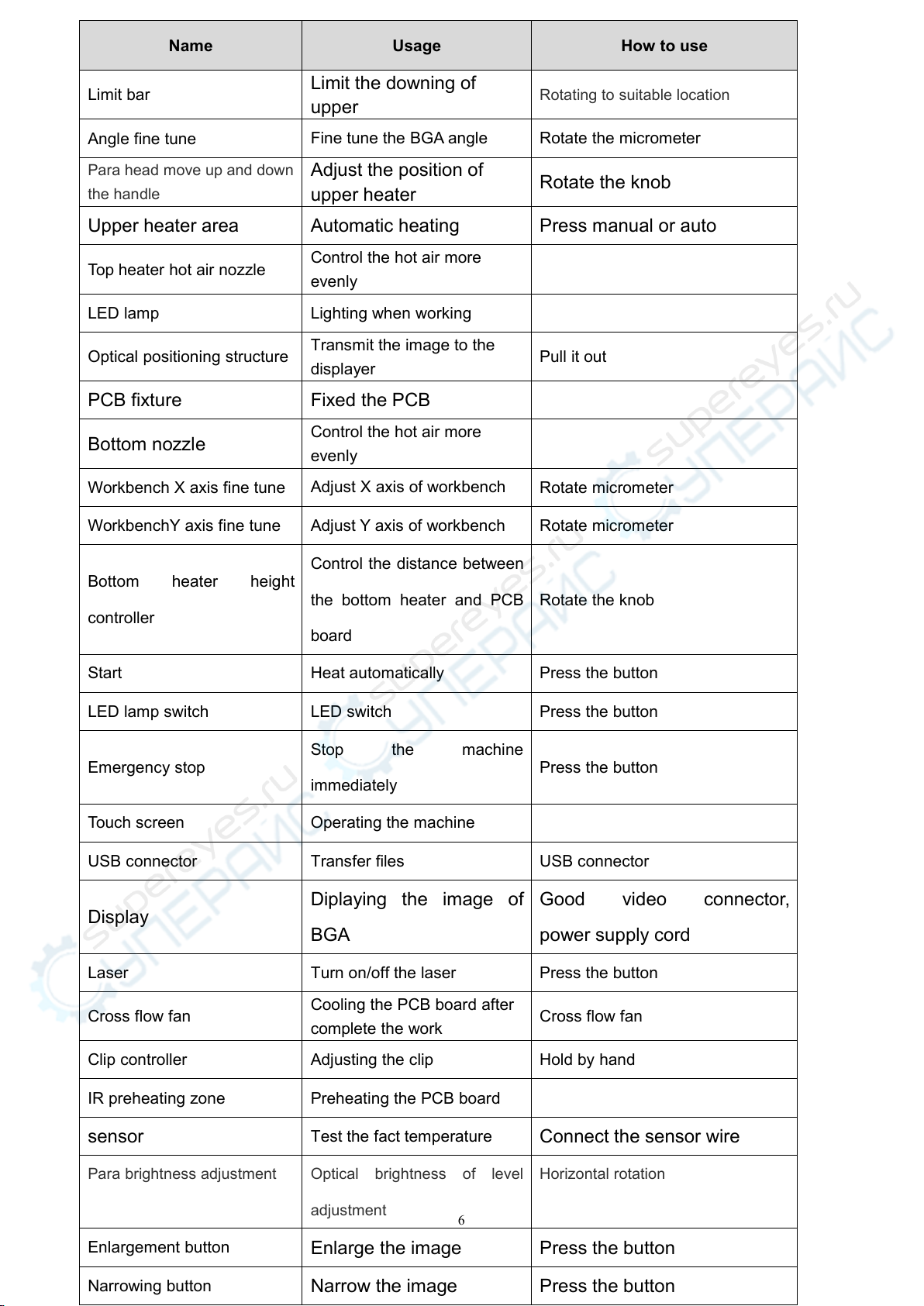

(二) Functions

6

Name

Usage

How to use

Limit bar

Limit the downing of

upper

Rotating to suitable location

Angle fine tune

Fine tune the BGA angle

Rotate the micrometer

Para head move up and down

the handle

Adjust the position of

upper heater

Rotate the knob

Upper heater area

Automatic heating

Press manual or auto

Top heater hot air nozzle

Control the hot air more

evenly

LED lamp

Lighting when working

Optical positioning structure

Transmit the image to the

displayer

Pull it out

PCB fixture

Fixed the PCB

Bottom nozzle

Control the hot air more

evenly

Workbench X axis fine tune

Adjust X axis of workbench

Rotate micrometer

WorkbenchY axis fine tune

Adjust Y axis of workbench

Rotate micrometer

Bottom heater height

controller

Control the distance between

the bottom heater and PCB

board

Rotate the knob

Start

Heat automatically

Press the button

LED lamp switch

LED switch

Press the button

Emergency stop

Stop the machine

immediately

Press the button

Touch screen

Operating the machine

USB connector

Transfer files

USB connector

Display

Diplaying the image of

BGA

Good video connector,

power supply cord

Laser

Turn on/off the laser

Press the button

