Dino-Power Titan 440i User manual

Operationmanual for Airlesspaint

sprayer

High PressureElectric Airless paint sprayerTitan 440i model

intelligentseries

Remark:thisguidemanualisthesamewithmodel DP-6389 ,the contentinclude :the

operationofequipment,cleaning,maintenance,andrepair,besuretopre-operational,read

themanualcarefullybeforeyou usethismachine.

2

1.warningand precautions

SafetyPrecautions

Thismanualcontainsinformation thatmust beread andunderstoodbeforeusing

theairlesssprayer equipment.Whenyoucometoan areathat hasone ofthefollowing

symbols,payparticularattentionand makecertaintoheedthe safeguard.

WARNING

Thissymbolindicatesapotentialhazardthatmaycauseseriousinjuryorloss of life.

Importantsafetyinformation will follow.

CAUTION

Thissymbolindicatesapotentialhazardtoyouortotheequipment.Important information

thattellshowtoprevent

damage totheequipmentorhowtoavoidcausesofminorinjurieswill follow.

NOTE: Notesgiveimportantinformation whichshouldbegiven specialattention.

WARNING

HAZARD:Injectioninjury Ahighpressurefluidstreamproducedbythisequipmentcan

piercethe

skinandunderlyingtissues,leading toseriousinjuryandpossibleamputation.See a

physician immediately.

DONOTTREATANINJECTIONINJURYAS A SIMPLECUT!Injectioncan leadto

amputation.See aphysicianimmediately.

Themaximumoperating rangeof thesprayeris3200PSI/221BARfluidpressure.

PREVENTION:

•NEVERaimtheairless spraygun at anypartof the body.

•NEVERallowanypartofthe bodytotouchthefluidstream.DONOTallowbodytotouch

aleakinthefluidhose.

•NEVERputhandinfrontofthegun.Gloveswillnot provideprotectionagainstan

injection injury.

•ALWAYSlockguntrigger,shutpumpoff, and releaseallpressurebeforeservicing,

cleaningtiporguard,changing

tip,orleavingunattended.Pressurewill not bereleasedbyturningoff themotor. The

PRIME/SPRAYvalvehandle

mustbeturned toPRIMEtorelievethe pressure. RefertothePRESSURERELIEF

PRESSUREdescribedinthepumpmanual.

•ALWAYSkeepairlesstipguard inplacewhilespraying.Thetipguardprovidessome

protection butismainlyawarningdevice.

•ALWAYSremovethe spraytipbeforeflushingorcleaning thesystem.

•Painthosecandevelopleaksfromwear, kinkingandabuse.Aleakcan injectmaterial

intothe skin.Inspect the hosebeforeeachuse.

•NEVERuseaspraygun withoutaworking triggerlockandtriggerguardinplace.

•Allaccessoriesmust beratedatorabove3200PSI/221BAR.Thisincludesspraytips,

guns,extensions,andhose.

3

NOTETOPHYSICIAN:

Injectionintothe skinisatraumaticinjury.Itisimportant totreattheinjuryassoonas

possible.DONOTdelaytreatment toresearchtoxicity.Toxicityisaconcernwithsome

coatingsinjected directlyintothebloodstream.Consultationwithaplasticsurgeonor

reconstructivehandsurgeonmaybe advisable.

HAZARD: EXPLOSIONANDFIRE Solventandpaint

fumescanexplodeorignite.Severeinjuryand/orpropertydamagecan occur.

PREVENTION:

•Provide extensiveexhaust andfreshairintroductiontokeepthe airwithinthesprayarea

freefromaccumulationof flammablevapors.

•Avoidall ignitionsourcessuchasstaticelectricitysparks,electricalappliances, flames,

pilotlights,hotobjects,andsparksfromconnecting anddisconnecting powercordsor

working light switches.

•Donotsmokeinsprayarea.

•Fireextinguishermustbe presentandingood working order.

•Placepumpatleast20feet(6.1m)fromthesprayobjectinawellventilatedarea(add

morehoseifnecessary).

Flammablevaporsareoften heavierthan air.Floorareamustbeextremelywellventilated.

Thepumpcontainsarcingpartsthat emitsparksandcanignitevapors.

•Theequipment andobjectsinandaroundthe sprayareamust beproperlygroundedto

preventstaticsparks.

•Useonlyconductiveorgroundedhigh-pressurefluidhose.Gunmustbegrounded

through hoseconnections.

•Powercordmustbe connected toagroundedcircuit.

•Alwaysflushunitintoseparatemetalcontainer,atlowpumppressure,withspraytip

removed. Holdgun firmlyagainstsideof containertogroundcontainerandpreventstatic

sparks.

•Followmaterialandsolventmanufacturer’swarningsandinstructions.

•Useextremecautionwhen usingmaterialswithaflashpoint below70°F(21°C).

Flashpointisthe temperatureatwhichafluidcanproduceenoughvaporstoignite.

•Plasticcancausestaticsparks. Neverhang plastictoenclosesprayarea.Donot use

plasticdrop clothswhensprayingflammablematerials.

•Uselowestpossiblepressuretoflushequipment.

GASENGINE (WHEREAPPLICABLE)

Always placesprayeroutsideofstructureinfreshair.Keepall solventsawayfromengine

exhaust.Neverfill fueltankwitharunningorhotengine. Hotsurfacecanignitespilledfuel.

Always attachgroundwirefrompumptoagrounded object.Refertoengineowner’s

manualforcompletesafetyinformation.

HAZARD: EXPLOSIONHAZARD DUE TOINCOMPATIBLE

MATERIALS willcausesevereinjuryorpropertydamage.

PREVENTION:

•Donotusematerialscontainingbleachorchlorine.

•Donotusehalogenated hydrocarbonsolventssuchasbleach, mildewcide,methylene

chlorideand1,1,1 trichloroethane. Theyarenotcompatiblewithaluminum.

4

•Contactyourcoatingsupplierabout the compatibilityofmaterialwithaluminum.

HAZARD:HAZARDOUSVAPORS Paints, solvents, insecticides,andothermaterials

canbeharmfulifinhaledorcomeincontactwithbody. Vaporscancauseseverenausea,

fainting,orpoisoning.

PREVENTION:

•Usearespiratorormaskif vaporscanbe inhaled. Readallinstructionssuppliedwiththe

masktobesureitwill provide thenecessaryprotection.

