HUSH FEATURE / ALARM SILENCE

If required, the audible alarm for smoke and CO conditions can be

silenced for 5 minutes by pushing the “Test/Hush” button. In addition, low

chirping can be silenced for 12 hours when the Test/Hush button is

pressed.

During a Smoke alarm, if an alarm condition still exists after the 5 minute

hush period, the alarm will sound. The hush feature will not operate at

levels above 4%/ft smoke concentration.

During a CO alarm, if carbon monoxide is still present after the 5 minute

hush period, the alarm will sound. The hush feature will not operate at

levels above 350 ppm (parts per million) carbon monoxide.

CO SENSOR END-of-LIFE FEATURE

When the CO sensor has passed end-of-

life, a trouble signal will be sent to

the control panel (if programmed). This indicates that the CO sensor inside

the detector must be replaced. If unresolved for 30 days, the detector will

chirp every 45 seconds. The typical life of the CO sensor is ten years from

the date of manufacture. It is recommended to periodically check the

“Replace by” date located on the label on the back of the detector head.

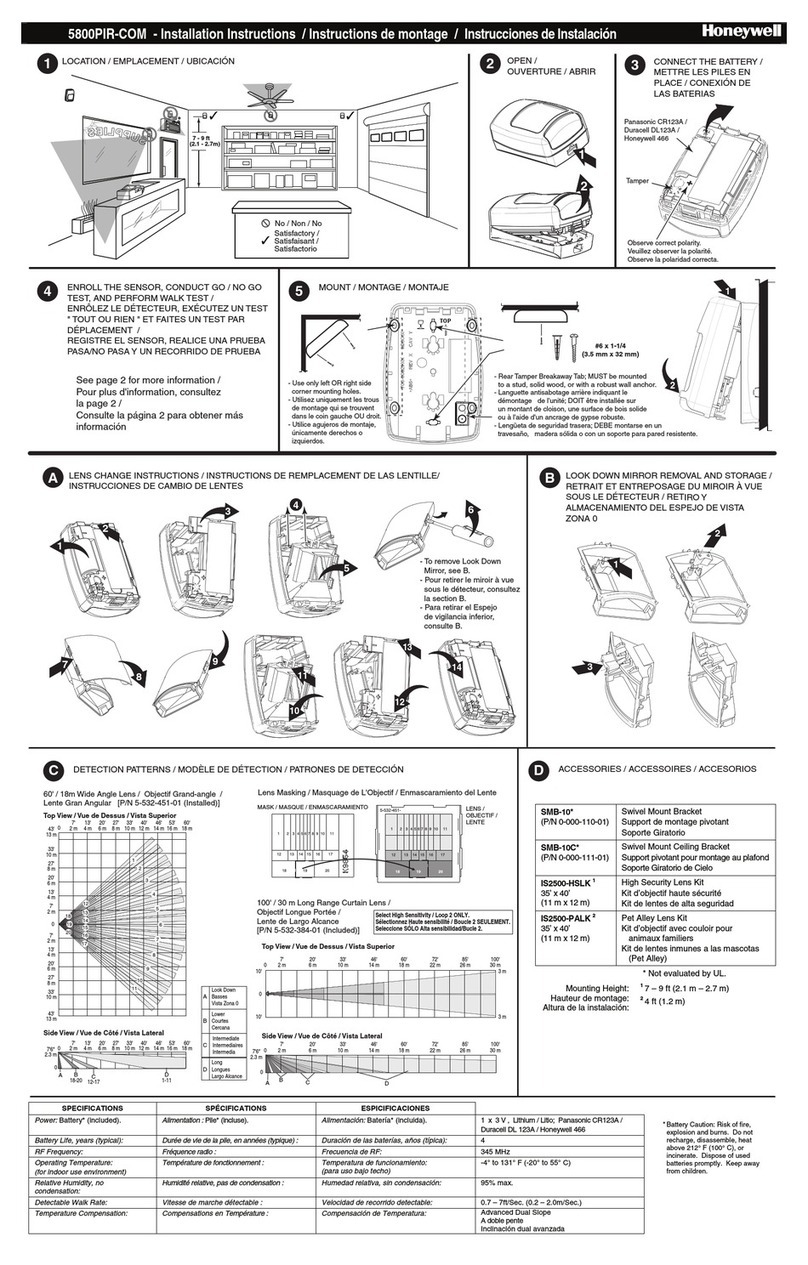

TESTING SIGNAL STRENGTH

Perform this test in accordance with NFPA 72 inspection, testing and

maintenance requirements to determine a strong communication path with

the control panel.

1. Activate the wireless system’s GO/NO GO TEST mode.

2. Press the detector’s Smoke TEST button (•) for 1-2 seconds. The

detector should immediately transmit an alarm signal to the control

panel. The built-in horn will start to sound about 2.5 seconds after

pressing the button.

3. The wireless system’s keypad should emit at least three beeps when

the alarm transmission is received and display the transmitting

detector’s zone number.

4. When the console has received the test signal, the horn will stop and a

few seconds later the detector’s zone number will clear from the co

display.

5. If the console does not respond as noted, and if this is an initial

installation, try moving the detector to another location that provides

proper reception. Also be sure that the detector has been “enrolled” by

the control panel (see Enrollment section). Then, repeat the test.

6. Turn off the system’s TEST mode (typically security code + OFF).

REPLACING THE BATTERIES

CAUTION: The batteries used in this device may present a fire or

chemical burn hazard if mistreated. Do not recharge, disassemble, heat

above 100°C (212°F) or dispose of in fire. Use only Panasonic CR123A

Lithium batteries. Use of other batteries may present a risk of fire or

explosion. Keep used batteries away from children. Dispose of used

batteries properly.

