Dino-Power DP6391C User manual

ModelNumber: DP6391

High-pressurePneumaticAirless paint sprayer

InstructionManual

(Please read carefully beforeusing)

http://www.airlesspaintsprayer-pump.com

1

SafetyWarning

Thisequipmentmust onlybeoperatedbytrained personnel.

Everyequipmenthasaspecificuse.PleaseconsulttheagentofDino-powerifyou haveany

questions.

Neverattempttomodifytheequipment,norexceedthemaximumworkingpressureofthe

system.

Checkthe equipmenteveryday. Maintainorreplaceoldorbroken partsimmediately.

Readthe warningsprovidedbythemanufacturersofcoatingsandsolvents.Makesurethatthe

usedcoatingsandsolventsareapplicabletothecontactpartsoftheequipment.

Donot drag equipment withthehigh-pressurehose,norput thehigh-pressurehoseinplaces

ofheavy traffic,onsharpedges, onmovingobjectsandonhotsurfaces.

Followall relevantlawsandregulationsoflocalgovernmentsandthecountryregarding fire

prevention, electricityusageandsafety.

Donotpointthespraygunat anybodyoranypartofthebody.Donotputyourhandorfingeron

thespraygun,norblockthecrackorleakpointwithyourhand,body,glove,ordustercloth.

Theinjurycausedbyhigh-pressurecoatingsprayed ontotheskinmayappearjustasacut, but

itisactuallyasevereinjury. Thevictimshouldgotosee aprofessionaldoctorimmediately.

Beforeoperatingtheequipment,pleasetightenallconnectorsand makesurethatthetrigger

safetyof sprayguncanbeoperated safely.

Whenthesprayingisstopped,pleaselockthetriggerofspraygun.

Checkthe high-pressurehoseandconnecting partseveryday.Replacebrokenparts

immediately.Donotrepairbrokenhigh-pressureconnectingparts,inwhichcasethewhole

pressurehosemustbereplaced.

Theintakehoseofair-drivenmotormustbetiedupandfirmlyconnected.

Whilethepressureisnotreleasedandtheintakeswitchisopened,donotloosen the

connecting partsamongcoatingpump, high-pressurehoseandspraygun.

Theequipmentmustbe wellgrounded whilebeingused.Ifthereareelectrostaticsparksor

you receiveanelectricshock,pleasestopsprayingimmediatelyuntilyoufind outthecause

andeliminatethetrouble.

Keepthecirculationof freshairtoavoidtheaccumulationof theflammablegasesinsolvents

andcoatingsduringsprayingoperations.

Inthesprayingarea,naked fireisforbidden. Donot smokeinthespraying area.

Inthesprayingarea,do notturnon oroff anylightduringspraying operations.

Donot start the gasoline engineinthespraying area.

2

Knowthe specialharmofthe coatingyouareusing.

Alwayswearprotectiveglasses,gloves,clothingandmuskrecommendedbythe

manufacturersofcoatingsand solvents.

Actionsofthrashing,knockingorthrowing thecylinderofthecoating machine areforbidden. If

thecylinderisfoundbroken, it shouldbereplacedwithanewone.Itisalsorecommendedthat

thecylindershouldbereplacedwithanewoneafterbeingusedfor5000hours(or3years)to

ensurethe safety.

Theboltsconnectingthecylinder,theuppercoverandthelowercoverofthecylindermustbe

tightened asperthetorquedefined inthefollowingtable.If abnormitiessuchasdistortionand

slidingarefoundonbolts,theyshouldbereplacedwithnewonesaspertheperformance

ratingsand specifications.

Betweenrealproductandthecorrespondingdescriptioninthe instructionmanual.Pleasetake

actualproductasstandard.Allmodificationsduetoerrorcorrectionorproductimprovement

willbeexplainedbyDino-PowerIndustry&TradeCo., Ltd.atanytimewithoutnotice.The

revisedpartswill be includedinthesecondedition of theinstruction manual.

