Direct Scientific DSM-502 Manual

DIGITAL SURVEY METER

OPERATIONS & MAINTENANCE

MANUAL

Direct Scientific

www.drct.com

tel (310) 589-0601

fax (310) 919-2981

WBJI DSM-502

PAGE 2

SECTION CONTENTS

1 ------------------------------ SPECIFICATIONS

2 ------------------------------ DESCRIPTION

3 ------------------------------ THEORY OF OPERATION

4 ------------------------------ OPERATING CONTROLS

5 ------------------------------ OPERATING INSTRUCTIONS

6 ------------------------------ MAINTENANCE

7 ------------------------------ PARTS LIST

8 ------------------------------ SCHEMATICS

WBJI DSM-502

PAGE 3

1.0 SPECIFICATIONS - APPLY TO EACH PROBE

PROBE LINEARIZATION Internal Adjustments for Calibration and Dead Time Customization

INTERNAL PROBE RANGE 0 – 999.9 R/hr, 0 – 999.9 kcpm. 0 – 999.9 cps, 0 – 10mSv/hr

COUNT TIME 0 -2550 SECONDS IN 10 SECOND INCREMENTS

RANGE ADJUSTMENT AUTO RANGING

ELECTRICAL LINEARITY ±5% OF FULL SCALE

RESPONSE TIME FULL SCALE FAST = 10 – 250 SEC. SLOW = 10-250 SEC.

DRIFT LESS THAN 5%

TEMPERATURE COEFFICIENT LESS THAN 0.2%/ DEGREE C

HIGH VOLTAGE ADJUSTABLE - 300 - 1500 VDC REGULATION ±1%

LOW VOLTAGE +5 VDC & -5 VDC REGULATION ±0.5 %

BATTERY 6 - "AA" ALKALINE

BATTERY OPERATION 200 HRS NOMINAL

LCD READOUT 4 DIGIT .75” (19mm) TALL

RS-232 DATA OUTPUT 9 PIN MINIATURE SUB-D CONNECTOR. DATA ON LCD

(OPTIONAL) READOUT DUMPED WHEN “DATA” SWITCH IS ACTIVATED

ON FRONT PANEL.

LCD BACKLIGHT 30 SECONDS PER ACTIVATION FRONT PANEL

“BACKLIGHT SWITCH"

TEMPERATURE RANGE -20°C TO 50°C

HUMIDITY RANGE 5 - 95% NON CONDENSING

DIMENSIONS 7¼"(184mm) X 2 ¾" (70mm) H X 4 5/8"(118mm) DEEP

WEIGHT 3 POUNDS INCLUDING BATTERIES

HOUSING 16 Ga. ALUMINUM WITH HEAVY DUTY CARRYING

HANDLE

HOUSING FINISH LIGHT GRAY & DARK GRAY CATALYZED POLYURETHANE

CALIBRATION SECURITY TOP AND BOTTOM ARE LATCHED TOGETHER

WBJI DSM-502

PAGE 4

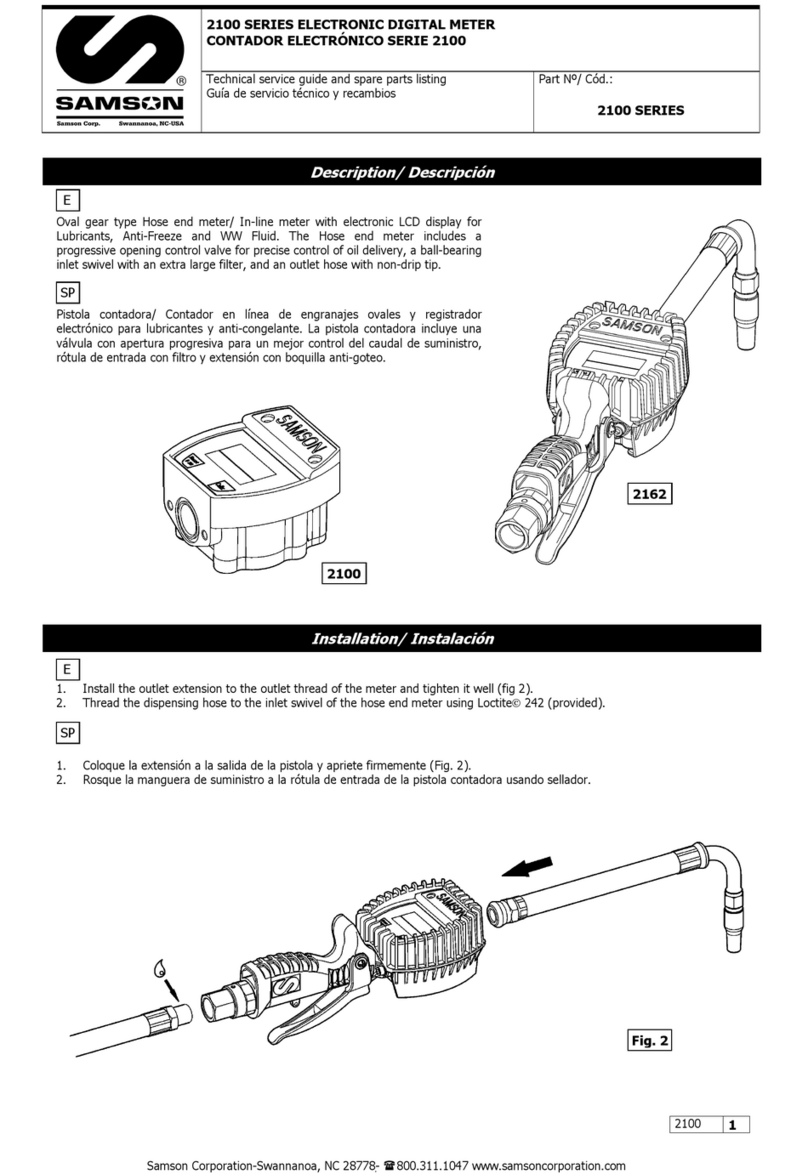

2.0 DESCRIPTION

The Model DSM-502 is a ruggedized, multi-purpose, state of the art, DIGITAL RATEMETER/SCALER with

