Dion PCHM-2 Manual

1

DION ENGINEERING LTD.

Bulgaria, Ruse 7019,

8 Nikola Tabakov Street

Phone: 00359 82 86 70 80;

Fax: 00359 82 86 70 91;

OPERATION AND MAINTENANCE INSTRUCTIONS:

PRE-CHILLING MODEL: PCHM-2

2

TABLE OF CONTENTS:

INFORMATION ABOUT THE INSTALATION

1. IDENTIFICATION AND TECHNICAL INFORMATION

-DECLARATION OF CONFORMITY

-MACHINE IDENTIFICATION

2. SUMMARY:

-INTRODUCTION

-APPLICATION

-SAFETY

3. TRANSPORT AND STORAGE

4. INSTALLATION:

4.1. PREPARATION FOR INSTALLATION

4.2. GENERAL DESCRIPTION OF THE INSTALLATION

4.3. GENERAL SCHEME OF THE INSTALLATION

4.4. EXTERIOR VIEW OF THE INSTALLATION

4.5. EXTERIOR VIEW OF THE CONTROL PANEL

4.6. PID –DIAGRAM

4.7. REQUIREMENTS OF THE SUPPLEMENTARY INSTALLATION AND STARTING MACHINE OPERATION

5. OPERATING THE MACHINE

6. WARRANTY

1. IDENTIFICATION AND TECHNICAL INFORMATION

1.1. DECLARATION OF CONFORMITY

3

DECLARATION OF CONFORMITY

Undersigned: “ Dion Engineering “ Ltd

Address: 8 , Nikola Tabakov str. , Rousse 7019 , Bulgaria

Declare under my sole responsibility that the product

Brand: PRE-CHILLING

Model: PCHM-2

Manufacturer: “ DION ENGINEERING“ LTD

Complies with the requirements of:

Directive №

Title of directive

2006/42/ЕС

Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)

2014/95/ЕС

Directive 2014/95/EC of the European Parliament and of the Council of 12 December 2006 on the harmonization of the laws of Member States relating to electrical

equipment designed for use within certain voltage limits (codified version)

2014/108/ЕС

Directive 2014/108/EC of the European Parliament and of the Council of 15 December 2004 on the approximation of the laws of the Member States relating to

electromagnetic compatibility and repealing Directive 89/336/EEC

and with the following standards:

EN ISO 12100:2010

Safety of machinery - General principles for design - Risk assessment and risk reduction (ISO 12100:2010)

БДС EN 60204-1:2006/A1:2009

Safety of machinery - Electrical equipment of machines - Part 1: General requirements(IEC 60204-1:2005/A1:2008)

БДС EN 61000-6-2:2006

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial environments(IEC 61000-6-2:2005)

БДС EN 1672-1:2014

Food processing machinery - Basic concepts - Part 1: Safety requirements

БДС EN 1672-2:2005+A1:2009

Food processing machinery - Basic concepts - Part 2: Hygiene requirements

БДС EN ISO 13850:2009

Safety of machinery - Emergency stop - Principles for design (ISO 13850:2006)

БДС EN ISO 1999:2004

Acoustics

БДС EN 894-4:2010

Ergonomics

БДС EN 1708-1:2010

Welding of steel

БДС EN 14532-1:2006

Additional Welding Materials

БДС EN 1435:1999

Welding control

When used properly and in accordance with the instruction!

(This declaration is related to the implementation of an Annex of the Machinery Directive 2006/42/EC

(internal production control - Module A) and the analogous annexes of other Directives.)

The product carries conformity mark:

17

Place: Rousse Signature:

Date: 1.04.2019

Name and position: Dipl. Eng. Vihren Genchev , manager

4

1.2. MACHINE IDENTIFICATION

5

1.3. ADDRESS OF THE MANUFACTURER

DION ENGINEERING LTD.

8, Nikola Tabakov Str.

