Dino-Power DP6388B Operation instructions

Owner’s Manual

For professional Use only

Do not use this equipment before reading this manual!

Airless Paint Sprayer

International Model

Original instruction

DP6388B

Ningbo Dino-power Machinery Co.,Ltd

No 168 MingGuang Road, Yinzhou District, Ningbo, China

www.dpairless.com or www.airlesspaintsprayer-pump.com

www.dino-power.com

NOTE: This manual contains important warnings and

instructions. Please read and retain for

reference

a

e

a

s

a

a

e

Table of Contents

Safety Precautions.......................................................... 2

General Description.........................................................4

Technical Parameter........................................................4

Operation............................................................................ 4

Setup.................................................................................... 4

Preparing to Paint.............................................................5

Painting................................................................................5

Electronic Pressure Control Indicators..................... 5

Pressure Relief Procedure............................................ 6

Spraying.............................................................................. 6

Spraying Technique......................................................... 6

Practice................................................................................7

Shutdown and Cleaning..................................................7

Troubleshooting................................................................ 8

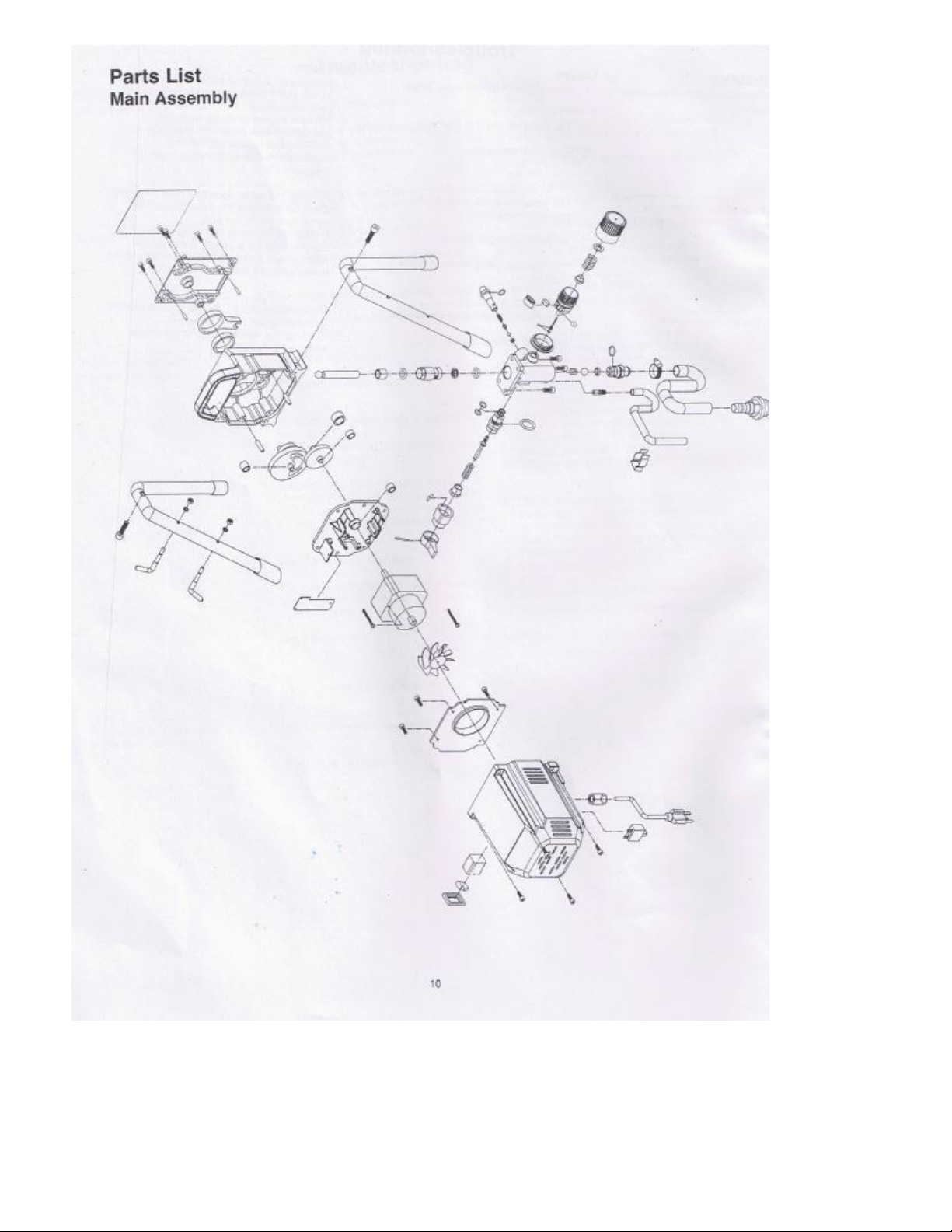

Parts Listings.................................................................... 10

Main Assembly............................................................10

Motor Assembly..........................................................11

Gear Box Assembly...................................................12

Suction Set Assembly............................................... 12

Stand Assembly.......................................................... 12

Fluid Section Assembly............................................ 13

Tip Selection................................................................ 14

Selecting Tip Hose Size................................................. 14

Choosing The Correct Tip..............................................14

Tip Hose Size.................................................................... 14

Fan width............................................................................ 14

Understanding Tip Number........................................... 14

Reversible Tip Selection Chart....................................15

Safety Precautions

This manual Contains Information that must be read and

understood before using the equipment, When you come to an

area thathas one of the following symbols, pay particular

attention and

N

m

O

a

T

k

E

e

:

c

N

e

o

rt

te

a

s

in

g

t

i

o

ve

he

im

ed

po

th

rt

e

an

s

t

a

i

f

n

e

f

g

o

u

rm

ar

a

d

ti

.

WARNING

This Symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information

will follow.

CAUTION

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injur ies will fo llow.

NOTE: Notes giv import nt inform tion which hould

be given speci l tt ntion.

WARNING

Airless units develop extremely high spraying pressures.

·Never put your fingers, hands or any other parts of the

body in to the spray jet.

·Never point the spray gun at yourself or anybody else.

·Never use the spray gun without the safety guard.

Attention! Danger of injury by injection!

In case of injury to sk in caused by coating materials or

solvents consult a doctor immediately. Inform the doctor of the

type of coationg material or cleaning agent with which the injury was

caused.

The operating instructions state that the following points

must always be observed before starting up:

1.

Faulty units should not be used.

2.

Secure spray gun using the safety catch on the trigger

3.

Ensure that the unit isproperly earthed.

4.Check the permissible operating pressure.

5.Check all connections for leaks.

The instructions regarding regular cleaning and

maintenance of the unit must be strictly observed.

Before any work is done on the unit or for every break in

work the following rules must be observed:

1.

Release the pressure from the spray gun and hose.

2.

Secure the spray gun using the safety catch on the

trigger.

