Distech Controls Allure EC-Smart-Vue Series User manual

Allure™ EC‑Smart‑Vue Sensor Series

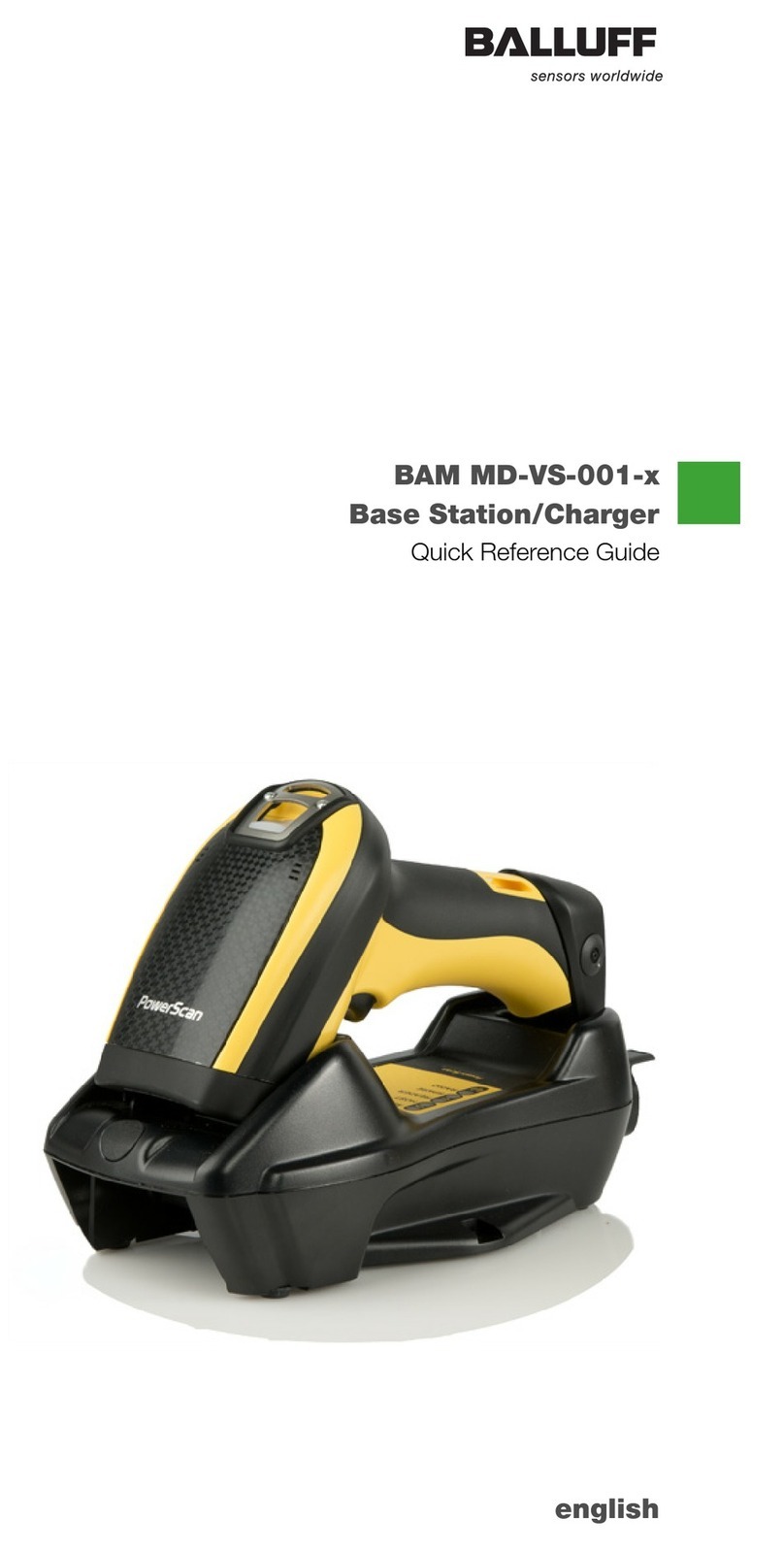

Figure1: (Left image) Allure EC Smart Vue, Allure EC Smart Vue-H/-C/-CH sensors. (Right image) Models equipped with a motion

sensing window in the upper left corner: Allure EC Smart Vue-M/-CM/-HM/-CHM sensors

Product Description

The Allure EC-Smart-Vue Series is designed to interface with Distech Controls’ ECLYPSE™ series BACnet/IP and Wi-Fi Controllers, ECB series BAC-

net® Controllers and ECL series LONWORKS® Controllers.

This line of communicating sensors with backlit display consists of eight models that provide precise environmental zone control. Models are available

with any combination of the following: temperature, humidity, CO2, and motion sensor.

General Installation Requirements

For proper installation and subsequent operation of the device, pay special attention to the following recommendations:

£Upon unpacking, inspect the contents of the carton for shipping damages. Do not install a damaged device.

£Allow for proper clearance around the device’s enclosure and wiring terminals to provide easy access for hardware configuration and maintenance.

£Orient the device with the ventilation slots towards the top to permit proper heat dissipation.

£Ensure proper ventilation of the device and avoid areas where corroding, deteriorating or explosive vapors, fumes or gases may be present.

Any type of modification to any Distech Controls product will void the product’s warranty

Take reasonable precautions to prevent electrostatic discharge to the device when installing, servicing or during operation. Discharge

accumulated static electricity by touching one’s hand to a well-grounded object before working with the device.

General Wiring Recommendations

Risk of Electric Shock: Turn off power before any kind of servicing to avoid electric shock.

£All wiring must comply with electrical wiring diagrams as well as national and local electrical codes.

£Comply with all network and power supply guidelines outlined in the Network Guide.

