DINGLI BA22ERT Manual

Part Nu

Rev2.0,

mber: SM

0

Second

E

0

419111

E

dition, De

c

c

embe

r

2

0

0

19 Printin

g

g

Operation & Maintenance Manual Version of the Record

Dingli Machinery

i

Version of the Record

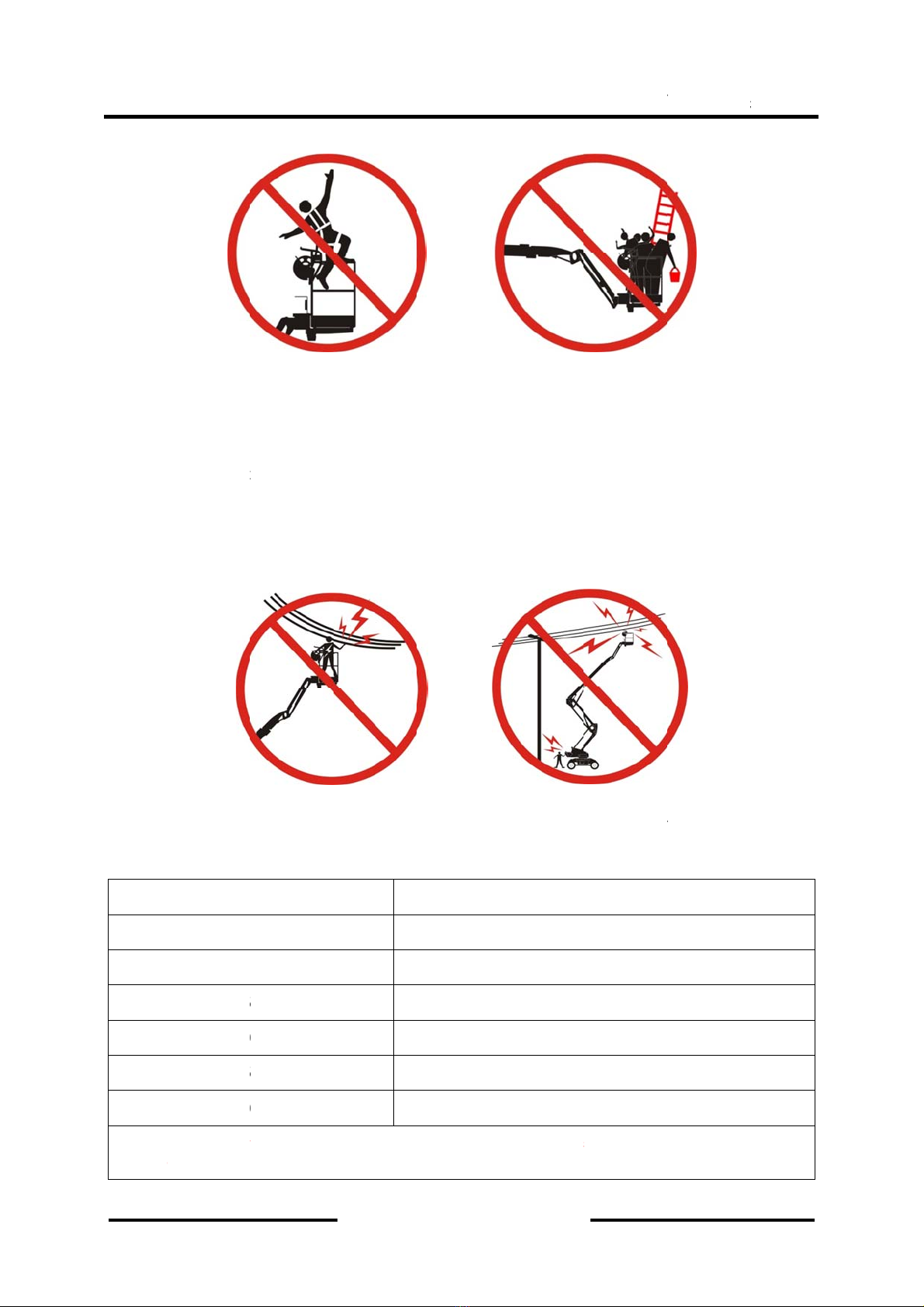

Version Number Create Date Founder Audit

SM0419111_ Rev1.0 September 2019

SM0419111_ Rev1.1 December 2019

SM0419111_ Rev2.0 May 2020

Operation & Maintenance Manual Table of Contents

Dingli Machinery

i

Table of Contents

Foreword.....................................................................................................................................1

Section 1 Safety Precaution

1.1 General..............................................................................................................................1

1.2 Safety Alert Symbols and Safety Signal Words .................................................................1

1.3 Safety Precaution ..............................................................................................................2

1.3.1 Operator Training and Knowledge...........................................................................2

1.3.2 Workplace Inspection ..............................................................................................2

1.3.3 Machine Inspection .................................................................................................3

1.4 Operation...........................................................................................................................3

1.4.1 General ...................................................................................................................3

1.4.2 Trip and Fall Hazards ..............................................................................................4

1.4.3 Electrocution Hazards .............................................................................................5

1.4.4 Tipping Hazards ......................................................................................................6

1.4.5 Crushing and Collision Hazards ..............................................................................8

1.5 Towing, Lifting and Hauling................................................................................................9

1.6 Additional Hazards / Safety ...............................................................................................9

Section 2 Specification

2.1 Machine Specification........................................................................................................1

2.2 Performance Specification.................................................................................................2

2.3 Hydraulic System Specification .........................................................................................4

2.4 Battery Specification..........................................................................................................4

2.5 Bolt Torque Specification ...................................................................................................5

Section 3 User responsibility, Machine Preparation and Inspection

3.1 Personnel Training.............................................................................................................1

3.1.1 Operator Training ....................................................................................................1

3.1.2 Training Supervision................................................................................................1

3.1.3 Operator Responsibility ...........................................................................................1

3.2 Preparation, Inspection and Maintenance .........................................................................2

3.2.1 General ...................................................................................................................2

3.2.2 Preparation for Use .................................................................................................2

3.2.3 Delivery and Frequent Inspection............................................................................3

Table of Contents Operation & Maintenance Manual

Dingli Machinery

ii

3.2.4 Daily Walk - around Inspection................................................................................7

3.2.5 Daily Function Check ............................................................................................ 11

