Dionex PDA-100 User manual

PDA-100 PHOTODIODE ARRAY DETECTOR

OPERATOR'S MANUAL

©2003 Dionex Corporation

Document No. 031644

Revision 02

September 2003

©2003 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR

CHANGES.

TRADEMARKS

BioLC, Chromeleon, DX-LAN, PeakNet, and Summit are trademarks or registered

trademarks of Dionex Corporation.

Teflon and Tefzel are registered trademarks of E.I. duPont de Nemours & Company.

PRINTING HISTORY

Revision 01, May 2000

Revision 02, September 2003

Doc. 031644-02 9/03 i

Contents

1 • Introduction

1.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Theory of Photodiode Array Detection . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.1 Advantages of Photodiode Array Detection . . . . . . . . . . . . . . .1-2

1.3 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3.1 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.4 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

2•Description

2.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Inside Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3 Optical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3.1 Flow Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.4 Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.5 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

3 • Operation and Maintenance

3.1 Operating Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 Mobile Phases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.2 Solvent Delivery System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

PDA-100 Photodiode Array Detector

ii Doc. 031644-02 9/03

3.3 Routine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 Panel Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.2 Programmed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.4 Optimizing Detector Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.5 Stand-Alone Analog Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3.6 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

4 • Troubleshooting

4.1 Flashing LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 No Detector Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Noisy Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Drifting Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5 Lamp Does Not Light or Lamp LED Is Flashing . . . . . . . . . . . . . . . . . 4-7

4.6 Deuterium Lamp Intensity Count Too Low . . . . . . . . . . . . . . . . . . . . . 4-7

4.7 Wavelength Calibration Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.8 Wavelength Verification Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.9 Faulty DX-LAN Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.10 No Spectra Collected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.11 Low Spectral Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.12 Peaks Too Large or Small . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.13 Poor Peak Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.14 Error Message: Not Enough Light to Perform Operation . . . . . . . . . 4-13

4.15 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.15.1 Moduleware Run-Time Diagnostics . . . . . . . . . . . . . . . . . . . 4-14

Contents

Doc. 031644-02 9/03 iii

4.15.2 Software Diagnostics and Calibration . . . . . . . . . . . . . . . . . .4-14

5•Service

5.1 Liquid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Cleaning the Flow Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3 Removing Trapped Air from the Flow Cell . . . . . . . . . . . . . . . . . . . . .5-2

5.4 Removing the Flow Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.5 Replacing the Flow Cell Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.6 Replacing the Flow Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.7 Replacing the Deuterium Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.8 Replacing the Tungsten Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.9 Replacing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

A • Specifications

A.1 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.3 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.4 Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.5 Flow Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.6 Heat Exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

B • Installation

B.1 Facilities Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

PDA-100 Photodiode Array Detector

iv Doc. 031644-02 9/03

B.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.3.1 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.3.2 Flow Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

B.3.3 Waste Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

B.3.4 Detector Output (Analog). . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

B.3.5 Relay/TTL Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

B.3.6 DX-LAN Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-8

C • Reordering Information

Doc. 031644-02 9/03 1-1

1 • Introduction

1.1 Product Overview

The PDA-100 Photodiode Array Detector is an optical detector capable of

measuring the absorbance spectrum from 190 nm to 800 nm. A deuterium lamp

optimizes the UV range (190 nm to 380 nm) and a tungsten lamp optimizes the

visible range (380 nm to 800 nm).

When using the PDA-100, up to five single wavelengths (2D chromatograms) can

be collected without being required to collect 3D data. Collecting individual

wavelengths instead of the spectra offers two advantages: it eliminates the need to

perform extractions for runs that do not require spectral data and it conserves disk

space.

Key PDA-100 features include:

•Deuterium and tungsten lamps ensure low baseline noise, high signal

intensity, and applications flexibility in the wavelength range from 190 nm to

800 nm.

•A 1024-element photodiode array optimizes spectral resolution.

•A built-in holmium oxide filter verifies wavelength calibration accuracy.

•Front panel LEDs indicate detector status at a glance.

•Four analog outputs support data collection on alternate data collection

systems.

The PDA-100 is controlled remotely by a host computer running PeakNet®6 or

Chromeleon®software (Release 6.1 or later). The detector communicates with the

host computer via the Dionex DX-LAN™interface.