£Use the screws, wall anchors, and wire nuts included for wall mounting and wiring.

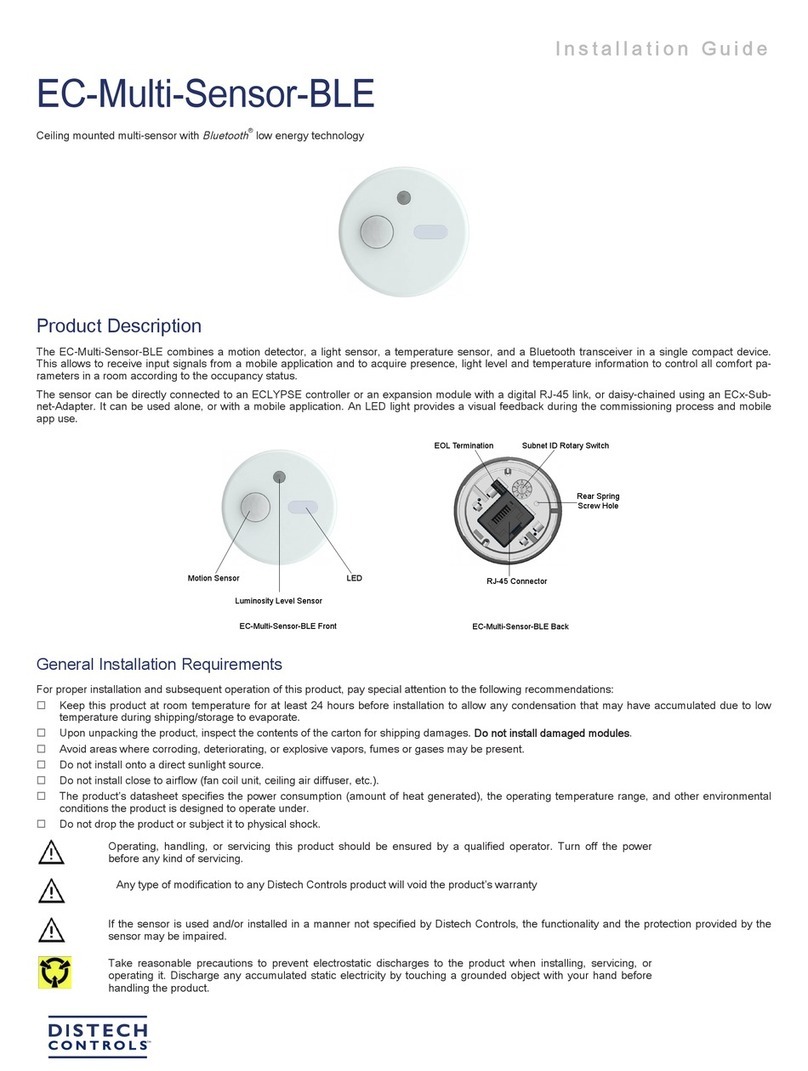

Installation Guide

2 / 16

Mounting Instructions

The Allure Allure EC-Smart-Vue has been specially designed for easy installation. However, certain conditions apply when choosing a suitable location

for the device:

£Install the device in a location of average temperature approximately 5 ft (1.5 m) above the floor

£The device should not be installed on an exterior wall.

£The device should not be installed near a heat source.

£The device should not be installed near an air discharge grill.

£The device should not be installed in a place where it can be affected by the sun.

£Install the device in an area that provides proper device ventilation. Nothing must restrain air circulation to the device.

The Allure Allure EC-Smart-Vue has not been designed for outdoor use.

Mounting hardware with a separate sub-base is provided with the device for installation on dry wall or on an electrical junction box.

Wall Mounting Installation Procedure

The Allure EC-Smart-Vue can be mounted on a dry wall using supplied screws.

1. Remove the security screw from the device (See Device Mounting [pg.3]).

2. Open the device by pressing in the two (2) tabs on the bottom of the device and pulling the bottom side of the front plate out.

3. Set any jumpers (see Connector and Jumper Location, Identification and Configuration [pg.3]).

4. Pull all cables 6” (15cm) out of the wall, and insert them through the central hole of the back plate.

5. Align the back plate with the wall and mark the location of the mounting holes on the wall. Make sure to orient the proper side of the back plate facing

upwards.

6. Remove the back plate and drill holes in the wall if necessary.

7. Install anchors in the wall if necessary.

8. Make sure that the mounting surface is flat and clean.

9. Screw the back plate onto the wall. Do not over tighten.

10. Plug the wire(s) into the connector(s).Gently push excess wiring back into the wall.

11. Reattach the front plate and make sure it clips tightly into place.

12. Install security screw.

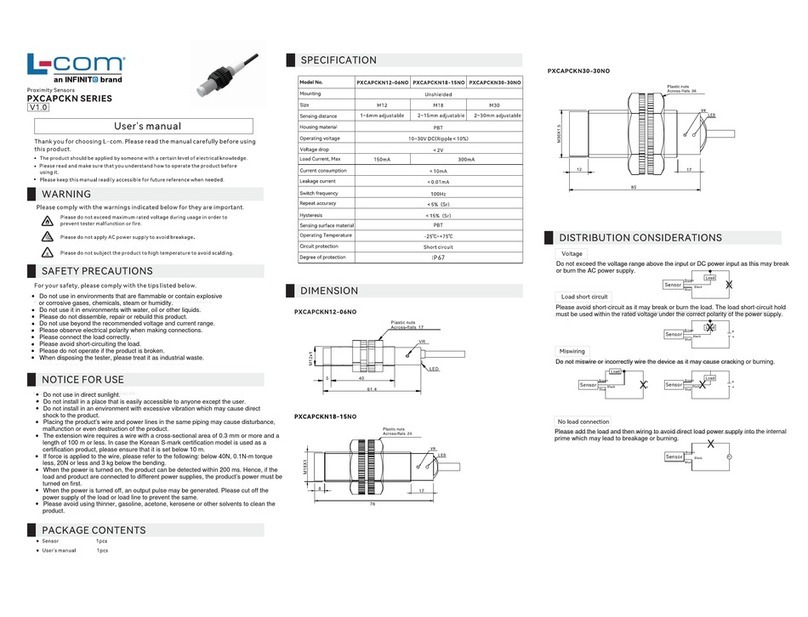

Device Dimensions

Model with

motion

sensor

1.15

(28.84)