•Wearprotectiveeyewear.

•Wearprotectiveclothingasrequiredbycoatingmanufacturer.

HAZARD:GENERAL Can causesevereinjuryorpropertydamage.

PREVENTION:

•Readallinstructionsandsafetyprecautionsbeforeoperatingequipment.

•Followallappropriatelocal,state,andnationalcodesgoverning ventilation, fire

prevention,and operation.

•TheUnitedStatesGovernmentSafetyStandardshavebeenadoptedunderthe

OccupationalSafetyandHealthAct(OSHA). Thesestandards,particularlypart1910of

theGeneralStandardsandpart1926 oftheConstruction Standards,shouldbeconsulted.

•Useonlymanufacturerauthorizedparts.Userassumesallrisksand liabilitieswhen

using partsthatdonot meettheminimumspecificationsandsafetydevicesofthepump

manufacturer.

•Beforeeachuse,checkallhosesforcuts, leaks,abrasion orbulgingof cover.Checkfor

damage ormovementofcouplings.Immediatelyreplacehoseif anyof thoseconditions

exist. Neverrepairapainthose. Replacewithagroundedhigh-pressurehose.

•Allhoses,swivels,guns, and accessoriesmust bepressurerated atorabove

3200PSI/221BAR.

•Donotsprayoutdoorson windydays.

•Wearclothingtokeep paintoffskinand hair.

•Alwaysunplugcordfromoutletbeforeworking onequipment.

GroundingInstructions

Thisproductmust begrounded.Intheeventofanelectricalshortcircuit,grounding

reducestheriskofelectricshockbyprovidingan escapewirefortheelectriccurrent. This

productisequippedwithacordhavingagrounding wirewithan

appropriategroundingplug. Theplugmustbepluggedintoanoutlet thatisproperly

installedandgroundedinaccordancewithalllocalcodesandordinances.

DANGER —Improperinstallationofthegroundingplug canresultinariskofelectric

shock.If repairorreplacementofthecordorplugisnecessary,donotconnectthegreen

groundingwiretoeitherflatbladeterminal.Thewirewithinsulation

havingagreenoutersurfacewithorwithoutyellowstripesisthe groundingwireand must

beconnectedtothegroundingpin.

Check withaqualified electrician orservicemanifthegroundinginstructionsarenot

completelyunderstood,orif youareindoubtastowhethertheproductisproperly

grounded.Donot modifytheplugprovided. Ifthe plugwill notfit the

outlet, havetheproperoutletinstalledbyaqualifiedelectrician.

GroundedOutlet

5

GroundingPin

Coverforgroundedoutletbox

CAUTION

Useonlya3-wireextensioncordthat hasa3-bladegrounding pluganda3-slot

receptaclethatwill accept theplugon theproduct. Makesureyourextensioncordisin

goodcondition.Whenusingan extensioncord, besuretouseone heavyenough tocarry

thecurrent yourproductwilldraw.Anundersizedcordwill causeadropinline voltage

resultinginlossofpowerandoverheating.

2.NameofequipmentComponentsandfeatures

introduction

A

Motor DC motor 220V 50HZ single-phase

B ICS intelligentPressurecontroller.

Pressuresensorsand equipmenthavesuggestedthat

the statusofthe equipmentfuction

C SuctionComponents

UseWithinthe upperandlowerComponentsforthe

twovalvecoatingwillbeaddedafterthesupercharger

andexhaust

D Pressureadjustment Knob /Button

ControlthecoatingPressureexport

E On/off switch Controlanequipment operationorstop

6

F Pumpfilters The percolationgetsintothe coating inthe equipment

G ReturnValvereturntoverticaldirectionforthestateopen,the

horizontaldirectionforsprayingstate(close)