Cross flow fan

Cooling the PCB board after

complete the work

Cross flow fan

Clip controller

Adjusting the clip

Hold by hand

IR preheating zone

Preheating the PCB board

sensor

Test the fact temperature

Connect the sensor wire

Para brightness adjustment

Optical brightness of level

adjustment

Horizontal rotation

Enlargement button

Enlarge the image

Press the button

Narrowing button

Narrow the image

Press the button

7

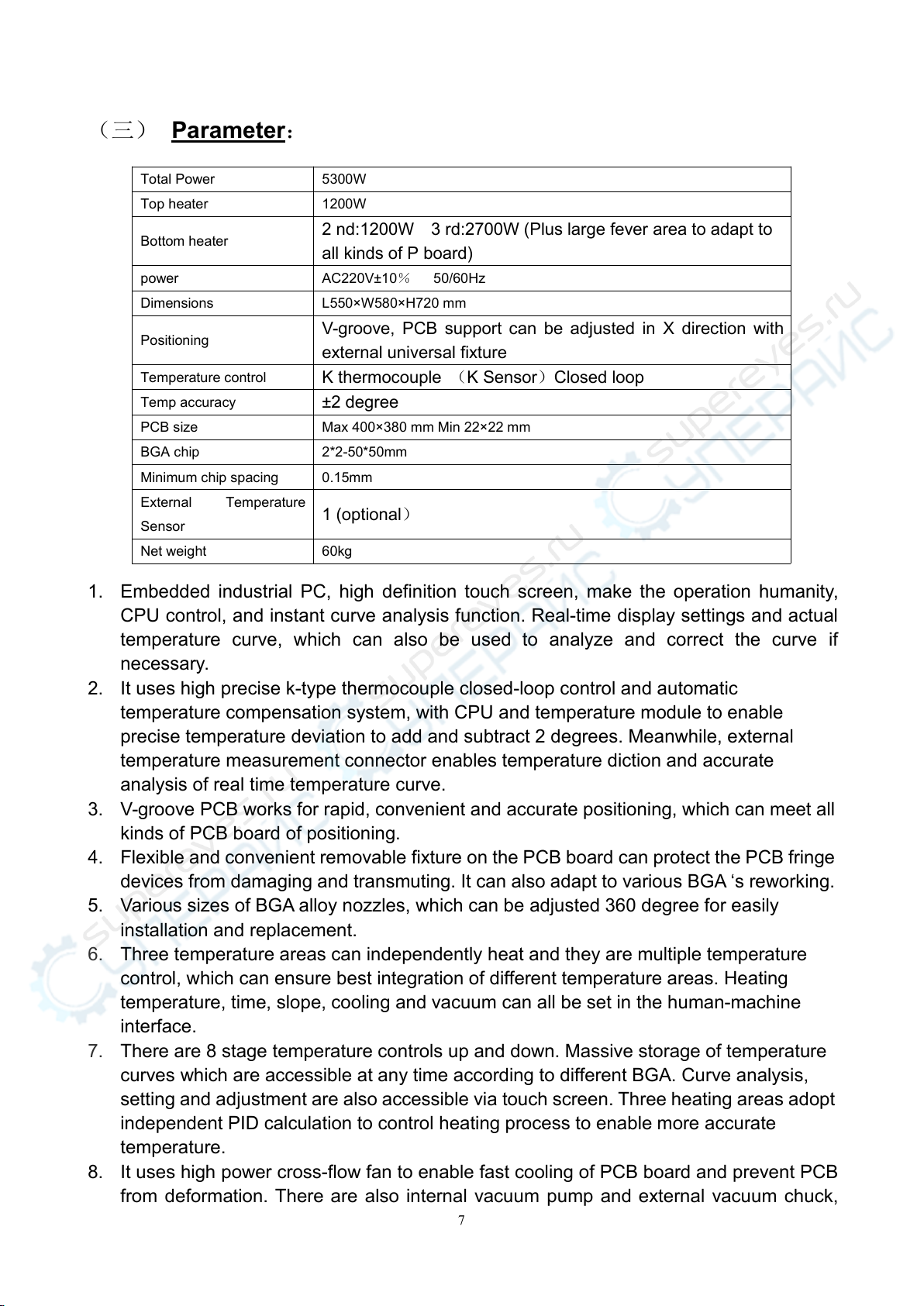

(三) Parameter:

1. Embedded industrial PC, high definition touch screen, make the operation humanity,

CPU control, and instant curve analysis function. Real-time display settings and actual

temperature curve, which can also be used to analyze and correct the curve if

necessary.

2. It uses high precise k-type thermocouple closed-loop control and automatic

temperature compensation system, with CPU and temperature module to enable

precise temperature deviation to add and subtract 2 degrees. Meanwhile, external

temperature measurement connector enables temperature diction and accurate

analysis of real time temperature curve.

3. V-groove PCB works for rapid, convenient and accurate positioning, which can meet all

kinds of PCB board of positioning.