3

Dino-Power Airless Spraying Machine

1General

1.1Application

ModelDP6391 high-pressureairless spraying machinesarethe 3rd generation sprayingequipments

developedbyourfactory.Theyareapplicabletoindustrialusagesuchassteelstructures,ships,

automobiles,railwayvehicles, geology,AeronauticsandAstronauticsand soon,forthespraying of new

coatingsorthick-film heavy-dutyanti-corrosivecoatingswhicharedifficult tooperate.

1.2ProductCharacteristics

ModelDP6391high-pressureairlesssprayersadoptadvancedtechnologyandareunique.Theyare

almostfreeof DeadPoint”faultduringreversionand shutdowncausedbythe Frosting”resultedfrom

the AdiabaticExpansion”ofexhaustparts.Thenewsilencingdevicegreatlyreducesexhaustnoise.The

air-distributing reversingdeviceisunique andmovesquicklyand reliably,withsmall amountof

compressed airand lowenergyconsumption.Compared withtheirforeigncounterpartswiththesame

mainparameters,theweightofthe formerisonlyone thirdofthelatterand thevolumeisonlyone quarter

ofthe latter.Moreover,theyhavehighoperationalreliabilities,whichareadvantageoustoensurethe

coatingperiod andenhanceandensurethecoating quality.

2MainTechnicalParameters

Model Pressure

ratio Coating delivery

capacity

L/min)

Airintake

pressure

MPa)

Air

consumption

L/Min)

GW

Kg)

DP6391A 30: 1 8.40 0.3~0.6 450-1200 75.00

DP6391A 45: 1 7.00 0.3~0.6 450-1200 75.00

DP6391B 38: 1 13.50 0.3~0.6 650-1400 87.00

DP6391B 46: 1 10.40 0.3~0.6 650-1400 84.00

DP6391B 69: 1 7.00 0.3~0.6 650-1400 84.00

DP6391C 45: 1 13.50 0.3~0.6 900-1650 99.00

DP6391C 60: 1 11.00 0.3~0.6 900-1650 96.00

DP6391C 76: 1 8.00 0.3~0.6 900-1650 93.00

4

3outlinedrawingof Dino-PowerAirless Sprayer(See Figure)

Themainworking partofthe sprayeristhe double-actingair-drivenhighpressurepaintingpump.The

reversing mechanismisthepilot all pneumaticcontrolair-distributingreversing devicewithspecialform.

Whenthecompressed airflowsintothe cylinder, the pistonmovestothe upperpartorlowerpartofthe

cylinder,forcingtheupperorlowerpilotvalvetooperate.Thecontrolairdrivesthe air-distributing

reversing devicetoactinaninstant,thereforerealizingstableandcontinuousreciprocating movementof

thepistonoftheair-drivenmotor.Thankstothe rigidconnection betweenthepistonand theplungerofthe

coatinghydraulicpump,and thegreaterareaof thepistonthanthatof theplunger, thesuckedcoating is

pressurized.Thepressurizedcoating isconveyed tothe airless spraygun viathehigh-pressurehose,

andfinallyreleased ofthe hydraulicpressureandatomizedat theairlessnozzle,andthenspayedtothe

surfaceofthe targettoformacoatinglayer.

4Operatinginstruction

4.1Beforeusing,firstcheck ifallbolts,nuts,pipe connectors,andthe connectingnutsandhoseclampsof

thesuctionsystemhavebeentightened. Learncarefullyabout theopening andclosingdirection of gate

valveon eachaircircuit, andthe rotatingdirectionsofpressureregulatingvalveand dischargevalve(for

thepressureregulatingvalve,turnthehandwheelclockwisetoopen and anti-clockwisetoclose).The

Airintake

5

capacityoftheequippedaircompressormustbe largeenough. Thelengthofthe usedairpipemustnot

exceed5m.