H Coating painting outlet LinkCoatingtubeand manometerPosition

I Suctiontube Willbefrombucketsinthepaintinhalationequipment

J Paint returntube Returntothestatepaintorsolventoutflowfromhere

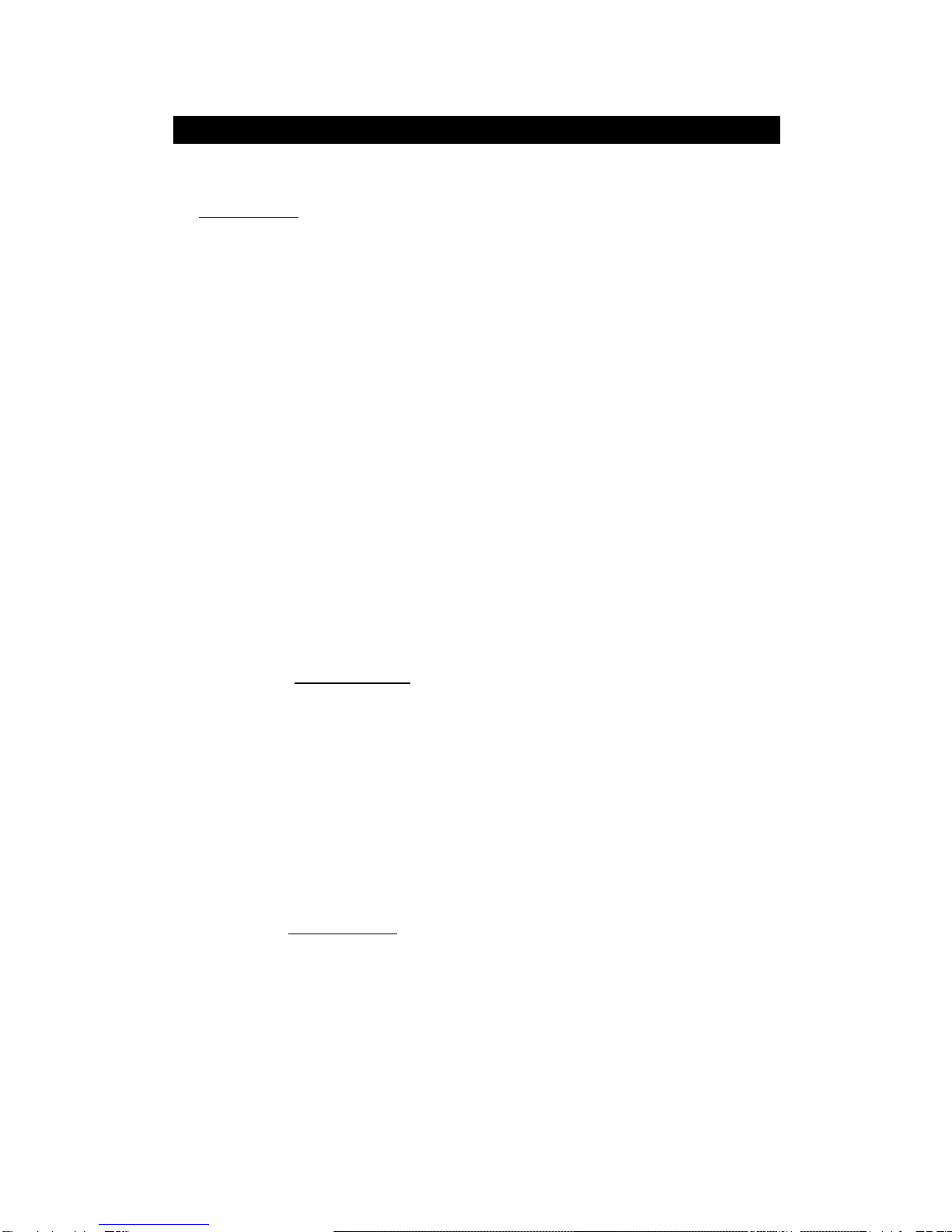

Thepressurecontrolbutton operating Constructions

Nopressurearea(yello

w) indicatethatclose

state

Middlepressurearea(green)

indicatethatmiddlepressure

High pressure(red)

indicatethathigh

pressure

pressurecontrolbutton

7

3.operation

I preparebeforeswitching on.

1. preparetool:

i.5-inch,6-inchall withinahexagonalwrench.

ii.Cross screw4

iii.14-17、17-19ofadouble-headed wrench

iv.ablenderorastirringrod

v.antivirusmaskand aset ofoveralls

vi.abrush

vii.somerags

viii.amultimeter

ix.30-meter 2.5MM²powerlineextension

x.apowerregulator

2. preparetorysteps:

⑴assurancesuctiontubeand therefluxtubelinktheright ofpositionandscrewedtightly

⑵firstlycontecton thecoatingmanometerexit ,then 15meterhighpresurenylon coating

ofpressuregaugesconnected totheexportterminaland screwedtightly(pressuregauge

inthefirstcoating totheexit)

⑶havigtousetwowrenchwillbe nohigh-pressureairlessspraygunconnectedtothe

headand anotherscrewedtightly.

⑷deteminepressuremanometercontrolbuttonssetinthe displaymorethan 150

locations

(5)multimeterdeteminedbymeasureing powersupplyis220-250(equipmentallowing

fluctutationofvoltage)voltsofvoltage.

(6)equipmentwillbedisplayed atthedistanceofatleast7.5metersinconstructionplace

dryregion.

8

3. the initialuseofnewequipment:

the newequipment of thefactorycontainaprotectiveeffect lubricants,so

theinitialuseofnewequipmentneedtojointhecleanwateroffewsoapto

takeintoclean ,theflollowingstep iscleaning:

⑴addtosuctiontube containingalittlesoapywaterinthebuckets

⑵addtothewastewillbereturnedinthepaintbarrels\buckets.

(3)returnvalvewillbeinstalledintheverticaldirection .

(4)openequipment powerswitch..

(5)letsoapywatertoperationequipmentintheequipmentwithinthecircle,untilthe

outflowofcleanwaterfromthereturntube .

II preparetivebeforespraying:

beforespraying,theymustfirstdeterminespraypainthasbeengood

andhavebeen initially harmonicfiltering ,otherwiseundesirablecoating

equipmentwill increaswearandreducethe lifespanofequipment.in

addition,eachtimebeforespraying,thepaintmustbeused bydelicated

diluent(suchasspraying latexpaintwatercanbeused)toallowequipment

tocycleagainandagainspraying,thefollowing is operationsteps:

⑴add suctiontube will be fittedwithspecialdiluentorcleaninthe bucket.

⑵add tothewastewill be returnedinpaintbucket.

⑶Pressurecontrolbuttonswillbeset inthemiddle(yellowareas)butthebottom

ofthelocationofequipment functioning.

⑷returnvalvewillbeinstalledinthe verticaldirection.

⑸Powerequipment opened.

⑹equipmenttooperation 15to30secondsuntiltheclean diluentfromtheoutflow

ofreturn

⑺shut thepowersswitch.

⑻settherefluxvalvetothepositionoflevel.