3.3 Oscillating Axle Lockout Test ..........................................................................................14

Section 4 Machine Controls and Indicators

4.1 General..............................................................................................................................1

4.2 Controls and Indicators......................................................................................................1

4.2.1 Ground Control Station............................................................................................1

4.2.2 Platform Control Station ..........................................................................................7

4.2.3 Analysis Panel .......................................................................................................12

4.2.4 Indicator Panel ......................................................................................................16

4.3 Tilt Alarm Warning ...........................................................................................................17

4.4 Footswitch/Enable Indicator ............................................................................................18

4.5 Charger ...........................................................................................................................18

4.6 Placards and Decals........................................................................................................19

Section 5 Operation Instruction

5.1 Description ........................................................................................................................1

5.2 Operating Characteristics and Limitations .........................................................................2

5.3 Traveling (Driving) Operation.............................................................................................5

5.4 Steering Operation ............................................................................................................5

5.5 Platform Operation ............................................................................................................6

5.6 Turret Swinging Operation.................................................................................................6

5.7 Boom Operation ................................................................................................................7

5.8 Auxiliary Pump Operation ..................................................................................................8

5.9 Jib Operation .....................................................................................................................9

5.10 Oscillating Axle Lockout Test ...........................................................................................9

5.11 Shut Down and Parking .................................................................................................10

5.12 Lifting and Tie Down ......................................................................................................10

5.13 Towing Operation...........................................................................................................12

Section 6 Emergency Procedures

6.1 General..............................................................................................................................1

6.2 Emergency Towing Procedures ........................................................................................1

6.3 Emergency Controls and Their Locations..........................................................................1

6.3.1 Power/Emergency Stop Switches ...........................................................................1

6.3.2 Ground Control Station............................................................................................1

Operation & Maintenance Manual Table of Contents

Dingli Machinery

iii

6.3.3 Auxiliary Power Switch ............................................................................................1

6.4 Emergency Operation........................................................................................................2

6.4.1 Use of Ground Controls...........................................................................................2

6.4.2 Operator Unable to Control Machine.......................................................................2

6.4.3 Platform or Boom Caught Overhead .......................................................................2

6.4.4 Post Incident Inspection and Repair........................................................................2

6.4.5 Emergency Stowing ................................................................................................2

6.5 Incident Notification ...........................................................................................................3

Section 7 General Maintenance

7.1 General..............................................................................................................................1

7.2 Lubrication Specification....................................................................................................1

7.3 Lubrication Diagram ..........................................................................................................1

7.4 Operator Maintenance.......................................................................................................3

7.4.1 Axles........................................................................................................................3

7.4.2 Rotation slewing ring gear and rotation reduction gear - lubrication........................5

7.4.3 Checking and replacement of hydraulic fluid...........................................................9

7.4.4 Hydraulic fluid filter-replacement ........................................................................... 11

7.4.5 Battery Maintenance .............................................................................................13

7.4.6 Tires & Wheels Maintenance.................................................................................14

7.4.7 Overload Sensor - checking and calibration..........................................................16

7.4.8 Telescopic boom sliding blocks .............................................................................17

Section 8 Schematics

8.1 General..............................................................................................................................1

8.2 Troubleshooting.................................................................................................................1

8.3 Hydraulic Circuit Checks ...................................................................................................1

8.3.1 Hydraulic Schematics..............................................................................................2

8.3.2 Electric Schematics .................................................................................................3

Section 9 Inspection and Repair Log

9.1 Inspection and Repair Log.................................................................................................1

Operation & Maintenance Manual Foreword

Dingli Machinery

1

Foreword

We are very appreciated for your interesting with Dingli machine and choosing it for your

application. Our priority above all is you can use the machine safely for your application and you

can benefit from the Dingli machine mostly. For these reason we hope you can:

1.Comply with employer, job site and local governmental rules.

2.The manual provides very important information about the machine. It is essential to the

owner or the operator who use the machine. So we strongly recommend that you should read

the manual thoroughly before attempting to do anything with the machine, so as to

understand and follow the instruction or other information in the manual, especially the safety

information.

3.Dingli cannot anticipate every possible circumstance that might involve a potential hazard.

The warnings in this publication and on the product are, therefore, not all inclusive. If a tool,

procedure, work method or operating technique that is not specifically recommended by Dingli

is used, you must satisfy yourself that it is safe for you and for others. You should also ensure

that the product will not be damaged or be made unsafe by the operation, lubrication,

maintenance or repair procedure that you choose.

4.The information, specifications, and illustrations in this publication are on the basis of

information that was available at the time that the publication was written. Due to the

continuous improvements, Dingli reserve the rights to make the specifications changes

without prior notification. Please contact with Dingli dealers or Dingli distributors to obtain the

complete and most current information.

5.Any one who read the manual or used the machine, is encouraged to notify Dingli Machinery

Co, Ltd of any errors or send in suggestions for improvement. All communications will be

carefully considered for future printings of this and other manuals, certainly if you have any

question about the machine, please contact with our team by dialing technical support phone,

sending email, or any methods you want, etc. Our contact information as bellow:

If you are in China Mainland, Please contact with:

Zhejiang Dingli Machinery Co.,Ltd. Domestic Office:

Phone: +86 572 8681766

Fax: +86 572 8681700

Email: [email protected]

If you are out of the China Mainland, Please contact with:

Zhejiang Dingli Machinery Co.,Ltd. International Office:

Phone: +86 572 8681688

Fax: +86 572 8681690

Email: [email protected]

Oper

a

Saf

e

1.1 G

e

This se

c

to prom

o

on instr

u

qualifie

d

The ow

n

manual

experie

n

operati

o

Most a

c

observ

e

potenti

a

hazard

s

function

Improp

e

result in

product

,

informa

t

1.2 S

a

This Sa

f

warning

hazard

s

DANG

E

empha

s

Indicate

SERIO

U

a

tion &

M

e

ty Pre

c

e

neral

c

tion prescri

o

te proper

u

u

ctions give

d

person an

d

n

er/user/op

e

has been r

e

n

ced and q

u

o

n, Dingli M

a

c

cidents tha

t

e

basic safe

t

a

lly hazardo

u

s

. This pers

o

s properly.

e

r operation

,

injury or d

e

,

until you h

a

t

ion.

a

fety Ale

f

ety Alert S

y

s are not h

e

s

are identifi

e

E

R, WARNI

N

s

ize these a

r

an IMMIN

U

S INJURY

M

aintena

n

c

autio

n

bes the pro

p

u

sage of the

n in this se

c

d

must be f

o

e

rator of the

e

ad and un

d

u

alified pers

o

a

chinery Co

t

involve pro

t

y rules or p

r

u

s situation

s

o

n should al

s

,

lubrication

,

e

ath. Do not

a

ve read an

rt Symb

o

y

mbol is us

e

e

eded, bodil

y

e

d by the “

S

N

G” or CAU

T

r

eas. They

a

ENTLY HA

Z

or DEATH.