3.

Turn off the motor.

Be safety-conscious!

All local regulation in force must be observed.

In order to ensure safe operation of the airless systems

the safety regulations listed below must be followed:

1.In

order to avoid dangers, read the operating instructions

carefully and follow the instructions laid down in them.

2.Do not use materials with flash point below 2

1℃

(7

0℉H

).

3.The use of this unit is prohibited in workshops which are

covered under the explosion prevention regulations.

4.

Never spray near sources of ignition; e.g. open flames,

cigarettes also cigars and pipes are sources of ignition

- sparks, hot wires and hot surfaces, etc.

5.Attention! Danger of injury by injection!

Never point the spray gun at yourself or anyone else.

Never put your fingers or hands into the spray jet. The

very high spraying pressures can cause very serious

injuries. Never use the spray gun without the safety guard.

When Installing an d removing the t ip and d uring bre aks in

wo rk the spray gun must alw ays be secured, so that it

cannot be activated.

6.

Wear respiratory equipment when spraying. The opera tor

must be provided w ith a protective mas k.

In order to prevent work related illness, the ma nufacturer

'

s

ag ents used must be observed when prepa ring, wo rking

with and cleaning the unit. Protective clothing, gloves and

in

certain cases, protective skin cre am are n ecessary to

protect the skin.

7.The spray gun and high pressure hose betw een the unit

an d spr ay gun mus t be of a sufficient standard for the

pressure p roduced in the unit.

The permissible operating pressure for the high- pressure

ho se, the manufacturer and the da te of manufacture must be

indicated by a permanent identification ma rking on the

ho se. Furth ermore, it must be constructed so that the

electrical re sistance between the connections to th e unit

an

d the sp ray gun is equal to or less than one megohm.

8.Und er certain cond itions the follow speed can cause an

electrostatic charge on the unit. This could cause sparks

or flames on discharging. It is, therefore, important that

the un it is always earthed over the electrical in stallation.

The con ta ct should be made us in g a sho ckpro of socket

ea rthed in accord ance with the re gulations.

9.Forbidden to use of electrostatic atomising and spraying

equipment with machines not specifically designed for this

equipm ent, because it may result in serious hazards for

the operators;

10.

Pay attention to hazards resulting from contact with and/or

breathing of toxic materials, gases, mists and vapours which

may be created by operation of the machine.

11.

Before installation and usage, visually inspection for damage

on hoses which may be subjected to friction should be done.

2.

3.

9. Attention! Please observe the following when working

inside and outside:

No Solvent Gasses Should be carried to the unit. No

solvent gasses should from near the unit. Set up the unit

on the opposite side to the object being Sprayed. When

spraying out doors, take the wind direction in to account.

When working in doors there must be sufficient ventilation

to ensure that the solvent gasses are carried away.A

minimum distance of 6.1m(20') must be observed

between the unit and object being sprayed.

10.

Extraction equipment Should be installed by the user in

accordance with the local regulations.

11. The objects being sprayed must be earthed.

12.

When cleaning the unit, solvent should never be sprayed

intoa container with only a small opening(bunghole). An

explosive gas/air mixture is likely to form. The container

must be earthed.

13. Cleaning the unit.

A harsh jet should never be used to spray the unit. In

particulara high-pressure cleaner or high-pressure steam

cleaner should never be used. There is a danger that

water will penetrate into the unit and causea short-circuit.

14.

Pulling the trigger causes a recoil force to the hand that is

holding the spray gun.

The recoil force of the spray gun is particularly powerful

when the tip has been removed anda high pressure has

been set on the airless high-pressure pump. Therefore,

when cleaning without tip set the pressure control valve to

the lowest pressure.

15.

The mains plug should only be disconnected from the

socket when work is being carried out on the electrical

components.

14.

Work or repairs should only be carried out on electrical

equipment by a trained electrician, even if the work is

described in the operating instructions. No liability will be

accepted for incorrectly installed electrics.

15. Positioning when the ground is uneven.

The front of the unit must point downward so that the

machine does not slip away.

HAZARD: INJECTION INJURY- A high pressure stream of

paint produced by this equipment can pierce

the skin and underlying tissues, leading to

serious injury and possible amputation.

DO NOT TREAT AN INJECTION INJURY ASA

SIMPLE CUT! Injection can lead to

amputation. See an physician immediately.

PREVENTION:

·

The maximum operating range of the unit is 221 BAR

(3200 PSI) fluid pressure.

·

Never aim the gun at any part of the body.

·

Never allow any part of the body to come in contact with

stream created by aleak in the fluid hose.

·

Never Put your hand in front of the gun. Gloves will not

provide protection against and injection injury.

·

ALWAYS lock the gun trigger, shut the fluid pump off and

release all pressure before servicing, cleaning the tip

guard, changing tips, or leaving unattended. Pressure will

not be released by turning off the engine. The

PRIME/SPRAY knob must be turned to PRIME to relieve

the pressure. Refer to the PRESSURE RELIEF

PROCEDURE described in this manual.

·

The tip guard must always be in place while spraying. The

tip guard provides some protection against injection

injuries but is mainly a warning device.

·

ALWAYS remove the spray tip before flushing or cleaning

the system.

·

The paint hose can develop leak from wear, kinking and

abuse. A leak is capable of injecting material into the skin.

Inspect the paint hose before each use.

NOTE TO PHYS ICIAN:

Injection in to the skin is a tr aumatic injury. It is

important to theat the injury surgically as soon as

possible. DO NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings injected

directly into the blood stream. Consultation witha

plastic surgeon or reconstructive hand surgeon may be

advisable.

HAZARD: EXPLOSION OR FIRE-Solvent and paint fumes can

explode or ignite, causing property damage and/or

severe injury.

PREVENTION:

·

Fire extinguishing equipment must be present and in go od

wo rking order.

·

Use only conductive or earthed high pre ssure flu id hoses

for airless applic ations, be sure that the gun is earthed

properly through hose connectio ns.

·

The pump mu st be connected to an earthed object. Use

the green earthing wire to connect the p ump to a water

pipe, steel beam, or other electr ically earthed surface.

·

When flushing equipment use the lowest po ssible

pressure.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS- May cause property damage or

severe injury.

PREVENTION:

·

Do not use bleach.

·

Do not use halogenated hydrocarbon solvents such as

methylene chloride and 1,1,1-trichloroethane. They are not

compatible with aluminum and may cause an

explosion. If you are unsure of a material's compatibility

with aluminum, contact your coating's supplier.

HAZARD: GENERAL-May cause property damage or

severe injury.

PREVENTION:

·

This high pressure airless pump is designed to be used

with manufacturer authorized parts only. When using this

pump with parts that do not comply with the minimum

specifications and safety devices of the pump

manufacturer, the user assumes all risks and liabilities.

