Diodes AP3917B User manual

Dual Output Off-Line Non-isolated Fly-back Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 1 of 17 06-21-2019

Rev 1.0 www.diodes.com

Table of Content

Chapter1 Induction.................................................2

1.1 General Description........................................2

1.2 AP3917B Key Features..................................2

1.3 Applications....................................................2

1.4 Board Picture..................................................2

Chapter2 Power Supply Specification..................3

2.1 system performance.......................................3

2.2 Environment...................................................3

Chapter3 Schematic and bill of material ..............4

3.1 Schematic.......................................................4

3.2 Bill of Material.................................................4

3.3 Transformer Specification ..............................5

3.3.1 Electrical Diagram...................................5

3.3.2 Transformer Instructions.........................5

3.3.3 Electrical Specifications..........................5

Chapter4 Evaluation Board Connections ............5

4.1 PCB Layout ....................................................5

4.2 Circuit Description..........................................6

4.2.1 Input EMI Filtering...................................6

4.2.2 Control IC................................................6

4.2.3 Flyback block..........................................6

4.2.4 Output Rectification ................................6

4.2.5 Output Feedback ....................................6

4.3 Quick Start Guide...........................................6

Chapter5. System test............................................7

5.1 Input & Output Characteristics.......................7

5.1.1 Input Standby Power ..............................7

5.1.2 Efficiency.................................................7

5.1.3 Line Regulation.......................................8

5.1.4 load regulation ........................................9

5.2 Key Performance test.....................................9

5.2.1 Start up performance..............................9

5.2.2 Voltage Stress.......................................10

5.2.3 Output Ripple & Noise ..........................11

5.2.4 Dynamic Response...............................12

5.3 Protection(SCP) test ....................................13

5.4 Thermal Test................................................14

5.5 System EMI Scan.........................................15

5.5.1 Conduction EMI test of 230V@full load15

5.5.2 Conduction EMI test of 110V@full load16

Dual Output Off-Line Non-isolated Fly-back Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 2 of 17 06-21-2019

Rev 1.0 www.diodes.com

Chapter1 Induction

1.1 General Description

AP3917B is an off-line universal AC Voltage input step-down regulator that provides accurate constant voltage (CV), outstanding

low standby power, light loading efficiency and dynamics performance. The chip supports non-isolated buck and buck-boost

topology, and also isolated and non-isolated flyback topology. The main applications are for cost-effective home appliance

power.

Working with a single winding inductor and integrating a 650V MOSFET when used in buck topology, the BOM cost is very low.

The AP3917B EV3 Evaluation Board contains two outputs specifications: 12V20mA and 3.8V20mA, with both non-isolations

flyback. The two outputs share a three-winding transformer. The feedback circuitry samples 3.8V output. The user’s guide

provides good design example for dual output power applications in home appliance power.

1.2 AP3917B Key Features

Universal 85V to 264V VAC Input

Internal MOSFET 650V (Rds(on) 10Ωmax. @25℃)

Maximum output Current: 170mA typ.@5V output

Low Standby Power Consumption

High Light Loading Efficiency and average efficiency can meet DOE IV and CoC V5 Tier

2

Frequency Modulation to suppress EMI to meet EN55032 and FCC part 15 class B

Rich Protection including: OTP, OLP, OLD,SCP

Extremely low system component count.

Totally Lead-free & Fully RoHS Compliant (SO-7)

Halogen and Antimony Free. “Green” Device

1.3 Applications

Non-Isolated Home Appliances including: AC Fans, Rice Cooker, Air conditioner, Coffee Machines, Soy Milk Machines, ect.

Auxiliary Power to IoT Devices.