4. Flexible and convenient removable fixture on the PCB board can protect the PCB fringe

devices from damaging and transmuting. It can also adapt to various BGA ‘s reworking.

5. Various sizes of BGA alloy nozzles, which can be adjusted 360 degree for easily

installation and replacement.

6. Three temperature areas can independently heat and they are multiple temperature

control, which can ensure best integration of different temperature areas. Heating

temperature, time, slope, cooling and vacuum can all be set in the human-machine

interface.

7. There are 8 stage temperature controls up and down. Massive storage of temperature

curves which are accessible at any time according to different BGA. Curve analysis,

setting and adjustment are also accessible via touch screen. Three heating areas adopt

independent PID calculation to control heating process to enable more accurate

temperature.

8. It uses high power cross-flow fan to enable fast cooling of PCB board and prevent PCB

from deformation. There are also internal vacuum pump and external vacuum chuck,

Total Power

5300W

Top heater

1200W

Bottom heater

2 nd:1200W 3 rd:2700W (Plus large fever area to adapt to

all kinds of P board)

power

AC220V±10%50/60Hz

Dimensions

L550×W580×H720 mm

Positioning

V-groove, PCB support can be adjusted in X direction with

external universal fixture

Temperature control

K thermocouple (K Sensor)Closed loop

Temp accuracy

±2 degree

PCB size

Max 400×380 mm Min 22×22 mm

BGA chip

2*2-50*50mm

Minimum chip spacing

0.15mm

External Temperature

Sensor

1 (optional)

Net weight

60kg

8

which can help to fetch the BGA chip;

9. Collocating with sound control "early warning" function. It can warn workers to make

some relative preparation 5-10 seconds before the completion of uninstalling or welding.

Cooling system will start after vertical wind stopped heating. When the temperature

drops to normal temperature, the cooling process will stop automatically, so that the

machine will not be aging after temperature heated up.

10. It use rocker controller for controlling the upper heater go up and down freely, and it

also has the function for zooming the picture.

CE approved, equipped with emergency stop switch and automatic power-off protection

device when emergency happens.