T

n

ce Man

u

Din

g

n

p

er and saf

e

machine, it

c

tion. A mai

n

o

llowed to e

n

machine s

h

erstood, an

d

o

n, has bee

n

.,Ltd. shoul

d

duct operat

i

r

ecautions.

A

s

before an

a

s

o have the

maintenan

c

operate or

p

d understo

o

o

ls and

S

e

d to call att

e

y

injury or d

S

afety Alert

S

T

ION, whic

h

a

re defined

a

Z

ARDOUS

T

his decal

w

u

al

g

li Mach

e

practices

f

t

is mandat

o

n

tenance pr

o

n

sure that t

h

h

ould not a

c

d operation

n complete

d

d

be consul

t

i

on, mainte

n

A

n accident

a

ccident oc

c

necessary

t

c

e or repair

p

erform an

y

o

d the oper

a

S

afety S

e

ntion to P

O

eath could

o

S

ymbol” an

d

h

have been

a

s follows:

SITUATIO

N

w

ill have a r

e

Sec

t

inery

f

or major ar

e

o

ry that a da

i

o

gram must

h

e machine

c

cept operat

of the mac

h

d

. If there is

ed.

n

ance and r

e

can often

b

c

urs. A pers

o

t

raining, ski

l

of this prod

u

y

lubrication

,

a

tion, lubric

a

ignal W

o

O

TENTIAL

H

o

ccur to yo

u

d

followed b

y

inserted th

r

N

, which if

n

e

d backgro

u

t

ion1-Saf

e

e

as of mach

i

ly routine b

e

also be est

a

is safe to o

p

i

ng respons

h

ine, under

t

a

question

o

e

pair are ca

e avoided

b

o

n must be

ls, and tool

s

u

ct can be

d

maintenan

c

a

tion, and m

a

o

rds

H

AZARDS, i

f

or to other

y

a “Signal

W

r

oughout thi

s

n

ot avoided

u

nd

f

ety Pre

c

h

ine usage.

I

e

establish

e

a

blished by

p

erate.

ibility until t

h

t

he supervi

s

o

n applicati

o

used by fail

b

y recognizi

n

alerted to p

o

s

to perform

d

angerous

a

c

e or repair

aintenance

f

these haz

a

persons. T

h

W

ord” such

s manual t

o

d

, WILL RE

S

Sec

t

1

c

aution

1-1

I

n order

e

d based

a

h

is

s

ion of an

o

n and/or

u

re to

n

g

o

tential

these

a

nd could

on this

& repair

a

rd

h

e

as

o

S

ULT IN

ion

Secti

o

1-2

Indicate

SERIO

U

Indicate

modera

t

Indicate

this dec

a

1.3 S

a

F

A

LI

S

D

A

D

E

1.3.1

O

Re

a

Re

a

ins

t

Do

aut

h

Us

e

All

o

op

e

Re

a

the

y

Re

a

1.3.2

W

Th

e

op

e

Do

o

n1-Safe

a potential

U

S INJURY

a potential

l

t

e INJURY.

T

a potential

al have a bl

a

fety Pr

e

A

ILURE TO

S

TED IN T

H

A

MAGE, P

R

E

ATH.

O

perator

T

a

d and und

e

a

d, unde

r

st

a

t

ructions on

not operate

h

orized and

e

the machi

n

o

perating p

e

e

ration of th

e

a

d, underst

a

y

pertain to

a

d, underst

a

W

orkplace

e

operator i

s

e

ration.

not operate

ty Preca

u

ly HAZAR

D

OR DEATH

l

y HAZARD

T

his decal

w

ly hazardou

ue backgro

u

e

caution

COMPLY

W

H

IS MANU

A

R

OPERTY

D

T

raining a

n

e

rstand this

a

nd, and ob

e

the machin

e

this machi

n

qualified p

e

n

e in a man

n

e

rsonnel m

u

e

machine

a

a

nd, and ob

e

operation o

f

a

nd, and ob

e

Inspecti

o

s

to take saf

e

or raise th

e

u

tion

Din

g

D

OUS SITU

A

. This decal

OUS SITU

A

w

ill have a y

e

s situation,

u

nd.

W

ITH THE

S

A

L COULD

R

D

AMAGE,

P

n

d Knowl

e

manual bef

o

e

y all DAN

G

e

and in thi

s

n

e until com

p

e

rsonnel ca

n

n

er which is

u

st be famili

a

a

s specified

e

y all applic

a

f

the machi

n

e

y national

t

o

n

e

ty measur

e

e

platform w

h

Op

g

li Mach

A

TION, whi

will have a

n

A

TION, whi

c

e

llow back

g

which if no

t

S

AFETY PR

E

R

ESULT IN

P

ERSONAL

e

dge

o

re operati

n

G

ERS, WA

R

s

manual.

plete trainin

n

operate th

s

within the

s

a

r with the

e

in this man

u

able emplo

y

n

e.

t

raffic regul

a

e

s to avoid

a

hile on truc

k

eration

&

inery

c

h if not b

e

n

orange ba

c

h if not av

o

round.

t

avoided,

c

E

CAUTIO

N

MACHINE

INJURY O

R

g the mach

i

R

NINGS, C

A

g is perfor

m

e machine.

s

cope of its

e

mergency

c

u

al.

y

er, local, a

n

a

tions.

a

ll hazards i

n

k

s, trailers,

r

&

Maint

e

e

en avoided

ckground.

o

ided, may

R

ould result

i

N

S

R

ne.