PDA-100 Photodiode Array Detector

1-2 Doc. 031644-02 9/03

To take full advantage of the capabilities of the PDA-100, order the 3D option for

the software. The 3D option is required in order to perform the following:

•3D data presentation and spectral analysis (real-time or post-run)

•Peak purity analysis with selectable criteria

•Spectral library search for positive peak identification

•Optimal integration path determination for method optimization

1.2 Theory of Photodiode Array Detection

Monochromatic variable wavelength detectors monitor eluting components of the

sample at a single wavelength (ideally, the wavelength of maximum absorbance),

whereas photodiode array (PDA) detectors scan a range of wavelengths every few

milliseconds and continually generate spectral information. Wavelength, time, and

absorbance can all be plotted.

PDA detectors provide three-dimensional information that allows an accurate

assessment of peak identity, purity, and quantitation in a single run. Software

support for PDA detectors includes peak purity and spectral library search

functions to help determine peak homogeneity and identity.

1.2.1 Advantages of Photodiode Array Detection

PDA detectors are useful in both research and quality assurance

laboratories. In the research laboratory, the PDA provides the analyst with

a variety of approaches to the analysis. In the quality assurance

laboratory, the PDA provides several results from a single run, thereby

increasing the throughput of the HPLC.

PDA detection offers the following advantages:

•Peak measurement at all wavelengths

In methods development, detailed information about the detector

conditions required for the analysis may not be known. When a

variable wavelength detector is used, a sample must often be injected

several times, with varying wavelengths, to ensure that all peaks are

detected. When a PDA detector is used, a wavelength range can be

programmed and all compounds that absorb within this range can be

detected in a single run.

1 • Introduction

Doc. 031644-02 9/03 1-3

•Determination of the correct wavelengths in one run

After all peaks have been detected, the maximum absorbance

wavelength for each peak can be determined. A PDA detector can

collect spectra of each peak and calculate the absorbance maximum.

•Detection of multiple wavelengths

A PDA detector can monitor a sample at more than one wavelength.

This is especially useful when the wavelength maxima of the analytes

are different. Wavelengths can be selected to analyze each compound

at its highest sensitivity.

•Peak purity analysis

It is difficult to determine component purity from a chromatogram.

However, a PDA detector can analyze peak purity by comparing

spectra within a peak. A pure peak has matching spectra throughout

the peak (at all wavelengths).

•Positive peak identification

In liquid chromatography, peak identification is usually based on

relative retention times. When a PDA detector is used, spectra are

automatically collected as each peak elutes. The PDA software

compares the spectra with those stored in a library to determine the

best fit matches; this method increases the likelihood of correctly

identifying peaks.

For example, Figure 1-1 shows an overlay of pyrene and an impurity

(obtained from two consecutive chromatographic runs). Based on 2D

data, or if the run had been performed with a conventional variable

wavelength detector, these peaks would have been misidentified as

the same component.

A PDA-100, under the control of Dionex software with the 3D

option, correctly identified and differentiated the components. The

spectra of pyrene and the impurity (see Figure 1-2) clearly indicate

that the two peaks are different components.

PDA-100 Photodiode Array Detector

1-4 Doc. 031644-02 9/03

Figure 1-1. Overlay of Pyrene and an Impurity

Figure 1-2. Spectra of Pyrene and an Impurity

Impurity

Pyrene

Impurity

Pyrene

1 • Introduction

Doc. 031644-02 9/03 1-5

1.3 About This Manual

Chapter 1

Introduction

Provides a brief overview of the PDA-100 and the theory

of photodiode array detection. Summarizes the

organization of the user’s manual. Explains the meaning of

safety messages and icons in the manual and the safety

labels on the detector.

Chapter 2

Description

Describes the PDA-100 front panel LED indicators, inside

front panel, optical system, and rear panel connections.

Chapter 3

Operation and

Maintenance

Presents an overview of PDA-100 operation, as well as

guidelines for optimizing detector performance. Lists

routine preventive maintenance procedures.

Chapter 4

Troubleshooting

Lists problems that may occur, along with step-by-step

instructions for resolving them.

Chapter 5

Service

Contains step-by-step instructions for routine service and

parts replacement procedures.

Appendix A

Specifications

Lists the PDA-100 specifications and installation site

requirements.

Appendix B

Installation

Describes how to install the PDA-100, including the DX-

LAN connections to the host computer running Dionex

chromatography software.

Appendix C

Reordering

Information

Lists spare parts for the detector.