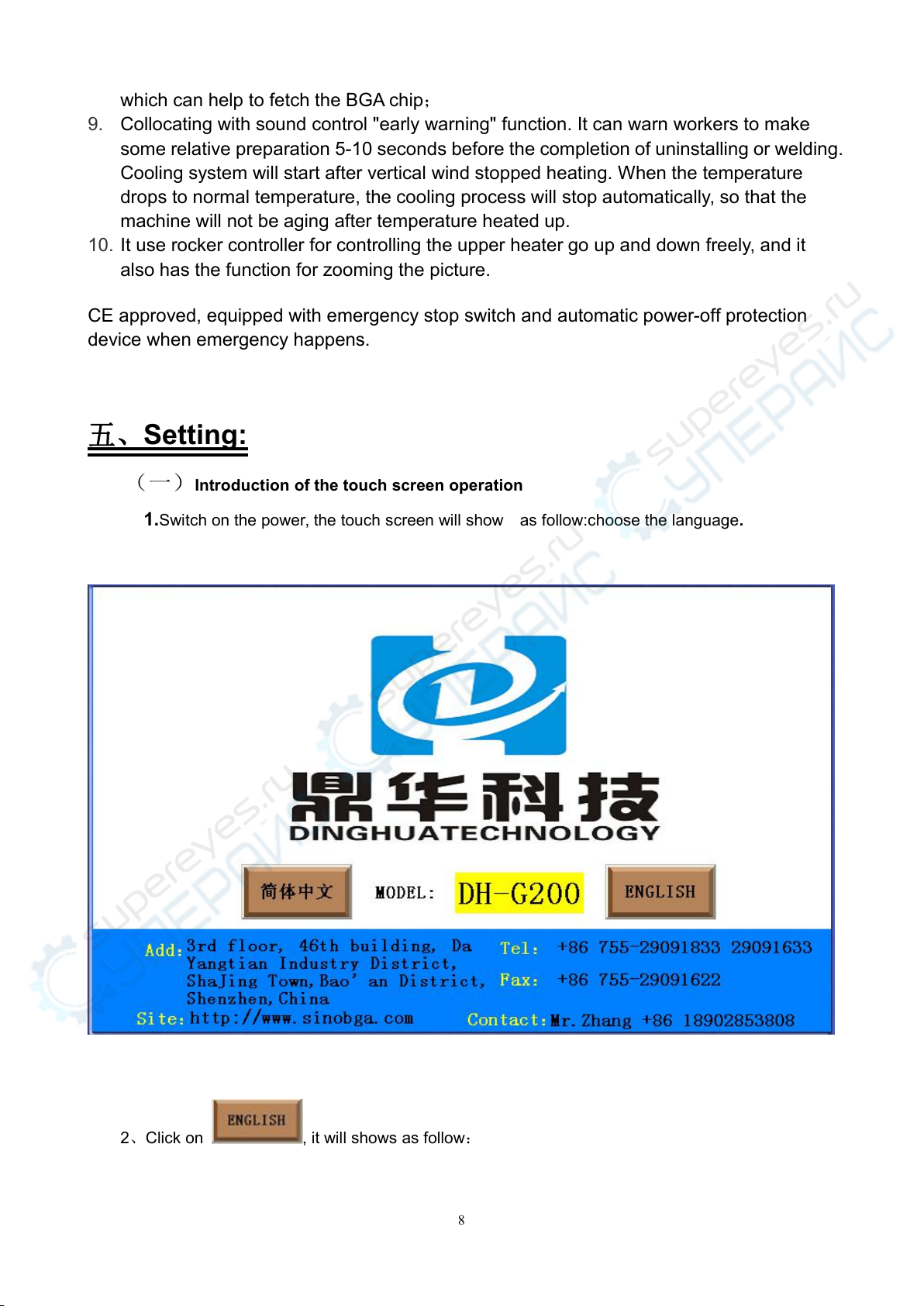

五、Setting:

(一)Introduction of the touch screen operation

1.Switch on the power, the touch screen will show as follow:choose the language.

2、Click on , it will shows as follow:

9

3、Click the input box, it will appear as follow:

10

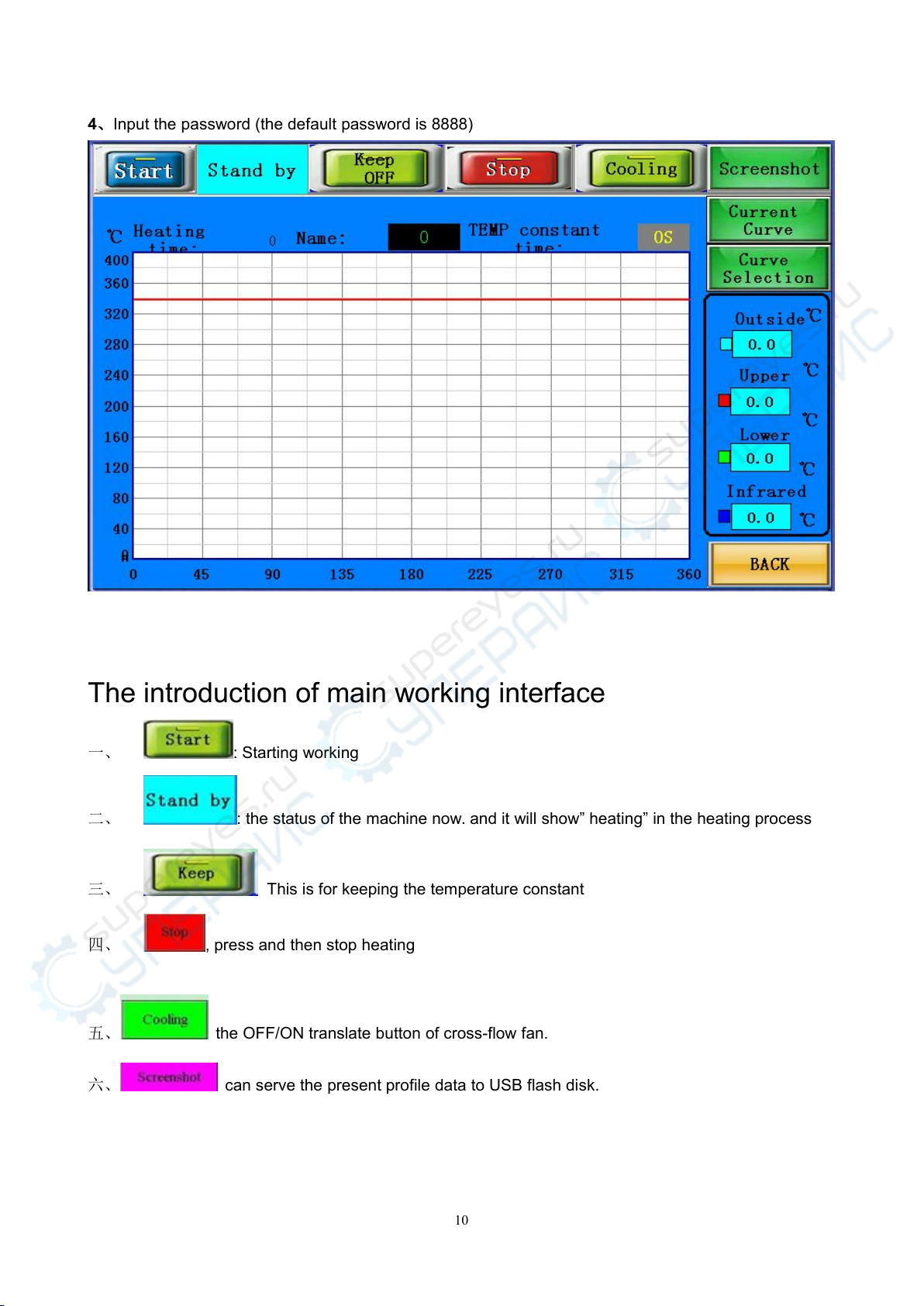

4、Input the password (the default password is 8888)

The introduction of main working interface

一、 : Starting working

二、 : the status of the machine now. and it will show” heating” in the heating process

三、 This is for keeping the temperature constant

四、 , press and then stop heating

五、 the OFF/ON translate button of cross-flow fan.