an Internal Detector that can be calibrated separately in dead time compensated cpm and dose. It has an

adjustable high stability HV supply that can operate any probe requiring voltages from 300 – 1500 vdc. The

probe can have a completely independent calibration in cpm/cps dead time compensated, dose that is

automatically activated when the probe is selected from the front panel. The large easy to read digital LCD

readout is utilized to display all relevant data in Counts, µR/hr, mR/hr R/hr & Sv units. The DSM-502 does

not require any external pc boards, pc downloads etc. to calibrate and operate. All of the controls

necessary to calibrate the DSM-502 with any of the probes available from Johnson are contained in the

instrument. Calibration data i.e. HV, dead time, count time, alarm setpoint & over range setpoint, fast tc,

slow tc & HV can be displayed on the LCD. Diagnostic circuitry constantly monitors the battery, high voltage

and detector condition and automatically indicates when operation is out of tolerance. A FAST/SLOW

RESPONSE switch (that is adjustable) is available on the front panel to change the full scale response from 10

- 250 seconds for FAST and 10-250 seconds for SLOW. A speaker that produces a loud AUDIBLE CLICK

for each probe pulse can be turned OFF or ON from the front panel. The ALARMS for OVERRANGE &

OPERATING ALARM have a visual ALARM indicator in the LCD and an audible indication when the alarm

has been activated. The OPERATING ALARM can be temporarily disabled from the front by toggling the

ZERO switch. Durability is enhanced by heavy duty, cast aluminum construction and the direct

interconnection of the industrial type printed circuit boards.

3.0 THEORY OF OPERATION

3.1 GENERAL

The DSM-502 utilizes the latest field proven, microprocessor circuitry to operate all of the Internal GM

probes. The instrument can function as a regular ratemeter without dead time compensation, regular

ratemeter with dead time compensation, scaler with counting times from 10 – 2550 seconds in 10 second

increments. The system changes ranges automatically and has separate non interacting controls for dose and

dead time compensated cpm or cps calibration for each input. Other adjustments with internal controls are:

HV, COUNT TIME, LCD REFRESH RATE, FAST TC & SLOW TIME CONSTANT. Operation in either

the counts/minute or dose mode for each probe is switch selectable from the front panel. The electronic

circuitry is located on 2 heavy duty industrial type printed circuit boards that are directly interconnected to

improve reliability and durability. All of the internal power is provided by highly regulated -5 vdc & +5 vdc

(±0.5%) low temperature coefficient power supplies. A separate high stability higher voltage power

supply is provided with a low temperature coefficient provides 300 - 1500 vdc (±1%) to operate probes

with different HV requirements. An OVER RANGE ALARM is available that produces a beeping audible

alarm when the usable range of the probe has been exceeded. Diagnostic circuitry constantly monitors the

power supply, high voltage supply and GM detector and indicates out of tolerance operation by indicators on

the LCD or by audible alert. An optional RS-232 data port is provided by a 9 pin sub-d connector. Data is

available at the connector when the “DATA” switch located on the front panel is depressed. .

3.2 DETECTOR SIGNAL – DIAGNOSTICS – CALIBRATION CONTROLS

A microprocessor meter operates much differently than an analog type meter. Most of the functions i.e. dead

time correction, diagnostics etc. are provided by the microprocessor programming (software). The DSM-502

contains two micro-processors. One processor controls and manipulates the data from the probes and

provides the HV and calibration support. The 2nd processor on the DISPLAY pc board controls the data to

the display and provides the RS-232 signal to the ‘DATA OUTPUT CONNECTOR”. Switch SW4 is an

internal switch on the CPU that controls the CALIBRATION FUNCTIONS of the DSM-502. SW5 is a push

button switch located by SW4 that is used to activate the calibration procedure selected and save the settings

of the potentiometers utilized to calibrate each particular function. FIGURE 2 shows SW4 and SW5 and

their position on the CPU pc board. Calibration of the ALL THE PARAMETERS IN THE SYSTEM is

completed by utilizing SW4, SW5, P1, P2 & P3. SW4 is utilized to select the function that will be calibrated or

set and P1, P2, & P3 are utilized to adjust the parameters. When a particular function has been set

(calibrated) to the desired levels SW5 is depressed to save the readings on P1, P2 & P3. Each position on SW4

represents a function or parameter that is being adjusted. As a result of this system the potentiometers P1, P2

& P3 are utilized over and over again to adjust the parameters. When the calibration procedure has been

completed SW4 IS ADJUSTED TO “0” ZERO POSITION FOR NORMAL OPERATION FIGURE 2

SHOWS THE LOCATION OF SW4, SW5, P1, P2 & P3. FIGURE 3 SHOWS THE COMPONENT LAYOUT

OF THE POWER SUPPLY PRINTED CIRCUIT BOARD AND THE LOCATION OF THE MAJOR

COMPONENTS.

WBJI DSM-502

PAGE 5

3.3 HIGH & LOW VOLTAGE POWER SUPPLIES

Six "AA" size batteries provide the LOW VOLTAGE power for all of the DSM-502 circuitry. The batteries

are connected to a positive power regulator on the POWER SUPPLY pc board designated E1. E1 converts

the 9 vdc to a very stable +5 vdc. The output of E1 (+5 vdc) is connected to the circuitry requiring +5 vdc and

the negative 5 vdc regulator U2. The output of U2 (-5 vdc ) is connected to the circuitry requiring -5 vdc.