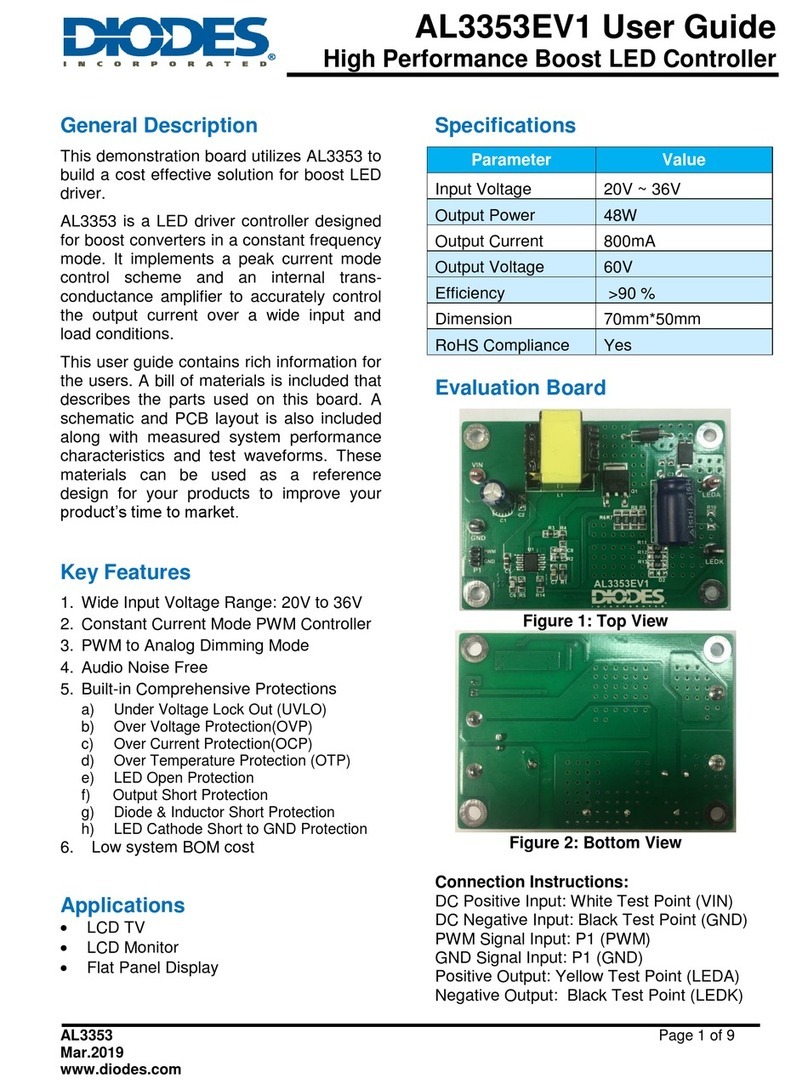

1.4 Board Picture

Fig.1-1, Top View

Fig. 1-2, Bottom View

Dual Output Off-Line Non-isolated Fly-back Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 3 of 17 06-21-2019

Rev 1.0 www.diodes.com

Chapter2 Power Supply Specification

2.1 system performance

The system performance included in and output characters, specifications, EMC, protection, ect.

Items

Min.

Typ.

Max.

Comments

input characters

Input AC voltage rating

100V/60Hz

115/230

240V/50Hz

Two wire, no PE

Input AC voltage range

85V/60Hz

-

264V/50Hz

Input AC frequency range

47Hz

50/60

63Hz

Output characters

Output voltage 1

11.1V

12.0V

12.9V

Test at board terminal

Output voltage 1

3.61V

3.8V

3.99V

loading current 1

0

-

20mA

mA

loading current 2

4

-

20mA

performance specifications

Standby power

-

12mW

@230V/50Hz

Efficiency

-

74.32%/72.98%

-

@full load, 115V/230V

Ripple & Noise

12V

-

192mV

220mV

@full load

3.8V

-

101mV

150mV

Start up time

-

16.8ms

20ms

@full load, 85V/60Hz

EMC test

ESD test

Air

±15kV

-

-

@full load condition

contract

±8kV

-

-

Surge Test

±0.5kV

-

-

Differential mode, 2ohm,

1.2/50us

Conduction

EMI

110V

6dB margin

-

-

FCC Part 15 Class B

230V

6dB margin

-

-

EN55032

Protection function

SCP test

-

-

-

OK

OLP test

-

-

-

OK

OTP test

135℃

150℃

165℃

OK

2.2 Environment

Operation temperature: -20℃~85℃

Operation Humidity: 20%~90% R.H.

Storage temperature: 0~40℃

Storage Humidity: 0%~95% R.H.

Dual Output Off-Line Non-isolated Fly-back Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 4 of 17 06-21-2019