PDA-100 Photodiode Array Detector

1-6 Doc. 031644-02 9/03

1.3.1 Safety Messages and Notes

This manual contains warnings and precautionary statements that can

prevent personal injury and/or damage to the PDA-100 when properly

followed. Safety messages appear in bold type and are accompanied by

icons, as shown below.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

1 • Introduction

Doc. 031644-02 9/03 1-7

Messages d’avertissement en français

Warnhinweise in Deutsch

Informational messages also appear throughout this manual. These are

labeled NOTE and are in bold type:

NOTE NOTES call attention to certain information. They alert

the user to an unexpected result of an action, suggest

how to optimize instrument performance, etc.

Signale une situation de danger immédiat qui, si elle n'est pas évitée,

entraînera des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures mineures à modérées. Également

utilisé pour signaler une situation ou une pratique qui pourrait

gravement endommager l'instrument mais qui n'entraînera pas de

blessures.

Bedeutet unmittelbare Gefahr. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zu kleineren

oder mittelschweren Verletzungen führen. Wird auch verwendet, wenn

eine Situation zu schweren Schäden am Gerät führen kann, jedoch

keine Verletzungsgefahr besteht.

PDA-100 Photodiode Array Detector

1-8 Doc. 031644-02 9/03

1.4 Safety Labels

The TUV GS, C, US Mark safety label and the CE Mark label on the PDA-100

indicate that the PDA-100 is in compliance with the following standards: EN

61010-1:1993 (safety), CAN/CSA-C22.2 No. 1010.1-92 (safety), UL 3101-

1/10.93 (safety), EN 50082-1:1992 (susceptibility), and EN 55011:1991

(emissions).

These symbols appear on the PDA-100 or on PDA-100 labels.

Alternating current

Protective conductor terminal

Power supply is on

Power supply is off

˜

Doc. 031644-02 9/03 2-1

2 • Description

2.1 Front Panel

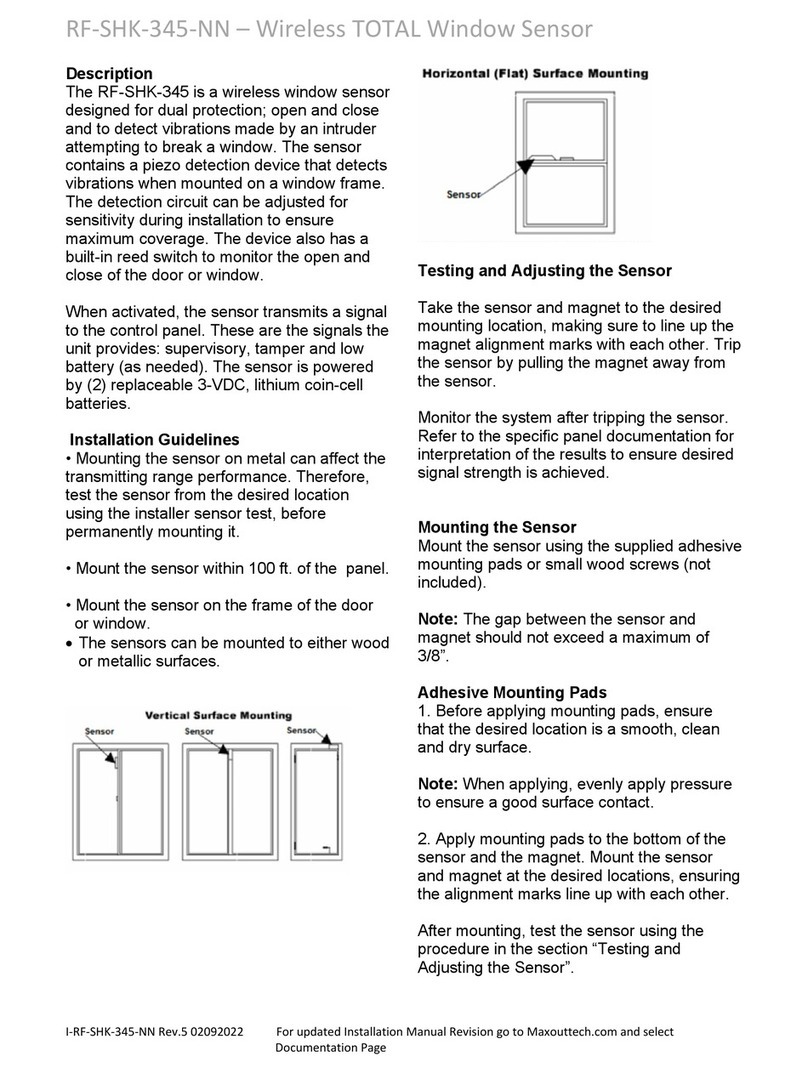

Figure 2-1 illustrates the front panel of the PDA-100 Photodiode Array Detector.