Both power regulators (E1 & U2) have very good regulation ±.5% and a low temperature coefficient. The

HIGH VOLTAGE supply is comprised of a special high efficiency transformer with a feedback winding and

oscillator circuitry to generate a low ripple, stable high voltage. The output of the transformer T1 is

connected to a voltage doubler circuit comprised of D1-D4 & C3-C7. The output of the doublers circuit is

filtered in a pi type filter and connected to the PROBE BNC through R1. R1 is also the load resistor for the

detector circuit. The HV oscillator circuit through R4 constantly monitors the high voltage. R4 provides U1

a low voltage signal that represents the high voltage. Any change in the high voltage will result in an

appropriate increase or decrease in the power Q1 & Q2 provide the high voltage transformer. This

"feedback" is utilized to regulate the high voltage to approximately ±1%. The power supply is designed with

two high voltage outputs that can be independently adjusted between 300 – 1500 vdc. Figure 3 show the power

supply pc board’s major components and calibration controls

4.0 OPERATING CONTROLS & INDICATORS

4.1 CONTROLS - MAIN FUNCTION SWITCH

CONTROL SETTING FUNCTION

OFF ALL POWER IS DISCONNECTED TO THE INSTRUMENT

RATEMETER NORMAL OPERATING RATEMETER MODE – CPM OR DOSE

(BASED ON CS137 CALIBRATION)

COUNT TIMED COUNT (SCALER) MODE FOR INTERNAL PROBE

4.2 CONTROL – DOSE /CPM

Selects the operating mode of the ratemeter to measure in either roentgen or sieverts (BASED ON CS 137

CALIBRATION) or counts per minute. Probe response is automatically displayed in the correct (micro,

milli or R/hr or sieverts) DOSE mode for the probe that has been selected on the MAIN SELECTION

SWITCH.

4.3 CONTROL – SPEAKER/ZERO

Control is momentary toggle switch with the center neutral. Momentary operation in speaker direction turns

speaker on or off. Momentary operation in zero direction instantly disables the AUDIBLE OPERATIONS

ALARM. THE AUDIBLE ALARM WILL REMAIN DISABLED UNTIL THE SIGNAL FALLS BELOW

THE SETPOINT AT WHICH TIME THE ALARM CIRCUIT WILL RETURN TO NORMAL

OPERATION. OPERATION OF THE SWITCH IN THE ZERO DIRECTION FOR AT LEAST 3

SECONDS WILL ZERO THE INDICATION ON THE LCD

4.4 CONTROL – DATA/BACKLIGHT

Control is momentary toggle switch with the center neutral. Momentary operation in data direction provides

the data being displayed on the LCD to the RS-232 DATA OUTPUT CONNECTOR.

Momentary operation in the BACKLIGHT direction will light the LCD BACKLIGHT FOR 30 seconds.

BACKLIGHT switch can be operated at the end of each 30 second cycle for another 30 second period for as

long as necessary. Continued operation of the BACKLIGHT will greatly reduce the instruments battery life.

WBJI DSM-502

PAGE 6

5.0 OPERATING INSTRUCTIONS

5.1 BEFORE OPERATION

5.1.1 The DSM-502 HIGH VOLTAGE and GAIN are adjusted to the operating characteristics of

the probe supplied with the meter. The GAIN (input sensitivity) is adjusted to 0.050 v-pp

with an input sensitivity of 0.050 v p-p. These high voltage and gain settings are satisfactory

for operation with the many probes but can produce large errors if the DSM-502 is not

calibrated with the internal probe. Refer to the MAINTENANCE SECTION 6.2 for High

Voltage adjustment procedure and SECTION 6.3, 6.4 for the calibration of the system. Be

sure the R/Sv and the CPM/CPS switch has be set to the proper units before calibrating the

system. Figure 4 shows the location of the switch on the LCD pc board.

5.1.2 NO OTHER CHECKS ARE NECESSARY PRIOR TO OPERATING THE DSM-502

EXCEPT TO OBSERVE THE DIAGNOSTIC INDICATORS IN THE LCD DISPLAY

WHEN THE UNIT IS FIRST TURNED ON. The internal microprocessor analyzes the

internal parameters for a few seconds when the instrument is first turned on and during the

instruments operation. All range, battery & probe diagnostic are turn on momentarily

during start-up to show they are working. The display then reverts to NORMAL operation.

The diagnostic circuits connected to the BATT & PROBE indicators continuously monitor

the Circuitry for out of range operation. Battery voltage below 6.8vdc will light the BATT

Symbol on the LCD. SATURATION of a GM detector in high radiation fields will light the

FAULT light. Exceeding the normal operating range of a probe in the DOSE mode will

result in an audible beep every few seconds until the radiation field is reduced within the

operating limits for the probe.

5.2 INSTRUMENT OPERATION

5.2.1 Adjust the MAIN SELECTOR switch to RATEMETER for normal ratemeter type operation.

5.2.2 Depress the SPEAKER/ZERO towards SPEAKER if a audible “tick” for each input pulse is

desired (to turn of the “tick” depress the switch again towards SPEAKER)

5.2.3 Select the mode of operation CPM or DOSE (BASED ON CS 137 CALIBRATION) with the

CPM/DOSE MODE SWITCH set to DOSE includes linearization & DEAD TIME for the

probe. Both corrections are automatically incorporated in the calibration procedure for each

probe.

