Weller WTQB 1000 User manual

Other Weller Rework Station manuals

Weller

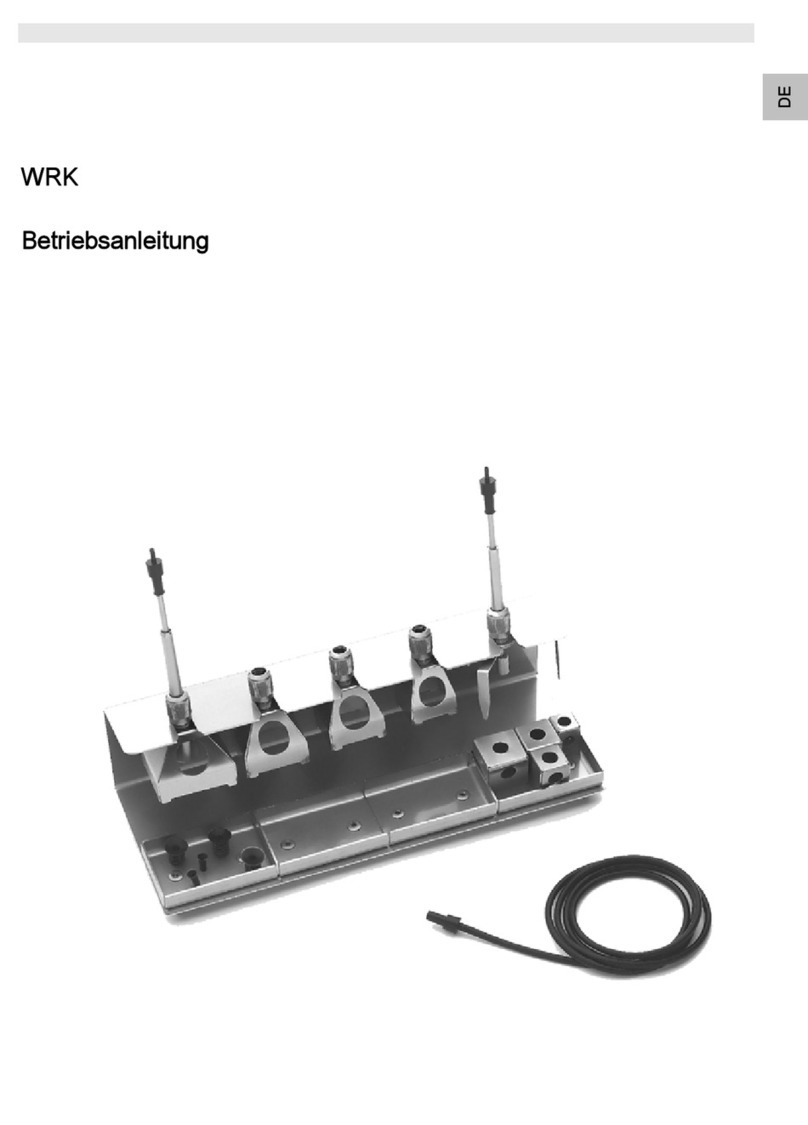

Weller WRK User manual

Weller

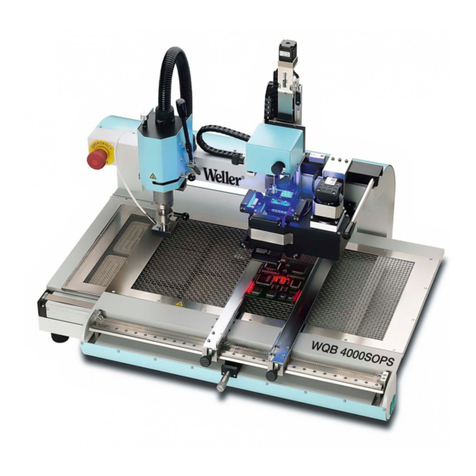

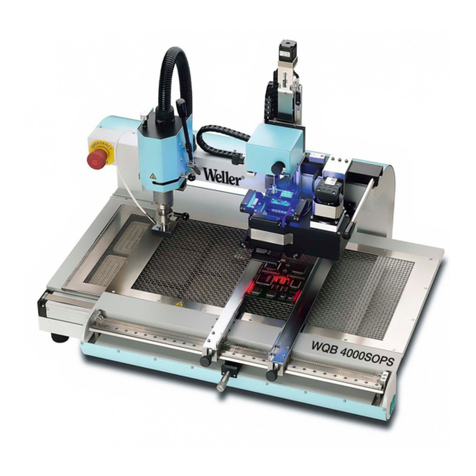

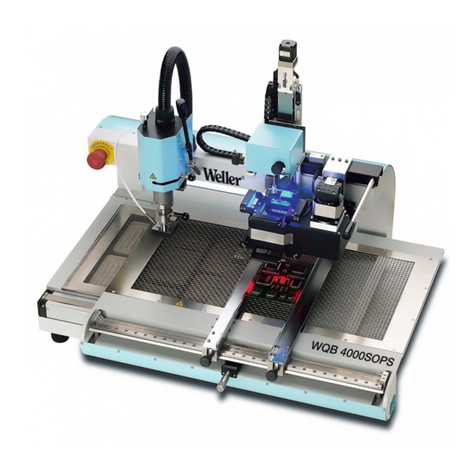

Weller WQB 4000SOPS Operator's manual

Weller

Weller WQB 4000SOPS User manual