六、 can serve the present profile data to USB flash disk.

11

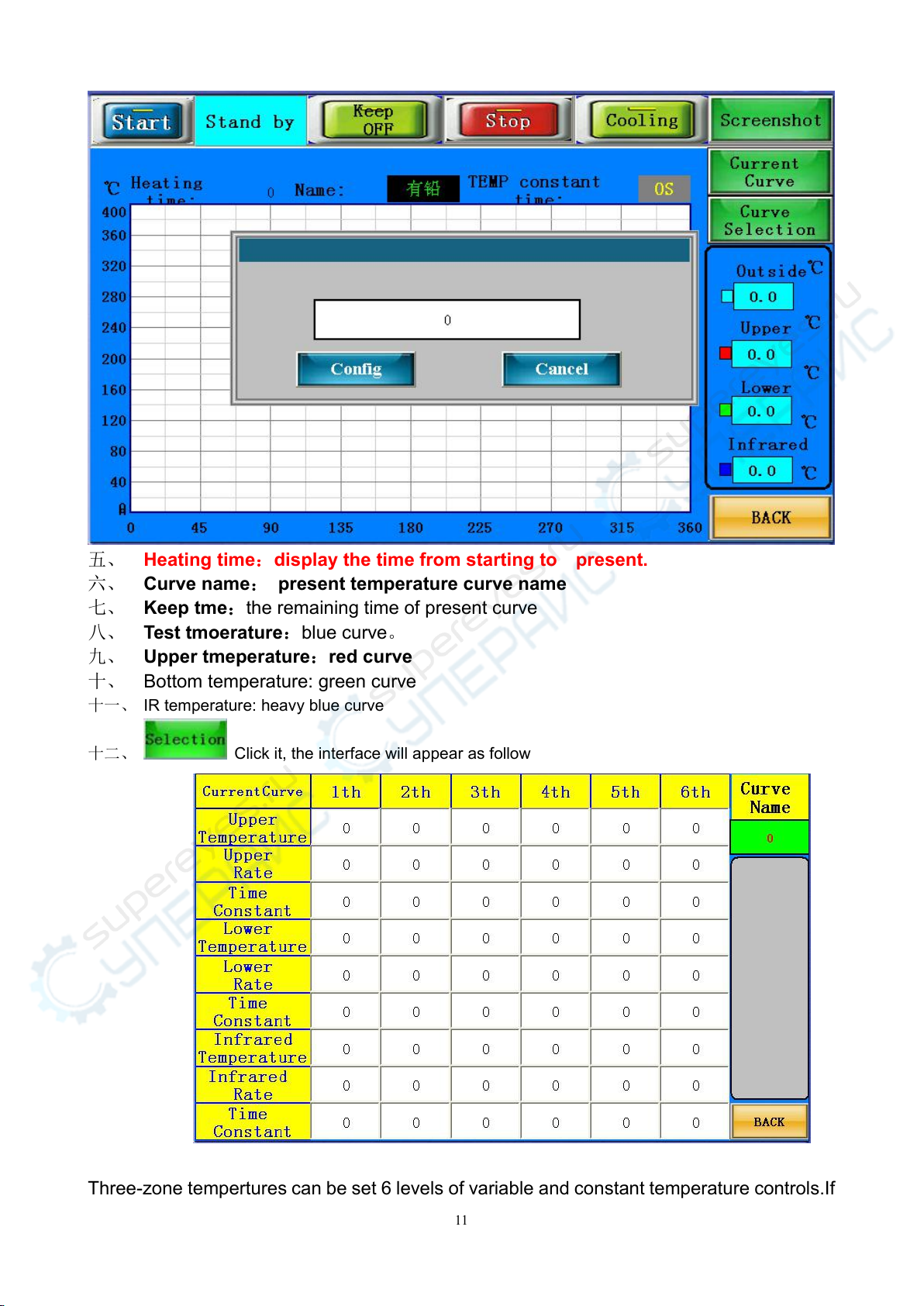

五、 Heating time:display the time from starting to present.

六、 Curve name:present temperature curve name

七、 Keep tme:the remaining time of present curve

八、 Test tmoerature:blue curve。

九、 Upper tmeperature:red curve

十、 Bottom temperature: green curve

十一、 IR temperature: heavy blue curve

十二、 Click it, the interface will appear as follow

Three-zone tempertures can be set 6 levels of variable and constant temperature controls.If

12

need,you can change the related parameters,but it’s not saved,just can heat it with this line.

If saveing is necessary, please refer to relative information of ingredient setting!Ifthe

temperature curve doesn’t meet to the needed welding temperature; please press the

return button, returning to the main Interface.