Rev 1.0 www.diodes.com

Chapter3 Schematic and bill of material

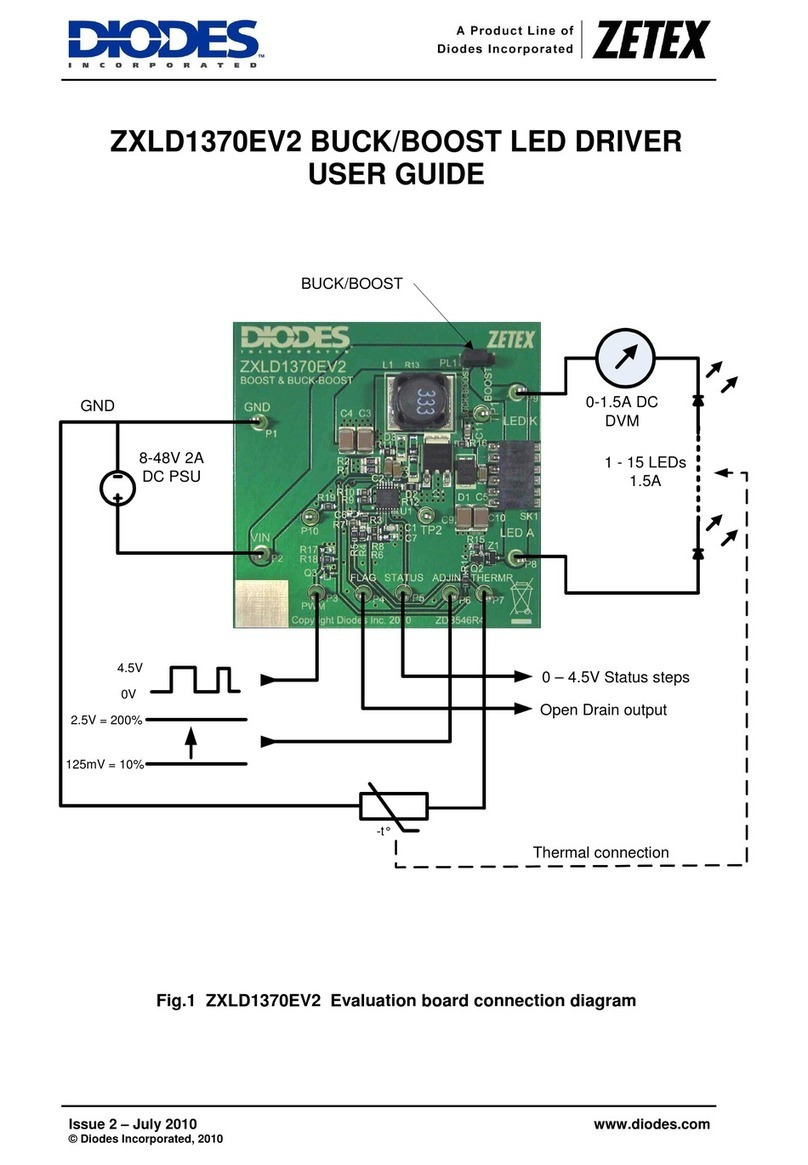

3.1 Schematic

Fig. 3-1, Evaluation Board Schematic

3.2 Bill of Material

Table 3-1, bill of material

Item

Designator

Description

Footprint

Qty.

Manufacturer

1

F1

8.2R, fusible resistor

Φ3*10mm

1

OAHE

2

BD1

ABS10A, bridge diode

SOPA-4

1

Diodes

3

C1

2.2uF/400V, electrolytic capacitor

Φ6*9mm

1

Aishi

4

C2

2.2uF/25V, X7R

SMD 0805

1

Telesky

5

C3

100uF/16V, electrolytic capacitor

Φ6*7mm

1

Aishi

6

C4

10uF/16V, X7R

SMD 0805

1

Telesky

7

C5

22uF/16V, electrolytic capacitor

Φ5*10mm

1

Telesky

8

C6

470pF/500V, X7R

SMD 0805

1

Telesky

9

C7

470pF/50V, X7R

SMD 0805

1

Telesky

10

D1

S1MWF-7, slow type diode, mark

F9

SOD123-FL

1

Diodes

11

D2

ES1J, 1A/600V, Trr 35ns

SMA

1

Diodes

12

D3

APD260, Schottky diode, 2A/60V

DO-41

1

Diodes

13

L1

2.2mH,choke inductor

DIP, 0406

1

Deloop

14

T1

EE8.3, Horizontal

DIP, 3+3Pin,

Horizontal

1

Deloop

15

R1

24.7k, thick film

SMD 0805, 1%

1

Panasonic

16

R2

13.0k, thick film

SMD 0805, 1%

1

Panasonic

17

R3

330k, thick film

SMD 0805, 5%

1

Panasonic

18

R4

27k, thick film

SMD 0805, 5%

1

Panasonic

19

U1

AP3917B

SO-7

1

Diodes

total

19pcs

R3

D1

C6

C7

BD1

F1

C1

C2

L1

L

T1

R1

R4

D2

N

U1

D3

C4C5

C3

Source

Source

VCC

Drain FB

12V-

/3.8V-

3.8V+

12V+

R2

Dual Output Off-Line Non-isolated Fly-back Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 5 of 17 06-21-2019