⑼turnonthepowerswitch

9

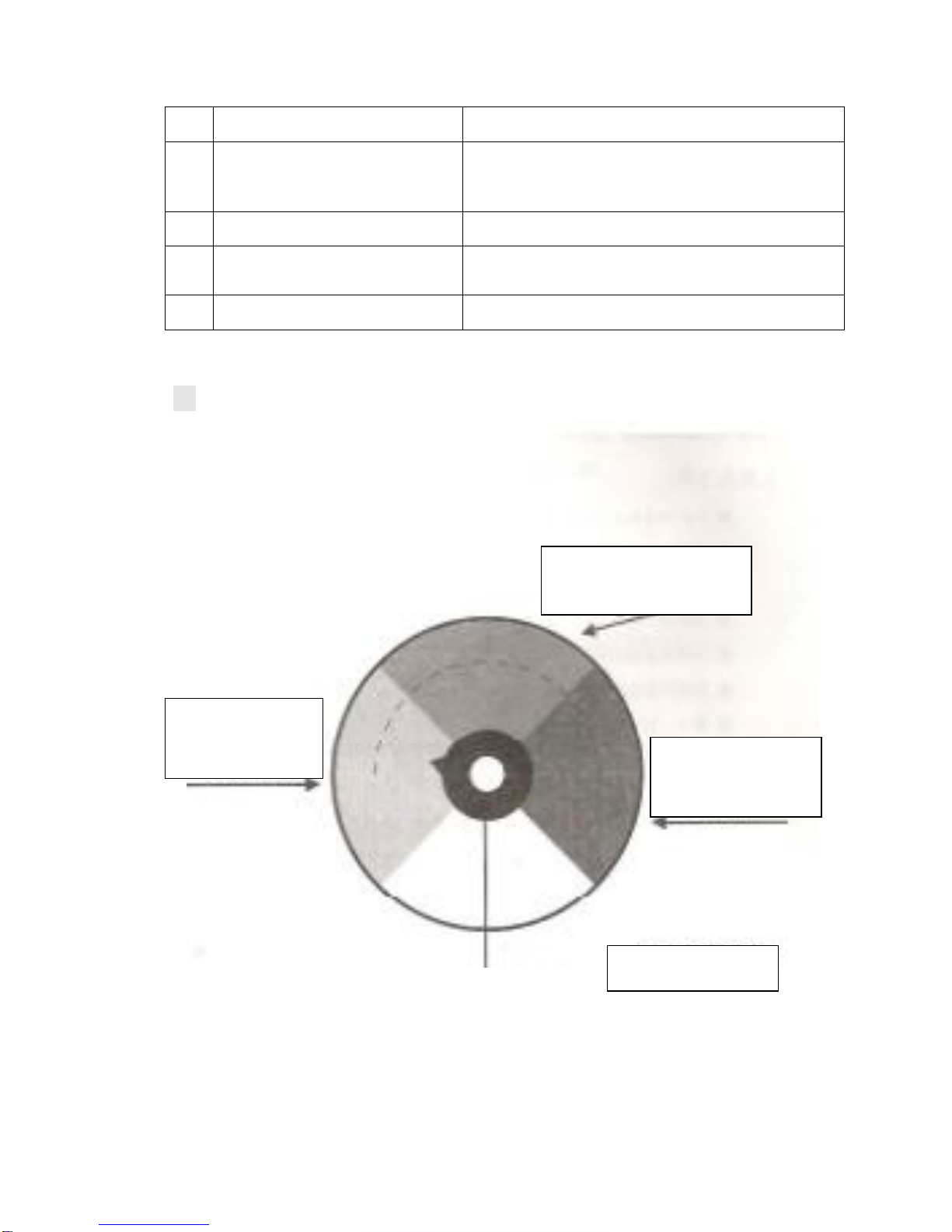

⑽openspraygun insurance.

⑾paintgunmouthtodiscardthepaintwall inside thebucket,deductionunderthe

trigger,andthesprayguntopaintthe originaloldsolventremoved ,untiltheclean

upofthenewsolventexclusion.(astheabovechart)

⑿closesprayguninsurance(astherightchart)

⒀slowlypressurecontrolbuttonswillbesetinthehigh pressure(greenareas)

position.

⒁carefullycheckthe equipmentineveryareawhetherthereisadripphenomenon

andifso,pleasefollowthe “pressurereliefsteps”forpressurerelief,then drip

screwedtightlyontothesite.

2.spraying:

⑴addsuction pipe will berequiredforsprayingpaint bucket .

⑵addtothewastewillbereturnedinpaint buckets.

⑶pressurecontrolbuttonwill besetinthe middle(yellowarea)butthebottomof the

locationofequipmentfunctioning.

⑷returnvalvewillbeinstalledintheverticalposition .

⑸startequipment

⑹equipmenttobeginoperationuntiltheoutflowofthepaint fromtherefluxtube .

⑺shut\closeequipment power.

⑻movethe refluxtubetothecoating buckets

⑼returnvalvewillbesetinthe horizontalposition.

⑽Turnonthepowerswitch.

⑾opensprayguninsurance.

⑿thedeductionunderthetriggerdevicesfromtheresidualsolventuntilatgunpoint

fromtheemitofpaint(asthe rightchart)

⒀closesprayguninsurance.(astherightchart)

⒁shutthe powerswitch.

⒂fittedjacketsandnozzleand nozzlescrewed tightly.

⒃turnonthepowerswitch.

⒄slowlypressurecontrolbuttonswillbeset tomiddleorhigh pressure(the yellow

orgreenarea),inthefirsttrialelsewherespray,paintandgraduallyincreasethe

pressureuntilthe coatingcompletelyfogging up ,you canbeginconstruction.

10

3.pressurereliefsteps

⑴closesprayguninsurance(astheright chart)

⑵shutthe powerswitch.

⑶pressurecontrolbuttonswillbe setonplacewithoutpressure(black areas)

potision.

⑷opensprayguninsuranceanda180-degree reversal.

⑸paintbarrelsofthegunsatthewall,thedeductionunderthe trigger,the

equipmentand piping inthe pressuresrelease.

⑹closesprayguninsurance.(astherightchart)

⑺returnvalvewillbesetinthe verticalposition ,allintheequipmentmaybe

remnantsfromthepressure.

III day-to-daymaintenancemeasures.

⑴beforeeachspraying,checkcompliancewithelectricity.

⑵Beforeeachspraying,wemustadd sealoilintothemouthdropPSL5-6.

⑶aftereachspraying,theequipmentmust be thoroughlycleanedandparts.

⑷aftereachspraying,pleashigh-pressurehosecoiledtoprevent damagetotie.

⑸Iflong-termstoragedoesnotwork, shouldbe usedtoprotectthebodyfluid(blue

bottle),abottleofprotectionagainstthebucket ofwatertodilutethe protectionof

theequipment, cycle,theroleistoprotecttheequipment,sparepartsfrom

corrosion,andthefinalLeta little lubricationequipmentinhalationsolution, andadd

thePSL.

warning

inanyequipment cleaning,repairand maintenance

orbeforethemiddleof thebreak,andyoumuststep

inaccordancewiththeventingpressurerelief.

11

IV.sprayingskills

1.Caution shouldbetakenwhen operatingspraygun,high-pressurehosesandoperatorof

physicalcoordinationbetweenthe two,theoperatorstandingatthe feetsprayingdistance

slightlyoverShoulderWidth,ahigh-pressurepipeintheirhands,high-pressurepipewill

benot stretched too tight,help toSpraywhentheshift easier.

2.Theright handgraspsspraygun, notproperbutton uptomoveatriggerwithindexfinger

andmiddlefingertootightly.