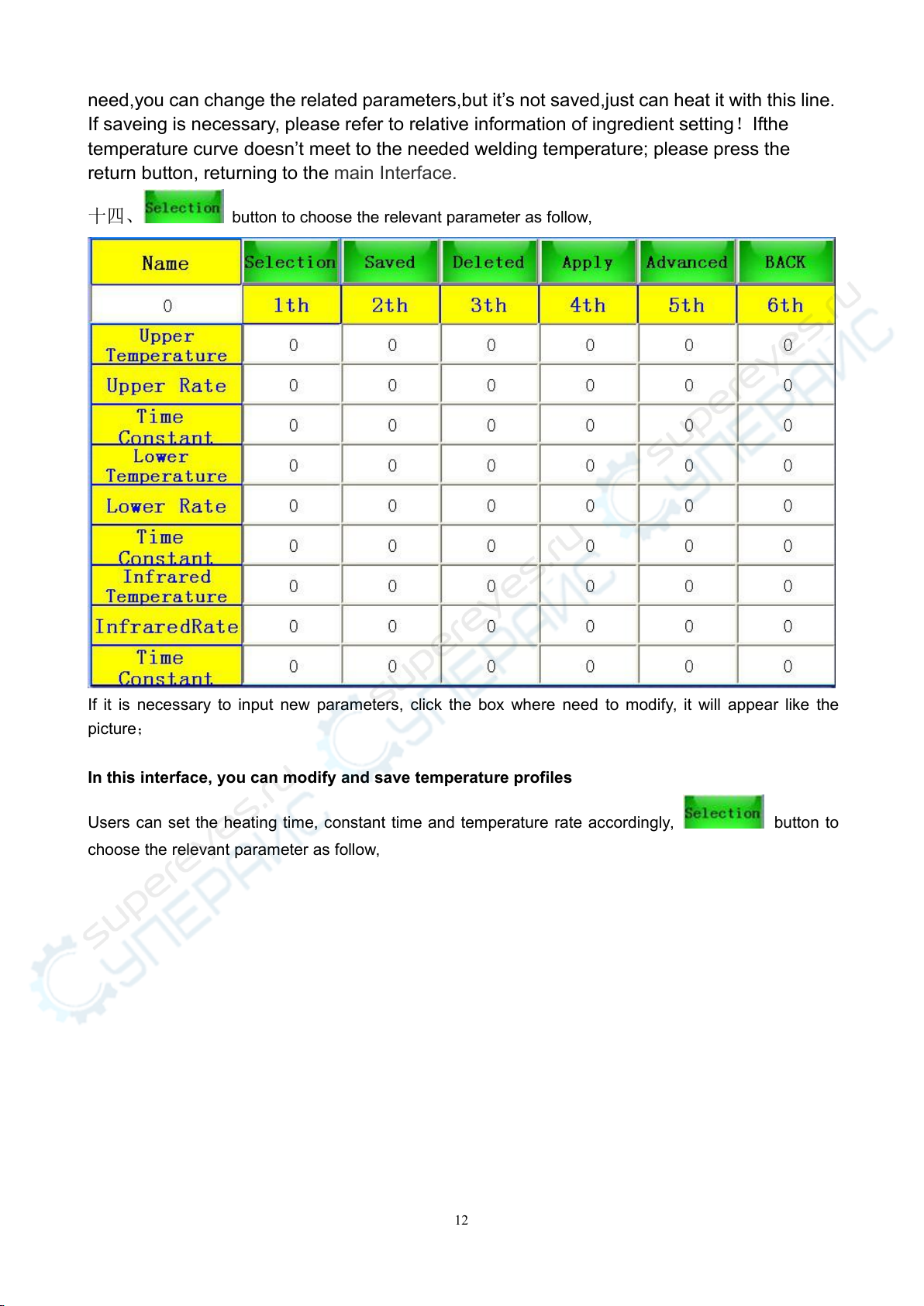

十四、 button to choose the relevant parameter as follow,

If it is necessary to input new parameters, click the box where need to modify, it will appear like the

picture;

In this interface, you can modify and save temperature profiles

Users can set the heating time, constant time and temperature rate accordingly, button to

choose the relevant parameter as follow,

13

If it is necessary to input new parameters, click the box where need to modify, it will appear like the

picture;

Input the parameter, press Then click after setting these three

temperature zones, then these parameters will be saved in the system with the displayed name Besides,

14

you can click the box below to change the curve’s name, the dialogue will appear as