Russe, 7019, Bulgaria

Phone: 00359 82 86 70 80;

Fax: 00359 82 86 70 91;

2. GENERAL INFORMATION:

1. THIS MANUAL HAS TO BE READ CAREFULLY BEFORE USING THE INSTALLATION

2. THIS INSTALLATION IS POWERED BY ELECTRICITY, HAS MOVING PARTS AND FLUIDS WITH DIFFERENT

TEMPERATURE

3. ONLY QUALIFIED PERSONNEL MUST WORK ON THE INSTALLATION

4. THIS MANUAL MUST BE AVAILABLE AND KEPT UP TO DATE. FURTHERMORE, A COPY MUST BE

PROVIDED FOR ALL POTENTIAL USERS OF THE INSTALLATION

5. THE INSTALLATION MUST NOT BE USED FOR THE PASTEURIZATION OF LIQUIDS, DIFFERENT FORM THE

SPECIFIED IN THIS MANUAL

6. ALL THE FIGURES AND SCHEMATICS IN THIS MANUAL ARE FOR EXPLANATORY PURPOSES ONLY. DUE

TO CONTINUOUS TECHNOLOGICAL DEVELOPMENTS, THERE MIGHT BE DEVIATIONS WITH THE

PHYSICAL INSTALLATION.

7. WHEN USING DISINFECTANTS AND OTHER AGGRESSIVE PRODUCTS, GLOVES AND OTHER SAFETY

EQUIPMENT ARE RECOMMENDED

2.1. INTRODUCTION

This instruction manual is intend to certify the manufacturer of the installation for feeling of liquid products, and contains important

and useful information. Before the assembly and operation of the installation, read the instructions carefully. This manual must be

stored in a safe and easily accessible place. The installation is constantly being improved and therefore might have some differences

between the purchased installation and the provided documents.

-Read the instructions and warnings carefully as they contain important information about the safety and maintenance when using

the installation. Furthermore, the manual must be kept by the buyer for future references.

-If the manual is lost, contact the manufacturer immediately. We recommend keeping it in a secure place and making additional

copies.

-The manufacturer is not held liable for any damages caused by incorrect usage of the installation.

6

2.2. APPLICATION

FIELD OF APPLICATION:

The current installation is meant for continuous filling of liquids such as egg mélange, egg yolk, egg white, juice, milk and other

similar in composition and viscosity fluids.

2.3. SAFETY

ONLY PERSONNEL FAMILIAR WITH THE SAFETY RULES MUST BE ALLOWED TO OPERATE THE

INSTALLATION.

THE INSTALLATION MUST NOT BE FUNCTIONING WITHOUT ANY FLUIDS IN THE SYSTEM

ALWAYS TURN OF THE INSTALLATION BEFORE STARTING ANY MAINTENANCE RELATED

ACTIVITIES

THE ASSEMBLY AND MAINTENANCE OF THE ELECTRICAL INSTALLATION MUST BE PERFORMED BY

QUALIFIED PERSONNEL ONLY

THERE MUST ALWAYS BE A CLEAR PATH TOWARDS THE CONTROL PANEL

IF ANY LOUD IRREGULAR NOISE OR VIBRATIONS START THE INSTALLATION MUST BE TURNED OFF

IMMEDIATELY

ANY MAINTENANCE WORK OR REPAIRS ON THE ROTOR SPINNING HEATER WHILE IT IS

OPERATIONAL IS STRICTLY FORBIDDEN

ALL LOADING AND UNLOADING AND ASSEMBLY WORK MUST BE PERFORMED ACCORDING TO THE

SAFETY INSTRUCTIONS

NOT FOLLOWING THE RULES IN THE MANUAL LEADS TO RISKING THE SAFETY OF THE OPERATOR,

POLLUTING THE ENVIRONMENT AND DAMAGING THE INSTALLATION.

7

3. TRANSPORT AND STORAGE

The installation can be transported - completely packaged. The transportation of the installation can be done by all suitable for the

purpose transport.

The loading and unloading of the installation must be performed using suitable equipment, like cranes, forklifts or pallet trucks.

Confirm that the device used for the loading and unloading of the machine is suitable for the weight of the installation, which is

specified in the identification label.

Use the center of gravity of the machine during the loading and unloading activities.

The installation must be placed on a flat surface.

NOTE: Dion Engineering Ltd. is not responsible for any damages that might occur during improper transportation or

loading/unloading activities.

4. INSTALLATION:

4.1. PREPARATION FOR INSTALLATION

The installation must be assembled in a closed, dry area, which follows the local regulations for sanitary and epidemiological

control.