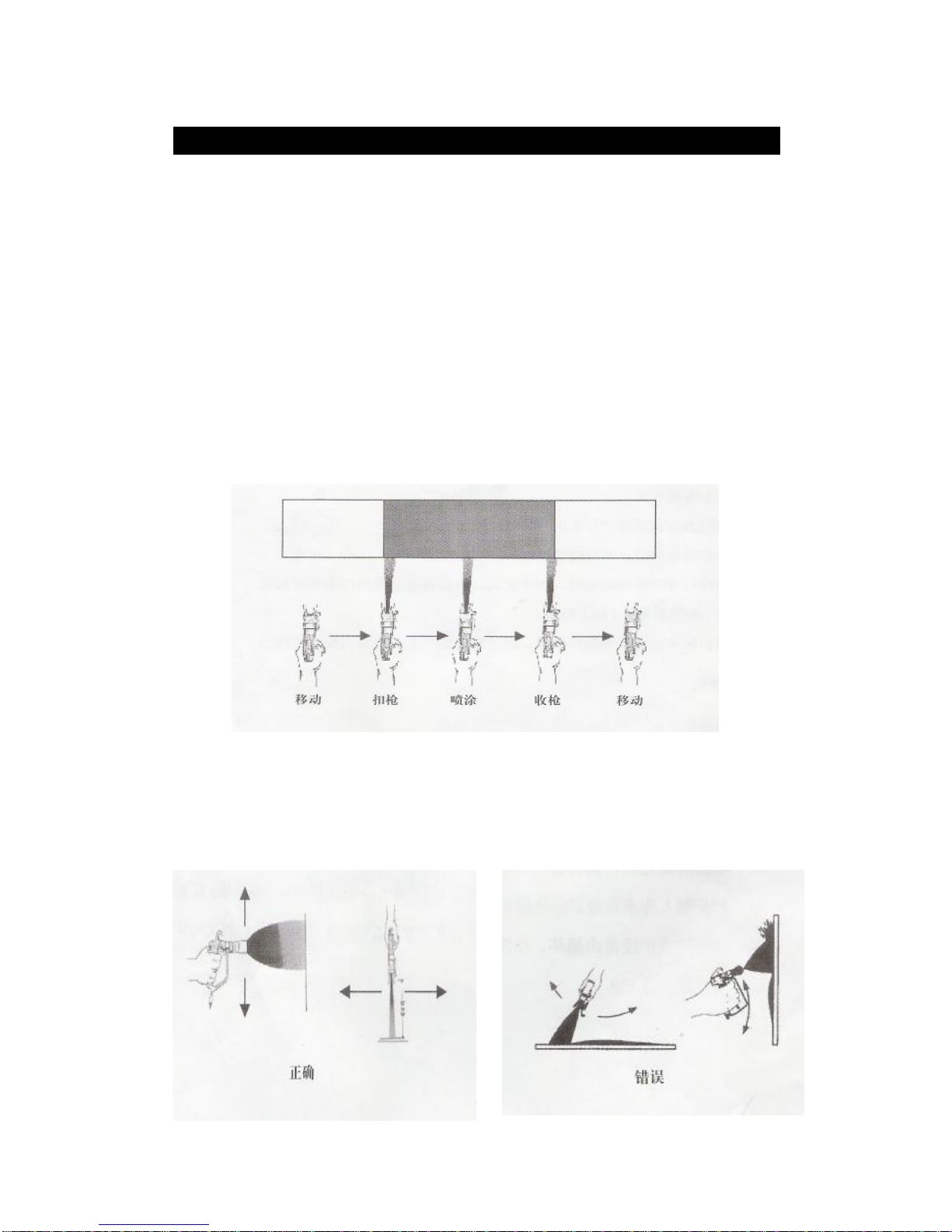

3.Eachspraygunshouldbeintheprocess ofmovinganddynamicrelaxation trigger

deduction,sotheworkpiecesurfacecan beavoided excessiveaccumulationof paintflow

andtheformationofpegging.(asforchart)

4.Spraygunshould beverticalwiththeworkpiecesurface,the surfacefrom25to30cm

distance,whenmobile,maintain the samespeed,notslowsuddenlyjumpedupquickly,and

wherepossible,tomaintain parallel,inordertoavoid surfacecoatingsorunevenflowpegged.

(asforchart)

12

5.Inorderto obtaincomplete and uniformcoating,weareheretoadvise you when thespray gun should

be coveredbefore eachshot50percent, thatis,50per centof the lap,so the entireworksurface coating

line Uniform

(asforchart).

6. Before Membersof thesprayingoperation,tofind the bestinthe vicinityof wood ornon-construction

of aworkpieceonthetestspraying, sprayingtoadjustthe distanceandspraypressure,asshown

below, the correct spraying distance and the pressure toachieve perfectionSpraying effect.

1

3

V.cleans

⑴Firstaccordingtothe"pressurereliefsteps"toejectthepressureandcoatinginside

equipment.

⑵Nozzlesandnozzlejacket willbe unloaded.

⑶Addsuctionpipe willbeputinto clearwaterbucket or the appropriationdilution.

⑷Put therefluxtube into Paint wastebarrels.

⑸Returnvalvewillbeinstalled intheverticaldirection

⑹Pressurecontrolbuttonswill beset inthewashingposition

(theredarea)

⑺Turnonthepowerswitch.

⑻Inthesolventrecyclingequipment, paintresiduesdischarged untilcleanwateror

solvent fromtheoutflowof refluxtube.

⑼Shutthepowerswitch.

⑽Returnvalvewill besetinthehorizontalpositionandopenspraygun insurance.

⑾turnon the powerswitch

⑿Buttonningupthetrigger makes solvents orclear waterflushtoremaincoating insidehigh

pressuretube and spray gun,until solvents or clearwater are jet fromthemuzzl

⒀shutspray gun insurance.(astherightchart)

⒁Loadednozzle jacketandopenspraygun insurance.

⒂Nozzlewillbe reversed180degrees, sustained gundeduction1~ 2seconds(cleaning

nozzles),nozzlesand nozzle jacketunloaded andcleaned withbrushes.(cleaning

nozzleattention toputintoawhite-washersandnozzlesBlock, pleasedonotlost.)

⒃Unloadingequipment andspraygunsonthe filternetthenclean

⒄Unload suctiontube filterandclean .

⒅Withpilesofragssolventorcleanwaterequipment,high-pressurehosesandspray

gun allthecomponentsoftheappearancewipecleanuntilasurfaceAdhesion without

coating.

⒆Equipmentintheinfusionfluidvalve5-6PSLdrop ofaclosedyellowliquid.