NOTE: ALL PROBES USING GM DETECTORS CAN BE DOSE CALIBRATED REFERENCED

TO Cs137. ONLY SOME OF THE PROBES USING SCINTILLATION DETECTORS

CAN BE DOSE CALIBRATED, PRIMARILY FOR MICRO R MEASURMENTS. MOST

SCINTILLATION PROBES MUST BE OPERATED IN THE CPM OR COUNT MODE IF

THEY ARE NOT DOSE CALIBRATED.

5.2.4 The LCD READOUT can display the probe signals in CPM, COUNTS, ROETGEN AND

SEIVERTS. When calibrating the system the decision to operate in CPM or CPS and

ROETGEN OR SEIVERTS MUST BE MADE AND THE APPROPORIATE SWITCHES

ADJUSTED BEFORE THE SYSTEM IS CALIBRATED. FIGURE 4 SHOWS THE

LOCATION OF THE R/Sv SWITCH AND THE CPM/CPS SWITCH.

5.3 INSTRUMENT OPERATION – COUNT

5.3.1 The count mode will count each individual pulse from the probe and display the count on the

LCD. The system will be activated when the MAIN SELECTOR SWITCH is placed in the

COUNT position. To start the counter from 0 counting time depress the ZERO SWITCH

FOR AT LEAST 3 SECONDS. The COUNTING will appear and continue until the count

cycle is complete. When the counting period is complete COUNT will appear indicating the

cycle is complete. To start another count cycle depress the ZERO switch FOR AT LEAST 3

SECONDS. If the system is adjusted to 0 seconds counting time then the system will

continue to count as long as the MAIN SELECTOR SWITCH IS IN THE COUNT

POSITION. See how to set count time.

WBJI DSM-502

PAGE 7

F I G U R E 2

F I G U R E 2

DSM- 5 0 2 F R O N T P A N E L C O N T R O L S

P / N 1 2 3 0 3 R E V 6

WBJI DSM-502

PAGE 8

F I G U R E 3

DSM- 5 0 2 P O W E R S U P P L Y A N D M A J O R C O M P O N E N T S

P / N 1 2 2 9 1 - 1 R E V 1

F I G U R E 4

DSM- 5 0 2 L C D D I G I T A L P C B O A R D C O M P O N E N T S A N D C O N T R O L S

P / N 1 2 9 2 3

WBJI DSM-502

PAGE 9

6.0 MAINTENANCE

GENERAL: The DSM-502 Digital Survey Meter has an Internal Probe that operate independently as

CPM/CPS RATEMETER, DOSE CALIBRATED RATEMETER, SCALERWITH TIMED

COUNTING FUNCTIONS . Once the instrument has been calibrated the only operator

intervention required is to select the probe with the MAIN SELECTORS SWITCH ON THE

FRONT PANEL. No external devices are required to calibrate the system except a NIST

traceable radioactive source and electronic pulse generator. ALL CONTROLS

NECESSARY TO CALIBRATE THE DSM-502 ARE LOCATED ON THE PC BOARDS OF

THE SYSTEM.

6.1 LOCATION AND FUNCTION OF CALIBRATION CONTROLS

GENERAL: The calibration procedure for the DSM-502 utilizes only 3 potentiometers and 2 switches to

calibrate all of the DSM-502 functions. FIGURE 1 SHOWS THE GENERAL LOCATION

OF THESE CONTROLS. SW4 located on the left side of the top pc board (next to SW5)

selects the function to be calibrated. These switch positions are as follows:

POSITION 0 NORMAL OPERATING POSITION

POSITION 1 DISPLAY & EDIT COUNT TIME 0 - 2550 SECONDS (10 SECOND INCREMENTS – ADJ

– P1

POSITION 2 DISPLAY & EDIT OPERATIONAL ALARM (5% - 95%) ADJ – P1 COARSE – P2 FINE

POSITION 3 DISPLAY & EDIT OVER RANGE ALARM ADJ – P1 COARSE – P2 FINE

POSITION 4 DISPLAY & EDIT CALIBRATION CONSTANT – ADJ – P1 COARSE – P2 FINE – P3

TENTHS

POSITION 5 DISPLAY & EDIT DEAD TIME - ADJ – P3

POSITION 6 DISPLAY & EDIT HIGH VOLTAGE - MAIN SELECTOR TO #1 PROBE – ADJ #1 HV

POSITION 7 DISPLAYS SOFTWARE NUMBER INSTALLED IN INSTRUMENT

POSITION 8 DISPLAY & EDIT FAST & SLOW TC – SET TO FAST ADJ P1 TO (10 – 250 SECONDS)

SET TO SLOW ADJ P1 TO (10 – 250 SECONDS

POSITION 9 DISPLAY & EDIT LCD REFRESH RATE (8 = 0.8 SECONDS TO 30 = 3.0 SECONDS)

ADJ P1 TO DESIRED REFRESH RATE

SW5 (located next to SW4) is utilized to ACTIVATE & SAVE CALIBRATION SETTINGS

(CAL is visible in the upper center of the display when SW5 activates the calibration

function) the function selected by SW4 and then save the data once the function has been

calibrated into the meters data base. Once a function has been selected by SW4 and

activated by SW5 the potentiometers P1, P2 & P3 are utilized to input the calibration data.

Once these potentiometers have calibrated the function SW5 is depressed and the data is

saved. This process is repeated for each SW4 position using the same P1, P2, & P3 for all

data input.

FIGURE 2 SHOWS THE LOCATION OF ALL THE CALIBRATION COMPONENTS.

6.2 ADJUSTING THE METER FOR CPM/CPS AND R/Sv OPERATION

6.2.1 The switches that adjust the DSM-502 for Roentgen or Sieverts are located on the LCD pc

board. To access these switches remove the DSM-502 from its housing . Looking at the

bottom of the instrument with the LCD at the top the CPM/CPS switch is on the left side of

the LCD pc board. The side of the board near the LCD will have CPS and CPM slide the

small black switch lever towards the type operation desired.