Rev 1.0 www.diodes.com

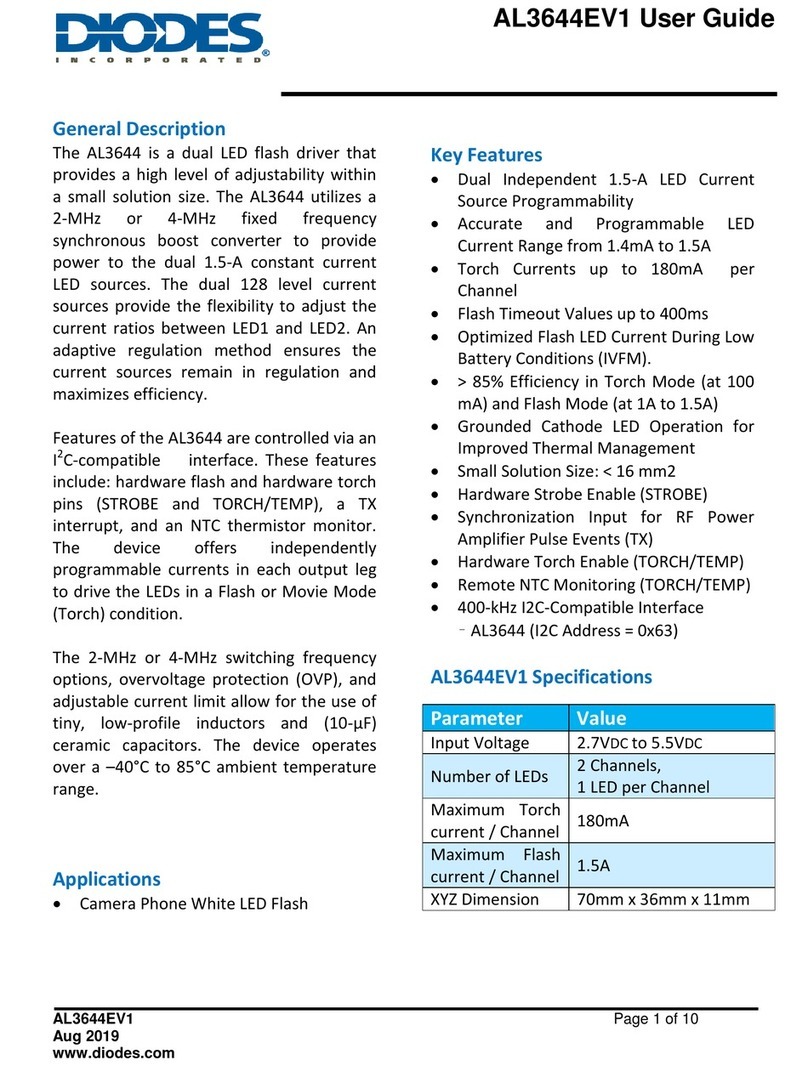

3.3 Transformer Specification

3.3.1 Electrical Diagram

Bobbin: EE8.3, 3+3Pin, Horizontal

Core: PC40, Ae=7mm2

Fig. 3-2, transformer electrical diagram

3.3.2 Transformer Instructions

Winding

Wire

Turns

Notes

5-6

0.11mm*1 UEW

123

three layer with tight tension

Tape

W=5mm

2

Full layer

3-4

0.17mm*2 UEW

10.5

One layer with tight tension

Tape

W=5mm

2

Full layer

1-3

0.17mm*1 UEW

23

One layer with tight tension

Tape

W=7mm

2

Full layer

Note: the transformer need be varnished. Put the transformer in the varnish for 30min, then remove it to the oven at 90℃for at

least 6 hours.

3.3.3 Electrical Specifications

Item

Pins

Inductance

Conditions

Main inductance

5-6

800uH±7%

1/3/4pin open, 1V/10kHz

Leak inductance

5-6

<50uH

1/3/4pin short, 1V/10kHz

Chapter4 Evaluation Board Connections

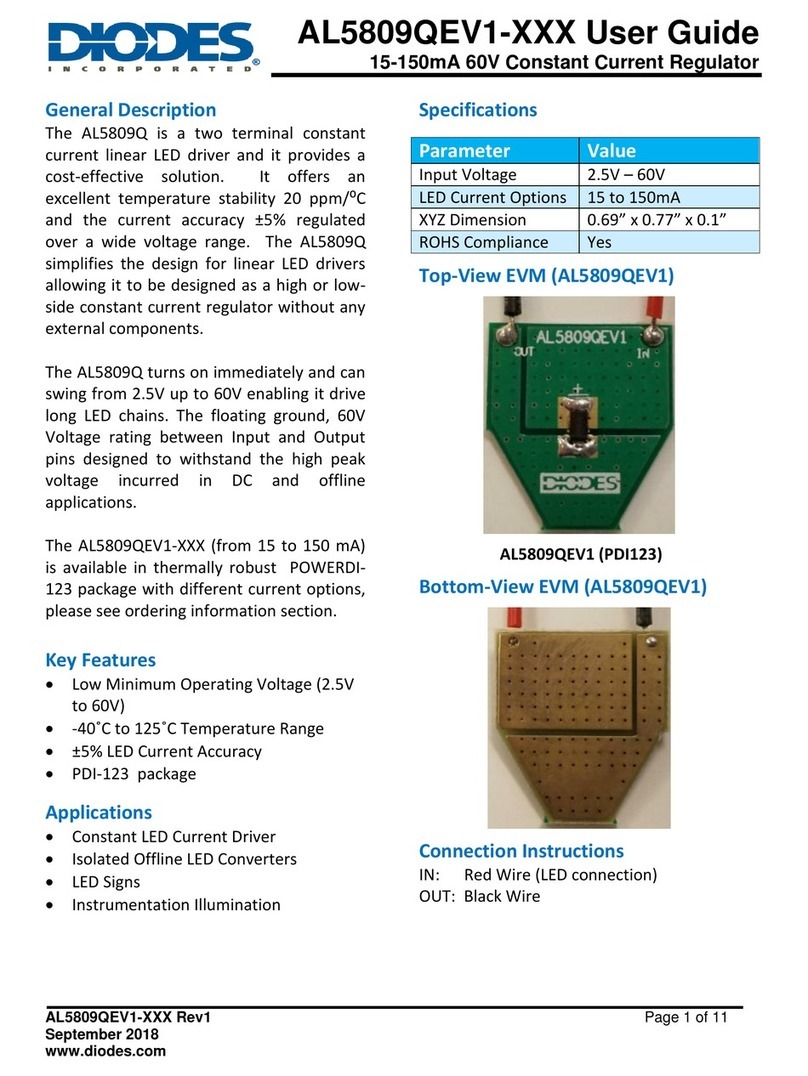

4.1 PCB Layout

6

4

5

3

WD1,

123Ts 0.11mm*1

WD2, 10.5Ts

0.17mm*2

1

WD3, 22Ts

0.17mm*1

Dual Output Off-Line Buck + Fly-back Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917 EV1 Draft 1.0 Page 6 of 17 www.diodes.com

Fig. 4-1, PCB Board Layout Top View

Fig. 4-2, PCB Board Layout Bottom View

4.2 Circuit Description

4.2.1 Input EMI Filtering

The input stage is composed of fusible resistor RF1, bridge diodes (BD1), Capacitors C1 and inductor L1. Resistor RF1 is a

flame proof, fusible, wire-wound resistor. It limits inrush current to safe levels for bridge diodes, provides differential mode noise

reduction and acts as an input fuse in the event of short circuit. Inductor L1 and Capacitor C1 constitute a LC filter, which can

smooth the input voltage and improve EMI conduction.