4.2Plugboththecoatingsuctionpipeandthedischargevalveintothetankcontainingdilutedcoating, put

through theairsource, and adjusttheairintakepressureaccordingtothetypeofcoating.Toensuresafe

use, themaximumairintakepressuremustnot exceed0.6MPa,andisbettertobekept atavalueaslow

aspossibleaslongasthe atomizationofthecoatingisgood.

4.3Openthedischargevalve(Donot open the spraygun), thenthe air-drivenhydraulicboosterpumpof

thesprayerwill moveto-and-froinacontinuousand stableway.Afterthecoating hydraulicsystemofthe

sprayerhascirculatedinidleconditionfor2to3minutes,closethe bleedvalve. Iftheair-driven hydraulic

pumpcan workinbalancepeacefullyafterthepressureofthecoating hydraulicsystemhasreached

balance,thesprayingoperationcanbestarted.

4.4During thespraying, the spraygunshouldbe pointedverticallyoralmostverticallyattheworkpiece

beingcoated;and themoving direction shouldbeparalleltothe surfacebeing coated. Thespeed should

beeven toavoidsagging.

4.5Thecoatingshouldbekeptclean.Fortheunclean coating,itisnotallowedtobeusedif notbeing

filteredfirstwithastrainerof40to100meshesaccording tothedimension andviscosityof thecoating

particle.If the coatingisnew, cleanandwithoutimpuritiessuchashornskinandsandgrain,it doesnot

needtobe filteredafterhaving beenevenlymixed.Forthecoatingapttodeposit,itshouldbemixed

regularlyandcontinuouslyduringthe sprayingprocess.

4.6Duringthe sprayingprocess,thetriggersafetyof spraygunshouldbelockedintimeifthenozzleis

beingcleanedorreplacedorthesprayingisstopped.Undernocircumstancesshouldthespraygunbe

pointed attheoperatororothers,incasethetriggerisaccidentallypressedcausing thehigh-pressure

coatingtosprayand injuresomeone.Ifthe spraygun can stillbeopenedafterthe triggersafetyhasbeen

locked,thesmall nutattheendofthedrawbarofthe gun’svalveplugshouldbe adjusted. Ifthenozzleis

blocked,itshouldbeimmersedandcleanedwithsolvent,orcleanedcarefullywithabrush.Donotpokeit

withhardthingsasthismaydamagingthenozzle.

4.7Ifaairlesstipisusedduringsprayingprocessand thenozzleisslightlyblocked, justturnthe handle

180degreesandtriggerthespraygun,thedirt inthenozzlewill beblownoffbythehydraulicpressureof

thehigh-pressurecoating itself. Ifthenozzleiscompletelyblocked,theconnectingnutofthe nozzlehas

tobeslightlyloosened.Thehandlecanonlybeturnedafterthe coating hasbeendepressurized.Ifthe

handleisturnedbyforcewhilethecoating isstillpressurized,thehandleiseasilydamaged. Whileusing

standardnozzleorairlesstip, asealing ringhastobe placedatthejointofthe nozzleand thespraygun.

4.8Ifthesprayerhasworkedcontinuouslyforalongtimeandasevere frosting”phenomenonhas

appearedinsideandoutsidethe silencer,awater-separating airfilterandanairdryercan be installed

beforethecompressedairentersthesprayer,andthe silencercanbedismantled.Anotherwayisto

replacetheengineoilintheoilcupofoilatomizerwith Anti-icing FluidforRadiator”.The

water-separatingairfilterandairdryerwillbe purchased ormanufactured bythe customeraccording to

actualneeds.The Anti-icingFluidforRadiator”isavailablenationwide.

4.9Ifthesprayingoperationisfinished orwill notbe usedforalongperiodsoftime,the suctionpipe

shouldbepulledoutofthecoatingtankintime.Theresidualcoating inthecoatingpump,the suction pipe,

thehigh-pressurehoseandthe spraygunshouldbedischargedbyrunning thesprayeridly.Thenthe

wholecoatinghydraulicloopincluding thecoatingpump,the suctionpipe,thedischargevalve,the

high-pressurehose,the airlessspraygunand thenozzleshouldbecleanedbyrunningthesprayeridly

withdilution agentorsolvent.Duringthecleaning, the openingofairintakeball valveshouldbesmall,the

reciprocaltimeof thesprayerisbettertobecontrolledwithin30to40timesperminute.