A

UTIONS, a

n

m

ed by auth

o

i

ntended ap

c

ontrols and

n

d governm

e

n

the work

a

r

ailway cars

,

e

nance

M

, Could RE

R

ESULT IN

in property

nd operatin

g

o

rized pers

o

p

plication.

emergenc

y

e

ntal regula

t

a

rea prior to

,

floating ve

s

M

anual

SULT IN

minor or

damage,

g

o

ns. Only

y

t

ions as

machine

s

sels,

Oper

a

sc

a

Do

Din

Be

de

c

Thi

s

out

s

1.3.3

M

Be

f

thi

s

Do

req

Be

the

s

M

O

W

O

W

R

M

A

Do

pla

c

Av

o

mu

d

foo

t

1.4 O

p

1.4.1

G

Do

eq

u

Ne

v

ma

c

Ne

v

swi

t

slo

w

ret

r

Do

a

tion &

M

a

ffolds or ot

h

not operate

gli.

sure that th

e

c

als located

s

machine

c

s

ide this ra

n

M

achine I

n

f

ore machin

e

s

manual for

not operate

uirements s

sure the fo

o

s

e devices i

O

DIFICATIO

N

O

RK PLAT

F

R

ITTEN PE

R

A

NUFACTU

R

not operate

c

ards or de

c

o

id any buil

d

d

, oil, greas

e

t

wear and p

p

eration

G

eneral

not use the

u

ipment.

v

er operate

c

hine for tr

o

v

er slam a

c

t

ch to neutr

a

w

and even

r

acted befor

e

not allow p

e

M

aintena

n

h

er equipm

e

the machin

e

ground c

o

on the mac

h

c

an be oper

a

n

ge.

n

spection

e

operation,

detailed in

s

this machi

n

pecified by

t

o

tswitch and

s a safety v

N

OR ALT

E

F

ORM SHA

L

R

MISSION

F

R

E

R

.

any machi

n

c

als are mis

s

d

up of debri

s

e

, and othe

r

latform floo

r

machine fo

a machine

t

o

ubleshootin

c

ontrol switc

a

l and stop

b

pressure.

H

e

shutdown

e

rsonnel to

t

n

ce Man

u

Din

g

nt.

e in hazard

o

o

nditions ar

e

h

ine.

a

ted in tem

p

perform in

s

s

tructions.

n

e until it ha

s

t

he manufa

c

all other s

a

i

olation.

E

RATION O

F

L

L BE MAD

E

F

ROM THE

n

e on which

s

ing or illeg

i

s

on the pla

t

r

slippery s

u

r

.

r

any purpo

s

t

hat is not w

g.

h

or lever t

h

b

efore movi

n

H

ydraulic cyl

i

or for long

p

t

amper with

u

al

g

li Mach

o

us environ

e

able to su

p

p

eratures of

s

pections a

n

s

been ser

v

c

ture.

a

fety device

s

F

AN AERI

A

E

ONLY WI

safety or in

s

i

ble.

t

form floor.

K

u

bstances fr

o

s

e other th

a

w

orking prop

e

h

rough neut

r

n

g the swit

c

inders shou

p

eriods of ti

m

or operate

t

Sec

t

inery

ments unle

s

p

port the m

a

-20℃to 4

0

n

d functiona

iced and m

a

s

are operat

A

L

TH

s

truction

K

eep

o

m

a

n positionin

e

rly. If a ma

l

r

al to an op

p

c

h to the ne

x

ld never be

m

e.

t

he machin

e

t

ion1-Saf

e

s

s approved

a

ximum load

0

℃. Consult

l

checks. R

e

a

intained ac

ing properl

y

g

personnel

l

function oc

c

p

osite direct

i

x

t function.