3.29

(83.57)

4.62

(117.27)

Mounting Base Plate Shown Detached

Unit Legend: inches (mm)

2.36

(60.00)

2.37

(60.30)

0.12

(3.00)

3.31

(84.00)

0.20

(4.98)

1.06

(26.81)

Model without

motion

sensor

Bottom View

Figure2: Front view, bottom view, back plate, and side view for models with and without motion sensor.

3 / 16

Device Mounting

Security

Screw

Wall

Anchors

Figure3: Mounting anAllure EC-Smart-VueSensor

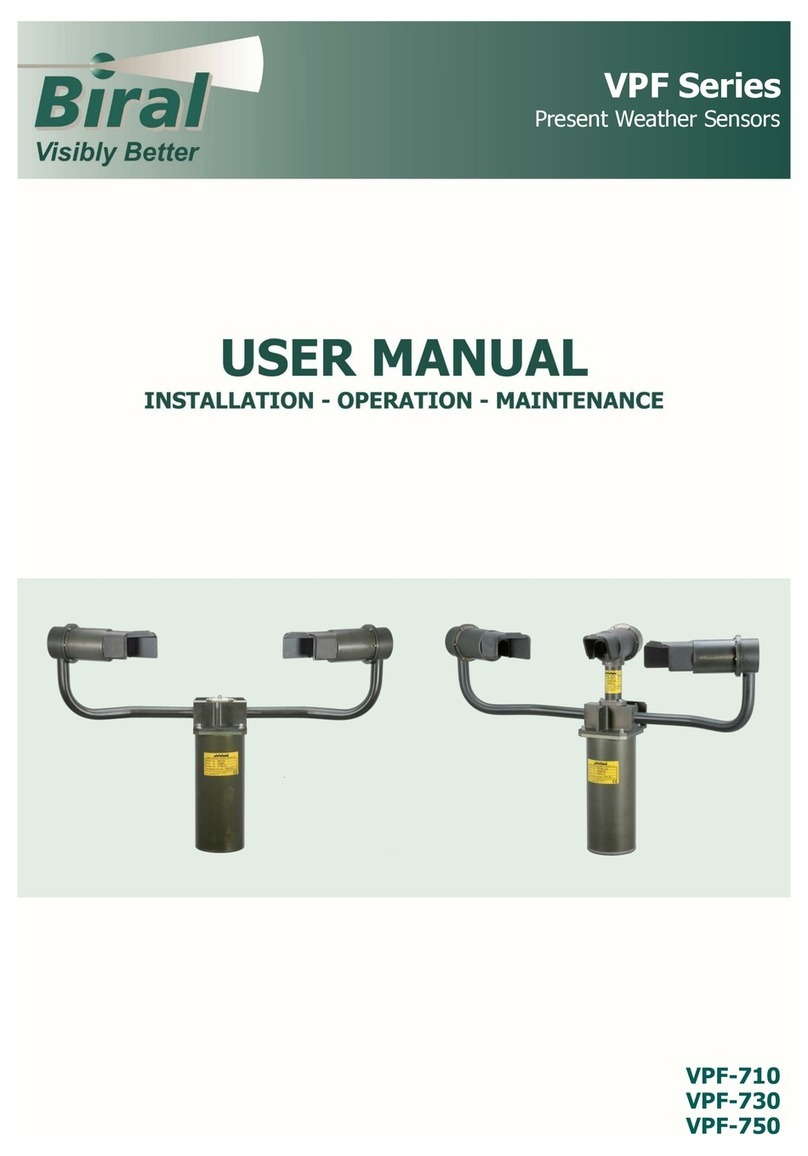

Connector and Jumper Location, Identification and Configuration

Allure EC-Smart-Vue sensors have the following onsite configurable jumpers.

ON

EOL

OFF

Front Cover, Interior View

BAC

LON

Local Area Network Type

Jumper

BACnet LONWORKS

3.5 mm (1/8”) Local

Area Network

Access Jack

Pass-Through Subnetwork RJ-45 Connectors

D

E

J11

J6

J18

PIR

LED

PIR LED

Motion Detection

Models Only

DisabledEnabled

Subnetwork End of Line

Enabled Disabled

Figure4: Connector and Jumper Locations

About an Allure EC-Smart-Vue Sensor Equipped with a CO₂ Sensor

The Allure EC-Smart-Vue C/-CM/-CH/-CHM sensors are factory calibrated to accurately read CO2 concentration levels at sea level. When these Allure

EC-Smart-Vue sensors are used in locations where the elevation is greater than 500ft (152m) above sea level, you must set the Elevation input of the

corresponding ComSensor block in EC-

gfx

Program to the current location’s elevation to obtain the most accurate readings.

For more information, refer to the ComSensor block section in the EC-

gfx

Program User Guide

Under normal conditions, an Allure EC-Smart-Vue sensor with CO2 sensor will typically reach its operational

accuracy after 25 hours of continuous operation on the condition that it was exposed to ambient air reference levels

of 400 ppm ±10 ppm CO2.