6.2.2 The switch that selects Roentgen or Sieverts is on the right side of the LCD pc board is

located directly above the push button switch SW5. Slide the small black switch lever in the

direction of the desired units of measurement (mR/hr or Sieverts).

6.2.3 This completes the adjustment of the DOSE UNITS AND COUNTING UNITS THAT WILL

BE DISPLAYED ON THE LCD.

WBJI DSM-502

PAGE 10

6.3 ADJUSTING THE HV

6.3.1 Remove the DSM-502 from its housing.

6.3.2 Determine if the HV that is required to operate the Internal probe is correct.

6.3.3 Adjust the MAIN SELECTOR SWITCH TO RATEMETER POSITION

6.3.4 Using a small screwdriver adjust SW4 to position 6. The number displayed will be the HV on

the Internal Probe. Adjust the #1HV potentiometer to read the required HV (±10 vdc) on the

display

6.3.5 Adjust SW4 to the 0 POSITION.

6.3.6 THIS COMPLETES THE ADJUSTMENT OF THE HV.

6.4 DISABLING THE ALARM & OVERANGE ALARM BEFORE CALIBRATION

6.4.1 To disable the OVER RANGE & REGULAR ALARM before calibrating adjust the MAIN

SELECTOR switch to RATEMETER OR COUNT depending on which alarms you want

disabled.

6.4.2 To disable the OVER RANGE ALARM adjust SW4 to position 3 and depress SW5 so that

CAL is visible on display

6.4.3 Adjust P1 & P2 until the display indicates 0.

6.4.4 Depress SW5. This completes disabling the OVERRANGE ALARM.

6.4.5 To disable the REGULAR ALARM

6.4.6 Leave the MAIN SELECTOR SWITCH at the same setting as was used to disable the OVER

RANGE ALARM

6.4.7 Adjust SW4 to position 2 and depress SW5 until the CAL is visible on the display

6.4.8 Adjust P1 & P2 until display indicates 0. Depress SW5 to save the reading.

6.5 ADJUSTING THE CALIBRATION CONSTANT FOR THE PROBE

GENERAL: The CALIBRATION CONSTANT adjustment is the CALIBRATION POINT for the

LOW END OF THE PROBES OPERATING RANGE. This adjustment is

completed utilizing P1, P2&P3. P2 acts as a COURSE adjustment and P1 acts as a

FINE adjustment. P3 is utilized to adjust the 0.1 part of the display these

potentiometers will become active for the calibration process when SW4 is in the

correct position and SW5 is depressed. The CAL on the display will be visible when

SW5 has been depressed and the meter is in the CALIBRATION MODE. SW5

MUST BE DEPRESSED AT THE END OF THE ADJUSTMENT OR THE DATA

WILL NOT BE SAVED

INTERNAL PROBE CC ADJUSTMENT

6.5.1 Remove the DSM-502 from its housing

6.5.2 Determine the DOSE range of the probe that will be calibrated for the Internal Probe.

6.5.3 Adjust the MAIN SELECTOR SWITCH TO THE RATEMETER POSITION.

6.5.4 Adjust SW4 to the #4 position. Depress SW5 so that CAL is visible.

WBJI DSM-502

PAGE 11

NOTE: GM TYPE PROBE’S CALIBRATION CONSTANT MUST BE CALIBRATED IN A

RADIATION FIELD THAT PRODUCES LESS THAN 15KCPM (APPROX. 1% FULL

SCALE ) TO PREVENT INTERACTION WITH THE DEAD TIME ADJUSTMENT.

SCINTILLATION TYPE PROBES CAN BE SET IN FIELDS THAT ARE SOMEWHAT

HIGHER DUE TO THE LOWER DEAD TIME OF SCINTILLATION PROBES.

HOWEVER SCINTILLATION PROBE SHOULD HAVE THE CC SET IN AS LOW A

FIELD AS PRACTICAL.

6.5.6 Adjust the DOSE/CPM switch to the DOSE POSITION.

6.5.7 Place the #1 probe in a calibrated radiation field that will produce less than 15kcpm (ABOUT

1% OF FULL SCALE.

6.5.8 Adjust P1, P2 & P3 until LCD indicates the correct radiation field

6.5.9 DEPRESS SW5 UNTIL CAL DISPPEARS.

6.5.10 THIS COMPLETES THE INITIAL SETTING OF THE CALIBRATION CONSTANT.

6.6 ADJUSTING THE DEAD TIME FOR THE INTERNAL PROBE

GENERAL: The DEAD TIME adjustment is the calibration point for the HIGH END OF THE

PROBE OPERATING RANGE. The adjustment is completed utilizing

potentiometer P3. The DEAD TIME adjustment will become active when SW4 is

adjusted to position 5. P3 will become active when SW5 is depressed and the CAL is

displayed on the readout.

INTERNAL PROBE DT ADJUSTMENT

6.6.1 Determine the full scale range for the Internal Probe

6.6.2 Be sure MAIN SELECTOR SWITCH is still in RATEMETER position and

DOSE/CPM switch is in the DOSE POSITION

6.6.3 Place the instrument in a calibrated radiation field that is 70% - 90% of the probes

NORMAL operating range.

6.6.4 Adjust SW4 to the #5 position. (The number that appears before depressing SW5 is the DT

in micro seconds that is currently in the system.) Depress SW5 ONCE until CAL is

displayed on readout.

6.6.5 Adjust P3 until the LCD indicates the correct value for the radiation field. Depress SW5 until

CAL is not displayed on the readout. THIS SAVES THE DATA.