⒇Equipment will be storedindry,cleanandwell-ventilated places

14

VI.maintenance

Beforemaintenance,youmustdeterminethe faultoftheequipment,otherwise,

the equipmentsunnecessaryequipmentaccessibilitywillseriouslyaffectthefunction and

greatlyreducetheservicelifeofequipments.

Alsoin themaintenanceofthe equipment,be suretobe dressedin overallsand

maintenancetoolstandards,andadequatelightingandchooseawell-ventilatedplacetocarry

outrepairsandprepareabucket ofclean

solvent, aswell asthe equipmentat thevariouscomponentswithin the washing.

1. Filterreplacementsteps

●pumpfilter:

⑴Using thewrenchwillpumpabodyfilteroutershelltounload

⑵Clockwisedirectiontorevolvingpump

filterslightly.

⑶Carefullycheckedfilteranet andseal ringcompletely,

when it'snecessary,Carryoncleaningorreplacement.

⑷Anti-clockwisedirectiontoreplaceor

cleanthe filter.

⑸Installedtofilterscrewedtightlyontotheoutshell.

●gunbodyfilter:

⑴Opensprayguninsurance.

⑵Unload pikestaffwiththewrench

⑶Togentlyclockwiserotationdirectionof

thefilterunderthegunbody.

⑷Willbecleanfiltersinstalledanti-clockwiseback of thegunbody.

⑸Indeterminingthecorrectlocationgripsring,it willbe grips

Screwedtightlyontotheback andloaded.

⑹Close spraygun insurance(astherightchart).

15

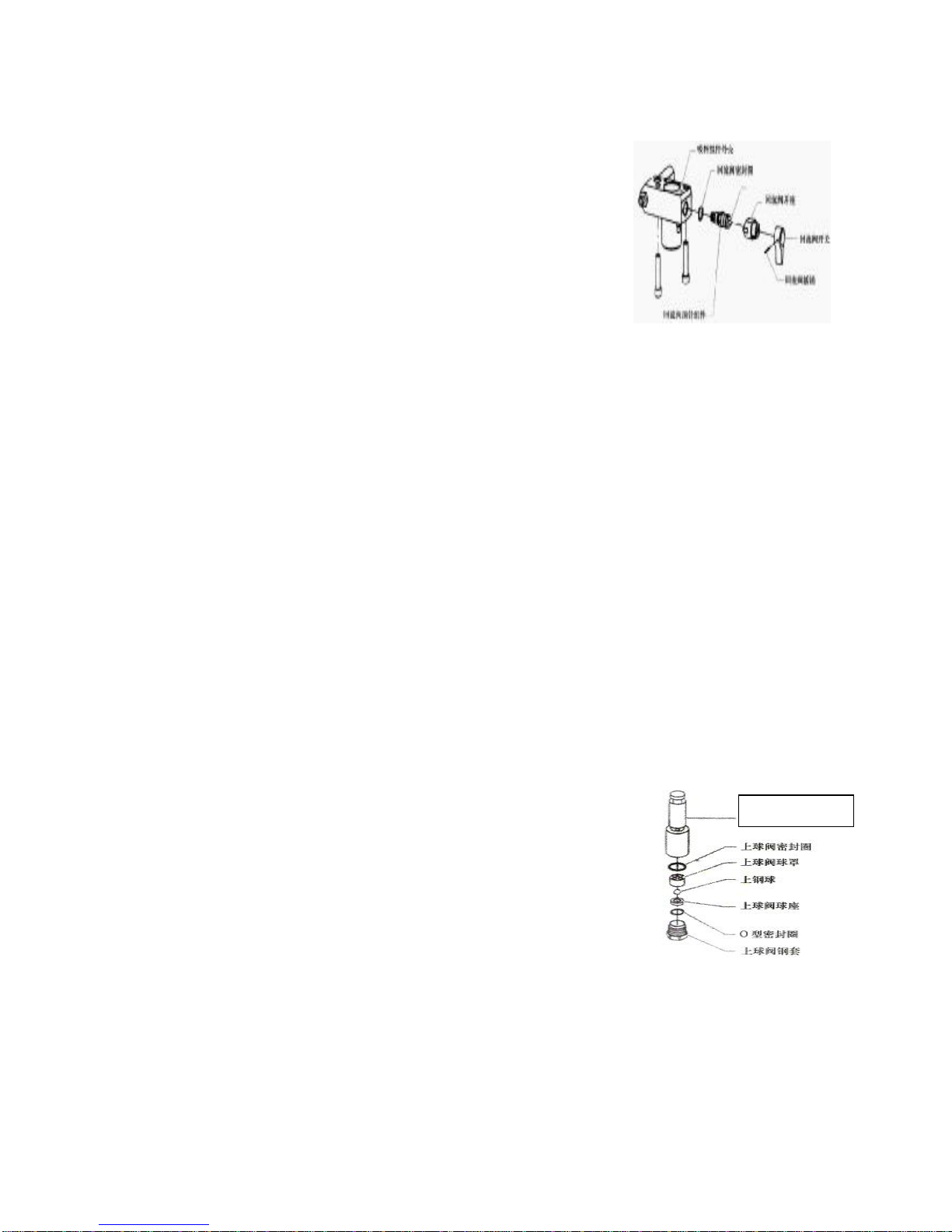

2.Return valvemaintenancesteps

⑴Removereturnvalveswitchonthebolt.

⑵Unloadingreturnvalveswitchandswitchback seat.

⑶Bywrenchreturnvalvecomponentsunloadedthimble.

⑷Determine returnvalvegasketsintherightposition.

⑸Willbeanewreturnvalveinstalledoncomponents

screwedtightlyonto.

⑹Inreturnvalveswitchappliedtoasmalllubricantsand install.

⑺thimble. toreturnvalvecomponentsexposedswitchatthefront.

⑻Loadedwithswitchesandplugswillbe fixedwithswitchthimble.

3. Suctioncomponentrepairsteps

●atthebeginningofanysuctioncomponentofmaintenanceorrepair,itmustbethe

suction tubeandthereturntubeofequipmentunloading,andthenformaintenanceor

repair,thefollowingisthesteps:

⑴Cross screwdriverswill be usedundertheplatecylinderon thetwoaspectsoffixedand

rotaryscrewunloaded.