4 / 16

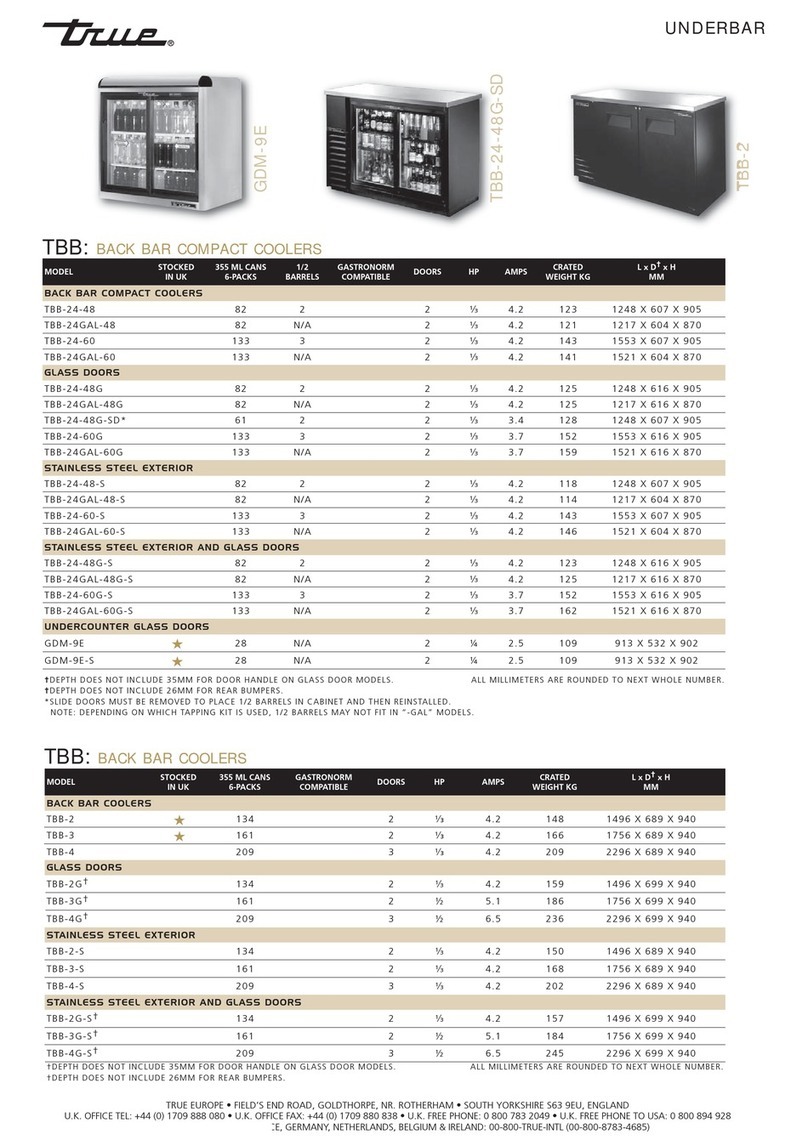

Supported Quantity

The Allure EC-Smart Vue sensor connects to the controller’s Subnet Port. Other expansion modules may also be connected to this port in a daisy-

chained fashion (see the controller’s datasheet for compatibility information and supported quantities).

Each controller supports a maximum number of Allure EC-Smart Vue sensors. The Subnet ID of all Allure EC-Smart Vue sensors must be set to be

within the shown addressing range.

Series Maximum Number of Allure EC‑Smart‑Vue sensors1Permitted Subnet ID Addressing

Range

ECB‑VAV

ECL‑VAV

ECY-VAV

ECY-VAV-PoE

ECY-303

Up to 421 to 4

ECB-VAV-O

ECL-VAV-O

ECB-VAVS

ECL-VAVS

ECB-VVTS

ECL-VVTS

ECB-VAV-N

ECL-VAV-N

ECB‑PTU Series

ECL‑PTU Series

ECB‑103

ECL‑103

ECB‑203

ECL‑203

ECY-TU/PTU

4 1 to 4

ECB‑300

ECL‑300

ECB‑400 Series

ECL‑400 Series

ECB‑600 Series

ECL‑600 Series

ECY-S1000 Series

12 1 to 12

Table1: Number of Allure EC-Smart-Vue sensors supported by controller model

1. A controller can support a maximum of two (2) Allure EC-Smart Vue sensor models equipped with a CO2sensor. Any remaining connectedAllure EC-Smart Vue sensor models must be without a

CO2sensor.

2. See the room device calculator spreadsheet available for download from our website to know the permitted quantities according to the controller model: VAV Smart Room Control Device

Calculator.xlsm.

About the Subnetwork Bus

The ECB-600 and ECL-600 controllers use the Subnetwork bus to support the ECx-400 Series I/O Extension Modules through the controllers Subnet+

and Subnet- terminals with 2-wire shielded cable.

The ECB-600 and ECL-600 controllers also use the Subnetwork bus to support one or more Allure Series(s) using standard structural (Cat 5e) cabling.