O

left fully ext

e

e

from the g

r

f

ety Pre

c

for that pu

r

d

shown on

t

Dingli for o

e

fer to Sect

i

c

cording to

y

. Modificati

o

l

, their tools

,

c

urs, shut d

o

ion. Always

O

perate con

t

t

ended or fu

r

ound with

p

c

aution

1-3

r

pose by

t

he

p

eration

i

on 3 of

o

n of

,

and

o

wn the

return

t

rols with

l

ly

ersonnel

Secti

o

1-4

in t

h

Do

Wh

ma

c

Al

w

the

Su

p

Wh

Re

m

Do

Onl

Do

str

u

Sto

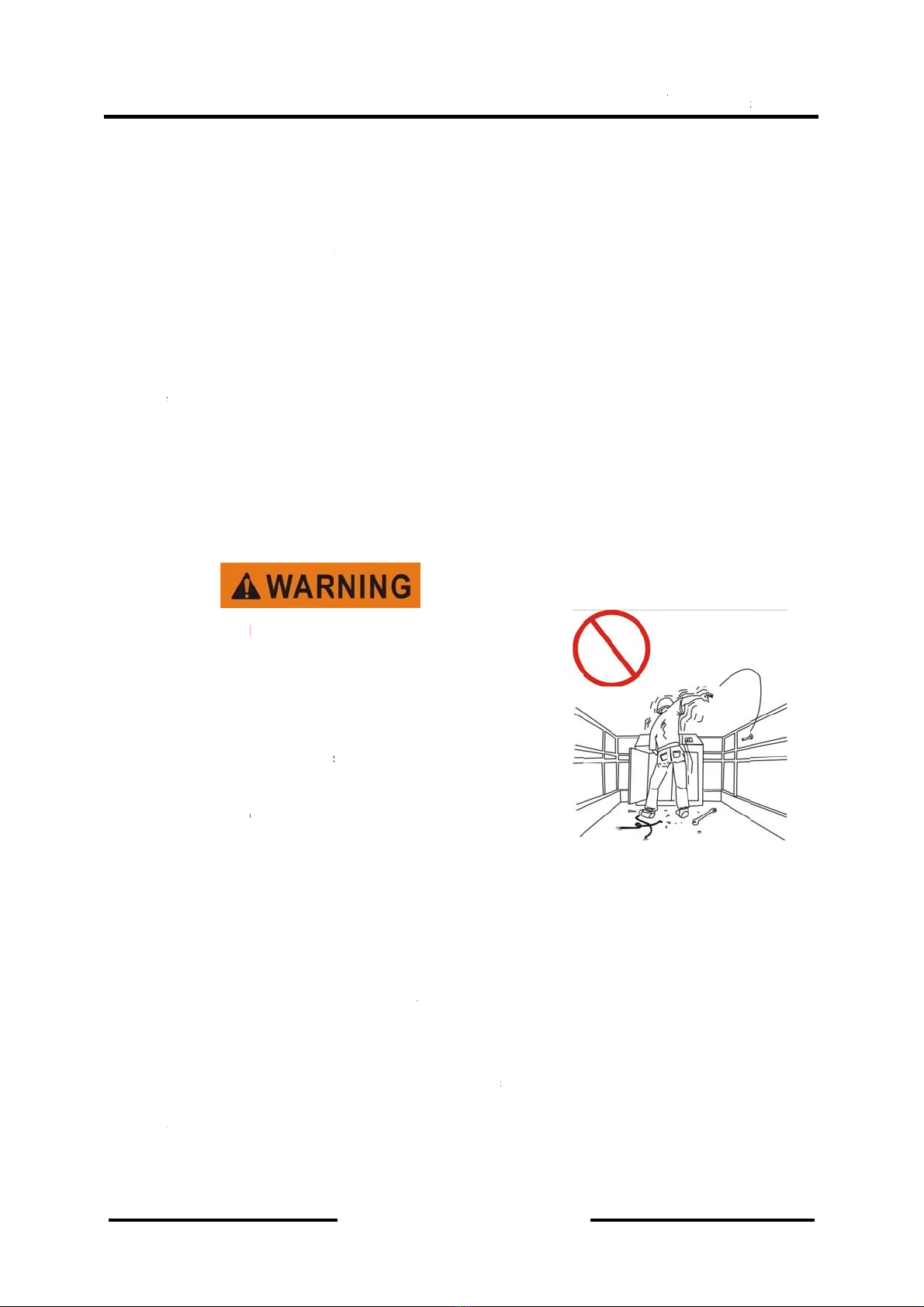

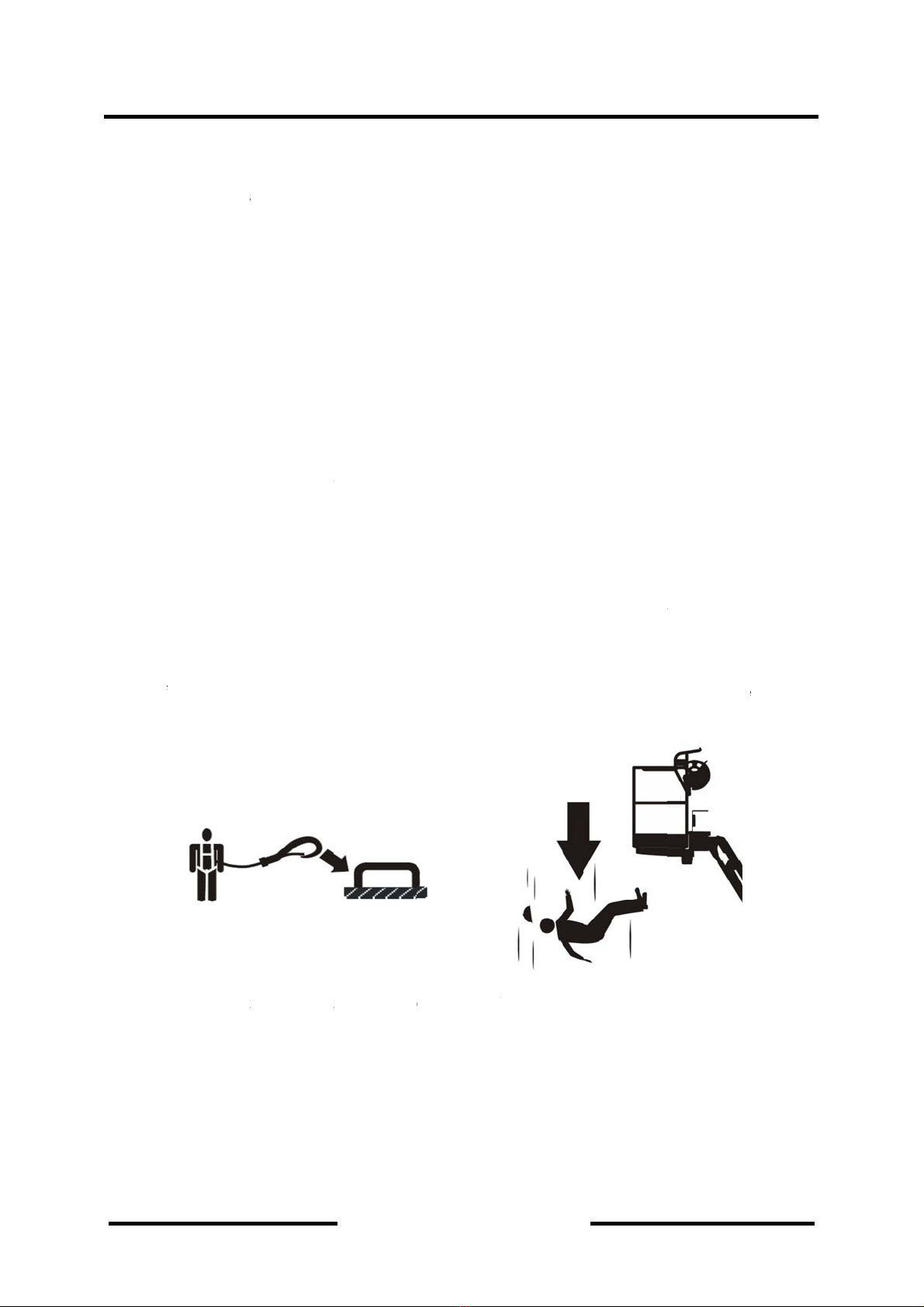

1.4.2

T

Du

r

att

a

an

c

Be

f

po

s

Ke

e

ste

p

o

n1-Safe

h

e platform,

not carry m

a

en two or

m

c

hine opera

w

ays ensure

platform w

o

p

plies or to

o

en driving,

a

m

ember, if

b

not assist a

l

y pull the u

n

not place b

o

u

cture.