6

5Common Faultsand Trouble-shootingMethod

Generally,thefaultsofairlesssprayercan bedividedintotwotypes:faultsinairsystemandfaultsin

coatingsystem.Ifafaultoccurs,it'sprohibitedtodismantleblindly.Thefaultshouldbeanalyzedand

eliminated step bystepasshowninthefollowingtable.Beforethat,thepressureswitchshouldbe

dismantledand theairintakeballvalveshouldbeclosed.

SN Phenomenon Reason Trouble-shooting Method

1 Notenoughpower

forreversing,small

flowduring

operation.

Airintakeamountnot enough. 1)Check ifthe pressureofairsourcemeetsthe

requirement?

0.6~0.8MPa)

2)Dothespecificationsofaircompressorandthe

drift diameterofairsourcepipelinemeetthe

requirements?(the deliverycapacityshouldnotbe

lessthan1.2m

3

/min,thedriftdiameterofthe

pipelineshouldnot belessthan20mm)

3)Aretheconnectorsoneachpipelinetightened?

4)Hastheairintakeswitchreachedthemaximum

opening?

2 Thesprayeris

whirring;the

coatingpressureis

notenough;the

atomization isnot

good.

1)Severeabrasionbetweenslide

boards;thecontactsurfaces

arenotparallel;thesealingis

not good;airpartiallyescapes;

airintakeamountofthe

cylinderdecreases;not

enough sprayingpressuredue

tothe reductionofpiston

thrust.

2)Deformationofslideblockafter

having beenusedforalong

term.Theairflowcan not

press oneslideblock onto

another,causingleakage.

3)TheO-shaperubbersealing

ringinthecylinderisabraded

andraised,resultinginan

insufficient airpressure.

4)Theairintakecartridgeis

blockedbyforeignobjects.The

airpathisnotsmooth,resulting

ininsufficientairintake

1)Dismantletheair-distributingblock andtheslide

blockandputthemonapieceofmetallographic

abrasivepaper,whichhasbeenspreadoutona

flatplate.Pushand grind themsmoothlywithboth

handsandthen cleanthem.Theflatnesscan be

checkedwithred lead powder.The even

distribution ofredsqueegeeoilonbothcontact

surfacesmeansthattheyareflat.Ifnot,grind

themagainwiththeabove-saidmethod.After

being grinded toflat,the slide boardand the

intra-cavityofthe slide blockmustbeoiledwith

20# engine oil,andassembled aspertheir

originalforms.

2)Dismantletheair-distributingblock andtheslide

block,andgrind themwithapieceofabrasive

paperuntiltheyareworkingsmoothlywiththe

reversingpiston.Oilthecavityoftheslide block

withclean20# engineoil.

3)Unscrewalltheboltsconnecting the uppercover

andthelowercovertothecylinder.Openthe

cylinder,replacethedamagedO-shape sealing

ring,andoiltheinwall ofthecylinderwithclean

20#engineoil.

4)Cleanorreplacetheairintakecartridge.

3 Thesprayerstops

afterstarting.Aair

streamsprays

continuouslyfrom

upperorlower

observationplug

hole.

Foreignobjectexistson theouter

edgeoftheO-shapesealingring

onthe reversingpiston;blowby

happensbetweentheupperand

thelowercavity.

Dismantletheair-distributingboardandtheupper

coverofthe reversing piston,takeout the reversing

piston andreplacethebrokenO-shape sealing ring.

