Dionex LC20 User manual

LC20 CHROMATOGRAPHY ENCLOSURE

OPERATOR’S MANUAL

© 1993 Dionex Corporation

Document No. 034859

Revision 02

September 1993

© 1993 Dionex Corporation

All rights reserved worldwide

Printed in the United States of America

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system,

or transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS,

ACCURACY, RELIABILITY, CURRENTNESS, OR OTHERWISE.

FURTHER, DIONEX CORPORATION RESERVES THE RIGHT TO REVISE

THIS PUBLICATION AND TO MAKE CHANGES FROM TIME TO TIME

IN THE CONTENT HEREIN WITHOUT OBLIGATION OF DIONEX

CORPORATION TO NOTIFY ANY PERSON OR ORGANIZATION OF

SUCH REVISION OR CHANGES.

TRADEMARKS

DX-LAN, Self-Regenerating Suppressor, SRS, and ThermoFlareare

trademarks of Dionex Corporation.

Teflonand Tefzelare registered trademarks of E.I. du Pont de Nemours and

Company.

PRINTING HISTORY

Revision 01, August 1993

Revision 02, September 1993

Contents

1•Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 About This Manual . . . . . . . . . . . . . . . . . 1-3

1.3 Product Safety Information . . . . . . . . . . . . . 1-4

2•Description

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Front Panel . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Rheodyne Injection Valve . . . . . . . . . 2-3

2.3 Interior Layout . . . . . . . . . . . . . . . . . . . 2-4

2.3.1 Component Panel . . . . . . . . . . . . . 2-5

2.3.2 Rheodyne Injection Valve . . . . . . . . . 2-6

2.3.3 Self-Regenerating Suppressor . . . . . . . 2-7

2.3.4 Leak Sensor . . . . . . . . . . . . . . . . 2-7

2.3.5 Separator Columns . . . . . . . . . . . . 2-7

2.3.6 Guard Columns . . . . . . . . . . . . . . 2-7

2.3.7 Column Select Valve . . . . . . . . . . . . 2-8

2.3.8 Detector Cells . . . . . . . . . . . . . . . 2-11

2.3.9 DS3 Detection Stabilizer (Optional) . . . 2-11

2.4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.1 Cell Cables . . . . . . . . . . . . . . . . . 2-13

2.4.2 Waste Line . . . . . . . . . . . . . . . . . 2-13

Doc. 034859-02 9/93 i

2.4.3 Solenoid Interface . . . . . . . . . . . . . 2-13

3•Service and Maintenance

3.1 Routine Operation . . . . . . . . . . . . . . . . . . 3-3

3.1.1 Sample Loading . . . . . . . . . . . . . . 3-4

3.2 Shutdown . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3 Routine Maintenance . . . . . . . . . . . . . . . . 3-7

4•Troubleshooting

4.1 Liquid Leaks . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 Excessive System Backpressure . . . . . . . . . . 4-4

4.3 Inoperative Column Select Valve . . . . . . . . . 4-5

4.4 Column Select Valve Air Leaks . . . . . . . . . . 4-5

4.5 Peak Ghosting . . . . . . . . . . . . . . . . . . . . 4-6

4.6 Non-Reproducible Peak Height or Retention

Time . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7 Abnormal Retention Time or Selectivity . . . . . 4-6