w boom an

d

T

rip and F

a

r

ing operati

o

a

ched to an

c

horage poi

n

f

ore operati

n

s

ition

.

e

p both fee

t

p

s, planks,

o

ty Preca

u

except in a

a

terials dire

m

ore person

s

tions.

that power

o

rk area.

o

ls which ex

t

a

lways posi

t

b

oom is ove

r

stuck or di

s

n

it from the

t

o

om or plat

f

d

shut off all

a

ll Hazard

o

n, occupa

n

authorized

n

t.

n

g the mac

h

t

firmly posi

t

o

r similar it

e

u

tion

Din

g

n emergen

c

ctly on platf

o

s

are in the

p

tools are pr

o

t

end outsid

e

t

ion boom o

v

r

the front a

x

s

abled mac

h

t

ie-down lu

g

f

orm agains

t

power bef

o

s

n

ts in the p

l

lanyard an

c

h

ine, make

t

ioned on th

e

ms on platf

o

Op

g

li Mach

c

y.

o

rm railing.

p

latform, th

e

o

perly stow

e

e

the platfor

m

v

er rear axl

e

x

le, steer a

n

h

ine by pus

h

g

s on the ch

t

any struct

u

o

re leaving

m

latform mu

s

c

horage poi

sure all ga

t

e platform

f

o

rm to provi

eration

&

inery

e

operator s

e

d and nev

e

m

are prohi

b

e

in line wit

h

n

d drive fun

c

h

ing, pulling

assis.

u

re to stead

y

m

achine.

s

t wear a f

u

nt. Attach

o

t

es are clos

f

loor at all ti

m

de addition

a

&

Maint

e

hall be resp

e

r left hangi

n

b

ited unless

h

the directi

o

c

tions will b

e

,

or by usin

g

y

the platfor

m

u

ll body har

o

nly one (1)

e

d and fast

m

es. Never

a

l reach.

e

nance

M

p

onsible for

a

n

g by their

c

approved.

o

n of travel.

e

reversed.

g

boom fun

c

m

or to sup

p

r

ness with

a

lanyard pe

r

t

ened in th

e

use ladder

s

M

anual

a

ll

c

ord from

c

tions.

p

ort the

a

lanyard

r

lanyard

e

ir proper

s

, boxes,

Oper

a

Ne

v

Us

e

It

m

Fa

c

foo

t

1.4.3

E

Thi

s

ele

c

Ma

i

par

t

V

oltag

e

0 to 50

Over 5

0

Over 2

0

Over 3

5

Over 5

0

Over 7

5

NOTE:

are m

o

a

tion &

M

v

er use the

b

e

extreme c

a

m

ay be nece

s

c

e the mach

t

or two fee

t

E

lectrocut

i

s

machine

i

c

trical curre

n

i

ntain dista

n

t

s accordin

g

T

e

Range (P

KV

0

KV to 200

0

0 KV to 3

5

5

0 KV to 5

0

0

0 KV to 7

5

5

0 KV to 1

0

This requi

r

o

re stringent

M

aintena

n

b

oom asse

m

a

ution when

s

sary to tel

e

ine, maintai

t

and one h

a

i

on Hazar

d

i

s not insul

a

n

t.

n

ce from el

e

g

to the Mini

T

able 1-1.

hase to Ph

a

KV

5

0 KV

0

0 KV

5

0 KV

0

00 KV

r

ement shall

.

n

ce Man

u

Din

g

m

bly to ente

entering or

e

scope out t

o

n “three poi

a

nd during e

d

s

a

ted and d

o

e

ctrical line

s

mum Appro

Minimum

a

se) M

I

1

0

1

5

2

0

2

5

3

5

4

5

apply exc

e

u

al

g

li Mach

r or leave t

h

leaving pla

t

o

position t

h

nt contact”

w

e

ntry and ex

i

o

es not pro

v

s

, apparatu

s

ach Distan

c

Approac

h

INIMUM A

P

0

(3)

5

(5)

0

(6)

5

(8)

5

(11)

5

(14)

e

pt where e

m

Sec

t

inery

h

e platform.

t

form. Be s

u

e platform

c

w

ith the ma

c

i

t.

v

ide protecti

s

, or any e

n

c

e (MAD) a

s

h

Distanc

e

P

PROACH

D

m

ployer, lo

c

t

ion1-Saf

e

re that the

b

c

loser to the

c

hine, usin

g

on from co

n

n

ergized (e

x

shown in T

a

e

s (M.A.D

.

D

ISTANCE i

c

al or gover

n

f

ety Pre

c

b

oom is full

y

ground for

e

g

two hands

n

tact or pr

o

x

posed or i

n

Ta

ble 1.1

.)

i

n Feet (Me

t

n

mental reg

c

aution

1-5

y

lowered.

e

ntry/exit.

and one

o

ximity to

n

sulated)

t

ers)

ulations

Secti

o

1-6

All

o

Ma

i

the

i

vol

t

Th

e

co

n

sh

a

red

det

e

go

v

1.4.4

T

Th

e

slo

p

Do

sur

f

Be

f

sur

f

Ne

v

o

n1-Safe

o

w for mach

i

ntain a cle

a

i

r tools, an

d

t

s. One foot

e

minimum

a

n

tact, and t

h

a

ll not be p

a

uced to a d

e

rmination

s

v

ernmental

r

DO NOT

M

ZONE (M

A

ENERGIZ

E

T

ipping H

a

e

user shoul

p

e and grad

not elevate

f

ace.

f

ore driving

o

f

aces.

v

er exceed

t

ty Preca

u

ine movem

e

a

rance of at

l

d

their equi

p

additional

c

a

pproach di

s

h

e barriers

a

a

rt of (or att

a

istance wit

h

s

hall be ma

d

r

equirement

s

M

ANEUVE

R

A

D). ASSU

M

E

D UNLES

S

a

zards

d be familia

e while driv

i

platform or

o

n floors, b

r

t

he maximu

m

u

tion

Din

g

e

nt and ele

c

l

east 10 ft. (

3

p

ment from

c

learance is

s

tance may

a

re rated fo

r

a

ched to) t

h

h

in the desi

g

d

e by a qua

s

for work p

R

MACHIN

E

M

E ALL EL

E

S

KNOWN

O

r with the s

u

i

ng.

drive with p

idges, truck

m

platform

c

Op

g

li Mach

c

trical line s

w

3m) betwe

e

any electri

c

required fo

r

be reduced

r

the voltag

e

h

e machine

.

g

ned worki

n

a

lified perso

n

ractices ne

a

E

OR PERS

O

E

CTRICAL

P

O

THERWI

S

u

rface befor

e

latform ele

v

k

s, and othe

r

c

apacity. Di

s

eration

&

inery

w

aying.

e

n any part

o

c

al line or

a

r

every addi

t

if insulatin

g

e

of the lin

e

.