Purgeandcleanthereversingpiston holewith

compressedair.Oiltheinwall andtheO-shape

sealing ringwithclean20# engineoilandassemble

themaspertheiroriginalforms

4Thesprayerstops

afterstarting.Aair

streamsprays

continuouslyfrom

the silencer.

1)Thereversingblock stopsat

thedead pointpositioninthe

middle.

2)TheO-shapesealingringof

thecylinderpiston isbroken.

3)TheM8nutofthe

air-distributingpiston rodis

lost.

1)Dismantlethescrewontheairintakecoverand

pushthe reversing piston tomakeitleavethe

deadpoint position.

2)Replacethe O-shapesealingringofthecylinder,

andoiltheinwall ofthecylinderwithclean20#

engineoil.

3)Re-tightentheM8nut.

5 Thepressuredrops

suddenlyduring

spraying;the

atomization isnot

good;thecoating

sprayslikeraysor

nocoatingsprays,

buttheair-driven

pumpworks

normally.

1)Thecoatingsuctioninletis

blocked.

2)Oneachvalveport, foreign

objectsraisethevalvepug.

3)Thespringabovetheplunger

valvebodyisfractured.

4) Cavitation Erosion”happens

oneachhigh-pressurevalve

port.

5)TheV-shape sealingringon

theplungervalvebodyhas

beenabraded.

1)Cleanthesuctioninlet.

2)Cleantheforeignobjectson eachvalveport.

Cleanthestrainerinside thepressurereservoir.

3)Replacethe spring.

4)Replacethesuctionvalvebody,theplunger

valvebody,the discharge valvebodyorthesteel

ball.

5)Replacethe V-shape sealing ring onthe plunger

valvebody.

7

6 Afterthedischarge

valveandthespray

gunhavebeen

closed,the

air-drivenmotorstill

movesto-and-fro

regularly.

1)TheV-shape sealingring on

theplungervalvebodyhas

beenabraded.

2)Thehigh-pressurevalveports

onthe plungervalve,the

suctionvalveandthe

dischargevalvearebroken.

1)Replacethe V-shape ringonthe plungervalve

body.

Caution:TheV-shapesealingringshouldbe

replacedingroupandasperitsquantityand

directionbeforeitisdismantled.

2)Replacethesuctionvalvebody,thesuction valve

body,the discharge valvebodyorthesteelball.

7 During spraying,

coatingisfoundin

the oilcupofthe

pumpbase.

TheV-shape sealing ringinthe

pumpbaseisabraded. ReplacetheV-shapesealingringinthepumpbase.

Caution:TheV-shapesealingringshouldbe

replacedingroupandasperitsquantityand

directionbeforeitisdismantled.

Generallyspeaking,thetrouble-shootingshouldbedone step bystep.At first,presumesomepartsare

normalandtheothersarenot,andcheckthe partsyouthinkarefaulty.Ifthechecked partsarenormal,

check otherparts,untilallfaultsareeliminated.

Caution:Beforethetrouble-shootingand maintenance operation,theairintakeball

valve mustbeclosedandthesystemmustbedepressurizedbyopeningthe

dischargevalve.

6Equipment Maintenance

6.1Toavoiddamaging thehigh-pressurehose,whileusing it,donotoverbend,steppedon, stressorroll

bywheels.

6.2Toensuregood filteringfunctions,strainerson theequipmentmustbemaintainedandcleaned

regularly strainersoncoatingsucker,pressurestoringfilter, andthe innertubeofthe pikestaff).

6.3Whenthenozzleholeisblocked,donotstab itwithaneedle, incasethe nozzlelipisdamaged and

theatomization qualityisaffected.

6.4The pumprodsofair-drivenpumpandplungerpumpshouldbeinjectedwithlubricantregularly(inthe

43#compactingscrew).

6.5The oilcupintheair-drivendualpartsmust befilledwith20#engineoilregularly.