·

Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover, as well as damage or movement of

couplings. If you any of these condition exist, replace the

hose immediately. Never repair a paint hose. Replace it

with another earthed hose.

·

Wear protective eyewear.

·

Do not spray on windy days.

Earthing Instructions

This product must be earthed. In the event of an electrical

short circuit, earthing reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is

equipped witha cord having an earthing wire with an

appropriate earthing plug. The plug must be plugged into an

outlet that is properly installed and earthed in accordance with all

local codes and ordinances.

DANGER-Improper installation of the earthing plug can

result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green earthing wire to either fla t blade terminal. The

wire with insulation havinga green outer surface with or without

yellow stripes is the earthing wire and must be

connected to the earthing pin.

Check with a qualified electrician or serviceman if the earthing

instructions are not completely understood, or if you are in

doubt as to whether the product is properly earthed. Do not

modify the plug provided. If the plug will not fit the outlet, have

the proper outlet installed by a qualified electrician.

4.

General Description

This airless spraye r is a precision power tool used for spraying

many types of mate rials. R ead and follow this ins truction

manual carefully for prope r operating instructions, and

safety informa tion.

The paint sprayer is compatible with the following water

soluble paints:phenol aldehyde paint series -nitryl paint

series alkyd paint series epoxy resin paint series oxidized

rubber paint series latex paint series etc.

Technical Parameter

Setup

Perform the following procedure before plugging in the power

cord of an electric unit.

1.

Ensure that the suction set and the return hose are

attached and secure.

2.

Using a wrench, attach a minimum of 7.5m 24.6' x 10mm

(1/4”) nylon airless spray hose to the unit. Tighten

securely.

3.

attach an airless spray gun to the spray hose. Using two

wrenches ( one on the gun and one on the hose), tighten

securely.

NOTE: Do not attach the tip to the spray gun yet.

Remove the tip if it is already attached.

WARNING

Make sure all airless hoses and spray guns are electrically

grounded and rated for at least 228 bar (3300 psi) fluid

pressure.

4.

Make sure the pressure control knob is in its OFF position

5.Make sure the ON/OFF switch is in its OFF position.

6.Fill the oil cup with 15g (one tablespoon) of piston sea l

lubricant (piston lube).

CAUTION

Never operate unit for more than ten seconds without

fluid. Operating this unit without fluid will cause

unnecessary wear to the packing.

7.

Make sure the electrical service is correct for the unit.

8.P lug the power cord in t o a proper ly ground ed outlet a t

least 7.6m (25') fr om the spray area.

CAUTION

Always use a minimum 12 gauge, three-wire extension cord

with a grounded plug. Never remove the third prong or use

an adapter.

Preparing a New Sprayer

If this unit is new, it is sh ipped with test flu id in the fluid section

to prevent corrosion during shipment and storage. This fluid

must be thoroughly cleaned out of the system with mineral

spirits before you begin spraying.

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

1.

Place the suction tube intoa container of mineral spirits

that has a flash point of 60

℃(

140

℉H

) or above.

2.

Place the return hose into a metal waste container.

3.Turn Pressure Control Knob all the way left

(counter-clockwise) to minimum pressure.

Operation:

WARNING

This equipment produces afluid stream at extremely high

pressure. Read and understand the warnings in the

safety precautions section at the front of this manual

before operating this equipment.

4.Move the PRIME/SPRAY valve down to the PRIME

position.

5.

Turn the unit on by moving the ON/OFF switch to the On

position.

6.

Allow the Sprayer to run for 15-30 seconds to flush the

test fluid out through the return hose and into the waste

container.

7.

Turn the unit off by moving the ON/OFF switch to the OFF

position.

Working pressure range

0-2800 psi(0-19MPa,0-193 bar)

Electric motor

6.0A (open frame, universal)

Operating horsepower

1/2

Maximum delivery(with tip)

0.24gpm (0.91lpm)

Paint Hose

1/4 in x 25 ft ( 6.4 mm x 7.5m)

Maximum Tip hole size

0.015 in. (0.38mm)

Weight, sprayer only

16 lb (7.3 kg)

Weight, sprayer,hose & gun

19.2 lb (8.7 kg)

Dimensions(upright):

Length

14.5in (36.8cm)

Width:

12.4in (31.5cm)

Height:

17.9in (45.5cm)

Dimensions(Folded):

Length:

19.3in (49.0cm)

Width:

15.3in (38.9cm)

Height:

29.2in (74.2cm)

Power Cord:

18AWG,3 wire,6ft(1.8m)

Fluid inlet fitting

3/4 in. internal thread (Standard garden hose thread)

Fluid outlet fitting

1/4NPSM external thread

Inlet screen (on suction tube)

35mesh (450 micro)

Wetted parts, pump & hose

Stainless steel, brass, leather, ultra-high molecular

weight polyethylene (UHMWPE), carbide, nylon,

aluminum, PVC, polypropylene, fluroelastomer

Wetted parts, gun

Alu minum , brass, carb ide, nylo n, plated steel,

stainless steel, UHMWPE, zinc

Generator requirement

1500 Watt minimum

Electrical power requirement

230V 50Hz, 15A 1 phase

Storage temperature range

-30°to 160℉(-35°to 71℃)

Operating temperature range

40°to 115℉(4°to 46℃)

Maximum allowable pressure for the

coating material(MPa)

Maximum allowabl e temperature of the

coating material(

℃

)

Typical coating material flow rate(l/min)

Sound power level ( LWA 4 m hem isphere ) dB(A)

97.9

Sound pressure level(LpAAirborne noise

1m away from working station) dB(A)

90

Uncertainty dB(A)

1.5

Vibration valve for spraying gun(

m/s2)

2.391

Uncertainty(

m/ s2 )

0.5

CAUTION

5.

WARNING

Preparing to Pain

Before painting, it is important to make sure that the fluid in the

system is compatible with the paint that is going to be used.

NOTE: Incompatible fluid and paint may cause the

valves to become stuck closed ,which would

require disassembly and cleaning of the

sprayer' s fluid section.

Always keep the trigger lock on the spray gun in the

locked position while preparing the system.

1.place the suction tube intoa container of the appropriate

solvent for the material being sprayed (refer to

recommendations of the material manufacture).An

example of the appropriate solvent is water for latex paint.

2.place the return hose intoa metal waste container.

3.

set the pressure to minimum by turning the pressure

control knob all the way left (counter-clockwise) to

minimum pressure.

4.

move the PRIME/SPRAY valve down to the PRIME

position.

5.

Trun the unit on by moving the ON/OFF switch to the ON

position.

6.

Allow the sprayer to run for 15-30 seconds to flush the old

solvent out through the return hose and in to the metal

waste container.

7.

Turn the unit off by moving the ON/OFF switch to the OFF

position.

NOTE: Make sure that the spray gun does not havea

tip or tip guard installed.

8.