4.2.2 Control IC

AP3917B co-packages a 650V power MOSFET and control circuitry into a cost-effective SO-8 package. The device gets its

start-up current from DRAIN pin with a small capacitor C3 connect to BP pin when AC source is applied.

4.2.3 Flyback block

The flyback system which coupled in a transformer contains two output, 12V and 3.8V. The 3.8V output winding and 12V output

winding are in series, so if the turn ratio of 12V winding to 3.8V winding approximate to 12/3.8, the output voltage can be fixed to

12V and 3.8V.

4.2.4 Output Rectification

During the ON time of U1, current ramps in the main inductance of transformer T1 until the current reaches to the Ipk. During the

OFF time the inductor current ramps down via diodes D2 and D3. D2 andD3 must be ultra-fast diode or schottky diode (Trr<50ns

or lower). Capacitor C3/C5 should be selected to have an adequate ripple margin.

4.2.5 Output Feedback

The voltage across C4/C5 is quite smooth, so the divider R1 and R2 can reflect the output voltage. The output voltage dividend

by R1 and R2 was sent to feedback pin to regulate the 3.8V output voltage, thus regulate the 12V output voltage. A small

capacitor C7 about several hundreds of pF was used to prevent sharp noise of sampling circuit.

4.3 Quick Start Guide

1. The evaluation board is preset at 12V/20mA+3.8V20mA from output.

2. Ensure that the AC source is switched OFF or disconnected before doing connection.

3. Connect the AC line wires of power supply to “L and N” on the left side of the board.

4. Turn on the AC main switch.

5. Measure output terminals to ensure correct output voltages of Vo1 and Vo2 respectively.

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 7 of 17 06-21-2019

Rev 1.0 www.diodes.com

Chapter5. System test

5.1 Input & Output Characteristics

5.1.1 Input Standby Power

The standby power and output voltage was tested after 10min burning. The voltage data was tested at the PCB terminal. All the

data was tested at room temperature.

Table 5-1, standby power and no load output voltage

Input Voltage

Pin (mW)

Vo1 (V)

Vo2 (V)

85V/60Hz

5.0

3.791

12.202

115V/60Hz

5.4

3.791

12.205

230V/50Hz

7.8

3.788

12.197

264V/50Hz

8.6

3.788

12.197

Fig. 5-1, Standby Power versus Vin Curve

5.1.2 Efficiency

The efficiency data was tested after 10min burning, and it was tested at the PCB terminal. All the data was tested at room

temperature. 12V and 3.8V full load, input voltage range from 85V/60Hz to 265V/50Hz.

Table 5-2, Full load efficiency VS Vin data

Vin

Vo1(V)

Vo2(V)

Pin(W)

Eff.

85V/60Hz

3.752

12.291

0.451

73.22%

115V/60Hz

3.746

12.280

0.452

72.98%

150V/60Hz

3.749

12.282

0.444

74.32%

180V/50Hz

3.748

12.280

0.446

73.97%

200V/50Hz

3.748

12.280

0.447

73.80%

230V/50Hz

3.746

12.280

0.452

72.98%

265V/50Hz

3.746

12.278

0.460

71.70%

0

2

4

6

8

10

12

80 100 120 140 160 180 200 220 240 260 280

Pin(mW)

Vin (V)

Standby Power

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 8 of 17 06-21-2019

Rev 1.0 www.diodes.com

Fig. 5-2, Full load efficiency VS Vin

5.1.3 Line Regulation

The line regulation data was tested after 10min burning. The voltage data was tested at the PCB terminal. All the data was

tested at room temperature. 3.8V and 12V full load, Vin ranges from 85V to 264V.

Table 5-3, line and load regulation data

Vin

Vo1 output(V)

Vo2 output(V)

Vin

Vo1(V)

Vo2(V)

85V/60Hz

3.752

12.291

115V/60Hz

3.746

12.280

150V/60Hz

3.749

12.282

180V/50Hz

3.748

12.280

200V/50Hz

3.748

12.280

230V/50Hz

3.746

12.280

265V/50Hz

3.746

12.278

Fig 5-3, 3.8V and 12V full load, output voltage versus input voltag

60.00%

64.00%

68.00%

72.00%

76.00%

80.00%

80 100 120 140 160 180 200 220 240 260 280

Efficiency

Vin(V)

Full load efficiency VS Vin

0

2

4

6

8

10

12

14

80 100 120 140 160 180 200 220 240 260 280

Output Voltage(V)

Vin(V)

Full Load Output Voltage VS Vin

3.8V

12V

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 9 of 17 06-21-2019

Rev 1.0 www.diodes.com

5.1.4 Load Regulation

The load regulation data was tested after 10min burning. The voltage data was tested at the PCB terminal. All the data was

tested at room temperature. The load of Vo1 and Vo2 terminals both ranges from 10% to 100%.

Table 5-4, Vo1 and Vo2 output voltage

Vin

10%

25%

50%

75%

100%

Vo1(V)

Vo2(V)

Vo1(V)

Vo2(V)

Vo1(V)

Vo2(V)

Vo1(V)

Vo2(V)

Vo1(V)

Vo2(V)

85V/60Hz

3.788

11.578

3.785

11.772

3.788

11.937

3.772

12.057

3.768

12.157

115V/60Hz

3.788

11.585

3.784

3.777

3.774

11.932

3.772

12.052

3.766

12.157

230V/50Hz

3.786

11.572

3.781

11.757

3.774

11.922

3.769

12.047

3.764

12.147

265V/50Hz

3.785

11.572

3.780

11.755

3.774

11.922

3.768

12.045

3.763

12.147

Fig. 5-4, 12V and 5V output voltage@ 3.8V no load

5.2 Key Performance test

5.2.1 Start up performance

The start-up time was measured with differential probe clipping on the input AC source, and the common low-voltage probe

clipping on the output terminal. Before start-up, the buck cap should be discharged.