The mini

m

n

g dimensio

n

n

in accord

a

a

r energize

d

O

NNEL INS

P

ARTS AN

D

S

E.

e

driving. D

o

v

ated while

o

r

surfaces,

c

s

tribute loa

d

&

Maint

e

o

f the machi

n

pparatus c

a

t

ional 30,00

0

barriers ar

e

e

being gua

r

m

um approa

c

n

s of the in

s

a

nce with th

e

d

equipment

I

DE PROHI

B

D

WIRING I

S

o

not excee

d

o

n a sloping

c

heck allow

a

s evenly on

e

nance

M

n

e and its o

c

a

rrying up t

o

0

volts or le

s

e

installed t

o

r

ded. Thes

e

c

h distance

s

ulating ba

r

e

employer,

.

I

BITED

S

d

the allow

a

, uneven, o

r

a

ble capacit

y

platform fl

o

M

anual

c

cupants,

o

50,000

s

s.

o

prevent

e

barriers

shall be

rier. This

local, or

a

ble side

r

soft

y

of the

o

or.

Oper

a

Do

lev

e

Ke

e

ob

s

Do

Ne

v

Do

Do

Do

Do

If b

o

per

s

tru

c

a

tion &

M

not raise th

e

e

l and smo

o

e

p the chas

s

s

tructions, d

e

not push or

v

er attempt

t

not tie off

m

not operate

not make a

n

not increas

e

o

om assem

s

ons must

b

c

ks, or othe

r

M

aintena

n

e

platform

o

o

th surfaces

.

s

is of the m

a

e

bris, conc

e

pull any ob

j

t

o use the

m

m

achine to a

n

the machin

n

y addition

t

e

the platfo

r

bly or platfo

b

e removed

r

appropriat

e

n

ce Man

u

Din

g

o

r drive from

.

a

chine at le

a

e

aled holes,

j

ect with th

e

m

achine as

a

n

y adjacent

e when win

d

t

hat would i

n

m size with

rm is in a p

o

before atte

m

e

equipmen

t

u

al

g

li Mach

an elevate

d

a

st 2 ft. (0.6

and other

p

e

boom.

a

crane.

structure.

d

condition

s

n

crease the

unauthoriz

e

o

sition that

o

m

pting to st

a

t

to stabilize

Sec

t

inery

d

position u

n

m) from hol

e

p

otential ha

z

s

exceed 28

wind loadi

n

e

d deck ext

e

o

ne or mor

e

a

bilize the

m

machine a

n

t

ion1-Saf

e

n

less the m

a

e

s, bumps,

d

z

ards on the

mph (12.5

m

g on the m

a

e

nsions or a

t

wheels are

m

achine. Us

e

n

d remove

p

f

ety Pre

c

a

chine is on

d

rop-offs,

floor/surfa

c

m

/s).

a

chine.

ttachments.

e

off the gro

u

e

cranes, f

o

p

ersonnel.

c

aution

1-7

firm,

c

e.

u

nd, all

rklift

Secti

o

1-8

1.4.5

C

Ap

p

Ch

e

low

Du

r

Us

e

Al

w

Ke

e

swi

Li

m

loc

a

Be

sp

e

Do

Ex

e

op

e

Be

wo

r

Wa

bar

o

n1-Safe

C

rushing

a

p

roved hea

d

e

ck work ar

e

w

ering platfo

r

r

ing operati

o

e

the boom

f

w

ays post a l

e

p non-ope

r

ng operatio

n

m

it travel sp

e

a

tion of per

s

aware of st

o

e

ed before s

not use hig

h

e

rcise extre

m

e

rating cont

r

sure that o

p

r

k platform’

s

rn personn

e

r

icades on

f

ty Preca

u

a

nd Collis

d

gear must

e

a for clear

a

r

m, and driv

o

n, keep all

f

unctions, n

o

ookout wh

e

r

ating perso

n

n

s.

e

ed accordi

n

s

onnel, and

o

pping dist

a

topping. Tr

a

h

speed dri

v

m

e caution

a

r

ols and per

s

p

erators of

o

s

presence.

e

l not to wor

f

loor if nece

s

u

tion

Din

g

i

on Hazar

d

be worn by

a

nces overh

ing.

body parts i

o

t the drive

f

e

n driving in

n

nel at leas

t

n

g to conditi

o

other factor

s

nces in all

d

a

vel grades

i

v

e in restrict

e

a

t all times t

s

ons in the

p

o

ther overhe

D

isconnect

k, stand, or

s

sary.

Op

g

li Mach

ds

all operatin

g

ead, on sid

e

nside platfo

function, to

areas wher

e

t

6 ft. (1.8m

)

o

ns o

f

grou

n

s

which ma

y

d

rive speed

s

in low spee

d

e

d or close

t

o prevent o

b

p

latform.

e

ad and floo

r

power to o

v

walk under

eration

&

inery

g

and grou

n

e

s, and bott

o

rm railing.

position th

e

e

vision is o

)

away from

n

d surface,

c

y

cause coll

s

. When dri

v

d

only.

quarters or

w

b

stacles fro

m

r

level mac

h

v

erhead cra

n

a raised bo

o

&

Maint

e

d personne

o

m of platfo

platform cl

o

bstructed.

machine d

u

c

ongestion,

i

sion or inju

r

v

ing in high

s

w

hen drivin

g

m

striking o

r

h

ines are a

w

n

es.

o

m or platfo

e

nance

M

l.