The area for assembly must have outlets provided for electricity, pasteurizer connection , water jacked tank connections and the

Chiller connections.

During assembly, the installation must be connected to those outlets. After assembly, the installation must be leveled and grounded.

The size of the facility, where the installation is going to be assembled, needs to provide the minimal working filed of the operator.

This is at least 1 meter between the installation and any other object or wall.

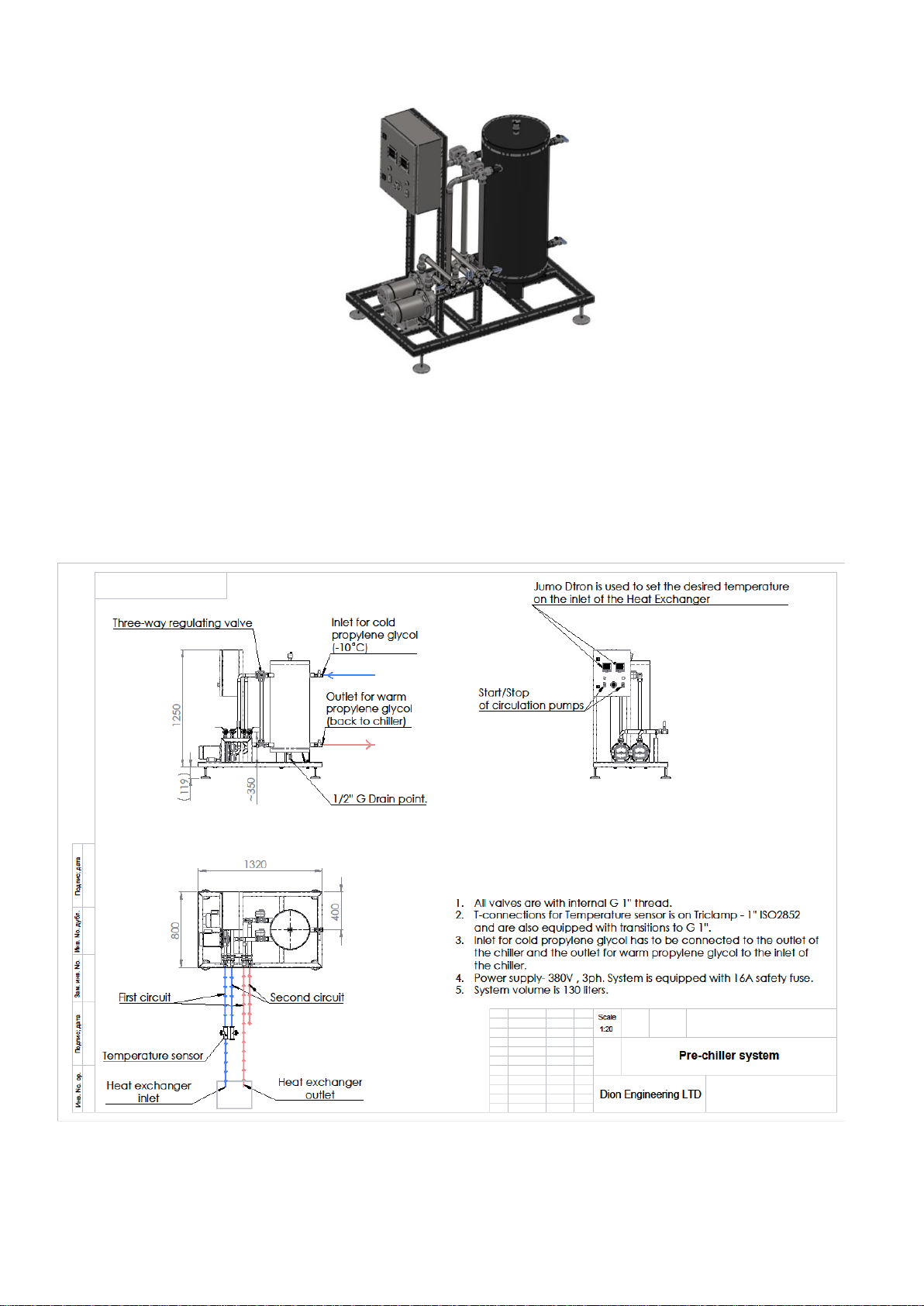

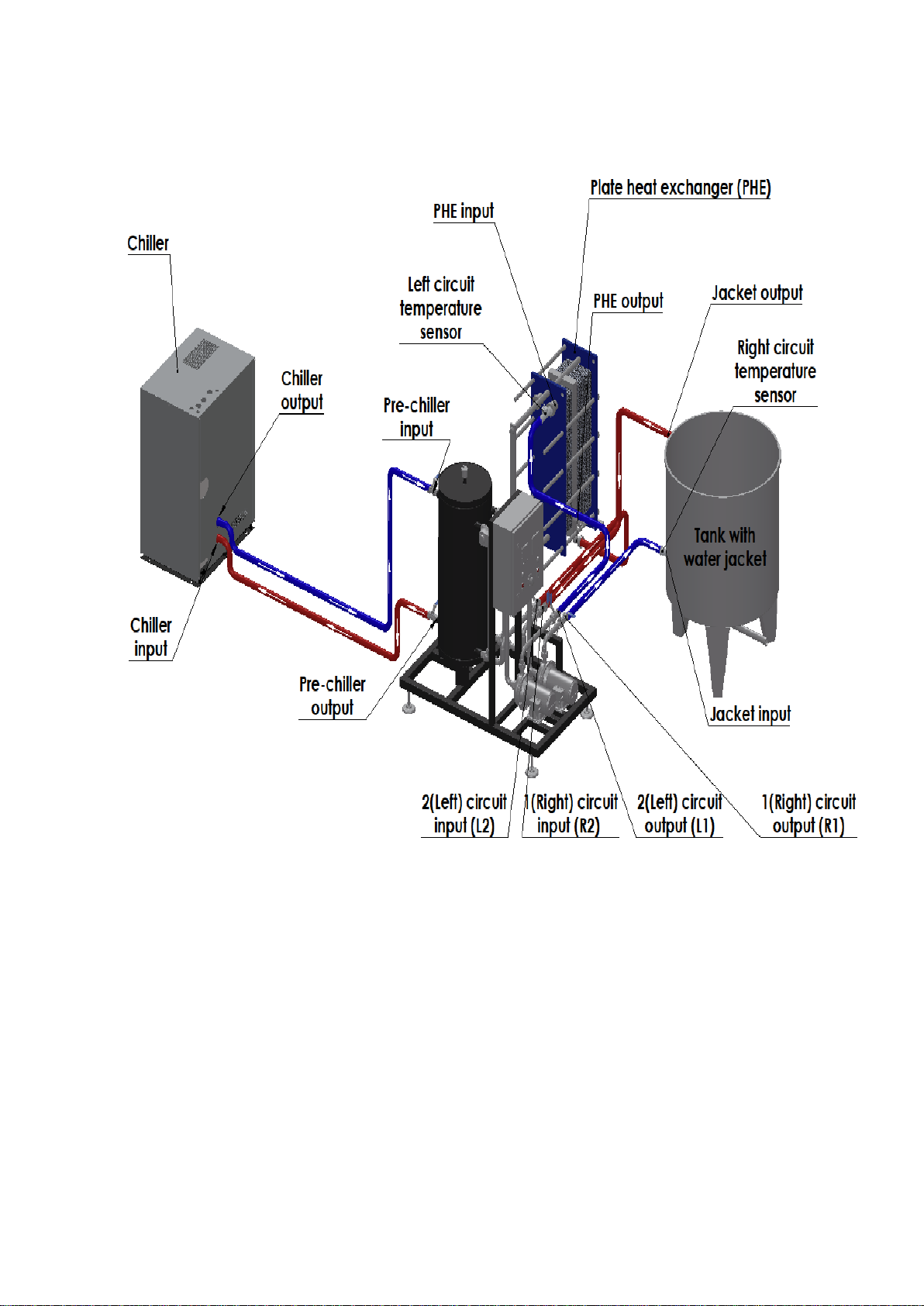

4.2. GENERAL DESCRIPTION OF THE INSTALLATION

PRE-CHILLING MODUL MODEL PCHM-2 regulate the cooling fluid ( propylene glycol) coming from chiller and goes to

devices ( pasteurizer PHE or water jacket tank) to be always with defined temperature ℃.