5 / 16

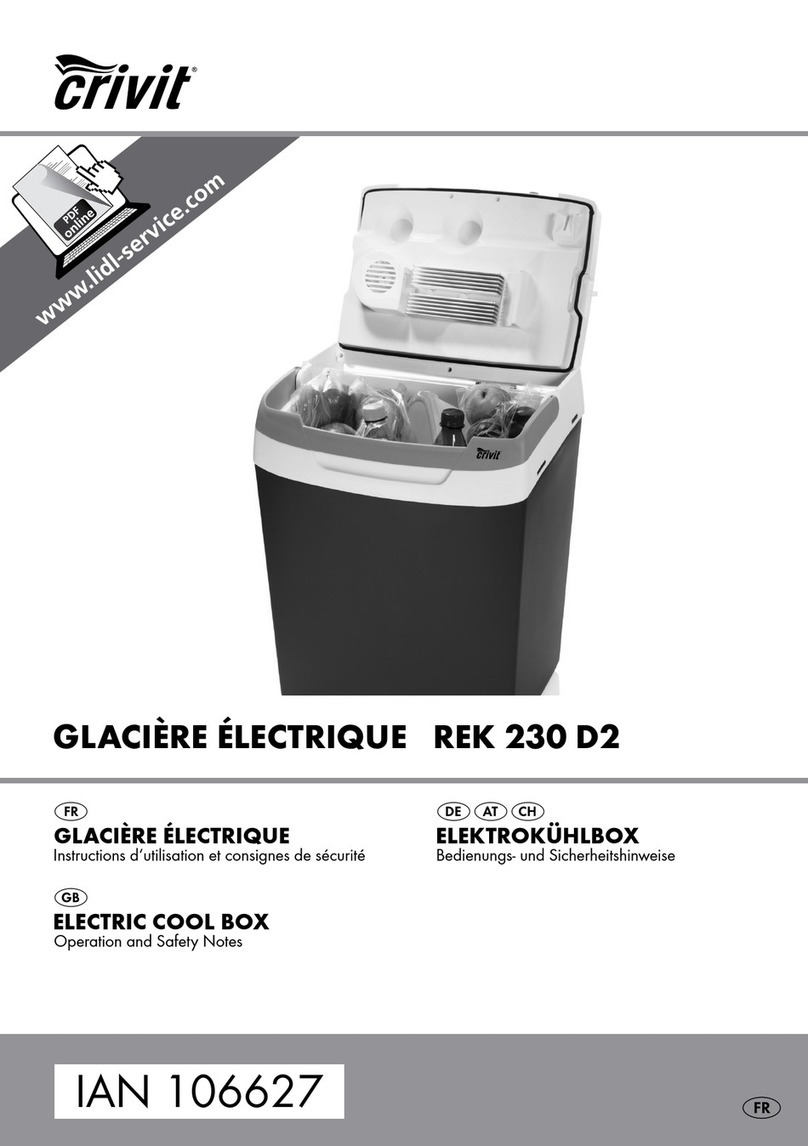

Subnetwork Bus Total Length

The total maximum length of all Subnetwork buses, including both the length of the Allure Series Communicating Sensor Subnetwork bus and the

ECx-400 Series Subnetwork bus is 300 m (1000 ft). The maximum length of the Allure Series Communicating Sensor Subnetwork bus is 200 m (650 ft).

The maximum length of the ECx-400 Series Subnetwork bus is 300 m (1000 ft).

Sub-Network Bus Total Length: 300 m (1 000 ft) Maximum

Sub-Network Bus: 200 m

(650 ft) Maximum

Allure EC-Smart-Vue

Sub-Network Bus: 300 m

(1 000 ft) Maximum

ECx-400

Typical Compatible

Controller Extension I/O Modules

ECx-400

Sub-Network Bus - Cat 5e Cable

with RJ-45 Connectors

Allure EC-Smart-Vue

Sub-Network Bus

ECx-400

2-Wire Shielded Cable

Figure5: Subnetwork Bus Overview Showing the Allure EC-Smart-VueSubnetwork Bus and the ECx-400 Series Subnetwork Bus.

A controller can support a maximum of two Allure EC-Smart-Vue sensor models equipped with a CO2 sensor; the remaining connected models must be

without a CO2 sensor. See Table 1 for the quantity of room devices supported by each controller model.

For instance, if the controller model supports a subnetwork with 12 Allure EC-Smart-Vue sensors in total, then 10 sensor models must be without a CO2

sensor and the other two can be equipped with a CO2 sensor. To ensure proper operation, it is recommended to distribute the sensors throughout the

length of the subnetwork.

Cat 5e Cable with RJ-45 Connectors

Sub-Network Bus Total Length: 1 000 ft (300 m) Maximum

10x...2x...

Bus: 600 ft (180 m) Maximum

Allure EC-Smart-Vue

Sensor Sub-network

ECB-600 ECL-600or

Typical

Controller

ECx-400

Sub-Network Bus

Figure6: Allure EC-Smart-Vue Sensor Subnetwork Length and Distribution

For ECB/ECL-PTU Series controllers, the maximum length between two consecutive devices on the sub-network bus

is 100 feet (30 m).

6 / 16

Subnetwork Bus Topology and EOL Terminations

Only a daisy chain topology is acceptable for the room device subnetwork bus. T connections are not allowed.

Some controller models support the connection of other devices to the Subnet Port as part of the Smart Room Control solution (see the controller’s

datasheet for more information).

For non ECB-600 or ECL-600 Series controllers, only the EOL terminations of the last subnetwork bus device are set to ON. All other subnetwork bus

devices must have their EOL terminations set to OFF. The controller must be the first device on the Cat 5e Cable Subnetwork bus as its internal EOL ter-

mination is permanently enabled.

See Table 1 for the number of Allure EC-Smart-Vue sensors that a given controller model can support.