7SparePartsPackagesList

ModelDP6391A30:1& DP6391B 46 : 1

SN Name Specification Quantity

Assemblingpart

146# Kraft V-shapesealingring ¢51.5X¢36.5X 6

6 Coating cylinder

245# PTFE V-shape sealing ring

¢51.5X¢36.5X 6

6 Coating cylinder

359# pumpbodywasher ¢74 X¢68X4 1 Coating cylinder

466#suction valvewasher ¢59 X¢51X4 1 Coating cylinder

ModelDP6391A45:1& DP6391B 69 : 1

SN Name Specification Quantity Assemblingpart

1 46#Kraft V-shape sealingring ¢42X¢30X7 6 Coatingcylinder

2 45#PTFEV-shapesealing ring

¢42X¢30X7 6 Coatingcylinder

3 59# pumpbodywasher ¢61.5X¢30X 7 1 Coatingcylinder

4 66#suction valvewasher ¢49X¢45X4 1 Coatingcylinder

8

ModelDP6391C45: 1

SN Name Specification Quantity Assemblingpart

1 KraftV-shape sealingring ¢60X¢40X8 2 Plungervalvebody

2 PTFE V-shapesealingring ¢60X¢40X7.5 3 Plungervalvebody

3 KraftV-shape sealingring ¢64X¢42.6X 9 4 Pumpbase

4 PTFE V-shapesealingring ¢64X¢42.6X 8 4 Pumpbase

ModelDP6391C60: 1

SN Name Specification Quantity Assembling part

1 46# Kraft V-shapesealingring ¢51.5X¢36.5X6

6 Coatingcylinder

2 45# PTFE V-shape sealing ring

¢51.5X¢36.5X6

6 Coatingcylinder

3 59# pumpbodywasher ¢74X¢68X4 1 Coatingcylinder

4 66#suction valvewasher ¢59X¢51X 4 1 Coatingcylinder

ModelDP6391C76: 1

SN Name Specification Quantity Assemblingpart

1 46# Kraft V-shapesealingring ¢42X¢30X 7 6 Coatingcylinder

2 45# PTFE V-shape sealing ring

¢42X¢30X 7 6 Coatingcylinder

3 59# pumpbodywasher ¢61.5X¢56.5X 4 1 Coatingcylinder

4 66#suction valvewasher ¢49X¢45X 4 1 Coatingcylinder

8PackingList

1Completeset ofairlesspumpmachine 1set

2.Airlessspraygun 1set

3.Airlesstip 1set

4. High-pressurehose ¢8mm X 10m)1set

5. High-pressurehose ¢6mm X 2m)1set

6Transitionjoint(M14X1) 1set

7. Repairkitsuppliedbymanufacturer 1set

8hookspanner78-85 1set

9hookspanner55-62 1set

10. Innerhexagonspanner5mm 1set

11.Innerhexagon spanner6mm 1set

12Productinstructionmanual 1copy

9

9 ExplodedDrawing

10

10 PartsList

SN Name SN Name SN Name SN Name

1 Plainwasher 32 Nut 63 Retainingring 95 Needle valve

2 One-wayvalve

cover 33 Bolt 64 Steelball 96 Inner hexagon

cheesehead screw

3 Rectangular

spring 34 Panel 66 Suctionvalve

washer 97 Uppercover of

air-distributing

cylinder

4 Sliding bush 35 Air intakejoint 67 Suctionvalve body

98 O-shapesealing

ring

5 Check valve

assembly 36 Packing pate 68 Suctionvalve nut 99 Nut

6 Capnut 37 Air intake pipe 69 Angle balljoint 100 Washer

7 Spring washer 38 Packing pate 70 Coating suction

pipe joint 101 O-shapesealing

ring

8 Uppercover of

cylinder 39 Joint 71 Packingpate 102 Air-distributing

shortpiston

9 Retaining ring 40 Air-drivendual

parts(assembly)