Table 5-5, start up performance

Input voltage

Start up time

figures

85V/60Hz

16.8ms

Fig. 15

115V/50Hz

16.1ms

Fig. 16

230V/50Hz

15.3ms

Fig. 17

264V/60Hz

14.6ms

Fig. 18

0

1

2

3

4

5

6

7

8

9

10

11

12

13

80 100 120 140 160 180 200 220 240 260 280

Output Voltage(V)

Vin(V)

Load Regulation

Vo1-85V/60Hz

Vo1-115V/60Hz

Vo1-230V/50Hz

Vo1-265V/50Hz

Vo2-85V/60Hz

Vo2-115V/50Hz

Vo2-230V/50Hz

Vo2-265V/50Hz

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 10 of 17 06-21-2019

Rev 1.0 www.diodes.com

Turn on Waveforms

CH1: Vin; CH2: 3.8V output; CH3:12V output

Fig. 5-5, Start up time is 16.8ms @full load, 85V/60Hz

Fig 5-6, Start up time is 16.1ms @full load, 115V/60Hz

Fig. 5-7, Start up time is 15.3ms @full load, 230V/50Hz

Fig 5-8, Start up time is 14.6ms @full load, 265V/50Hz

5.2.2 Voltage Stress

The voltage tested below was between the source and the drain pin of IC. The test need use differential probe. The Vak voltage

is tested between the anode and cathode of flyback diode D2/D3.

Table 5-6, MOSFET drain-source and flyback diodes Vak voltage stress

Input voltage

Voltage stress

figures

Vds(V)

Vak1(V)

Vak2(V)

85V/60Hz

221

17

57

Fig. 19

115V/50Hz

265

21

65

-

230V/50Hz

429

37

119

-

264V/60Hz

484

42

129

Fig. 22

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 11 of 17 06-21-2019

Rev 1.0 www.diodes.com

CH1: Vds/Vak2; CH2: Vak1

Fig. 5-9, MOS drain-source 221V@85V/60Hz, full load

Fig. 5-10, Vo1 terminal Vak 17V, Vo2 Vak 57V@85V/60Hz, full

load

Fig. 5-11, MOS drain-source 484V @265V/50Hz, full load

Fig. 5-12,Vo1 terminal Vak 129V, Vo2 Vak 42V@264V/50Hz,full

load

5.2.3 Output Ripple & Noise

The ripple and noise was tested at PCB terminal, using coaxial cable (1:1). The bandwidth was limited to 20MHz. A 10uF

electrolytic capacitor and a 104 ceramic capacitor should be paralleled to the output terminal.

Table 5-7, ripple & noise

Conditions

Input voltage

R&N(mV)

Figures

Vo1 terminal

Vo2 terminal

3.8V full load, 12V full load

85V/60Hz

96

184

Fig. 23

115V/50Hz

96

184

-

230V/50Hz

101

192

-

264V/60Hz

101

190

Fig. 24

CH1:Vo1 output; CH4:Vo2 output

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 12 of 17 06-21-2019

Rev 1.0 www.diodes.com

Fig.5-13, Output R&N 96/184[email protected]and 12V full load, 85V/60Hz

115V/60Hz

230V/50Hz

265V/50Hz

5.2.4 Dynamic Response

The dynamic response output voltage was tested at the PCB terminal, and the bandwidth was limited to 20MHz. The loading is

set 0mA as low load and 20mA as high load, and last for 0.1s respectively. The ramp is set at 40mA/us.

Table 5-8, dynamic response

Conditions

Vin

Output voltage(V)

Figures

Vo1

Vo2

Max (V)

Min (V)

Max (V)

Min (V)

12V full load,

3.8V loading

0~100%

85V/60Hz

4.16

3.62

12.94

8.65

Fig. 27

115V/60Hz

4.10

3.65

12.87

8.52

-

230V/50Hz

4.06

3.65

12.87

8.71

-

264V/50Hz

4.10

3.65

12.94

8.31

Fig. 28

3.8V full load,

12V loading

0~100%

85V/60Hz

3.98

3.63

15.01

12.00

Fig. 29

115V/60Hz

3.95

3.63

15.01

11.94

-

230V/50Hz

4.02

3.63

15.01

11.94

-

264V/50Hz

4.02

3.63

15.07

11.94

Fig. 30

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 13 of 17 06-21-2019

Rev 1.0 www.diodes.com

CH3:12V output; CH2:3.8V output

Fig. 5-18 dynamic response@3.8V 0~20mA,12V FL, @265V/50Hz

Fig.5-19, dynamic response@12V 0~20mA,3.8V FL, @85V/60Hz

Fig. 5-20, dynamic response@12V 0~20mA,3.8V FL, @265V/50Hz

5.3 Protection (SCP) test

The SCP test was measured under the condition of output cable terminal short circuit.