The system are consists from two pumps , two PID regulation d TRONE model JUMO , one receiver tank 120 l , two automatic

three-way regulating valves, valves, automatic sensors for pipe and etc.

8

9

10

5. OPERATING THE MACHINE

After the final installation - switching to the electric and connected to the other installations that meet the assembly requirements,

with observing of all safety requirements, you can proceed towards the pre-chilling machine putting into operation.

-HOW TO ACTIVATE THE PRE-CHILLING FROM THE CONTROL PANEL?

-Unlock the control panel and take up all safety fuses. Close it.

-Check whether the emergency button is not activated. If it is activated, deactivate by turning it. The dTrone JUMO display

should started loading. Wait. When is activate , you can see the moment temperature inside the pipes.

-Set the desired temperature from dTrone JUMO .

-When set the temperature , the automatic three-way regulating valves start to control the flow in the pipe ( photo 2).

-On the display of dTrone JUMO you can see two parameters .

-First parameter is in percentages ( %) , and show in ( % ) how many % the automatic three-way regulating valves is close

the pipe. ( photo 1)

Photo 1

11

Photo 2

-Second parameter is in degrees ( ℃ ) , and show in ( ℃ ) the desired temperature. ( photo 3). You can to change this

temperature from control buttons to be suitable for your process. For example for pasteurizer PHE the temperature is good

to be 1 or 2 (℃) degrees and for water jacked tank around 2 -4 degrees (℃)