72 Coating suction

hose 103 O-shapesealing

ring

10 O-shapesealing

ring 41 Connecting screw

73 Feeding pipe 104 End cap

11 Sealing base 42 Connecting nut 74 Gland nut 105 Air-distributing

pistonrod

12 O-shapesealing

ring 43 Housing pin 75 Pressurestoring

cylinder 106 Air-distributing

body

13 Screw stud 44 Sealing baseplate

76 Lscrewplug 107 Sealing gasket

14 Cylinder body 45 V-shape ring

(leather) 77 Coating passing

pipe 108 Gasket

15 Nut 46 V-shape ring

(Plastic) 78 Strainer assembly 109 Air-distributing

plate

16 O-shapesealing

ring 47 Sealingpressure

plate 79 Strainerframework

110 Air-distributing

slide block

17 Piston 48 Round nut 80 Gasket 111 Spring

18 Gasket 49 Fixing plate 81 Check valve body 112 Spring base

19 O-shapesealing

ring 50 Plain washer 82 Steelball 113 O-shape ring

20 Piston gasket 51 Pumpbase 83 Spring 114 Airintake cover

21 Pistonrod 52 Pumpbodygasket

84 Spring base 115 Inner hexagon

cheesehead screw

22 O-shapesealing

ring 53 Spring¢62X¢

5X40 85 Union 116 Air-distributing

piston

23 Guiding packing

gland 54 Pumprod 86 Unionnut 117 Coverof

air-distributing

cylinder

24 Nut 55 Spring 87 Discharge

connector 118 Silencer

25 Plainwasher 56 Steelball 88 Mainbodyof

pressurereservoir 120 Inner hexagon

cheesehead screw

26 Boltgasket 57 Nut 89 Joint 121 Frame assembly

27 O-shapesealing

ring 58 Gasketbody 90 Needle valve

28 O-shapesealing

ring 59 Pumpbodygasket

91 Discharge

connector

29 Cylinder baseplate

60 Pumpbody 92 Nut

30 Plainwasher 61 Pumpbody nut 93 End cap

31 Lightspring

washer 62 Spring ¢52X¢

4.5X28 94 Joint

11

Dino-Power”serieshigh-pressureairless sprayersareapplicabletothe coatingsofsteelstructures,

ships,encaustictiles,bigbuildings,bigoverpasssteelstructurepavements,bridges,pressurevessels,

leather,locomotives,railwayvehicles,cars,airplanes,chemicalequipments,windpowerequipments,

furniture,racks,containers,pipelines,storagetanks,tabletsugarcoatingsinpharmaceuticalindustry,

andsoon.

Tocustomers:

1、Variousmodelsofhigh-pressureairlesssprayersareavailableforyourselection asperyour

different coatingrequirements.

2、Theequippednozzlefortheproductleavingthefactorymaynotmeetyouractualneedsfor

spraying.Therearemorethan30specificationsofnozzlesmanufacturedbyourfactory,which

youcan orderseparatelyaspertherequirementsforthecoatinganddesign ofyourproductsand

projects.

3、Ifthesprayingequipmentisfaultyandthefaultcannotbeeliminated afteryou havecarefully

readtheinstructionmanual,youcancall uson 86-574-88278841 orsendemailtousat

dpairless@gmail.com and clearlydescribethefaultandthedetailedprocessoftheoccurrenceof

thefault.Wewillpromptlyadviseyou ofthetrouble-shooting methods.Personneloperatingand

maintainingthisequipment must befamiliarwithallrequirementsofthisinstruction manual.

4、Ourproductsareverypopularinthemarket.Ourcompanyisthefirstprofessionalenterpriseto

manufacturehigh-pressureairless spraying equipmentandhigh-pressureoilinjection

equipment.

5、Thanks tothetrustandcooperation ofourcustomersoverthelongterm,seriesproductsof

Dino-Power”sprayingequipmenthaveexcelledinthe fieldofcoatingtechnologyinallindustrial

departments.Wesincerelyhopethatyou ordercompletesetsorpartsof Dino-Power”spraying

equipmentsviavarioussources.