Weller

Weller WTHA 1 User manual

Weller

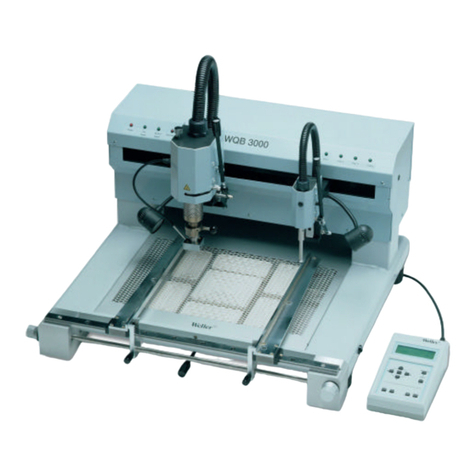

Weller WQB 3000 Safety guide

Weller

Weller WXR 3 User manual

Weller

Weller WQB 4000SOPS User manual

Weller

Weller WXAir User manual

Weller

Weller WXR 3 User manual

Weller

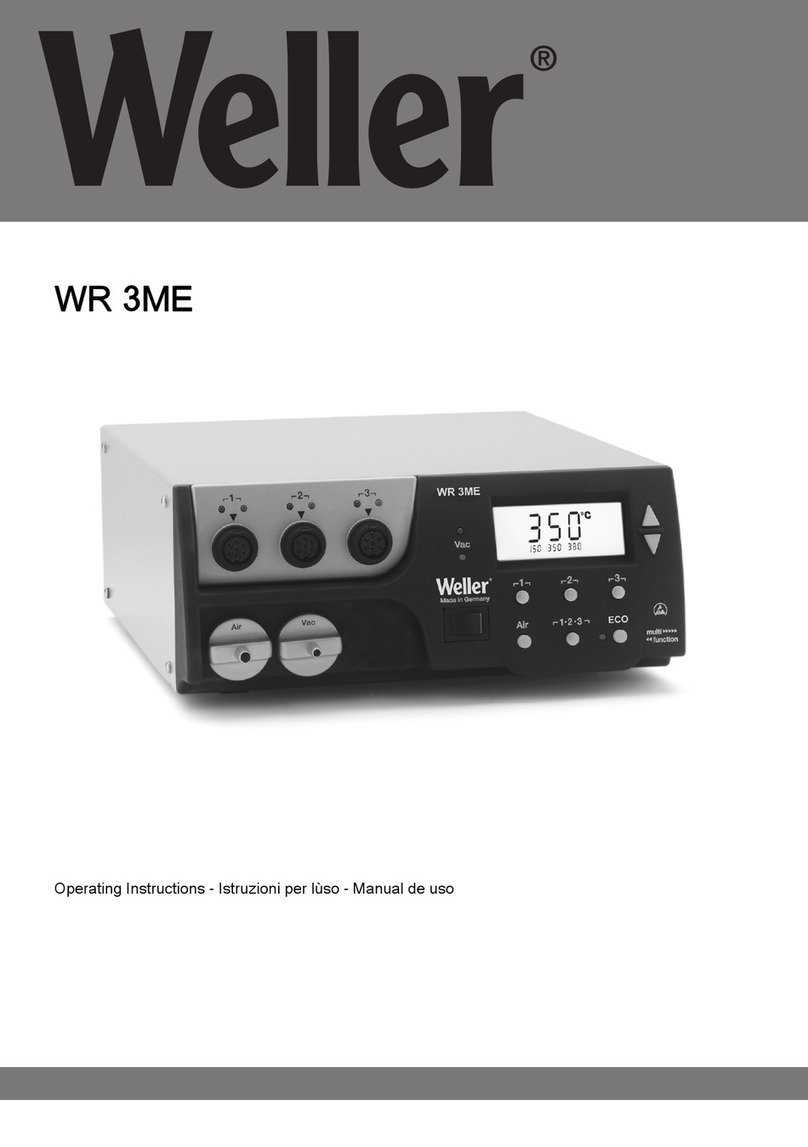

Weller WR 3ME User manual