rm when lif

t

o

se to obst

a

u

ring all driv

visibility, sl

o

r

y to person

s

peed, swit

c

g

in revers

e

r

interfering

w

are of the

a

o

rm. Positio

n

M

anual

ing or

a

cles.

i

ng and

o

pe,

nel.

c

h to low

.

with

a

erial

n

Oper

a

1.5 T

o

Ne

v

Thi

s

fail

u

em

e

En

s

Th

e

Wh

of

a

Re

f

1.6 A

d

Do

Wh

the

Ba

t

Do

fla

m

ve

n

a

tion &

M

o

wing, L

i

v

er allow pe

s

machine

s

u

re, or loadi

e

rgency to

w

s

ure boom i

s

e

platform

m

en lifting m

a

a

dequate ca

f

er to the M

a

d

ditional

not use ma

c

en pe

r

formi

chassis fro

m

t

tery fluid is

not operate

m

mable or e

n

tilated area

M

aintena

n

i

fting an

d

rsonnel in

p

s

hould not b

e

ng/unloadin

w

ing proced

u

s

in the sto

w

m

ust be com

p

a

chine, lift o

n

pacity.

a

chine Ope

r

Hazard

s

c

hine as a

g

ng welding

o

m

direct ex

p

highly corro

the machin

xplosive ga

s

.

n

ce Man

u

Din

g

d

Haulin

g

p

latform whil

e

towed, ex

c

g. Refe

r

to

t

u

res.

w

ed position

p

letely emp

t

n

ly at desig

n

r

ation sectio

s

/ Safet

y

g

round for

w

o

r metal cut

t

p

osure to w

e

sive. Avoid

c

e or charge

s

es or parti

c

u

al

g

li Mach

g

e towing, lif

t

c

ept in the

e

t

he Emerge

n

and the tur

t

y of tools.

n

ated areas

n of this m

a

y

w

elding.

t

ting operati

o

e

ld and met

a

c

ontact wit

h

the batteri

e

c

les may be

Sec

t

inery

t

ing, or haul

e

vent of em

e

n

cy Proced

u

ret locked p

of the mac

h

a

nual for lifti

n

o

ns, precau

t

a

l cutting sp

h

skin and cl

e

s in hazard

o

present. C

h

t

ion1-Saf

e

ing.

e

rgency, m

a

u

res section

rior to towin

h

ine. Lift th

e

n

g informati

o

t

ions must

b

a

tter.

o

thing at all

o

us locatio

n

h

arge batter

f

ety Pre

c

a

lfunction, p

o

n

of this ma

n

n

g, lifting or

h

e

unit with e

q

o

n.

b

e taken to

p

times.

n

s where po

t

r

ies only in

a

c

aution

1-9

o

wer

n

ual for

h

auling.

q

uipment

p

rotect

t

entially

a

well

This manual suits for next models

1

Table of contents

Other DINGLI Boom Lift manuals

Popular Boom Lift manuals by other brands

Upright

Upright Snorkel TB66J Operator's manual

Oshkosh Corporation

Oshkosh Corporation JLG 1850SJ Service and maintenance manual

Snorkel

Snorkel TB125J Repair parts manual

Loxam

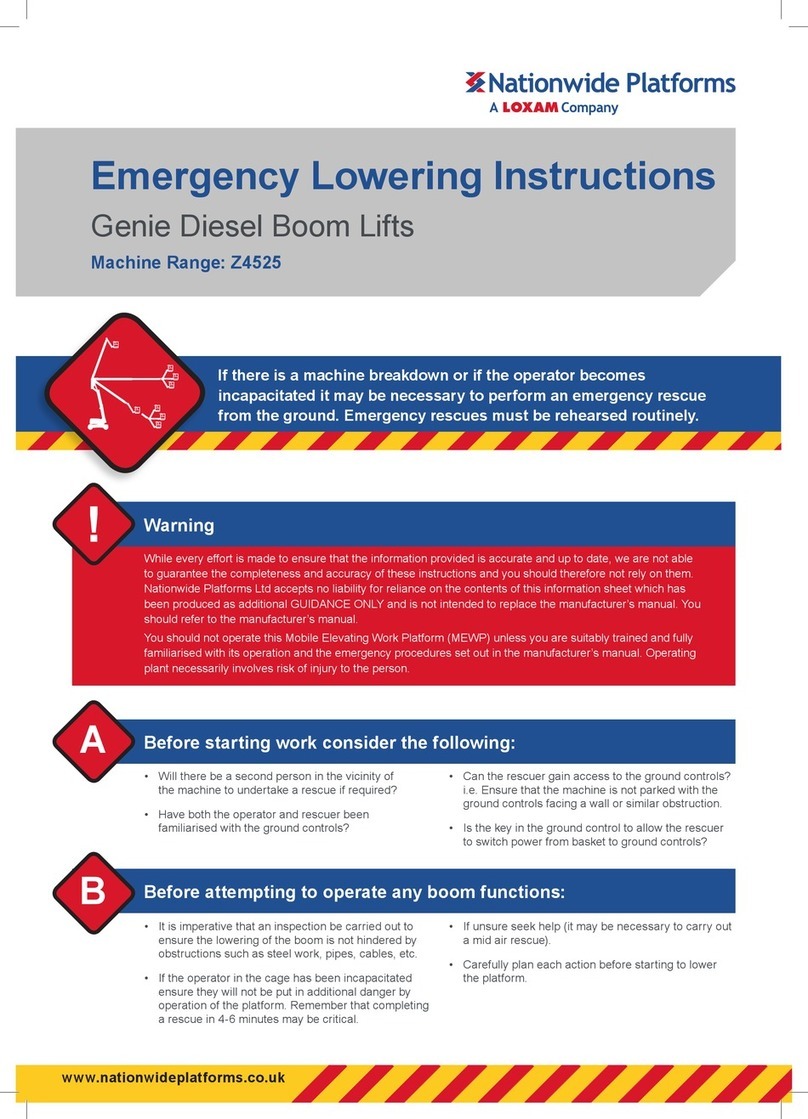

Loxam Nationwide Platforms Genie Z4525 Emergency Lowering Instructions

Snorkel

Snorkel MHP1335 Repair parts manual

Enerpac

Enerpac SBL1100 Instruction and maintenance manual