Move the PRIME/SPRAY valve up to the SPRAY position.

9.Turn the unit on.

10.

Unlock the gun by turning the gun trigger lock to the

unlocked position.

WARNING

Ground the gun by holding it against the

edge of the metal container while flushing.

Failure to do so may lead to a static

electric discharge ,which may causea fire.

11.Trigger the gun into the metal waste

container until the old solvent is gone

and fresh solvent is coming out of the gun.

12.

Lock the gun by turnig the gun

t rigger lock to the locked position.

13.

Set down the gun and increase the

pressure by turning the pressure

control knob slowly clockwise into

the high pressure spray.

WARNING

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose ,including

servicing or adjusting any part of the spray system,

changing or cleaning apray tips,or preparing for cleanup.

Painting

1.Place the suction tube into a container of paint.

2.Place the return hose into a metal waste container.

3.Set the pressure to minimum by turning the pressure

control knob to the Min setting in the low pressure spray.

4.Move the PRIME/SPRAY valve down to the PRIME

position.

5.

Turn the unit on by moving the ON/OF switch to the ON

position.

6.

Allow the sprayer to run until paint is coming through the

return hose into the metal waste container.

7.

Turn the unit off by moving the ON/OFF switch to the OFF

position.

8.Remove the return hose from the waste container and

place it in its operating position above the container of paint

9.Move the PRIME/SPRAY valve up to the Spray position.

10.

Turn the unit on

11.

Unlock the gun by turning the gun trigger lock to the

unlocked position

WARNING

Ground the gun by holding it against the

edge of the metal container while flushing.

Failure to do so may lead toa static electronic

discharge, which may cause a fire. 12.Trigger

the gun in to the metal waste

container until all air and solvent is

flushed from the spray hose and paint is flowing freely

from the gun.

13.

Lock the gun by turning the gun

trigger lock to the locked position.

14.

Turn the unit off.

15.

Attach tip guard and tip to the gun

as instructed by the tip guard or tip

manuals . Trigger lock

in locked position

POSSIBLE INJECTION HAZARD. Do not spray without the

tip

guard in place .Never trigger the gun unless the tip is in

either the spray or the unclog position .Always engage

the

gun trigger lock before removing ,replacing or

cleaning tip.

16.Turn the unit on

17.

Increase the pressure by turning the pressure control

knob slowly clockwise toward the high pressure spray and

test the spray pattern on a piece of cardboard. Ajust

the pressure control knob until the spray from the gun is

completely atomized.Try to keep the pressure control

14.

Check the entire system for l ea k s .

ifleaks occur,follow the Pressure

Trigger lock

in locked position

knob at the lowest setting that maintains good

atomization.

Relief Procedure”in this manual before t ightening any f

ittings or hoses

15.

Follow the “Pressure Relief Procedure” in this manual

before changing from solvent to paint.

CAUTION

Note: Turning the pressure up higher then needed to

atomize the paint will cause premature tip wear

and additional overspray

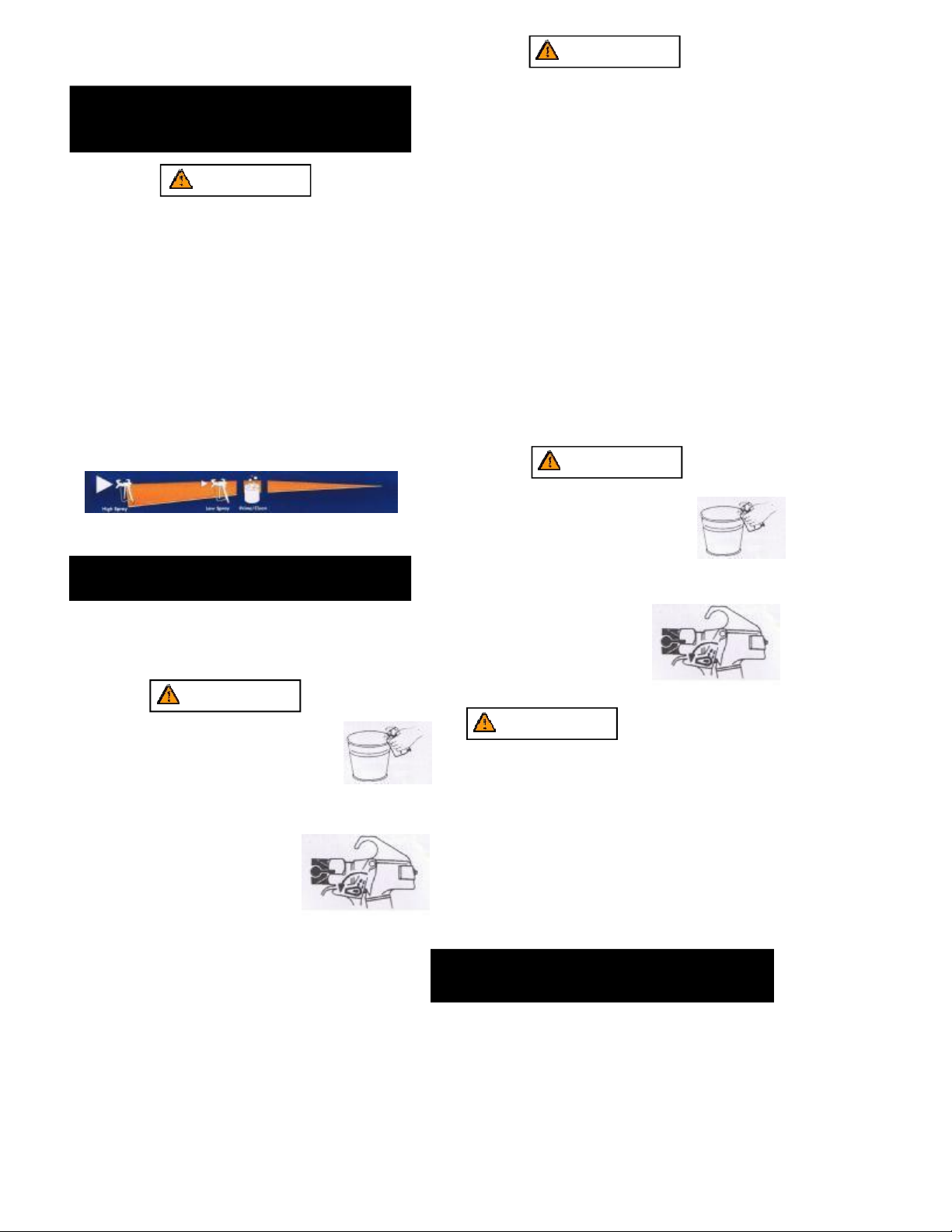

6.

Off spray

Too thick

Start Pull

stroke trig ger

Release End

trigger

stroke

Pressure Relief Procedure

WARNING

Avoid arcing or holding the gun at an angle ,This will result in

an uneven finish.