5•Service

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . 5-3

5.2 Tube Fitting Installation . . . . . . . . . . . . . . 5-3

5.3 Restriction in the Hydraulic System . . . . . . . . 5-4

5.4 Injection or Column Select Valve Liquid Leaks . 5-4

5.5 Column Select Valve Air Leaks . . . . . . . . . . 5-5

Contents

ii Doc. 034859-02 9/93

5.6 Cleaning the Column Select Valve Slider . . . . . 5-6

5.7 Replacing Column Select Valve Port Face . . . . 5-9

5.8 Servicing the Rheodyne Injection Valve . . . . . 5-9

A•Specifications

A.1 Environmental . . . . . . . . . . . . . . . . . . . . A-3

A.2 Physical . . . . . . . . . . . . . . . . . . . . . . . A-3

A.3 Hydraulics . . . . . . . . . . . . . . . . . . . . . . A-3

A.4 Insulation . . . . . . . . . . . . . . . . . . . . . . A-4

B•Installation

B.1 Facilities Required . . . . . . . . . . . . . . . . . B-3

B.2 Installation Instructions . . . . . . . . . . . . . . . B-4

B.2.1 Stacking Modules . . . . . . . . . . . . . B-4

B.2.2 Waste Lines . . . . . . . . . . . . . . . . . B-5

B.2.3 Leak Control . . . . . . . . . . . . . . . . B-6

B.2.4 Liquid Line Connections . . . . . . . . . B-6

B.2.5 Detector Cells . . . . . . . . . . . . . . . B-9

B.2.6 Column Installation . . . . . . . . . . . . B-12

B.2.7 SRS Installation (Optional) . . . . . . . . B-13

B.2.8 Solenoid Valve Connections

to the Pump . . . . . . . . . . . . . . . . B-14

Contents

Doc. 034859-02 9/93 iii

Contents

iv Doc. 034859-02 9/93

LC20 Chromatography Enclosure

1-2 Doc. 034859-02 9/93

1 •Introduction

1.1 Overview

The LC20 Chromatography Enclosure is an integral part of the

Dionex DX 500 Chromatography Systems. It can house the

following system components, which must be ordered separately or

as part of another module: Separator columns, optional guard

columns, SRS(Self-Regenerating Suppressor), DS3 Detection

Stabilizer, and detector cell(s) for the ED40 Electrochemical

Detector and CD20 Conductivity Detector.

The LC20 is available in two configurations, depending on

the type of injection valve installed:

•LC30, PEEK automated injection valve (P/N 044088)

•LC30, stainless steel automated injection valve (P/N 044171)

1.2 About This Manual

This manual describes the operation, maintenance, and use of the

L20 Chromatography Enclosure.

Chapter 1, Introduction, introduces the product and conventions

used in the manual, and provides safety information.

Chapter 2, Description, is a description of the physical aspects of

the LC20 Chromatography Enclosure, followed by a functional

description of the operating features.

Chapter 3, Operation and Maintenance, discusses the operating

features and routine maintenance.

Chapter 4, Troubleshooting, provides step-by-step procedures to

isolate problems and lists possible causes.

Chapter 5, Service, presents step-by-step procedures to perform

service and parts replacement routines.

Doc. 034859-02 9/93 1-3

Appendix A Specifications contains the LC20 specifications.

Appendix B, Installation, describes the installation and interface

necessary to place the LC20 into operation.

1.3 Product Safety Information

This instrument was designed in conformance with the safety

requirements set forth in IEC 1010 Safety Requirements for

Electrical Equipment for Measurement, Control, and Laboratory Use.

Section of this manual are flagged with key words and symbols to

denote the nature of potential hazards. These safety directives apply

to all operators and service personnel.

The following safety reference symbols are marked in the instrument

and this manual where necessary to alert the operator.

Indicates a potential hazard to the operator, or

damage to the instrument or other property.

Example: Overtightening valve bolts may break them

off.

LC20 Chromatography Enclosure

1-4 Doc. 034859-02 9/93

2 •Description

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Front Panel . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Rheodyne Injection Valve . . . . . . . . . 2-3

2.3 Interior Layout . . . . . . . . . . . . . . . . . . . 2-4

2.3.1 Component Panel . . . . . . . . . . . . . 2-5

2.3.2 Rheodyne Injection Valve . . . . . . . . . 2-6

2.3.3 Self-Regenerating Suppressor . . . . . . . 2-7

2.3.4 Leak Sensor . . . . . . . . . . . . . . . . 2-7

2.3.5 Separator Columns . . . . . . . . . . . . 2-7

2.3.6 Guard Columns . . . . . . . . . . . . . . 2-7

2.3.7 Column Select Valve . . . . . . . . . . . . 2-8

2.3.8 Detector Cells . . . . . . . . . . . . . . . 2-11

2.3.9 DS3 Detection Stabilizer (Optional) . . . 2-11

2.4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.1 Cell Cables . . . . . . . . . . . . . . . . . 2-13

2.4.2 Waste Line . . . . . . . . . . . . . . . . . 2-13

2.4.3 Solenoid Interface . . . . . . . . . . . . . 2-13

Doc. 034859-02 9/93 2-1

LC20 Chromatography Enclosure

2-2 Doc. 034859-02 9/93

2 •Description

2.1 Overview

Eluent from the gradient pump enters the Rheodyne injection valve

port inside the enclosure. From the injection valve, eluent and

sample flow through the guard column (if used), the separator

column, the suppressor or other post-column device, and finally

through the detector cells.