Typical Room Devices

Cat 5e Cable Subnetwork Bus

EOL set to ON

at the last

sensor at the

end of the Bus

ON

EOL

OFF

Controller Series:

· ECB-VAV-O

· ECB-VAVS

· ECB-VVTS

· ECB-VAV-N

· ECB-103

· ECB-203 Series

· ECB-300 Series

· ECB-400 Series

Back of Allure

EC-Smart-Vue

· ECL-VAV-O

· ECL-VAVS

· ECL-VVTS

· ECL-VAV-N

· ECL-103

· ECL-203 Series

· ECL-300 Series

· ECL-400 Series

Figure7: Setting the EOL Terminations on the Allure EC-Smart-Vue Sensor for non ECB-600 or ECL-600 series, non-Smart Room Con-

trol controllers

Typical Room Devices

Cat 5e Cable Subnetwork Bus

EOL set to ON

at the last

sensor at the

end of the Bus

ON

EOL

OFF

Controller Series:

· ECB-VAV

· ECL-VAV

· ECLYPSE (ECY-VAV, ECY-S1000)

· ECB-PTU Series

· ECL-PTU Series

Back of Allure

EC-Smart-Vue

ECx Subnet

Adapter

Figure8: Setting the EOL Terminations on the Allure EC-Smart-Vue Sensor for Smart Room Control-compatible controllers

When one or more Allure EC-Smart-Vue sensors are installed with an ECB-600 or ECL-600 (without an ECx-4xx IO Extension Module), only the EOL

terminations on the ECB-600 / ECL-600 and the last Allure EC-Smart-Vue sensor are set to ON. All other Allure EC-Smart-Vue sensors must have their

EOL terminations set to OFF.

7 / 16

ON

EOL

OFF

EOL OFF

EOL ON

Controller:

ECB-600

ECL-600

Cat 5e Cable Subnetwork Bus

Inside

Controller Back of

Allure EC-Smart-Vue

Sensor

EOL set to ON

at the last

sensor at the

end of the Bus

For the controller, set the

Subnetwork EOL to ON

Figure9: Setting the EOL Terminations on the Allure EC-Smart-VueSensor for ECB-600 or ECL-600 Seriescontrollers

When ECx-400 Series I/O Extension Modules are installed with an ECB-600 or ECL-600 Series controller and with Allure Series Communicating Sen-

sors, only the EOL terminations on the last I/O Extension Module and the last Allure Series Communicating Sensor are set to ON. The ECB-600 /

ECL-600 and all other I/O Extension Modules and Allure Series Communicating Sensor s must have their EOL terminations set to OFF.

EOL OFF

ON

EOL

OFF

EOL ON

Typical Compatible

Controller I/O Extension Modules

ECx-4xx

ECx-4xx

I/O Extension Modules 2 - Wire Shielded

- Last daisy-chained I/O Extension Module:

EOL Jumper is ON

- All other I/O Extension Modules:

EOL Jumpers are OFF

- Last daisy-chained Communicating Sensor:

EOL Jumper is ON

- All other Communicating Sensors:

EOL Jumpers are OFF

Communicating Sensor Sub-Network Bus

- Cat 5e Cable with RJ-45 Connectors

Figure10: Setting the EOL Terminations on the ECx-400 SeriesSubnetwork Bus when Allure EC-Smart-VueSensors are used

ECx-400 Series devices and Allure EC-Smart-Vue sensors are factory-set with the EOL set to OFF by default.

If inserting multiple wires in the terminals, ensure to properly twist wires together prior to inserting them into the terminal connectors.

For more information and detailed explanations on network topology and wire length restrictions, refer to the Network Guide, which can be downloaded

from our website

www.distech-controls.com

.

8 / 16

Setting the Communicating Sensor Subnet ID

Controllers can be commissioned with an Allure EC-Smart-Vue sensor.

The default Subnet ID for an Allure EC-Smart-Vue Series Communicating Sensor is 1. To commission an ECB Series controller, the sensor’s Subnet ID

must be set to 1. If the sensor’s Subnet ID has been set to another value (for example, the display flashes error code 1 with the Bell icon when the sen-

sor is connected to a controller for commissioning), change the Subnet ID to 1 as follows:

1. Connect an an Allure EC-Smart-Vue Series Communicating Sensor to the controller with a Cat 5e patch cable. Wait for the Bell icon and the number

1 to flash on the display.

2. Press and hold the Menu button for 5 seconds to enter the password menu. 10000 is shown on the display.

OR

Screen Timeout: 15 seconds

3. Press the down button to set the number to 9995 (this is the default password).

OR

Screen Timeout: 15 seconds

4. Press the Menu button to submit the password. Upon submitting the password, the GEN CFG menu appears on the display.

OR

Screen Timeout: 30 seconds

5. Press the down button once to enter the GEN CFG submenu.

6. Press the Menu button several times until SUBNET ID appears on the display. The current controller’s Subnet ID is shown.

OR

Screen Timeout: 30 seconds

7. Use the up and down buttons to set the controller’s Subnet ID to 1.

Tip

: Hold down either the up or down button to fast-advance the display

value.

8. Press the Menu button once.

9. Press and hold the Menu button for 5 seconds to exit the configuration menu.

The an Allure EC-Smart-Vue Series Communicating Sensor can now be used to go from one ECB series controller to the next for commissioning pur-

poses.

Commissioning Controllers

For ECB series controllers: to commission a controller with a MAC Address DIP switch located on the faceplate or under the cover in the case of an

ECB-VAV Series controller, first set the DIP switch to 0 (all off). When using an Allure EC-Smart-Vue sensor for commissioning a controller (before code

is downloaded to the controller from EC-

gfx

Program), connect an Allure EC-Smart-Vue sensor to the controller with its Subnet ID set to 1. (see Setting

the Allure EC-Smart-Vue Sensor Subnet ID).

9 / 16

For controllers embedding a pre-loaded application, commissioning can be used to perform application selection if needed. Pre-loaded applications are

factory-loaded programs that enable the controller to control a typical equipment. See the Pre-Loaded Application User Guide for more information.

For ECB Series controllers only, during commissioning, the Allure EC-Smart-Vue sensor is used to set the controller’s BACnet® MAC Address. Set the

connected ECB Series controller’s MAC Address as follows:

Set the connected controller’s MAC Address as follows:

1. Connect an Allure EC-Smart-Vue Series Communicating Sensor to the controller with a Cat 5e patch cable. Wait for the display to show the room

temperature.