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose ,including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for clean up.

1.

Lock the gun by turning the gun

trigger lock to the lock position.

2.

Turn the unit off by moving the

ON/OFF switch to the OFF position.

3.Turn the pressure control knob

counterclockwise to its OFF position

4.Unlock the gun by turning the gun

Trigger lock

trigger lock to the unlocked position in locked position

5.Hold the metal part of the gun firm ly to

the side of a metal container to ground

the gun and avoida build up of static

electricity.

6.

Trigger the gun to remove any

pressure that may still be in the hose

7.

Lock the gun by turning the gun trigger lock to the locked

position.

8.

Move the PRIME/SPRAY valve down to the PRIME

position.

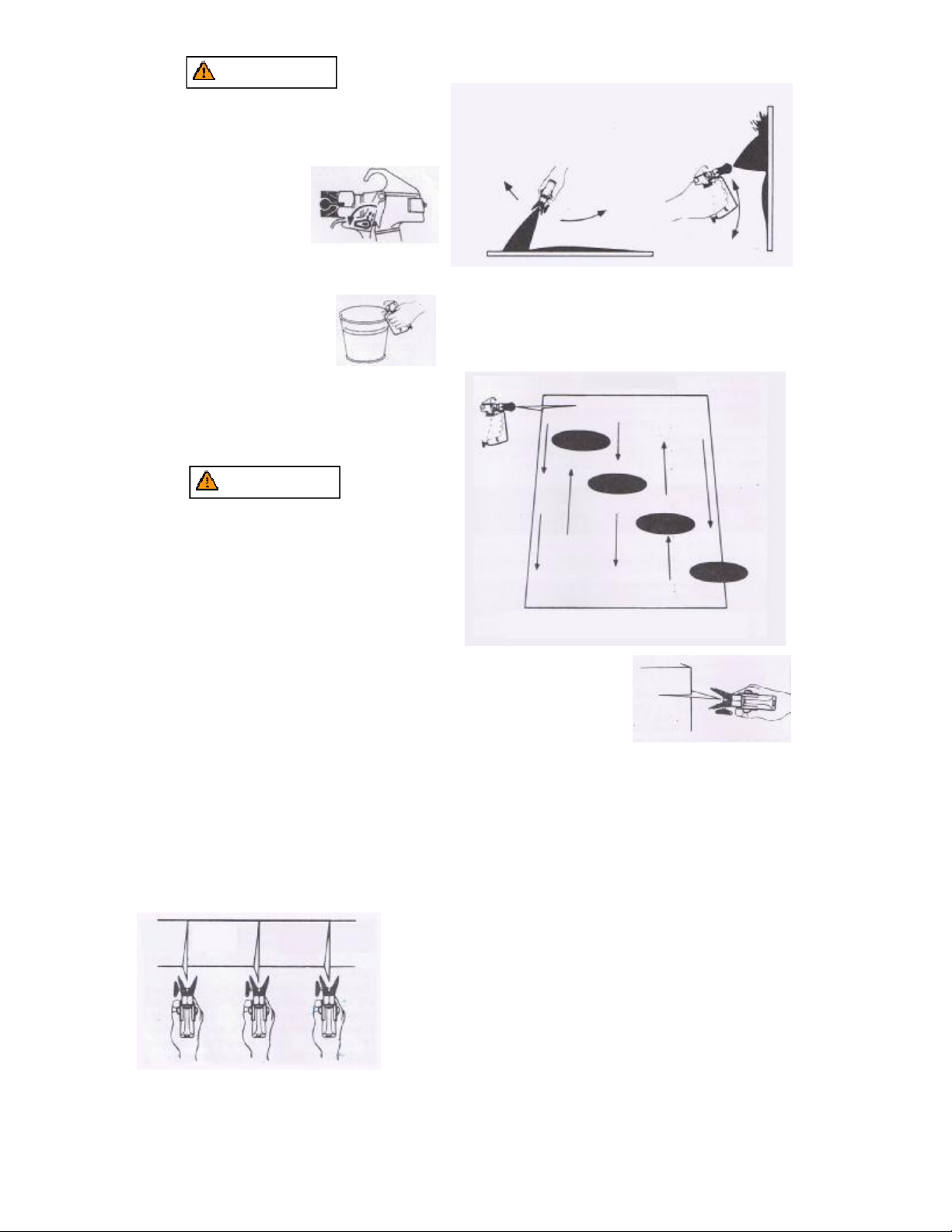

Spraying

Arcing Gun at angle

Proper lapping(overlap of spray pattern) is essential to an

even finish. Lap each stroke .If you are spraying horizontally,

aim at the bottom edge of the preceding stroke, so as to lap

the previous pattern by 50% .

WARNING

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place .Never trigger the gun unless the tip is

in either the spray or the unclog postion ,Always engage

the gun trigger lock before removing ,replacing ,or

cleaning tip.