Photo 3

12

-Security pressure valve

-Dranage valve

13

4.3. EXTERIOR AND INTERIOR VIEW OF THE CONTROL PANEL

14

15

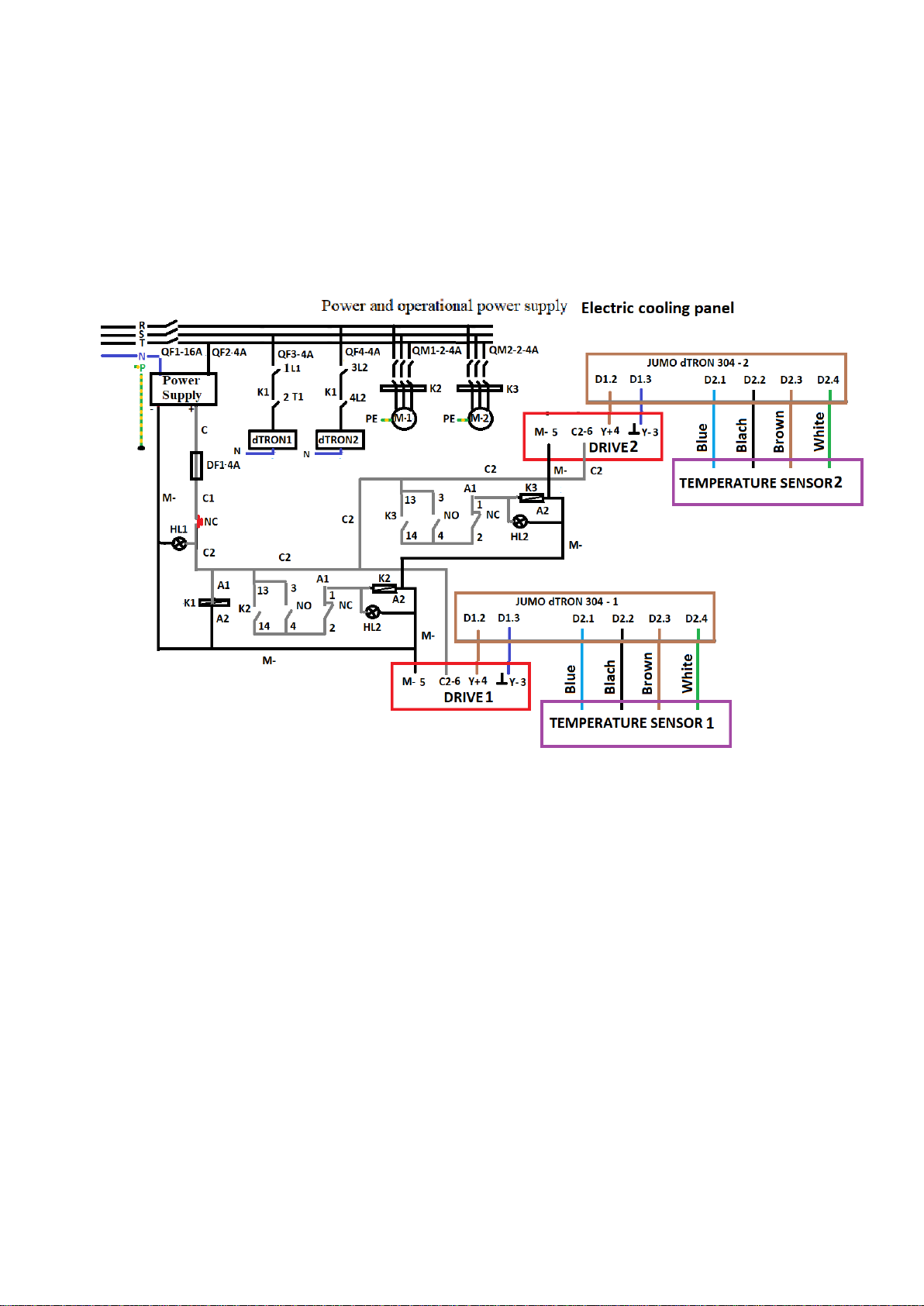

4.4. PID –DIAGRAM

4.4.1. Electric diagram

16

4.5. REQUIREMENTS OF THE SUPPLEMENTARY INSTALLATION AND DIMMENSION

SUPPLEMENTARY INSTALLATION

PRE-CHILLING MODEL PCHM-2

Power supply

380 V, three phases, 50 Hz,

16 A, 4kW

Grounding - 1 16 m2copper cable

Debit propylene glycol min:

20 l/min

Debit propylene glycol max.

110 l/min

Dimension:

1500 mm / 800 mm / 1700 mm (h)

5. DISASSEMBLY AND TRANSPORT

Qualified personnel must perform the disassembly of the installation, which follows all the safety rules for work with electricity and

loading-unloading operations. The loading and unloading must performed with the appropriate equipment- cranes, forklifts or pallet

trucks.

Confirm that the device used for the loading and unloading of the machine is suitable for the weight of the installation, which

specified in the identification label.

Use the center of gravity of the machine during the loading and unloading activities.

The transportation has be done by all suitable modes of transportatio

17

6. WARRANTY

WARRANTY № 018/ 01.04.2019

For the delivered equipment, under invoice №1000000000 / 01.04.2019,

for manufacture of FILLING MACHINE MODEL: FM2H

The manufactured equipment with serial number: 021/ 03-2019

WARRANTY

1. After signing the handover protocol, the equipment produced by “Dion Engineering” Ltd. are going to

lack defects for three (3) years, under the conditions that all the requirements for transport, assembly,

correct operation and storage are fulfilled.

2. This warranty is only valid if the assembly and commissioning is done by a team of the company “Dion

Engineering” Ltd.

3. The guarantee covers repairs and replacement of defective parts.

4. The defective part must be sent to the repair base of “Dion Engineering” Ltd. and must be accompanied

by:

- warranty (original)

- a description of the malfunction

- Logo screen 600 paperless recording of data for minimum 3 months before defects or damages( IF

HAVE)

5. The transport costs to the repair base of “Dion Engineering” Ltd are not covered by the warranty

6. Normal wear and tear is not covered by the warranty

7. The warranty of the equipment, which is part of the whole line, but comes from external suppliers, is

handled by their corresponding manufacturer. This equipment is delivered with their original warranty

from the manufacturer.

8. “Dion Engineering“ Ltd. Is not held responsible for defects and damages due to incorrect transport.

9. The warranty is made void in any of the following cases:

- Incorrect operation

- Lack of an accompanying warranty with a marked serial number.

- Mismatch between serial numbers.

- Changes and redesign of the installation.

- Lack of Logoscreen 600 paperless recording of data for minimum 3 months before defects or

damages(IF HAVE)

-

Commercial Director:........................ Vihren Genchev

“Dion Engineering” Ltd., based in 8, Nikola Tabakov str, Russe, Bulgaria, VAT: 202945942, represented by

Vihren Genchev

Date: 01/04/19

18

Table of contents