2. Press and hold the Menu button for 5 seconds to enter the password menu. 10000 is shown on the display.

OR

Screen Timeout: 15 seconds

3. Use the down button to set the number to 9995 (this is the default password).

OR

Screen Timeout: 15 seconds

4. Press the Menu button to submit the password. Upon submitting the password, the GEN CFG menu appears on the display.

OR

Screen Timeout: 30 seconds

5. Press the down button once to enter the GEN CFG submenu. The MAC ADDRESS menu is shown with the current controller’s BACnet MAC Ad-

dress.

OR

Screen Timeout: 30 seconds

6. Use the up and down buttons to set the controller’s MAC Address. Only addresses from 1 to 127 are recommended to be used.

7. Press the Menu button once to apply the value.

8. Press and hold the Menu button for 5 seconds to exit the configuration menu.

Once the controller’s network is operational, the controller can be programmed with EC-

gfx

Program. For each Allure EC-Smart-Vue Series Communicat-

ing Sensor, set its Subnet ID number to the block number of its associated ComSensor block in EC-

gfx

Program. This is done in the sensor’s GEN CFG

menu under SUBNET ID.

10 / 16

Setting the BAUD Rate (optional – ECB series controllers only)

By default, the BAUD rate for the controller is set to automatically detect the current communication BAUD rate of the connected BACnet MS/TP network

(AUTO). This is the preferred setting for a controller. However, at least one controller on the BACnet MS/TP network data bus must have its BAUD rate

set. The preference is to set the building controller’s BAUD rate (if present). Otherwise, set the BAUD rate on one controller that will set the BAUD rate

for all other controllers (to act as the master for setting the BAUD rate).

When the BAUD rate is set to AUTO, the controller cannot initiate any communication until it has detected the baud

rate of the BACnet MS/TP network. If all controllers on the BACnet MS/TP network are set to AUTO, then all

controllers will not communicate.

Set the connected controller’s BAUD rate as follows:

1. Connect an Allure EC-Smart-Vue Series Communicating Sensor sensor to the controller with a Cat 5e patch cable. Wait for the display to show the

room temperature.

2. Press and hold the Menu button for 5 seconds to enter the password menu. 10000 is shown on the display.

OR

Screen Timeout: 15 seconds

3. Use the down button to set the number to 9995 (this is the default password).

OR

Screen Timeout: 15 seconds

4. Press the Menu button to submit the password. Upon submitting the password, the GEN CFG menu appears on the display.

OR

Screen Timeout: 30 seconds

5. Press the down button once to enter the GEN CFG submenu.

6. Use the Menu button several times until BAUD RATE appears on the display. The current controller’s BAUD rate is shown.

OR

Screen Timeout: 30 seconds

7. Use the up and down buttons to set the controller’s Baud rate. The AUTO setting detects and uses the current baud rate being used by the

BACnet MS/TP network.

8. Press the Menu button once to apply the value.

9. Press and hold the Menu button for 5 seconds to exit the configuration menu.

11 / 16

Set the LAN Type

Set the BAC/LON jumper for the type LAN in use: BAC for a BACnet network, LON for a LONWORKS network.

BAC

LON

3.5 mm (1/8”) Network

Access Jack

Network Type

Jumper

Figure11: BAC/LON Jumper Set to the BAC (BACnet) Position when used with ECBSeriesControllers

BAC

LON

3.5 mm (1/8”) Network

Access Jack

Network Type

Jumper

Figure12: BAC/LON Jumper: Set to the LON (LONWORKS) Position when used with ECL SeriesControllers

Setting Up an Allure EC-Smart-Vue Sensor Equipped with a Motion Sensor

The following procedure describes how to commission and test an Allure EC-Smart-Vue sensor equipped with a motion sensor as well as adjust the mo-

tion sensitivity (Allure EC-Smart-Vue M/-CM/-HM/-CHM sensors).

1. Connect an Allure EC-Smart-Vue sensor equipped with a motion sensor to the controller with a Cat 5e patch cable.

2. After a 30-second warm-up period, if movement is detected, the motion sensor light will turn on.

3. To test the sensor functionality, aim the sensor in the direction you want to detect motion and walk at a normal pace across the typical detection zone

and verify that the sensor light turns on. The light will turn on and after 2 seconds of non-movement, the motion sensor light will turn off.

4. Now to set the motion sensitivity, on the Allure EC-Smart-Vue sensor, press and hold the Menu button for 5 seconds to enter the password

menu. 10000 is shown on the display.

OR

Screen Timeout: 15 seconds

5. Press the down button to set the number to 9995 (this is the default password).

OR

Screen Timeout: 15 seconds

6. Press the Menu button to submit the password. Upon submitting the password, the GEN CFG menu appears on the display.

OR

Screen Timeout: 30 seconds

12 / 16

7. To enter the GEN CFG submenu, press the down button once.

8. Press the Menu button several times until MOTION SENSITIVITY appears on the display. The current motion sensitivity level is shown.

OR

Screen Timeout: 30 seconds

9. Use the up and down buttons to set the motion sensitivity level to 0 (low), 1 (medium - typical default setting), or 2 (high). The default and rec-

ommended level of sensitivity is medium (1) and should typically work with all installations. This setting should not be changed unless for some rea-

son you are experiencing false detections, then a low sensitivity (0) setting may be used, or if working with larger room installations a high sensitivity

(2) setting can be used.

10. Press the Menu button once to apply the value.

11. Press and hold the Menu button for 5 seconds to exit the configuration menu.

The motion indicator LED provides a visual confirmation of motion detection. By default, the indicator (PIR LED

jumper) is enabled. If you wish to disable it, set jumper J18 to Disabled. See Connector and Jumper Location,

Identification and Configuration [pg.3].