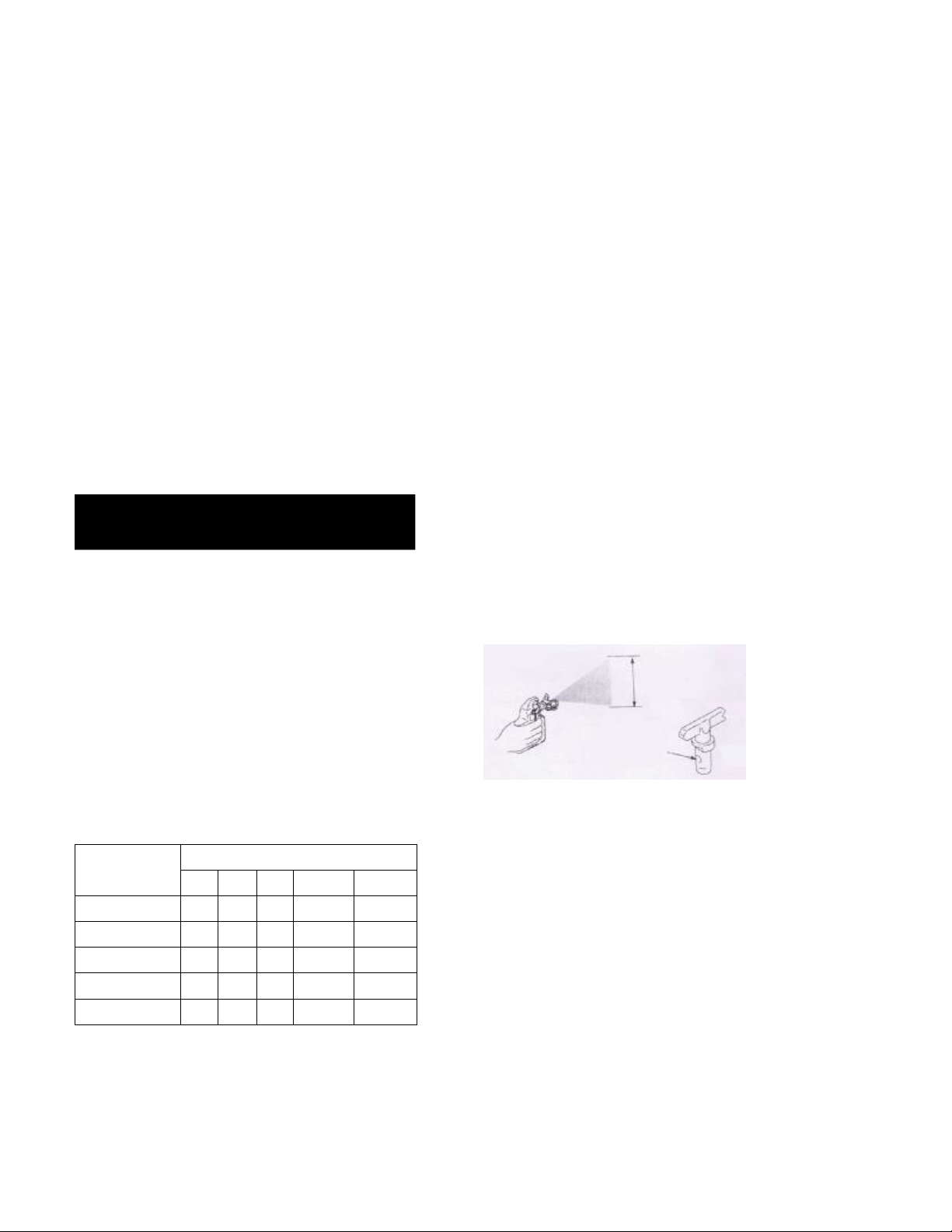

Spraying Technique

The following techniques ,if followed,will assure professional

painting results.

Hold the gun perpendicular to the surface and always at equal

distance from the surface. Depending on the type of material,

surface ,or desired spray pattern,t he gun should be held ata

distance of 30 to 50 cm (12 to 14 inches)

Move the gun either across or up and down the surface ata

steady rate. Moving the gun at a consistant speed conserves

material and provides even coverage .The correct spraying speed

allows a full ,wet coat of paint to be applied without runs or sags.

Holding the gun closer to the surface deposits more paint on

the surface and produces a narrow spray patern.. Holding

the gun farther from the surface produces a thinner coat and

wide spray pattern .If runs ,sags ,or excessive paint occur,

change to a spray tip with a smaller orifice . If there is an

insufficient amount of paint on the surface or you desire to

spray faster ,a larger orifice tip should be selected.

Maintain uniform spray stroke action ,Spray alternately from

left

to right and right to left. Begin movement of the gun before

the

t rigger is pulled.

For corners and edges ,split the

center of the spray pattern on the

corner or edge and spray

vertically so that both adjoing

sections receive approximately

even amounts of paint.

When spraying with a shield ,hold it firmly against the surface.

Angle the spray gun slightly away from the shield and toward

the surface This will prevent paint from being forced underneath.

Shrubs next to housed should be tied back and covered witha

canvas cloth .The cloth should be removed as soon as possible.

our gun extensions are extremely helpful in these situations.

Nearby objects such as automobiles ,outdoor furniture,etc.

should be moved or covered whenever in the vicinity ofa

spray job.Be careful of any other surrounding objects that

could be damaged by overspray.

Overlap edges

1st 2st 3st 4st

5st

pass pass pass pass pass

7.

PRACTICE

1.

Be sure that the paint hose is free of kinds and clear of

objects with sharp cutting edges.

2.

Turn the pressure control knob counterclockwise to its to

its lowest setting.

3.

Turn the PRIME/SPRAY valve up to it s SPRAY position.

4.Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as paint begins to

flow through it.

5.

Unlock the gun trigger lock.

6.

Trigger the spray gun to bleed air out of the hose.

7.

When paint reaches the spray tip,spray a test area to

check the spray pattern.

Use the lowest pressure setting

necessary to get a good spray

pattern, If the pressure is set too

high,the spray pattern will be too

light. If the pressure is set too

low, tailing will appear or the

paint will spatter out in gobs

rather than ina fine spray.

Shutdown and Cleaning

1.

Pressure Control Knobs Settings

2.

Remove tip and guard assembly from gun and

place in flushing fluid.

3.

Lift suction tube and prime tube from paint pail

Let them drain into paint pail for a while.

4.

Separate prime tube (smaller)

from suction tube(larger)

5.

Place empty waste and

water or solvent pails

side by side.

6.

Place prime tube in waste

pail.

7.

Submerge suction tube in

water or flushing solvent.

8.

Turn pressure control knob to

the PRIME/CLEAN setting.

9.

Turn the power switch ON.

10.

Flush until approximately 1/3 of the flushing

fluid is emptied from the pail.

11.

Turn power switch OFF.

When storing the paint station for 16 hours or more,a

thorough cleaning is recommended:

1.shutdown paint sprayer

2.

thoroughly clean paint sprayer and station according

instruction;

3.

be sure that machine and tubes are clear any water or

fluid as these may freeze;

4.

Coil high pressure hose and store on back of tool with

hook and loop straps;

5.

Store filter spraying gun, and sprayer in plastic bag

and seal;

8.

Troubleshooting

Problem Cause Solution

The unit will not run 1.The unit is not plugged in

2.Tripped breaker

3.

The pressure is set too low(pressure

control knob set at minimum setting

does not supply power to unit)

4.

Faulty or loose wiring.

5.Excessive motor temperature.

6.ON/OFF switch is defective.

1.Plug the unit in

2.Reset the breaker.

3.

Turn the pressure control knob

clockwise t supply power to the unit

and increase the pressure setting.

4.

Inspect or take to a authorized service

center.

5.

Allow motor to cool.

6.

Replace the ON/OFF switch.

The unit will not prime.

1.The PRIM E/SPRAY valv e is in the

SPRAY position

2.Air leak in the position tube/suction set.

3.The siphon tube f ilter and /or inlet

screen is c logged.

4.The siphon tube/suction set is clogged.

1.

Rotate the PRIME/SPRAY valve

clockwise to the PRIME position.

2.

Check the siphon tube/suction set.

Connection and tighten or re-tape

the connection with Teflon tape.

3.

Remove the inlet screen and clean.

Rem ove the siphon tube/ suction set

and clearn.

The unit will not build or

maintain pressure

1.

The spray tip is worn.

2.the Spray tip is too large

3.

The pressure control knob is not set

properly

4.

The pump filter ,gun filter, or inlet

screen is clogged.

5.

Material flows form the return hose

when the PRIME/SPRAY valve is in

the SPRAY position.

6.

There is external fluid leak.

7.

