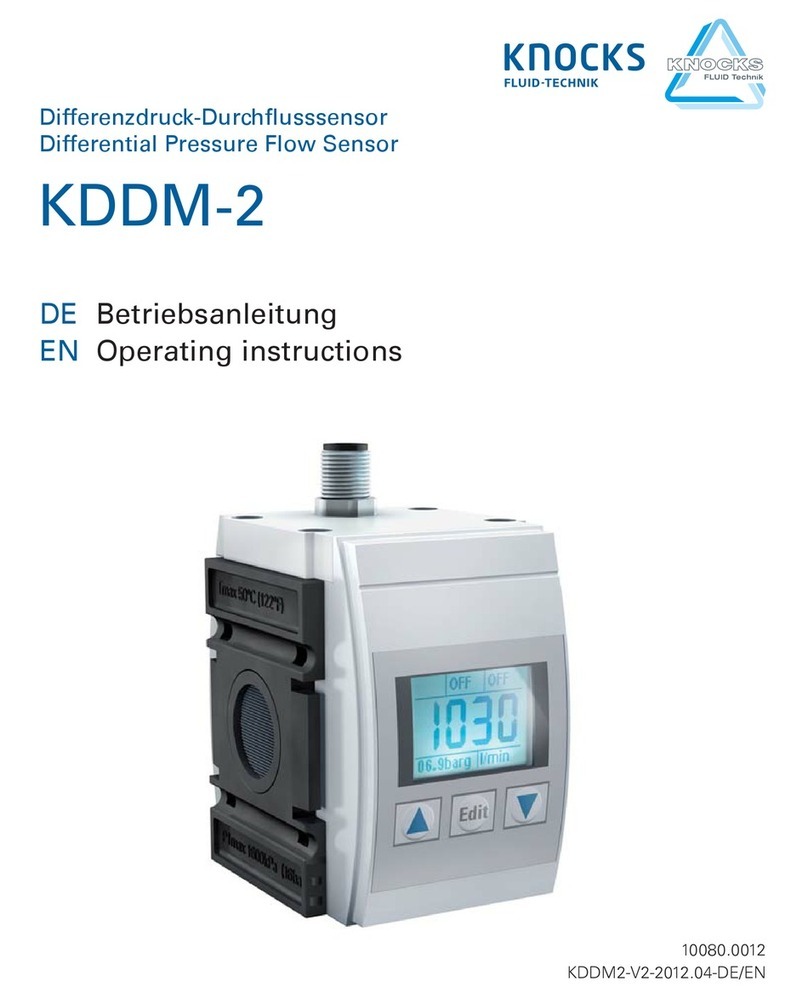

Operation - Start-up - Analog

After applying power to the device, it will enter the start-up mode and the LCD will indicate the software version number and the output signal type for two

seconds each. Then the device will start normal operation.

Operation - Normal

During normal operation, the installed sensor measurements are read and displayed on the LCD. The analog outputs are updated with the appropriate

values and alarm conditions are monitored.

The relative humidity output signal is scaled 0-100 %RH = 4-20 mA or 0-5 Vdc depending on the device model. For the voltage output model, the output

signal may be changed to 0-10 Vdc by using the Setup Menu.

The temperature output signal is scaled 0-50 °C = 4-20 mA or 0-5/0-10 Vdc depending on the device model. The temperature range may be changed to

32-122 °F via the Setup Menu.

If the model also includes a carbon dioxide sensor, then the output signal is scaled 0-2000 ppm = 4-20 mA or 0-5/0-10 Vdc as above. If required, the CO2

scale can be changed via the Setup Menu to span values up to 5000 ppm.

The sensor readings are also displayed on the LCD depending on the device model and can also be configured with the Setup Menu. There are several

configurations on how information is displayed, see the Menu section for full details. Example displays are shown below.