6.6.6 Adjust SW4 to the 0 position (normal operating position). A GM PROBE THAT HAS A

NORMAL OPERATING RANGE OF 0 – 200mR/hr would be tested as follows to verify

the accuracy of the overall calibration.

Range 1 = 20% & 80% of 200 mR/hr

Range 2 = 20% & 80% of 20 mR/hr

Range 3 = 20% & 80% of 2 mR/hr

Range 4 = 20% & 80% of 0.2 mR/hr

NOTE: This procedure indicates after the CC & DT have been adjusted the meter readings should

verified to ±10% at each of the radiation fields calculated for Range 1 – Range 4. If the meter does

not measure the 8 calibration points then the CC & DT calibration process will have to be repeated.

WBJI DSM-502

PAGE 12

6.7 ADJUSTING THE OVER RANGE ALARM

GENERAL: The OVER RANGE ALARM is utilized to make the person operating the survey

meter aware that they have exceeded the normal operating limits of the survey meter

and that the data is becoming inaccurate. The OVER RANGE ALARM is audible

and visual. ALARM is indicated by the audio and LCD alarm pulsing

approximately 1 once per second. The alarm will stop when the field at the detector

returns to normal operating range. In this procedure P1 & P2 will utilized to make

the adjustments. P2 acts as a COURSE adjustment and P1 will act as a FINE

adjustment. PROBE DOES NOT HAVE TO BE IN RADIATION FIELD FOR

THIS ADJUSTMENT

6.7.1 Adjust the MAIN SELECTOR switch to RATEMETER position for the OVERRANGE

ALARM ADJUSTMENT.

6.7.2 Adjust SW4 to the #3 position. The number that appears will be the alarm setting that is

currently established.

6.7.3 Depress SW5 (UNTIL CAL APPEARS) &Adjust P1 & P2 until the LCD indicates a reading

that is 10% - 15% above the FULL SCALE range of the probe.

6.7.4 Depress SW5 until CAL disappears to save the data. Adjust SW4 to the NORMAL

OPERATION POSITION 0 (ZERO)

6.7.5 The survey meter is now ready for NORMAL OPERATION.

6.8 ADJUSTING ALARM SETPOINTS

GENERAL: THE DSM-502 HAS AN AUDIBLE ALARM THAT CAN BE SET

INDEPENDENTLY FOR RATEMETE DOSE, RATEMETER CPM & COUNTS.

THE SAME CONTROLS SW4, SW5, P1 & P2 ARE UTILIZED TO MAKE THESE

ADJUSTMENTS. ADJUSTING THE ALARM SETPOINT TO 0 (ZERO)

DISABLES THE ALARM. TO TEMPORARILY DISABLE THE AUDIBLE

ALARM WHEN IT IS ALARMING. DEPRESS THE ZERO SWITCH

MOMENTARILY AND AUDIBLE ALARM WILL BE DISABLED. VISUAL

ALARM ON LCD WILL STILL OPERATE. ALARM WILL RETURN TO

NORMALOPERATION WHEN SIGNAL FALLS BELOW SETPOINT.

ALARM SETPOINT DOSE

6.8.1 Adjust the MAIN SELECTOR switch to RATEMETER.

6.8.2 Adjust the DOSE/CPM switch to DOSE

6.8.3 Adjust SW4 to position 2. Depress SW5 until CAL appears.

6.8.4 Adjust P2 & P1 until the readout indicates the correct alarm setting

6.8.5 Depress SW5 until CAL disappears to save data

6.8.6 Return SW4 to the 0 (ZERO) POSITON FOR NORMAL OPERATION

ALARM SETPOINT CPM

6.8.7 Adjust the MAIN SELECTOR switch to RATEMETER.

6.8.8 Adjust the DOSE/CPM switch to CPM

6.8.9 Adjust SW4 to position 2. Depress SW5 until CAL appears.

6.8.10 Adjust P2 & P1 until the readout indicates the correct alarm setting

WBJI DSM-502

PAGE 13

6.8.11 Depress SW5 until CAL disappears to save data.

6.8.12 Return SW4 to the 0 (ZERO) POSITON FOR NORMAL OPERATION

ALARM SETPOINT COUNT

NOTE: THE DOSE/CPM SWITCH IS NOT IN SERVICE WHEN THE METER IS IN

THE COUNT MODE OF OPERATION

6.8.13 Adjust the MAIN SELECTOR switch to COUNT

6.8.14 Adjust SW4 to position 2. Depress SW5 until CAL appears.

6.8.15 Adjust P2 & P1 until the readout indicates the correct alarm setting

6.8.16 Depress SW5 until CAL disappears to save data.

6.8.17 Return SW4 to the 0 (ZERO) POSITON FOR NORMAL OPERATION

6.9 TIMED COUNT

GENERAL: THE DSM-502 HAS A TIMED COUNT FUNCTION AND CAN BE SET

INDEPENDTLY FOR EACH PROBE. THE RANGE OF THE TIMED COUNT

IS 0 – 2550 SECONDS IN 10 SECOND INCREMENTS. THE TIMED COUNT

FUNCTION IS ONLYAVAILABLE FOR THE PROBE IN THE COUNT

POSITION OF THE MAIN SELECTOR SWITCH. THE SAME CONTROLS SW4,

SW5, P1 & P2 ARE UTILIZED TO MAKE THAT ADJUSTMENTS. FOR THE

TIMED COUNT FUNCTION.

ADJUST THE COUNT TIME

6.9.1 Adjust the MAIN SELECTOR SWITCH TO COUNT. Adjust SW4 to position 1.

This displays the counting time in seconds currently in the system.