Air leak in the siphon tube/suction

set.

8.

There is an internal fluid section leak

(packings are worn and/or dirty, valve

balls are worn).

9.

Worn valve seats.

10.

Motor power but fails to rotate.

1.

Replace the spray tip following the

instruction that came with the spray

gun.

2.

Replace the spray tip witha tip that

has a smaller orfice following the

instructions that came with the spray

gun.

3.

Turn the pressure control knob

clockwise to increase the pressure

setting.

4.

Remove the pump filters element

and clean. Remove the gun filter and

clean. Remove the inlet screen and

clean.

5.

Clean or replace the PRIME/SPRAY

valve.

6.

Check the siphon tube/suction set

connection and tighten or re-tape the

conncetion with Teflon Tape.

7.

Check for external leaks at all

connections. Tighten connections,

if necessary.

8.

Clean the valves and service the

fluid sectio n.

9.

Reverse or replance the valve seats.

10.Take unit to authorized service

center.

Fluid leakage at the upper

end of the fluid section.

1.

The upper packings are worn.

2.The piston rod is worn.

1.

Repack the pump following this

manual .

2.

Replace the piston rod.

9.

Troubleshooting

Problem Cause Solution

Excessive surge at the

spray gun.

1.Wrong type of airless spray hose.

2.The Spray tip worn or too large.

3.Excessive pressure.

1.

Replace hose with a minimum of 5m

(50 ”)X10 mm(1 /4 ”) ground textiled

braid airless paint spray hose.

2.

Replace the spray tip following the

instructions that came with the spray

gu

n.

3.

Rotate the pressure control knob

co unterclockwise to decrease spray

pressure.

Poor spray pattern. 1.The spray tip is too large for the

material being used.

2.

Incorrect pressure setting.

3.

The material being sprayed is too

viscous.

1.

Replace the spray tip with a new or

smaller spray tip fo lling the instructions

that came with the spray gun.

2.

Rotate the pressure control knob to

adjust the pressure for a proper spray

patter.

3.

Add solvent to the material according

to th e man ufac tu re s re co m me nda tio n s .

The unit lacks power. 1.The pressure adjustment is too low. 1.Rotate the pressure control knob

2.Improper voltage supply.

clockwise to increase the pressure

setting.

2.Connect the input voltage to the proper

voltage for the unit.

10 .

11 .

Motor Assembly

Motor Assembly

1.Motor.................................................. 1

9.ON/OFF switch................................1

2.Screw.................................... 2 10.Screw.................................................4

3.Motor fan............................... 1 11.Circuit breaker.................................1

4.Screw.................................... 4 12.Pin...................................................... 2

5.Gasket.................................. 1 13.Motor holder.....................................1

6.Motor cover labels.................. 1 14.Couper oring....................................1

7.Strain relief............................ 1 15.Screw.................................................4

8.Power cord............................ 1 16.Electric main board........................1

12 .

2

3

1

4

5

6

7

5

1

2

3

4

Gear Box Assembly

1.Cover laber........................................ 1

2.Screw................................................... 8

3.Front cover w/label......................... 1

4.Rod.......................................................1

5.Rod couper o-ring............................1

6.Pump housing...................................1

7.Crankshaft/gear assembly........... 1

Suction Set Assembly

Suction Set Assembly

1.Return tube assembly...................1

2.Retaining Clip..................................1

3.Siphon hose..................................... 1

4.Inlet screen...................................... 1

5.Clip......................................................1

8.Gear wrap..................................1

9.Wrap............................................1

10.2nd stage gear.............................. 1

11.Pin.....................................................1

12. Gear wrap.......................................2

13. Pin.................................................... 2

14. Gear wrap...................................... 1

Stand Assembly

Stand Assembly

1.Leg...................................................... 2

2.Screw................................................. 2

3.Cord wrap......................................... 2

4.Nut...................................................... 2

5.Mater washer...................................2

6.Drip cup............................................. 2

7.Drip cup2.......................................... 2

Gear Box Assembly

13 .