⑵rotaryandremoved.the returntubewithwrench

⑶Suctiontubering will beremoved , andsuction tubeoutfromthebelowcylinder.

⑷when drawingOut,theequipmentwillbeslightlytilted tothefutureoperationmore

convenient.

●BallValverepairsteps:all thecomponentsin theequipment,ballvalvesarethe most

vulnerable tonotclean and cleaningequipmentcannotbeplugged sothatthe normal

operationsitting position,sothe ballvalvecleaningand maintenanceisveryimportant,

thefollowingisthe ball valvedisassemblysteps:

⑴10-inchwrenchestogetherwiththewholeoftheballvalveand cylinderbushingsremoved

⑵Carefullycheckingandcleaningpartsofthis

in everyarea, if damaged, Must be replaced.

⑶Bywrenchafterspin ontheballvalveand

plungerrodremoved.

⑷Similarlycheck ontheballvalvewhetherplugor

wear, ifnecessary,cleanedOrreplacement.

⑸Indeterminingupperand lowerball valvecomponentscleanintact, withthesameball valve

willbeinstalledin ordertosuction components.

Note:absorptionisnotnormallyundertheball valveplug,ifthe ball valveundernormal

ballvalveonanotherdemolition, cleaning ballvalvecan onlyusecleansoft cottoncloth,and

wipeprohibitedtheuseofahardobject.

Plungerrob

16

●Suctionringcomponent replacement

⑴Inaccordancewiththe"ballvalvemaintenancesteps"

tounload theupperand lowerballvalve.

⑵Suctioncomponentwillbebelowthetwo-position

rotarynutremoved.

⑶Suctiontubecomponentswillbe slightlyshellandpulled

downsothattheshell about1.5cm fromthe equipment.

⑷Fromthefield inthesuction componentswillbe

introducedslowlyshell straightPlungerrodtothe

crankshaft andconnectingrodofthebottomof the

T-mount separation.

⑸Willbedownfromthe suctionplungerrod componentsfromtheshell launched.

⑹Suctioncomponentsshellwillbefixedonthenutsandlocatorremoved.⑺Willbe removed

within theshellonthethree ring .

⑻CleaningsuctioncomponentsshellwillbeinstalledwithnewwhiteringbackShell.

(Installationoftheorderanddirectionof makingreferencetothefollowing diagram).

Note:newsuctionequipmentmanufacturedcomponentsfortheblackring,and

suction component repairpacketringiswhite.

上部密封圈安装方向 下部密封圈安装方向

O型密封圈在安装时应将上部 O型密封圈在安装时应将下部

密封圈上的凸起面朝下 密封圈上的凸起面朝上

⑼Carefullycheckplungerrod, ifwearorscratches,needimmediatereplacement.

⑽Willbeloaded back ontheballvalveandplungerrodscrewedtightly.

Note:thislinkcan be usedon thecrankshaft T-type cardwhichbescrewedtightlyonto

the pistonrodfixation.

⑾Willbe embeddedin theupperlocatornutfixed,andfixedequipmenttosuction nutshell

components, the manpowertohandrotation.

17

⑿Indeterminingsealsring and locatorinstalledinthecorrectposition,thepiston rodwillbe

componentsfromthe suction casingfromthe bottomtobottom-upequipment,andrubber

hammertoknockplungerrod gentlyintothesuction components, until theplungerrodintothe

correctposition.

Note:plungerrodandallcomponentsrequiredin theload applied toasmall lubricants.

⒀fixednut screwedtightlywiththewrench

⒁Willbe installedsuction componentsembedded in thetopofthe bottomofthecrankshaft

connectingrod T-typeCardnotch.

⒂Will be installed suctioncomponentspushedupuntil the suctionequipmentand

componentsshellcasing notseamless.

⒃thebottomshell ofsuctionComponentswill befittedwithscrewsand screwedtightly.

⒄Will beinstalledunderthe blockcomponentstogetherwiththe ballvalveandcylinder

componentsinstalled tosuctionscrewedtightlyontothe shell.

⒅Suctionpipe willbeinstalledundertheblockand backwithafixedclasp.

⒆Willbereturntubebacktotheinstallation of suctionscrewedtightlyontothecomponents.

⒇Accordingtothe"operation steps"toactivatetheequipmentand inspectionequipment

availabilitydrip.

(

21

)

According tothe "operationsteps"toactivatetheequipmentandinspection equipment

availabilitydrip.

Note:Evenifthereisaseal ringdamage,butalsotheneed toreplacetheentire

maintenancepackage AccessoriesGroup.

7.Frequentlyaskedquestionsand troubleshooting

equipmentFrequentlyAskedQuestions

1.Power circuit ornotto poorcontact 1. Checkcircuit

2.Set toolow pressure 2. Set toolow pressure

3 electricalBrush damaged or bad contact. 3.electrialBrushreplacementor

inspection.

4.Motorburn 4. Replacement motor

5.Switchdamage 5. Replacementswitch

Motordoesnot

operate

6.Equipmentoverload, powerswitchup 6. pressedto the powerswitch

warning

Refrain in theinstallation,useballvalveplungerrod ortube

clamp-vices, thiswill causethe piston-cylinderdamagecaused

bytheleakingofphenomenon.

18

1.airinthe tube 1.Checksuctiontubes and opento

returnvalves

Nosuctionequipment

2.Inadequateequipment pressure 2. increase pressure

1.Nopaintsupply 1. Inspection

2 Suction tube filter plug. 2.Cleaning or replacementfilters

3.Gun body filter plug 3.Cleaning or replacementfilters

fluxingistoosmallor

no fluxing

4.highcoating viscosity 4. Diluted paint

1.Equipment leakage 1. 1.Screwedtightlyonto the

equipmentcomponents

2.Suctiontubeleak 2.Screwed tightly onto thesuction

tube and check

3.the lower ball valve plug 3. Cleaning the lower theballvalve

4.Cylinderseals under wear 4. Sealring replacement.