6.9.2 To set the count time to change COUNT time Depress SW5 until CAL appears.

6.9.3 Adjust P3 until readout indicates the correct counting time in seconds

6.9.4 Depress SW5 until CAL disappears to save the data.

OPERATION IN THE TIME COUNT MODE

6.9.5 Adjust the MAIN SELECTOR SWITCH to the COUNT position.

6.9.6 If count time is unknown adjust SW4 to the #1 position and COUNT TIME in seconds

for that probe will be displayed. (CAUTION) DO NOT DEPRESS SW5 OR TIME COULD

BE CHANGED)

6.9.7 Return SW4 to the 0 position and instrument is ready for normal operation.

6.9.8 To start a time count cycle. Depress the ZERO SWITCH on the front panel FOR AT

LEAST 3 SECONDS TO START COUNT CYCLE.

6.9.9 When the ZERO switch is depressed the time count cycle will begin and the word

COUNTING will appear on the display. When the cycle is complete the COUNTING will

disappear and the words COUNT will appear. This indicates the count cycle has been

completed.

6.9.10 The total counts will remain on the display until the ZERO switch is depressed for at least 3

seconds or the instrument is turned OFF.

WBJI DSM-502

PAGE 14

6.9.11 If the instrument remains ON a new count cycle can be started by DEPRESSING THE

ZERO SWITCH on the front panel for at least 3 seconds

WBJI DSM-502

PAGE 15

PARTS LIST

WBJI DSM-502

PAGE 16

7.0 PARTS LIST

7.1 DSM-502 LCD PC BOARD -- P/N 12472

JOHNSON P/N DESCRIPTION REFERENCE QUANTITY

REQUIRED

******************************************************************************************

12923-1 LCD DRIVE BRD REV-1 1

116200 I.C 4Kb FRAM SERIAL MEMORY 1

116199 I.C. 80 PIN FLASH MICRO CONTROLLER 1

105291 SWITCH ON-OFF-ON SW1 1

107424 SWITCH TOGGLE SW2 1

107591 TERMINAL STRIP 50 PIN J7 6

108119 RESISTOR 100 OHM – 5% R30,31 2

108392 RESISTOR 10 OHM – 5% R29 1

109162 CAP. 10 PF – 50 V C4, 5 2

109413 CAP. 100PF – 50 V C11 1

110197 RESISTOR 47K 5% R1 1

110199 RESISTOR 10K 5% R9,11,12,13,

R14,15 6

110201 RESISTOR 1K 5% R7 1

110202 CAP 0.1 MF 16 V 10% C1,6,7,8,9,13

C14,15,18,20

C21,22,23,27 14

110226 CAP 47 MF 20V 10% C26 1

110387 JUMPER 0 OHM R10 1

110653 RESISTOR 100 OHM 5% R33 1

110754 RESISTOR 100K 5% R2,3,4,5,6,21

R22,23,24,25

R26,27,28,32 14

111143 TERM STRIP 50 PIN J2 10

112729 TRANS. 60V 500ma Q1 1

114115 FERRITE CHIP 2.5 A- 120 OHM FB2, FB3 2

114206 CRYSTAL 10 MHZ (SMT) X1 1

114293 SLIDE SWITCH SW3,SW4 2

114939 DUAL SCHOTTKY DIODE 30V D1 1

116001 CAP 2.2µF 25V 10% C2,3,10,12,19

C24,25 7

116014 HEADER MALE PIN3 POS J11 1

116020 I.C.OP AMP AD8628 U4 1

116196 LCD DISPLAY JOHNSON LCD 1

116197 TERM STRIP LOW PROF. 50 PIN 33

116198 I.C. 3V – 5.5 RS-232 DRIVER/REC U2 1

7.2 DSM-502 LOGIC BOARD -- P/N 12472

JOHNSON P/N DESCRIPTION REFERENCE QUANTITY

REQUIRED

************************************************************************************************

105291 SWITCH ON-OFF-ON SW1 1

107424 SWITCH TOGGLE SW2 1

108433 6-32 X 5/8” STANDOFF SWAGE 2

113013 RF CONN GOLD CONTACT PROBE 1,2 2

100201 RESISTOR 2K 5% R28 1

100234 RESISTOR 2.2K 5% R6,R76 2

100242 CAP .01MF 50 V 20% C32,41 2

100703 RESISTOR 20K 5% R17 1

100711 RESISTOR 15K 5% R13 1

101278 SWITCH RIGHT ANGLE PUSH BUTTON SW5 1

103742 SWITCH 2 POL 6 POS SW3 1

WBJI DSM-502

PAGE 17

105462 SPACER #5 X 3/16” 2

107479 SWITCH RIGHT ANGLE BCD SW4 1

108030 I.C ON TIME PROG 8 BIT U1 1

108117 RESISTOR 10K 5% R1,14,15,16,20,21,24

R26,47,59,60 11

108118 RESISTOR 4.7K 5% R23 1

108119 RESISTOR 100 OHM 5% R50 1

108123 DIODE 100V D2,3,12,13 4

108128 CAP .22MF 50V 10% C7 1

108217 RESISTOR 220K 5% R4 1

108349 RESISTOR 1K 5% R29,52,53,54 4

108350 RESISTOR 1MEG 5% R22,31,33,55,56,58 6

108358 CAP 0.1 MF 50 V 20% C1,3,5,8,14,15,16,17,

C20,23,24,25,26,27,28,