The Power switch provides on/off control of the detector power. LED indicators

identify the status of four functions: the detector power, the deuterium and

tungsten lamps, and the run. A solid lighted LED indicates that the corresponding

function is in progress. A flashing LED indicates that an error occurred; for an

explanation, check the Audit Trail in PeakNet 6 or Chromeleon.

Figure 2-1. PDA-100 Front Panel

LED LED Status Function

Run Lighted Data is being acquired by the host computer.

Flashing An alarm was activated; for example, the leak sensor in

the drip tray may have been triggered.

Off Data is not being acquired by the host computer.

Deuterium Lighted The deuterium lamp is on.

Flashing A command was issued to turn on the deuterium lamp,

but the lamp failed to turn on (see Section 4.5).

Off The deuterium lamp is off.

Run

Deuterium

Tungsten

Power

PDA-100 Photodiode Array Detector

PDA-100 Photodiode Array Detector

2-2 Doc. 031644-02 9/03

Tungsten Lighted The tungsten lamp is on.

Flashing A command was issued to turn on the tungsten lamp, but

the lamp failed to turn on (see Section 4.5).

Off The tungsten lamp is off.

Power Lighted The detector power is on. Press the Power switch to turn

the detector on and off.

Flashing The detector failed one of the electrical checks or optical

checks performed during the power-up sequence (see

Section 4.15.1).

Off The detector power is off. Press the Power switch to

turn the detector on and off.

LED LED Status Function

2 • Description

Doc. 031644-02 9/03 2-3

2.2 Inside Front Panel

NOTE For an illustration of the inside front panel with the flow

cell cover and lamp cover removed, see Figure 5-1.

Grasp the PDA-100 front panel by the sides and pull straight off to access the

inside front panel (see Figure 2-2).

•The flow cell cover protects the cell from dust, ambient light, fluctuations in

ambient temperature, and vibration.

•The lamp cover enhances the thermal stabilization of the optical bench. The

optical bench is housed in a compartment behind the inside front panel.

•Because the flow cell is located behind a cover, leaks from the cell tubing

connections are not immediately apparent. To prevent damage to detector

components, the bottom of the optical bench contains a built-in leak tray. A

sensor in the sump of the leak tray responds to changes in the index of

refraction when wet.

If the leak sensor is activated, it triggers an alarm in the detector and the front

panel Run LED begins flashing (see Figure 2-1). In addition, the leak is

reported to the host computer and PeakNet 6 or Chromeleon displays an error

message.

Figure 2-2. PDA-100 Inside Front Panel

Power

Switch

Component Identification

Label

Leak

Sensor

Flow Cell

Cover

Lamp Cover

056345-01

Sensor

Leak

Lamp

Tung st en

Lamp

Deuterium

Cell

Flow

INJURY.

CAUSE PERMANENT EYE

INTENSE LIGHT MAY

INTO LIGHT SOURCES.

AVOID LOOKIN G DIRECTLY

WARNING

On/Off

Power

Run

Deuterium

Tungsten

Power

PDA-100 Photodiode Array Detector

2-4 Doc. 031644-02 9/03

2.3 Optical System

Figure 2-3 is a schematic of the PDA-100 optical system.

Light from the tungsten lamp is focused through an opening in the internal

structure of the deuterium lamp. Light from the tungsten and deuterium lamps is

then focused through the flow cell by the source lens. After exiting the cell, the

light passes through the spectrograph lens to the filter paddle and is focused into

the slit. The light then passes through the slit to the grating, where it is separated

into its component wavelengths and diffracted to the photodiode array. Each diode

measures a narrow portion of the spectrum.

Figure 2-3. PDA-100 Optical System

Grating Slit

Flow Cell

Filter Paddle

Photodiode Array

Spectrograph Lens

Source Lens

Vi

s

ibl

e

F

ocus Lens

Deuterium Lamp

Tungsten Lamp

2 • Description

Doc. 031644-02 9/03 2-5

Optical System

Component

Function

Tungsten Lamp The light source for visible and near-infrared wavelengths

(380 nm to 800 nm). The tungsten lamp is focused through an

opening in the internal structure of the deuterium lamp; this

allows the lamps to share the optical axis to the source lens.