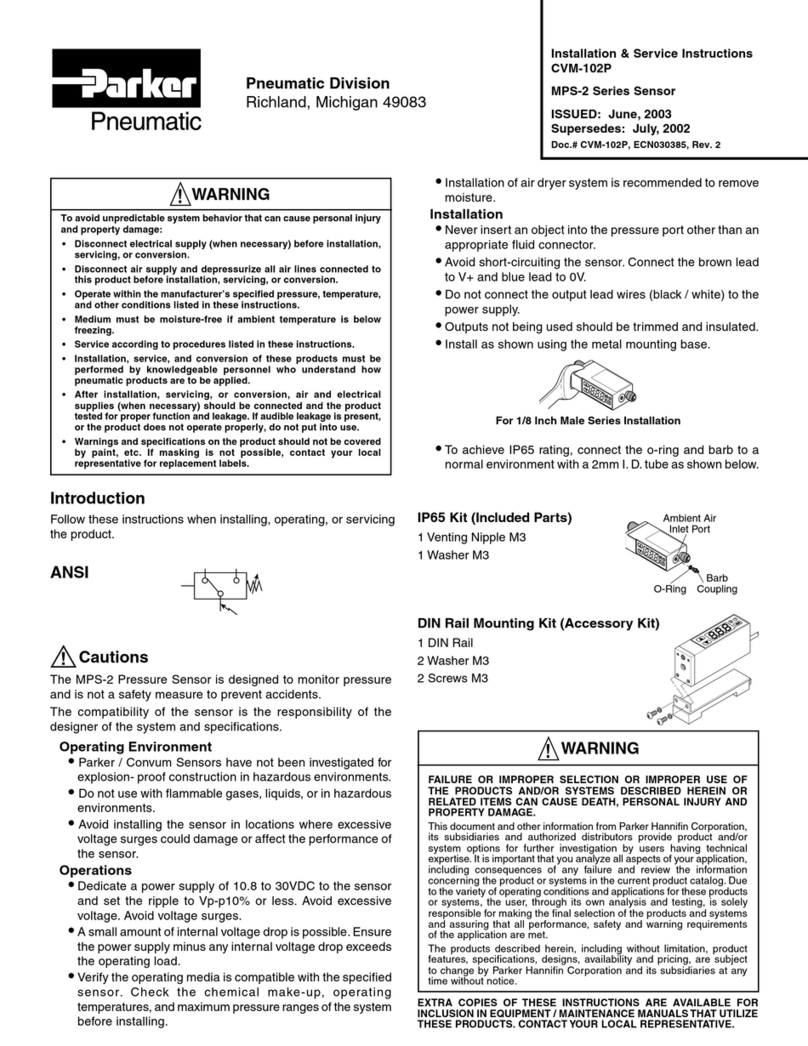

Operation - Alarms

The device may also have one or two alarm relays installed, depending on the model. Each relay may operate as a high or low alarm and may be assigned

to either RH or temperature. For each alarm assignment, there are default values for the setpoints, hysteresis and time delay. The default values may be

changed within limits as required using the Setup Menu. The details of each setting and operation is explained in the Setup Menu section.

Operation - Setup Menu

The Setup Menu has several items as shown below. To enter the menu, press and release the <MENU> key while in normal operation. This will enter the

Setup Menu step 1, pressing the <MENU> key a second time advances to step 2. Each press of the <MENU> key saves the selection and advances the

menu item.

The <UP> and <DOWN> keys are used to make changes to program variables by scrolling through the available options.

<MENU> Press and release the <MENU> key to enter the Setup Menu

1. Temperature Scale

The temperature scale defaults to Celsius (°C). Use <UP> or <DOWN> to change to Fahrenheit (°F).

<MENU> Press to save and advance.

2. Temperature Offset

This item allows calibration of the temperature sensor. Use <UP> or <DOWN> to add an offset to the temperature

measurement. Use <MENU> to save and advance. -1 subtracts 1 degree from the temperature and +1 adds 1 degree

to the temperature. The range is –10 to +10 °F or -5.0 to +5.0 °C. Resolution is 1 °F or 0.5 °C. Units depends on the

previous C/F setting and resets to 0° if C/F is changed.

<MENU> Press to save and advance.

3. Humidity Offset

This item allows calibration of the RH sensor. Use <UP> or <DOWN> to add an offset to the RH measurement. Press

<MENU> to save and advance. -1 subtracts 1 %RH and +1 adds 1 %RH. The range is –10 to +10 %RH.

<MENU> Press to save and advance.