C29,30,31,33,34,35,36

C37,38,39,40,42 27

108385 CAP 10MF 25V 10% C9,10,11,19 4

108433 6-32X5/8 SWAG STANDOFF 2

108661 TRAN BIPOLAR NPN 40V Q1,2,3 3

108667 CAP 1MF 16V 10% C4,6 2

108791 RESISTOR 82K 5% R2 1

108793 RESISTOR 56 OHM R19 1

108847 ECONORESET U4 1

108865 DUAL DIODE D7 1

109127 RESISTOR 560K 5% R18 1

109134 LP339M I.C. U7 1

109150 RESISTOR 1.6K 5% R6,7,8,9,10,11 6

109156 I.C U3 1

109262 RESISTOR 10 MEG 5% R27 1

109263 CAP 22PF 50 V 5% C21,22,25 3

109641 CAP 470 PF 16 V 10% C18 1

109930 52 PIN SOCKET U1 1

110162 FERRITE 1000 OHM 400ma FB1,FB2 2

110634 RESISTOR 91K 5% R64 1

111037 CAP 100PF 1KV 10% C12A 1

111888 DIODE SCHOTTKY 30V 30 ma D1,4,6,7,8, 5

112341 RESISTOR 249K 1% R25,51 2

112426 RESISTOR 120 OHM 5% R57 1

112452 SOCKET 10 PIN J3 1

7.3 DSM-502 LOGIC BOARD -- P/N 12472

JOHNSON P/N DESCRIPTION REFERENCE QUANTITY

REQUIRED

************************************************************************************************

112948 2.5 X2MM RED LIGHT LED 1,2,3,4,5,6 6

112995 JUMPER O OHMS J3 1

112997 TEST POINTS TP1,2,3,4,5, 5

113013 RF CONN GOLD CONTACT PROBE 1 1

114058 I.C. 3 mhz OP AMP U6 1

114074 RECTIFIER 12V 4.3 AMP Q4 1

114185 2 FORM C 5 V 2 COIL LATCH RELAY RY1 1

114186 8 mhz 18PF FUND Y1 1

114187 10 PIN CONNECTOR J2 1

114188 4 PIN CONNECTOR J1 1

114189 15 V BUZZER 3kc SPK 1 1

113191 2K POT 1 TURN P8 1

115253 DIODE SCHOTTKY D10 1

116203 1K POT 1TURN P10 1

116278 50K 12TURN POT P1,2,3,4,5,6 6

WBJI DSM-502

PAGE 18

12929-1 PC BOARD W/LCD SUP 1

9021-3 SPEAKER GASKET DIE #518 1

9077-4 ROTARY SWITCH MOD 103742 1

7.4 DSM-502 POWER SUPPLY BOARD -- P/N 12291

JOHNSON P/N DESCRIPTION REFERENCE QUANTITY

REQUIRED

100231 51K 1/8W 1206 PKG R43 1

100242 0.01MF 50V 1206 PKG C13 1

100703 20K 1/8W 1206 PKG R46 1

102804 4-40 KEPNUT B1, 2 4

104539 W/MTG STRAP TRANSFORMER T1 1

106712 4-40X 2/8 UNDERCUT B1, 2 4

108117 10K 1/8W 1206 PKG R16, 19, 20 3

108118 4.7 1/8W 1206 PKG R11 1

108123 100 VDC 200 MW DIODE D5, 7 2

108303 3AA PC MOUNT BL. BAT. HOLDER B1, 2 2

108349 1K 1/8 1206 PKG R4, 21 2

108350 1M 1/8W 1206 PKG R8 1

108353 1.5K 1/8W 1206 PKG R9 1

108358 0.1 50V 1206P C8, 11, 12, 14, 18,

22, 23, 25-27 10

108661 NPN 40V SOT-23 Q2 1

108667 1MF 16V 1206 PKG C24 1

108829 47K 1/8W 1206 PKG R18 1

109011 SOT-23 60V 150A PNP BIPOLAR Q1 1

109133 5V REGULATOR E1 1

109156 MC33172D I.C. U1, 3 2

109163 110K 1/8W 1206 PKG R 6, 14 2

109641 470MF 16V C15 1

109896 2.4K 1/8 W 1206 R12 1

110481 1MF 50V 6032 PKG TANT. C10 1

110656 10MF 16V 3528 PKG. TANT C9, 17, 19 3

110761 1A 600V RECTIFIER DIODE D1-4 4

110824 200 OHM 1/8 1206 PKG R22 1

111128 100 MF 20V 7343 PKG ROHS COMP C16 1

111180 1M ½W 2010 PKG R1-3 1

112074 CMOS VOLTAGE CONVERTER U2 1

112118 100PF 3000V 1808 PKG C1 1

112298 0.027 MF 2KV 2225 PKG C2, 3, 20, 21 4

112341 249K 1/8 1206 PKG R13 1

112695 0.001MF 1KV 1808 PKG. C4-7 4

112995 0 OHM JUMPER 1206 PKG R44 1

112997 MINIATURE TEST POINTS TPG1, 2 TP 1-4 6

113143 2.7M 1/8 W 1206 PKG. R45, 47 2

114190 50K 4MM SQ. SINGLE TURN TRIMMING R7, 15, 17 3

114193 10 PIN .25” SQ SINGLE SOCKET J2 1

114194 4 PIN .025” SQ SINGLE SOCKET J1 1

114220 22M 1/10W 0805 PKG R23-42 20

114737 MUX/DMUX TRI 2CH ANLG. 16 SOTC 1.C. U4 1

WBJI DSM-502

PAGE 19

SCHEMATICS

WBJI DSM-502

PAGE 20

Table of contents

Popular Measuring Instrument manuals by other brands

Velleman

Velleman E305EM5 user manual

LaserLiner

LaserLiner AirCheck Clima instructions

Technifor

Technifor TD412 OPERATING AND MAINTENANCE MANUAL INTEGRATION

OHAUS

OHAUS a-AB33M1 instruction manual

Toledo Transducers

Toledo Transducers MoniTTor N269 Installation and operation manual

SPECTRO

SPECTRO SPECTROLAB Original operating instructions