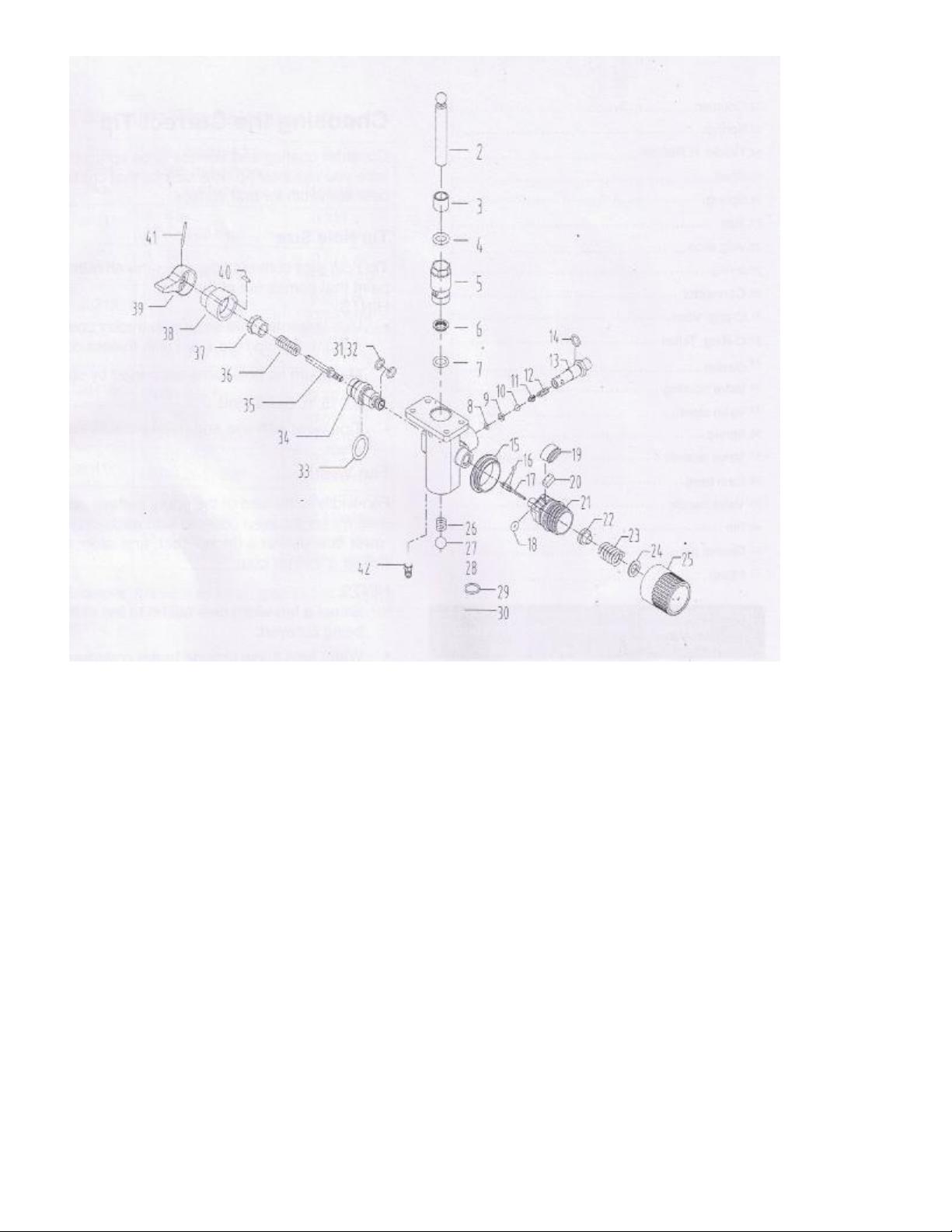

Fluid Section Assembly

Fluid Section Assembly

1.Fluid section................................... 1

2.Piston............................................... 1

3.Piston wrap A..................................1

4.O-ring................................................1

5.Piston wrap B................................. 1

6.O-ring................................................1

7.O-ring................................................1

8.Lvasher............................................ 1

9.Alloy slice........................................ 1

10.Ball.................................................... 1

11.................................................................Rocl 1

12.Spring.................................................1

13.Coupler.............................................. 1

14.O-ring................................................. 1

15.Cover.................................................. 1

16.O-ring................................................. 2

17.Pressure rocl....................................1

18.O-ring................................................. 1

19.Switch.................................................1

20.Plastic cover.....................................1

14 .

22. Coupler...........................................1

23. Spring............................................. 1

24. Holder H Needle.......................... 1

25. Shell................................................ 1

26. Spring............................................. 1

27. Ball.................................................. 1

28. Allg Slice........................................ 1

29. O-ring..............................................1

30. Connector......................................1

31. O-ring, Viton................................. 1

32. O-ring, Teflon................................1

33. Gasket............................................ 1

34. Valve Housing.............................. 1

35. Valve Stem.................................... 1

36. Spring............................................. 1

37. Valve Retainer..............................1

38. Cam base...................................... 1

39. Valve Handle................................ 1

40. Pin....................................................1

41. Groove Pin.................................... 1

42. Fitting..............................................1

Choosing The Correct Tip

Consider Coating and Surface to be Sprayed. Make sure

you use best tip hole size for that coating and best fan

width for that surface.

Tip Hole Size

Tip hole size controls flow rate the amount of paint

that comes out of the gun.

HINTS:

·

Use large tip hole size with thicker coatings

and smaller tip hole sizes with thinner coatings.

·

Maximum tip hole sizes supported by sprayer:

0.015 in. (0.38mm)

·

Tip wear with use and need periodic replace-ment.

Fan Width:

Fan width is the size of the spray pattern, which

determines the area covered with each stroke.

Narrower fans deliver a thicker coat, and wider fans

deliver a thinner coat.

HINTS:

·

Select a fan width best suited to the surface being

sprayed.

·

Wider fans allow provide better coverage on

broad, open surfaces.

·

Narrower fans provide better control on small,

confined surfaces.

Tip Selection

Selecting Tip Hole Size

Tips come in a variety of hole sizes for spraying a range

of fluids. Your sprayer includes an 0.015 in (0.38mm) tip

for use in most spraying applications. Use the following

table to determine the range of recommended tip hole

sizes for each fluid type. If you need a tip other than the

one supplied, see the Reversible tip Selection Chart

on page 15.

HINTS:

·

As you spray, the tip wears and enla rges, Starting

with a tip hole size sma ller than the maximum

w ill allow you to spray within the rated flow

capacity of the sprayer.

·

Maximum tip hole sizes supported by the sprayer.

0 .015 om (0.38mm)

Understanding Tip Number

The Last Three digits of tip number (i.e.:221413)

Contain information about hole size and fan width on

surface when gun is held 12 in. (30.5cm) from surface

being sprayed.

First digit when doubled

= approximate

fan width 413 tip has

8-10 in.

Fan with

413 tip has

a 0.013 in

hole size

Last two digits= tip hole size in thousands of an inch

Tip Hole Size

Coatings

Stains

Enamels

Primers

In te rior Pa ints

Exterior Paints

0.011in.(0.28mm)

√

0.013in.(0.33mm)

√

√

√

√

0.015in.(0.38mm)

√

√

√

√

0.017in.(0.43mm)

√

√

√

0.019in.(0. 48mm)

√

NOTE: When Using “HOT” solvents, replace Viton O-

ring (item 32) with optional Teflon o-ring install

with o-ring tool

15.

Reversible Tip Selection Chart

Tip Part No:

Fan Width 12 in

(305 mm) from

surface

Hole Size

Alt311

6-8 in.

(152-203mm)

0.011 in.

(0.28mm)

Alt411

8-10 in.

(203-254mm)

0.011 in.

(0.28mm)

Alt313

6-8 in.

(152-203mm)

0.013 in.

(0.33mm)

Alt413

8-10 in.

(203-254mm)

0.013 in.

(0.33mm)

Alt415

8-10 in.

(203-254mm)

0.015 in.

(0.38mm)

Alt515

10-12 in.

(254-305mm)

0.015 in.

(0.38mm)

Alt417

8-10 in.

(203-254mm)

0.017 in.

(0.43mm)

Alt517

10-12 in.

(254-305mm)

0.017 in.

(0.43mm)

Alt519

12-14 in.

(305-356mm)

0.019 in.

(0.48mm)

Example: For an 8 to 10 in. (203 to 254mm) fan

width and 0.013 (0.38mm) hole size, order Part

No. alt413

Piston Lube

Specially Formulated to prevent materials

from adhering to the piston rod, which

become abrasive to the upper seals.

Pistonlube will break down any material

that may accumulate in the oil cup and

keep it from drying.

Part # Description

Alm-481.............4 ounce bottle

Miscellaneous

Part No. Description

Alm-012........Hose coupling, 1/4”x1/4”

Alm-397........High Pressure Fl. Gauge

Alm-171........Lubriplate, 14 ounce individual

Alm-172........Lubriplate, 6 lb. Can

Alm-1037......Electrostatic discharge

(ESD) wrist strap

Table of contents

Other Dino-Power Paint Sprayer manuals

Dino-Power

Dino-Power DP-6336iB User manual

Dino-Power

Dino-Power DP-X Series User manual

Dino-Power

Dino-Power DP-X Series User manual

Dino-Power

Dino-Power DP-X5 User manual

Dino-Power

Dino-Power DP-X6 User manual

Dino-Power

Dino-Power DP-6840iB User manual

Dino-Power

Dino-Power DP-X3 User manual

Dino-Power

Dino-Power Titan 440i User manual

Dino-Power

Dino-Power DP6391C User manual