The LC20 may be configured for optional dual-channel operation. It

will then include a second Rheodyne injection valve and component

panel. There is enough tubing in the LC20 Ship Kit (P/N 046300) to

plumb two systems.

The LC20 does not require power. Internal components are operated

by the GP40/IP20 pump.

2.2 Front Panel

The front panel of the enclosure is the door. It contains access to

one or two Rheodyne injection valves.

2.2.1 Rheodyne Injection Valve

The Rheodyne injection valve is mounted on the component

panel in a manner that allows its control knob to extend

through the front door for access. If the LC20 is configured

as a dual-channel module, a second Rheodyne injection valve

will be installed on the left-side component panel and extend

through the adjacent port.

Doc. 034859-02 9/93 2-3

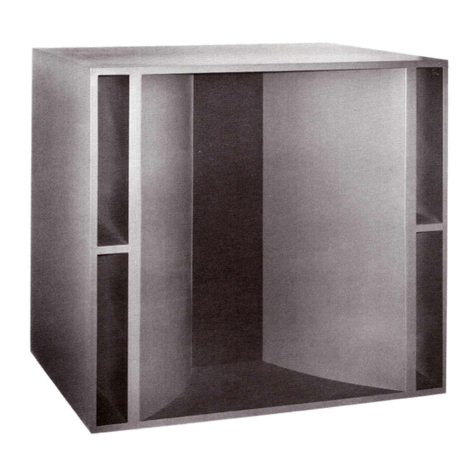

2.3 Interior Layout

The interior of the LC20 is an insulated, passive chamber. It

contains a slide-out panel for mounting components. Figure 2-1

illustrates the LC20 chassis. See Section B.2.1 for recommended

stacking configurations. See Figure 2-2 for an illustration of the

slide-out component panel.

Figure 2-1. LC20 Interior Chassis

LC20 Chromatography Enclosure

2-4 Doc. 034859-02 9/93

2.3.1 Component Panel

Components are mounted on the slide-out panel. The panel

on the right side is standard in all LC20 enclosures. When a

dual-channel module is ordered, an opposite panel is

factory-installed on the left side (see Figure 2-2).

Figure 2-2. Component Panel Layout

2 •Description

Doc. 034859-02 9/93 2-5

The component panel has two slide releases to lock it in a

fully closed (in) or open (out) position. Press the slide release

at the upper horizontal edge of the panel to release the detent.

The panel will lock at about three quarters of its total travel

when you pull it out. This prevents it from being pulled

entirely out of the tracks and possibly damaging the

components. To reinsert the panel, press the second slide

release and push it back into its closed position. The fully

closed position locks the panel and prevents it from being

forced outward by pressure from the various tubing

arrangements.

The panel can be pulled completely out by pressing the

second slide release and pulling the panel until it clears the

top and bottom tracks. Hold the panel securely when it

disengages the tracks. To replace the panel, align it with the

top and bottom tracks and push inward until it engages the

second detent. Press the second slide release and push the

panel to its closed and locked position.

Various component arrangements are made possible by

multiple mounting holes and slots. The configuration shown

here is only one of many offered by the enclosure.

2.3.2 Rheodyne Injection Valve

The Rheodyne injection valve is mounted at the bottom of the

component panel. Its control knob extends through the door

to allow manual operation with the door closed. The valve

has two operating positions: INJECT and LOAD.

The injection valve is a low-volume, metal-free, 35 MPa

(5000 psi) rotary injection valve. It accommodates syringe

injections or pressurized sample loading.

The Rheodyne injection valve is equipped with a microswitch

for detection of the valve position. The microswitch can be

wired to a module that can process the signal to verify the

position of the valve.