Visible Focus Lens Focuses the visible light from the tungsten lamp to the through-

hole of the deuterium lamp.

Deuterium Lamp The light source for UV wavelengths (190 nm to 380 nm); also

used to check the wavelength calibration.

Source Lens Receives the light from the tungsten and deuterium lamps and

focuses it so that the beam passes through the flow cell.

Flow Cell The measurement site for sample absorbance. The cell has a flat

window on each side.

Spectrograph Lens Receives the light from the flow cell and focuses it onto the slit.

Filter Paddle The motorized filter paddle in the spectrograph has three

positions:

•Open = Light passes, unobstructed, along the light path when

the holmium oxide filter is moved out of the light path.

•Blocked = No light passes along the light path; used to

measure the dark signal without turning off the lamps.

•Holmium = Places the holmium oxide filter in the light path;

used to verify wavelength accuracy.

Slit The width of the slit (equivalent to 1 nm) optimizes the optical

resolution.

Grating Diffracts the light beam into its component wavelengths and

directs the light onto the photodiode array.

Photodiode Array A series of 1024 photosensitive elements. Each element measures

a narrow band of the spectrum. A spectrum is obtained by

measuring the light intensity of each wavelength and reporting the

range of results.

PDA-100 Photodiode Array Detector

2-6 Doc. 031644-02 9/03

2.3.1 Flow Cell

The PDA-100 flow cell assembly (see Figure 2-4) is available in PEEK or

stainless steel. Two built-in heat exchangers, one on the cell inlet tubing

and one on the cell handle, help stabilize the temperature of the mobile

phase before it enters the cell.

Figure 2-4. Flow Cell Assembly

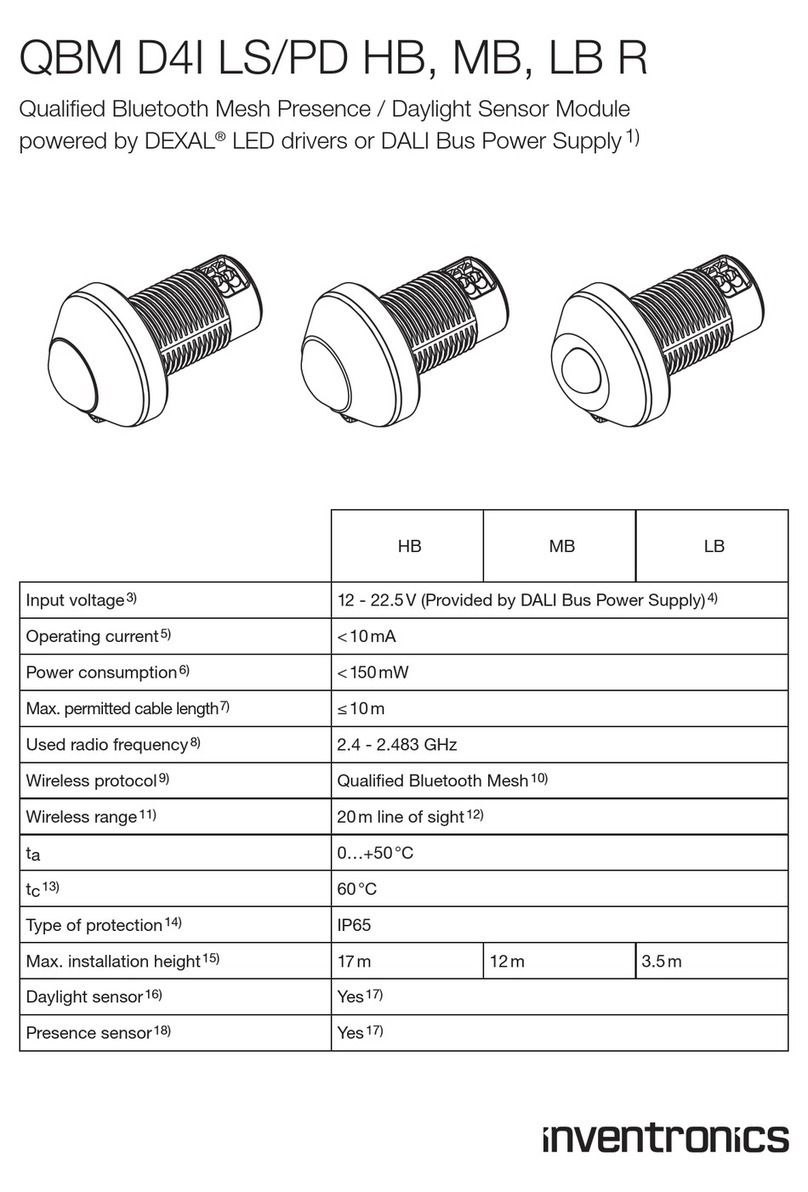

Flow Cell Cell Path Length Cell Volume Heat Exchanger Volume

PEEK

(P/N 056346)