Table 5-9, the short circuit protection test

Condition

Vin

Vo1 max(V)

Vo2 max(V)

Figures

12V terminal output short

85V/60Hz

0.416

0.508

Fig. 31

115V/60Hz

0.425

0.512

-

230V/50Hz

0.463

0.503

-

264V/50Hz

0.480

0.508

Fig. 32

3.8V terminal output short

85V/60Hz

0.544

2.81

Fig. 33

115V/60Hz

0.562

2.90

-

230V/50Hz

0.588

3.05

-

264V/50Hz

0.608

3.07

Fig. 34

CH2:3.8V output; CH3:12V output

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 14 of 17 06-21-2019

Rev 1.0 www.diodes.com

Fig. 5-21, SCP @12V output short and 3.8V full load, 85V/60Hz

Fig. 5-22, SCP @12V output short and 3.8V full load, 265V/50Hz

Fig. 5-23, SCP@12V output short and 3.8V full load, 85V/60Hz

Fig. 5-24, SCP@12V output short and 3.8V full load, 265V/50Hz

5.4 Thermal Test

The thermal test was under room temperature after burning 1 hour. The board has no case, and using thermal imager to observe

the surface temperature of IC.

Fig. 5-25, IC 32.1℃, 12V flyback diode 31.9℃, RCD diode

33.1℃@full load, 85V/60Hz, ambient temperature 26.9℃.

Fig. 5-26, Transformer 33.3℃, 3.8V flyback diode 31.7℃@full

load, 264V/50Hz, ambient temperature 25.8℃.

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 15 of 17 06-21-2019

Rev 1.0 www.diodes.com

Fig. 5-27, IC 34.5℃, 12V flyback diode 31.5℃, RCD diode

31.9℃@full load, 265V/50Hz, ambient temperature 26.3℃.

Fig. 5-28, Transformer 33.5℃, 3.8V flyback diode 31.8℃@full

load, 264V/50Hz, ambient temperature 25.4℃.

5.5 System EMI Scan

The power supply passed EN55022 Class B (for 230V input) and FCC part 15 (for 110V input) EMI requirement with more than

6dB margin.

5.5.1 Conduction EMI test of 230V@full load

The test result can pass EN55022 Class B limitation with more than 6dB margin.

Fig. 5-29, L line conduction waveform@230V, full load.

Fig. 5-30, L line conduction data@230V, full load.

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 16 of 17 06-21-2019

Rev 1.0 www.diodes.com

Fig. 5-31, N line conduction waveform@230V, full load.

Fig. 5-32, N line conduction data@230V, full load.

5.5.2 Conduction EMI test of 110V@full load

The test result can pass FCC part 15 limitation with more than 6dB margin.

Fig. 5-33, L line conduction waveform@110V, full load.

Fig. 5-34, L line conduction data@110V, full load.

Fig. 5-35, N line conduction waveform@110V, full load.

Fig. 5-36, N line conduction data@110V, full load.

Dual Output Off-Line Non-isolated Flyback Power Solution

AP3917B 12V/20mA+3.8V20mA EV3 Board User’s Guide

AP3917B EV3 Page 17 of 17 06-21-2019

Rev 1.0 www.diodes.com

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS

TO THIS DOCUMENT, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE

LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or

other changes without further notice to this document and any product described herein. Diodes Incorporated does not assume

any liability arising out of the application or use of this document or any product described herein; neither does Diodes

Incorporated convey any license under its patent or trademark rights, nor the rights of others. Any Customer or user of this

document or products described herein in such applications shall assume all risks of such use and will agree to hold Diodes

Incorporated and all the companies whose products are represented on Diodes Incorporated website, harmless against all

damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through

unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers

shall indemnify and hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or

unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product

names and markings noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this

document is the final and determinative format released by Diodes Incorporated.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems

without the express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for

use provided in the labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices

or systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements

concerning their products and any use of Diodes Incorporated products in such safety-critical, life support devices or systems,

notwithstanding any devices- or systems-related information or support that may be provided by Diodes Incorporated. Further,

Customers must fully indemnify Diodes Incorporated and its representatives against any damages arising out of the use of

Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2016, Diodes Incorporated

www.diodes.com

Table of contents

Other Diodes Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens SINAMICS V90 operating instructions