LC20 Chromatography Enclosure

2-6 Doc. 034859-02 9/93

The LC20 Ship Kit includes two accessories for the

Rheodyne injection valves: a 25 µL gas-tight syringe

(P/N 041389) and a 25 µL sample loop (P/N 042857). For

more information about the valve, including important

operating precautions, refer to the Rheodyne Valve Operator’s

Manual (Document No. 034468), included in the LC20 Ship

Kit.

2.3.3 Self-Regenerating Suppressor

The Self-Regenerating Suppressor (SRS

) is held in place

by a special support plate. Align the two slots on the bottom

of the SRS case with the tabs on the support plate. Press in

and then down to lock the SRS in place. Pull up and then out

to remove (see Figure B-8 in Appendix B).

2.3.4 Leak Sensor

This sensor detects leaks and spills in the bottom of the

enclosure, and generates a signal when a leak occurs. The

sensor is located at the lower front corner of the left wall in

the bottom tray. Its cable exits through the rear service chase,

and must be connected to the GP40 pump.

2.3.5 Separator Columns

The column mount near the front of the component panel can

accommodate up to two separator columns. The column

mount supports 4-mm columns on one side and 2-mm

columns on the other. The column mount can be removed by

pressing on each side of its mounting tab and pulling away

from the slot in the panel. You can then reverse it and press it

back into the panel to change column size and maintain the

columns at the outer position (see Figure B-7 in Appendix B).

2.3.6 Guard Columns

The smaller guard columns (if used) are held in place by the

tubing below the separator columns.

2 •Description

Doc. 034859-02 9/93 2-7

2.3.7 Column Select Valve

The column select valve (P/N 044858), when included, will

be supported on the component panel by a mounting plate.

The column select valve is controlled by the pump through a

pair of air solenoids on the back of the LC20.

The column select valve is not normally plumbed into the

system. However, enough tubing is provided in the LC20

Ship Kit to plumb up to two column select valves into two

systems. When plumbed, the optional 28 MKa (4000 psi)

column select valve directs the flow of eluent and sample

from the Rheodyne injection valve to either column A or B.

The column select valve can alternatively be used to switch in

and out a separator column.

The column select valve is actuated by a pair of solenoids

mounted on the rear panel, which will be included only when

the column select valve is installed. The solenoids are

electrically connected to and controlled by the GP40 or IP20

pump. Refer to the pump manual for operating instructions.

Figure 2-3 shows the assembly of the column select valve.

LC20 Chromatography Enclosure

2-8 Doc. 034859-02 9/93

The groove around the valve body indicates the top of the

valve. The ports are numbered clockwise around the valve

body. The small vent hole is between ports 1 and 5. Pressure

bolts provide an intermediate connection between the valve

slider and all tube fittings. These bolts must be tightened

evenly to provide uniform sealing pressure against the

valve slider and ensure leak-free operation.. For valve

maintenance information, refer to the Installation and

Maintenance of the Dionex High Pressure Valve (Document

No. 032678).

Figure 2-3. Column Select Valve

2 •Description

Doc. 034859-02 9/93 2-9

The valve is operated by air pressure pushing against pistons

inside the valve cap. The piston pushes a slider up and down

inside the valve body. Applying pressure to the top piston

pushes the slider down; applying pressure to the bottom

piston pushes the slider up. The slider connects the valve

ports as follows (see Figure 2-4).:

Switch in OFF position, selecting column A (slider down):

1 →4 and 2 →3,

5 →8 and 6 →7

Switch in ON position, selecting column B (slider up):

1 →2 and 3 →4,

5 →6 and 7 →8

The valve is tested to operate leak-free at 28 MPa (4000 psi).

After testing, the valve pressure bolts are loosened to reduce

stress on critical parts during storage. Before shipment, the

pressure bolts are tightened to provide leak-free operation at

pressures up to 17 MPa (2500 psi) or 90 in-oz torque. If you

Figure 2-4. Column Select Valve Slider Connections

LC20 Chromatography Enclosure

2-10 Doc. 034859-02 9/93

Table of contents