This manual suits for next models

2

Table of contents

Other Dino-Power Paint Sprayer manuals

Dino-Power

Dino-Power Titan 440i User manual

Dino-Power

Dino-Power DP-6336iB User manual

Dino-Power

Dino-Power DP-6840iB User manual

Dino-Power

Dino-Power DP6388B Operation instructions

Dino-Power

Dino-Power DP-X3 User manual

Dino-Power

Dino-Power DP-X5 User manual

Dino-Power

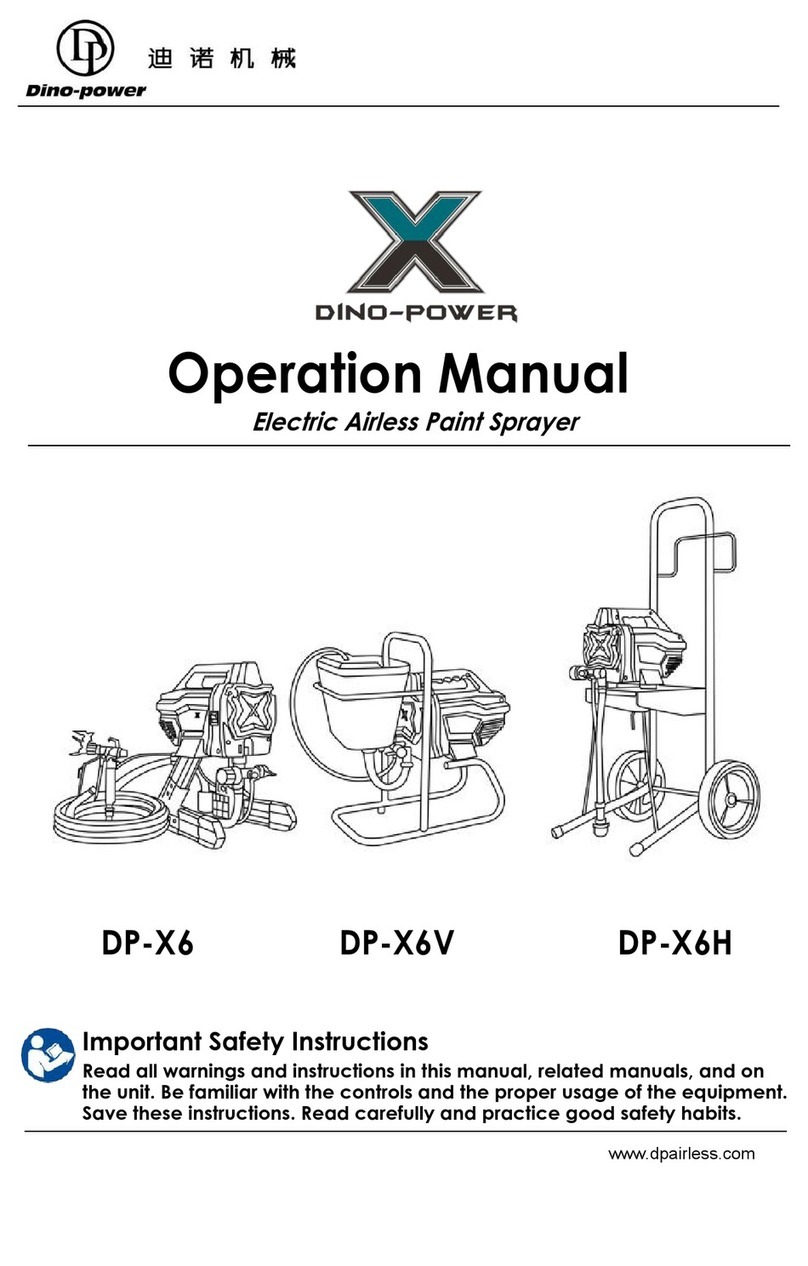

Dino-Power DP-X6 User manual

Dino-Power

Dino-Power DP-X Series User manual

Dino-Power

Dino-Power DP-X Series User manual