follow

You can also click to modify the curve name

After the profile, click , the curve name and parameters displayed will be the

newest applicable data It will return to the main interface when click button

15

图8

After the profile, click , the curve name and parameters displayed will be the

newest applicable data It will return to the main interface when click button

16

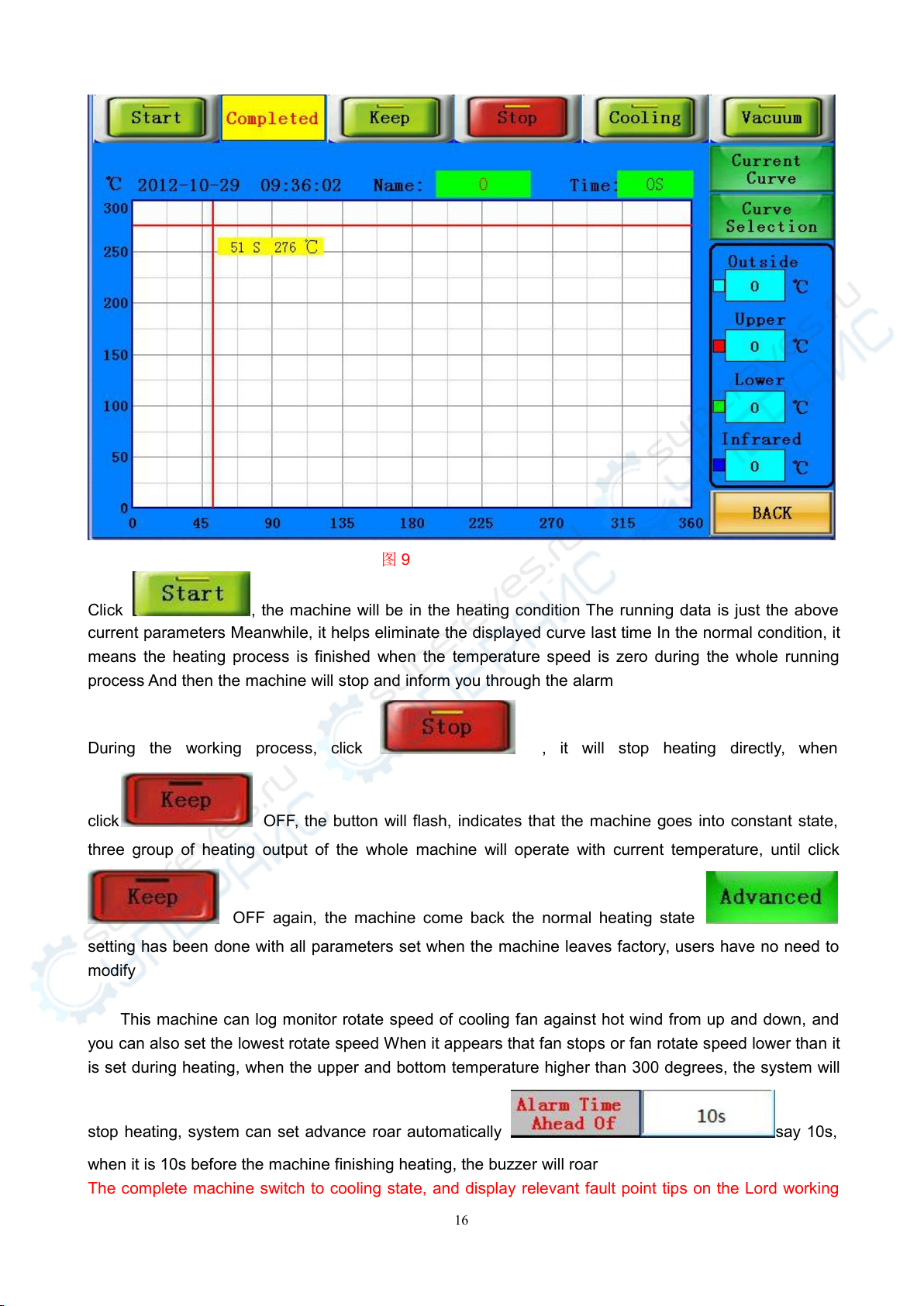

图9

Click , the machine will be in the heating condition The running data is just the above

current parameters Meanwhile, it helps eliminate the displayed curve last time In the normal condition, it

means the heating process is finished when the temperature speed is zero during the whole running

process And then the machine will stop and inform you through the alarm

During the working process, click , it will stop heating directly, when

click OFF, the button will flash, indicates that the machine goes into constant state,

three group of heating output of the whole machine will operate with current temperature, until click

OFF again, the machine come back the normal heating state

setting has been done with all parameters set when the machine leaves factory, users have no need to

modify

This machine can log monitor rotate speed of cooling fan against hot wind from up and down, and

you can also set the lowest rotate speed When it appears that fan stops or fan rotate speed lower than it

is set during heating, when the upper and bottom temperature higher than 300 degrees, the system will

stop heating, system can set advance roar automatically say 10s,

when it is 10s before the machine finishing heating, the buzzer will roar

The complete machine switch to cooling state, and display relevant fault point tips on the Lord working

17

interface, can help workers judge the fault point rapidly

When you click the following picture will appear

Attention:

When it alarm because of stoppage, all function buttons are in locked state! After managing the

stoppage and starting up, it can recover to normal state!

