5. Health and Safety Information

Important: Read all the Health and Safety instructions

before attempting to operate, maintain or repair this

product. Non-compliance with these instructions may

result in injury or damage to the user or the product.

5.1 General Health and Safety

Precautions

• Only authorised personnel who have carefully read

and understood this manual may operate, adjust and

repair this product.

• Observe all standard safety precautions and good

practices when working with air tools.

• Always wear adequate eye protection and a face mask

when using this product.

− Some products suitable for use with this product

may contain chemicals or toxic components.

− Avoid inhalation or contact with materials used

with this product.

− If contact occurs, seek medical advice as soon

as possible.

• Wear ear defenders and protective gloves while using

this product.

• Keep your work environment clear and well-lit,

with bystanders at a safe distance.

• Use this product ONLY in well-ventilated areas to

avoid the build-up of fumes and allow paint particles

to disperse.

• Keep out of reach of children.

• Before every use, inspect the tools for missing,

broken, loose or corroded parts.

Important: DO NOT use this product if it is damaged

in any way. Contact Draper Tools to discuss repair and

replacement options.

• Ensure that all accessories and attachments are

securely tightened before use.

• Use the product only in the manner instructed in

this manual.

• DO NOT modify this product in any way.

• ONLY use spare parts supplied by Draper Tools.

• Stay alert at all times; DO NOT use this product while

tired or under the inuence of alcohol, drugs or

other medication.

5.2 Additional Safety Instructions for

Air Tools

• Compressed air can cause severe injury.

− ALWAYS turn o and disconnect the air supply

before making any adjustments to the product or

leaving it unattended.

− NEVER direct this product towards yourself

or others.

− Ensure that compressed air is not blocked by or in

contact with any part of your body.

• ONLY use clean, dry and regulated compressed air.

WARNING! NEVER use oxygen, combustible

gases or other bottled gases as a supply for

this product. Use of these substances may

cause the product to explode.

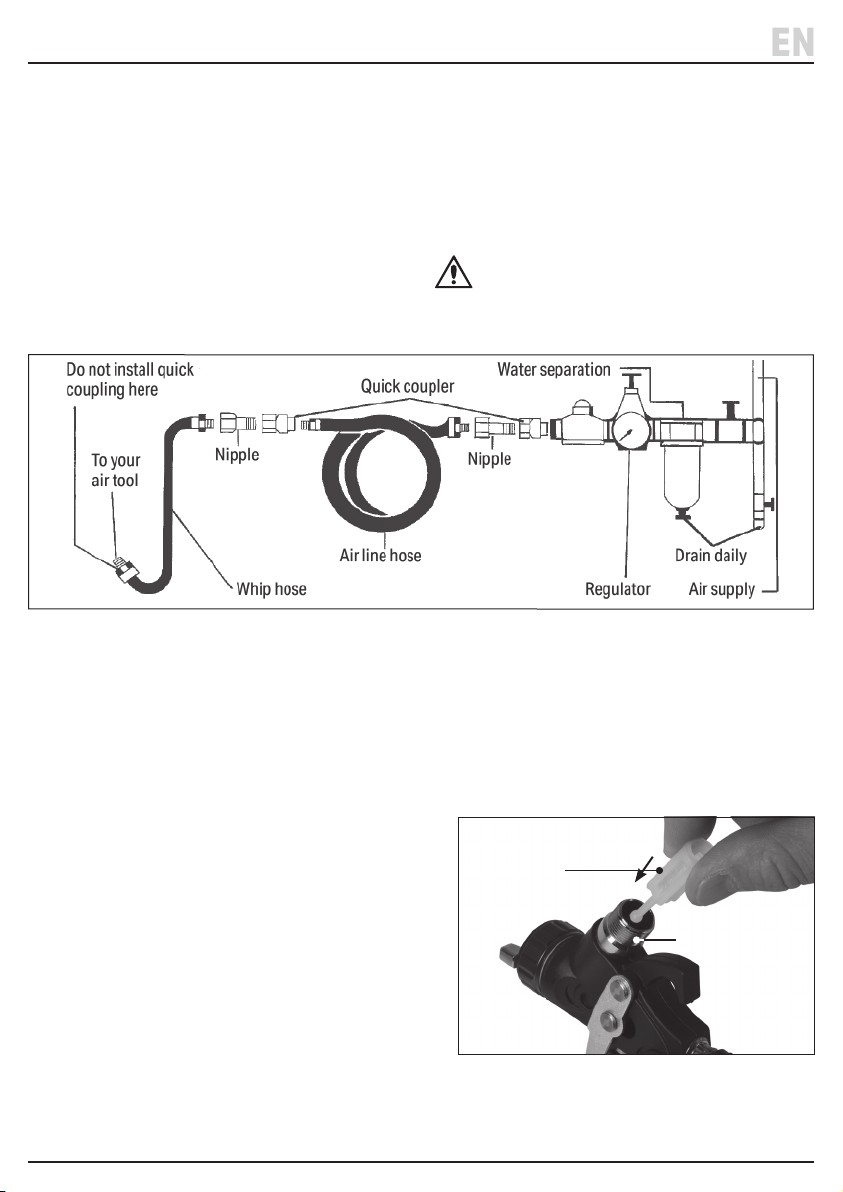

• Draper Tools recommends the use of a whip

hose between the tool and the air supply to

reduce vibration.

CAUTION! Whipping hoses can cause

severe injury. Always check for and replace

damaged or loose hoses and ttings.

• Ensure that the product is compatible with the air

supply before use.

• Ensure all connections are securely tightened.

• DO NOT exceed the maximum stated air pressure.

− The pressure of the connected air supply MUST

NOT exceed more than 10% of the rated pressure

of the product.

• DO NOT obstruct the ability of the trigger to release

once depressed.

• NEVER carry the tool by the air line.

• Some parts of the spray gun may become hot

during use.

− Allow the nozzle and paint cup to cool after use

before handling or adjusting them.

• NEVER spray ammable substances near open ames

or sources of heat and ignition.

− DO NOT smoke in the vicinity of this product.

• DO NOT use this tool in temperatures that do not fall

within 0–40°C.

– 6 –