Special Limitations

SB66JRT – 0084221 5

Special Limitations

Travel with the platform raised is limited to creep speed

range. Elevating the platform is limited to firm, level

surfaces only.

ADanger

The elevating function shall ONLY be used when the

work platform is level and on a firm surface.

The work platform is NOT intended to be driven over

uneven, rough, or soft terrain.

Platform Capacity

Twopeopleand toolsmayoccupytheplatform.The maxi-

mum platform capacity for the aerial platform is stated in

the “Specifications” on page 20.

ADanger

DO NOT exceed the maximum platform capacity or

the platform occupancy limits for this machine.

Manual Force

Manual force is the force applied by the occupants to

objects such as walls or other structures outside the

work platform.

The maximum allowable manual force is limited to 200N

(45 lbs) of force per occupant, with a maximum of 400 N

(90 lbs) for two occupants.

ADanger

DO NOT exceed the maximum amount of manual

force for this machine.

Platform Overload Sensing System

All functions are stopped from the upper and lower con-

trols, when the platform overload limit is exceeded. The

horn will sound intermittently and the platform overload

light will blink until the excess load is removed from the

platform. At that time, the machine functions are again

operational.

If the platform becomes significantly overloaded, or if an

upwardforceontheplatformexceedsapproximately2225

N(500lb), thesystemwill enterintoerrormode,stopping

all functions from the upper and lower controls. The horn

will then sound constantly and the overload light will stay

illuminated at the upper and lower controls.

The system will remain in error mode until the excess

load is removed from the platform and the emergency

stop button or start switch is cycled off and back on,

resetting the system.At that time, the machine functions

are operational.

ACaution

The emergency power system is for emergency low-

ering and stowing only. The length of time the pump

can be operated depends on the capacity of the bat-

tery. Do not use this system for normal operation.

If the platform overload sensing system is tripped while

operating the machine or if the system is in error mode

and can not be reset, the emergency power system may

still be used for emergency machine operation.

ADanger

The aerialplatformcan tipover ifit becomesunstable.

Death or serious injury will result from a tip-over ac-

cident. Do not exceed the capacity values indicated

on the platform rating placard.

The overload sensing system is not active when the

machine is being driven with the booms in the stowed

position. This allows the machine to be driven without

the system sensing an overload due to rough ground

conditions.

To eliminate repeated tripping of the system during ma-

chine operation, there is a five second delay in machine

functions following:

starting the engine.

placing the drive/boom selector switch in the boom

position when the main boom is below horizontal and

fully retracted.

removing excess load from the platform.

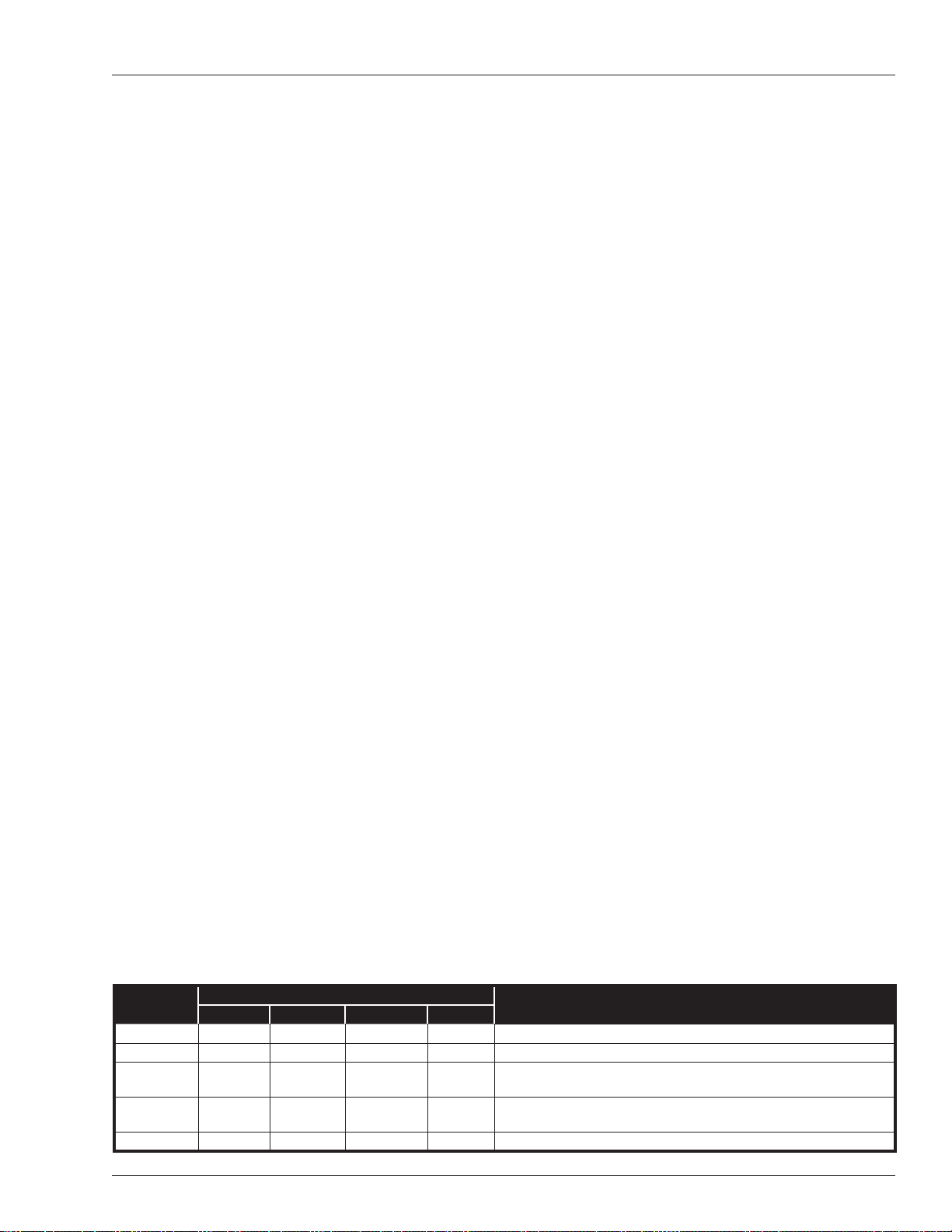

Beaufort Scale

Never operate the machine when wind speeds exceed

12.5 m/s (28mph) [Beaufort scale 6]. Refer to Figure 1.

•

•

•

BEAUFORT

RATING WIND SPEED GROUND CONDITIONS

m/s km/h ft/s mph

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, flags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are apparent in ponds

or swamps.

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is difficult to open an

umbrella.

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is difficult to walk against the wind.

Figure 1 – Beaufort Scale