10 mm 13 µL20µL

Stainless Steel

(P/N 056126)

10 mm 13 µL9µL

Do not touch the cell windows. If you touch a window, clean it with

denatured alcohol and a clean lens tissue.

Do not use the PEEK flow cell with normal phase or chlorinated

solvents; these solvents will damage the cell.

Do not use the stainless steel flow cell with high pH salts; the salts

can cause corrosion, contamination, and metal leaching.

Cell Inlet Tubing

Cell Outlet Tubing

Heat Exchangers

Flow Cell

Handle

Sprin

g

Clip

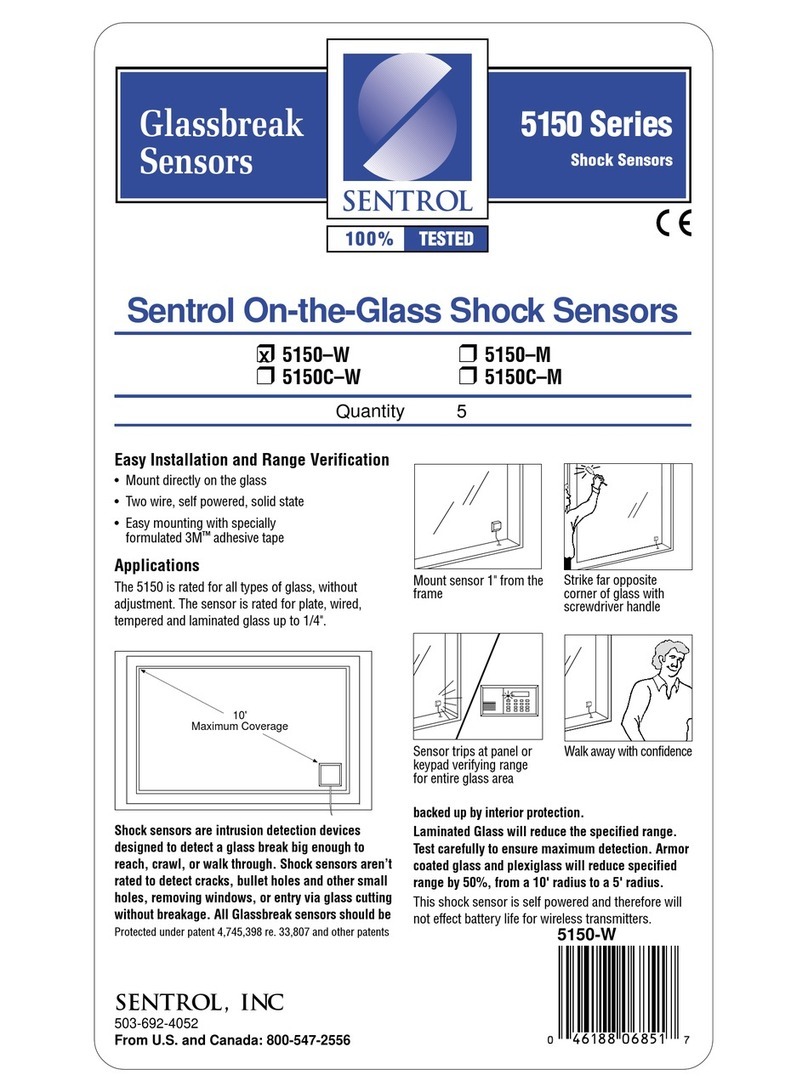

Table of contents

Other Dionex Security Sensor manuals

Popular Security Sensor manuals by other brands

Bosch

Bosch AVENAR detector4000 user manual

Inventronics

Inventronics QBM D4I LS HB manual

Honeywell

Honeywell 5800COMBO Installation and setup guide

Sentrol

Sentrol 5150-W - Security Glassbreak Shock Sensor installation instructions

Inficon

Inficon HLD6000 Translation of the original operating instructions

Emerson

Emerson Rosemount CT4215 Reference manual