18

六、Operation:

This machine could apply to in soldering and desoldering the BGA chip

1. Preheating:

Preheating before reworking, the temperature of constant temperature oven is set at 80 ℃-100 ℃,

for 4-8 hours to demoist the PCBA ,to prevent the explose during reworking

2. Desoldering

1).Swith the power on , the touch screen will enter the main working interface (picture 5)click

to select the proper profile (If the profile are not suitable, you can set the profile as

mentioned above )

2).Keep the center of upper and bottom heaters in a vertical line when positioning, then fix the PCB clip

Keep the bottom of the nozzle of upper heater 2-3mm above BGA chip Click to run the

, then it will work as you settled After the process finished, raise up the Upper heater,

then take the BGA chip off with vacuum pen The procedure of desoldering is finished

图12

3.Clean-up the pad

You can clean-up the BGA pad with wick line; the best way to dismounting the tin right after the BGA

removed and the temperature difference make less damage to the pad; It can improve the activity of

soldering tin with the flux and is better to clean the soldering tin Pay attention that do not to damage the

PCB pad, and in order to ensure the reliability of BGA solder, try to use some volatile solvents when

cleaning the pad, such as plate washer water, industrial alcohol

4.BGA re-balling

Apply the paste flux evenly with the brush pen on the BGA pad, fix it on the BGA reball fixture, choose the

right stencil, and then plant tin balls properly

5.Soldering BGA balls

After setting the BGA reball station properly, put the reballed BGA chip on it, remove it after the ball is

soldered

6.Apply paste flux

Apply the paste flux with the brush pen on the PCB pad If you apply so much, it will cause connected

welding, on the contrary, it will cause null welding In order to wipe off dust and impurity of tin balls, and

enhance welding effect, the welding paste must be wiped equally

7、Place the BGA chip

Place the BGA chip on the PCB board with manual alignment and silk-screen borders,

meanwhile the tension of the solder joint when melt will have a good self- alignment effect.

19

8.Alignment

1).Turn on the laser, make sure the laser is pointed to the center of the pad for the BGA, put the BGA chip

on the PCB board

2).Select the proper profile, choose the mouting model Then click

3).The upper sucker will goes down to welding position as settled in picture 6 to pick up the

BGA chip, and goes up the Optic position settled in picture 6 ,

4).Pull the optical lens out, the BGA tin ball and welding pad will be displayed on the screen You can

check images of tin balls on the screen through the adjusting angle handle.X axis.Y axis The tin ball and

PCB welding position must be coincide completely on the screen

5).Push the CCD carmera back, the screen will appear like this. Click yes to soldering the chip

9. Soldering

1. Switch on the power, select the proper stored temp profile or set for yourself if needed.

2. Switch on the laser, put the BGA soldering pad center to the laser. Fasten the supporter. Install the

proper nozzle, 2mm-3mm larger than the BGA.

3.install the right nozzle 2mm larger than the BGA chip, click .heating as your

chosen data Cool the BGA chip after the procedure finished Raise the upper heater to make the bottom

of upper heater has 3-5mm distance from the upper surface of BGA chip, and keep cooling for 30-40

seconds Or you can move away the warm heater after the starting light off Then take away the PCB

board from the supporter

(1) Null welding:

Because of counterpoint by hand will cause deviation between chip and welding plate, surface tension of

tin ball will have a process of automatic correction between BGA chip and welding pad Once heating,

BGA falls not evenly, which will cause that the chip drops not evenly It will cause the phenomenon of

missing weld and false weld if stop reflowing at this time, the chip will not fall normally So it is necessary

for you to extend heating time of third .forth temperature zones or add the bottom pre-heating

temperature to make the tin balls meltdown and drop evenly

(2) short-circuiting:

When the ball reached the melting point, it is in a liquid state , if too long or too high temperature and

pressure, it will destroy surface tension of solder balls and the supporting role, resulting in short-circuit

phenomenon when reflows, the chips fall entirely on the PCB pads the , so we need to appropriately

20

reduce the heating section of the third and fourth soldering temperature and time , or reduce the bottom

of the preheat temperature

Attention: It will cause occur odor in the normal working process In order to assure safe and healthy

operation environment, please keep ventilation in and out of the room

七 、 Outer temperature measurement

couple usage

(A)the function of external temperature sensor

a To measure actual temperature more accurately during the welding process

b Because it can move freely, it is more convenient to measure different parts of ready to be measured

component

c It has correct function, which can make the temperature of welding parts is more familiar with the

setting temperature

(B)The installation of couple

a Check that whether the couple line is in good condition

b Put the plug of couple line in the socket of external couple

c After right installation of couple, the touch screen will show the current temperature of couple

(C)Use the couple to measure actual temperature

a Put the PCB board on the BGA Rework station Use tinfoil paper to fix the couple line on the PCB board

b Adjust the detector and make it 1-2mm higher than the ready to be measured parts

c Adjust the position of PCB board so that the ready to be heated parts is under the

upper warm wind nozzle (Like picture sixteen)

d Adjust the adjusting knob of head blow-dryer up and down so that the upper warm wind nozzle is

2-3mm higher than the surface of PCB board

e Choose the touch screen interface (like picture five), click “start”, then the upper heater begin to heat

f Now the screen will show red. light blue.green three curves (Picture seventeen)

The temperature curve of external couple (light blue)

The current temperature curve of internal couple of upper heater (red)

The current temperature curve of internal couple of bottom heater (green)

Table of contents

Other Dinghua Rework Station manuals