Remove old batteries. Wait 10 seconds and then replace with four new

batteries. To avoid a low battery indication when installing new batteries,

all 4 batteries must be installed within 15 seconds of installing the first one

Any low battery condition that may have occurred should clear when the

base plate is installed.

CLEANING

NOTE:Notify the proper authorities when the system

will be temporarily out of service.

IMPORTANT: This detector must be tested and

maintained regularly following NFPA-72 requirements.

The detector should be cleaned at least once a year.

1.

Remove the detector from the base plate by turning

counterclockwise.

2.

Clean the outside casing with a cloth. Ensure that

the holes on the front of the alarm are not blocked

with dirt and dust. Canned air can be used to

remove any dust or debris.

3.

Reattach the detector to the base plate by rotating

clockwise.

4.

Test the detector to insure it is fully functional. (See

Testing section).

5.

Notify the proper authorities and Central Station

when the system is back in service.

MAINTENANCE

Do not paint, and do not use cleaning agents, bleach

or polish the detector.

NOTE: Before performing any maintenance on the detector,

notify the proper authorities and Central Station that

maintenance is being performed and the system will be

temporarily out of service. Disable the zone or system

undergoing maintenance to prevent any unwanted alarms.

Power must be removed from the detector before performing

maintenance of any kind.

The 5800COMBO detector reports maintenance issues

to the control panel and communicates them visually

and audibly per Table 2.

Trouble feature: When the sensor (supervision) is in a

trouble condition (such as a detector that is dirty or CO

sensor non-functioning), the detector will send a trouble

signal to the control panel. Depending on the issue, the

detector must then be serviced or replaced.

NOTE: Smoke detectors are not to be used with detector

guards unless the combination is evaluated and found

suitable for that purpose.

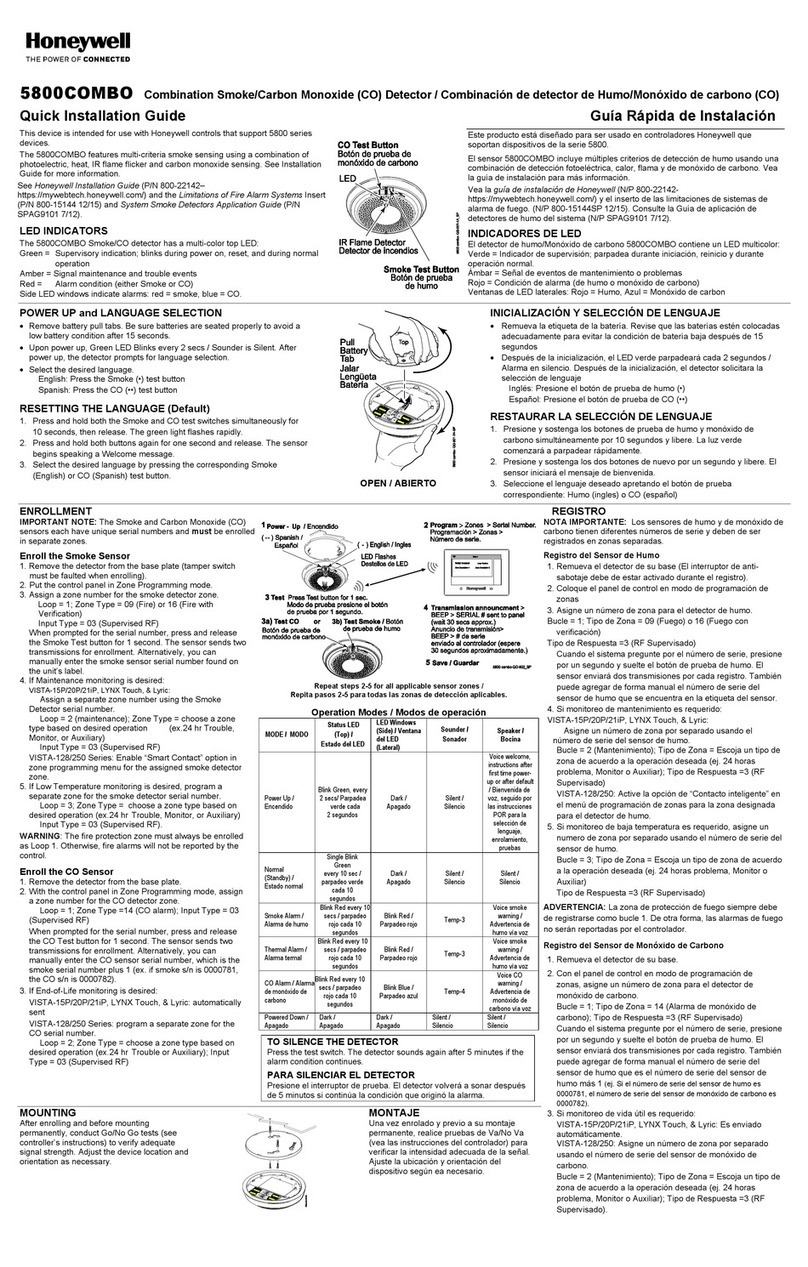

LED INDICATORS

The 5800COMBO has a multi-color top LED:

Green = Supervisory indication; blinks during power on,

reset, and during normal operation

Amber = Signal maintenance and trouble events

Red = Alarm condition (either Smoke or CO)

Side LED windows indicate alarms:

red = smoke

Table 3: Carbon Monoxide Detector: Events and Their ID Codes

Event Alpha Keypad

CS Report

detector

CO Trouble

RF sensor supervision

(CID 381)

detector end-of-

life/trouble CO Trouble sensor trouble - end-of life

(CID 380)

tamper

armed = CO Alarm

RF sensor tamper

(CID 383)