5.Ballvalve wear orplug 5. Cleaning or replacing the ballvalve

6.BallValve seatwear 6.ball valve seatreplacement

Equipment is

impossibleto

maintainpressure

7.Returnvalve wear 7.Returnvalve replacement

1.set Returnvalve too low 1. increase pressure

2.Filter plug 2.Cleaning or replacementfilters

Pressureshortage

3.nozzle Excessive or wear 3. Replacementnozzles

1.Incorrectpaint\coating pipe1.Replacementof therightpaintpipe

2.nozzle too muchor wear 2. Replacementnozzles

Spraygunabnormal

vibration

3.Toomuch pressure 3. Reduce pressure

The paintfromthefuel

leakage

1.Cylinderseals ring under wear 1. Replacementsealring

2.、spraygun Frequentlyasked questions

1.airinthe Equipment 1. checking

2.spray gun withdirty 2. cleanpray gun

The spray gun has coating to

leak

3.spray gun sealring wear 3. Sealringreplacement

1.spray needle sealring wear 1.sprayneedleorseal ring

replacement

spraygun cannotstop

discharging

2.spray gun withdirty 2. Cleaning spraygun

19

1 Supplyfree paint. 1. checking

2.nozzle Or filter plug 2. Cleaning spraygunand sealring

spraygunnotexpecting

3.spray needle wear 3. sprayneedlereplacement

3. SprayFrequentlyaskedquestions

1.Spraying underpressure 1. increased Coatingspressure

2.Paintcannot be totally

atomized

2. Replacesmaller nozzle

3.Paint enoughvelocity 3.cleaningspraygunand

equipment sealring

4.Paint high viscosity 4. Reduce the viscosityof paint

Trailing spray sitesare

phenomena

5.nozzleWear 5. Replacementnozzles

Unevenspray sites 1.Nozzleclogging or wear 1. Replacementnozzles

Middle thick 1.there aregaps for Nozzle 1. Replacementnozzles

Spray rate distortions side 1.Nozzleclogging or wear 1. Replacing or cleaningnozzle

1.Suctiontube leakage 1.checkand Screwed tightly

2.Incorrectuseofpaint 2. The correctuse ofpaint

Spray ratejumps(Mandrax

largest Mandraxsmall)

3.nozzletoomuch orWear 3. Replacementnozzles

20

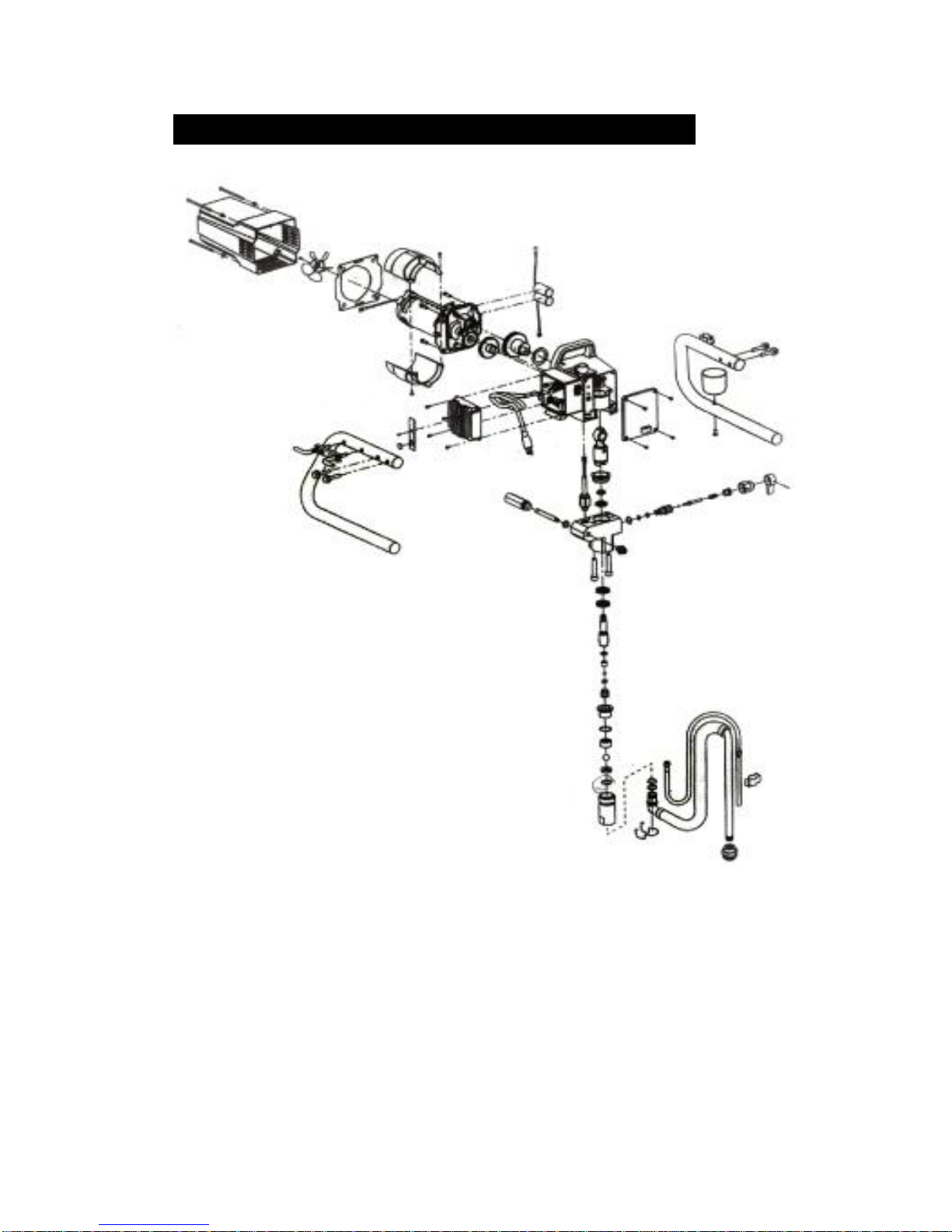

8、explodeddrawing and partslist

Suction componentdecomposition map

Table of contents

Other Dino-Power Paint Sprayer manuals

Dino-Power

Dino-Power DP-X Series User manual

Dino-Power

Dino-Power DP-X6 User manual

Dino-Power

Dino-Power DP-6840iB User manual

Dino-Power

Dino-Power DP6391C User manual

Dino-Power

Dino-Power DP-6336iB User manual

Dino-Power

Dino-Power DP-X5 User manual

Dino-Power

Dino-Power DP-X3 User manual

Dino-Power

Dino-Power DP-X Series User manual

Dino-Power

Dino-Power DP6388B Operation instructions