Dräger

Dräger REGARD-1 Instructions for use

Franke

Franke AQUA802 Installation and operating instructions

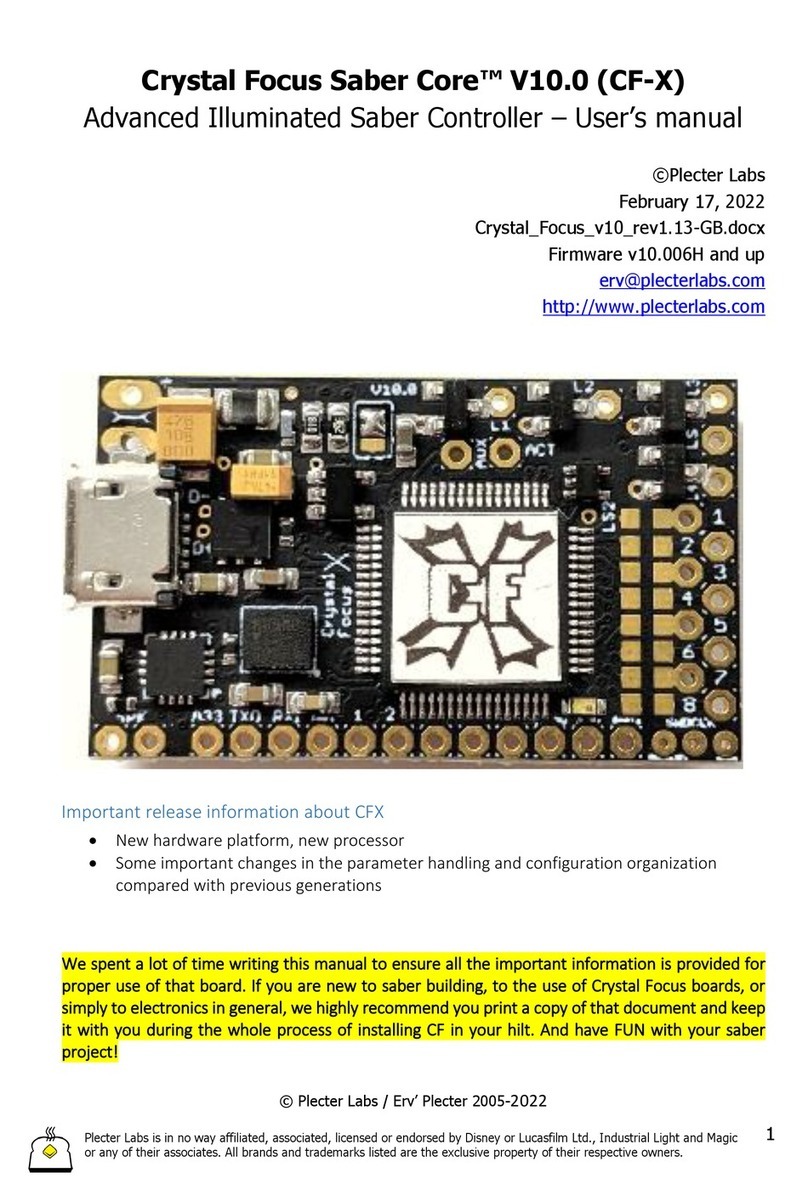

Plecter Labs

Plecter Labs Crystal Focus Saber Core V10.0 user manual

NDS

NDS Dometic EM12-150 Installation and operating manual

TIME LED

TIME LED 781296 Installation and operating instructions

Plasmatronics

Plasmatronics DINGO D8040N user guide

Rockwell Automation

Rockwell Automation Allen-Bradley MicroLogix 1400 user manual

Eaton

Eaton SVX9000 Series manual

Savant

Savant CPT-1212 Quick reference guide

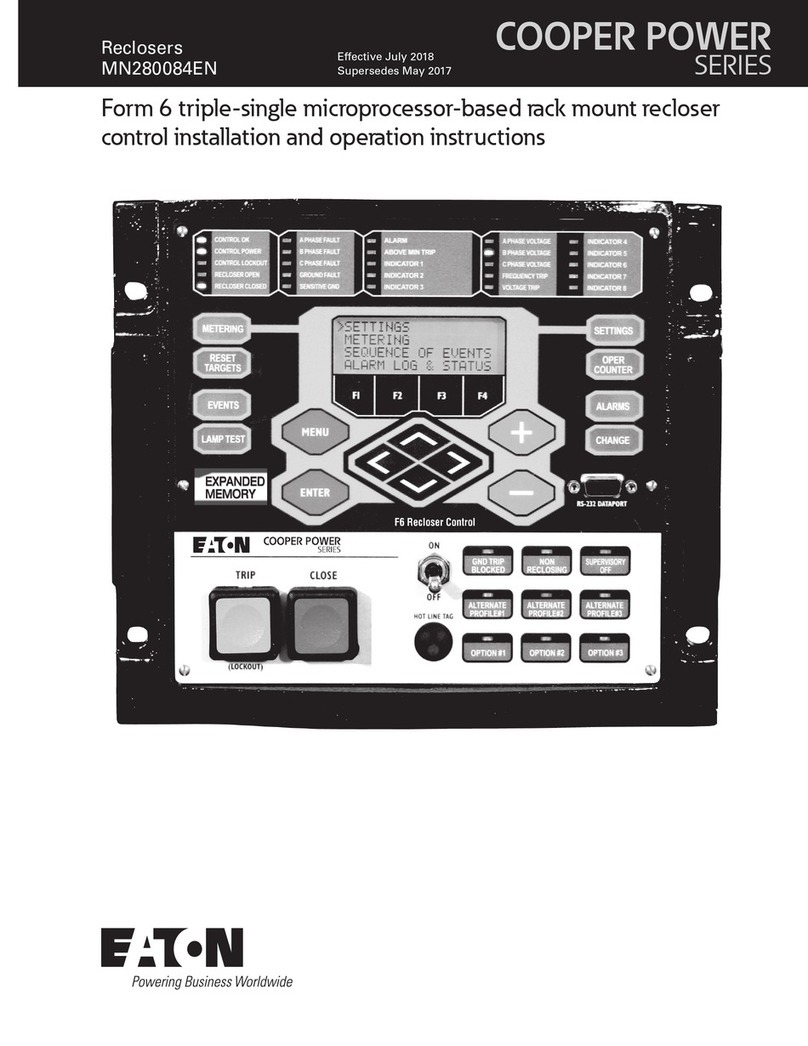

Eaton

Eaton COOPER POWER SERIES Installation and operation instructions

Hach

Hach AS950 AWRS Basic operations