BACnet Network Access from the Sensor

To temporarily access the BACnet MS/TP LAN for commissioning and maintenance purposes (not available with either the ECB-PTU series controllers,

the ECLYPSE series controllers, or the ECB-VAVS), connect a BACnet MS/TP Adaptor to the audio plug port located on the lower edge of the Allure EC

Smart Vue sensor. Wire a standard ⅛” (3.5 mm) three-conductor stereo jack as shown below.

The BACnet MS/TP Adaptor must have an electrically-isolated RS-485 port. Otherwise a ground path from the

BACnet network will be made through the computer that will disrupt BACnet network communications.

To BACnet MS/TP

Adaptor

NET+

NET-

Shield

LAN Access

Connector

- Temporary

Commissioning and

Maintenance

Connection

- No EOL Resistors are

Necessary

BACnet MS/TP Adaptor

with Isolated RS-485 Port

Cable Supplied with

BACnet MS/TP Adaptor

NET+ (White)

NET- (Red)

Shield (bare)

Figure13: ⅛” (3.5 mm) Stereo Jack Connection for a Portable Router

13 / 16

LONWORKS Network Access from the Sensor

For commissioning and maintenance purposes, the LONWORKS network is optionally available from the Allure EC-Smart-Vue sensor audio plug port (not

available with ECL-PTU series controllers, or the ECL-VAVS).

Setting the two (2) Net to Subnet Port Settings jumpers inside the ECL Series controller to Enable will connect the main LONWORKS network to the Allure

EC-Smart-Vue sensor subnetwork Cat 5e cable.

Recommendation: Only a limited number of controllers on a LONWORKS network segment should have their Net to

Subnet Port Settings jumpers enabled. Enabling too many Allure EC-Smart-Vue sensors with network access may

cause network communication issues. If there are any network communication problems, see the

Troubleshooting

section in this document.

The Cat 5e cable length is restricted by the maximum allowable subnetwork bus length (see Subnetwork Bus Total Length [pg.5]). The standard Net to

Subnet Port Settings jumper setting is Disable.

Enable

Disable

Enable

Disable

Net to Subnet

Port Settings

Figure14: ECL Series controller: Net to Subnet Port Settings Jumpers

E

D

Enable

Disable

Net to Subnet

Port Settings

Figure15: ECL-VAV Series controller: Net to Subnet Port Settings Jumpers

14 / 16

Controller

Bus Network Topology: 22AWG (0.65mm) Unshielded Twisted Pair Network Cable

Cat 5e Cable Subnetwork Bus Provides:

· Room Device Data communication

· LONWORKS Network when Net to Subnet

Port Settings jumpers are Enabled

E

D

Enable

Disable

For a Few

Controllers ONLY:

Standard Net to

Subnet Port

Settings:

DISABLED - this

is the factory

default setting

Communicating Sensor

Net to Subnet Port Settings

Optionally Enabled

Figure16: LONWORKS Network: Bus Topology

To temporarily access the LONWORKS LAN for commissioning and maintenance purposes, connect a LONWORKS USB network interface to the audio plug

port located on the lower edge of the Allure EC-Smart-Vue sensor. Wire a standard ⅛” (3.5 mm) three-conductor (stereo jack) or two-conductor (mono

jack) as shown below.

- Temporary

Commissioning and

Maintenance

Connection

LON USB Network

Interface

To LON USB

Network Interface

LON1

LON2

LAN Access

Connector

LON1

LON2

Mono Jack Stereo Jack

OR

LAN Access

Connector

Figure17: ⅛” (3.5 mm) Stereo or Mono Jack Connection for a LONWORKS Network Interface

15 / 16

Troubleshooting

Allure EC-Smart-Vue sensor’s screen is blank & back light is on for about 30 to 45 seconds – Normal Operation

Firmware upgrade in progress Wait for the upgrade to complete. Do not disconnect the sensor from the controller as

the upgrade will restart once it is reconnected.

Allure EC-Smart-Vue sensor’s screen is blank & back light is off.

Is the Allure EC-Smart-Vue sensor connected to the controller? Verify that the Allure EC-Smart-Vue sensor is connected to the controller and that the

patch cables are plugged into the connectors. Refer to Wall Mounting Installation

Procedure for more information.

Is power being supplied to the controller? There may be no power being supplied from the controller. Check if the controller has

power or if the controller’s internal fuses have blown or tripped.

Is the cable connected to the controller and Allure EC-Smart-Vue

sensor?

Verify wiring.

Was the patch cable made onsite? Verify that the RJ-45 crimp connectors were installed on the cable correctly.

Device not communicating with controller

Is the address correctly set to a unique address? Each Allure EC-Smart-Vue sensor must be set to a unique address for each

controller. See Setting the Communicating Sensor Subnet ID [pg.8].

Is the device too far from controller? Verify the distance between the device and the controller. See Subnetwork Bus Total

Length [pg.5].

Is there a configuration problem? With EC-

gfx

Program, check the configuration of the sensor; for example, is it

enabled? Refer to the EC-

gfx

Program User Guide for more information.

Have the subnetwork EOL settings been correctly set? Only the last Allure EC-Smart-Vue sensor must have its EOL termination set to ON.

See Figure 10 and Figure 12. When one or more ECx-400 Series IO Extension

modules are connected to the controller, only the last ECx-400 must have its EOL

termination set to ON. See Figure 13.

Controller cannot communicate on the LONWORKS network

Too many Allure EC-Smart-Vue sensors are providing network

access

Disable the Net to Subnet Port Settings jumpers on all controllers (for jumper location,

see Connector and Jumper Location, Identification and Configuration [pg. 3]). If

communications are re-established, re-enable only a few Allure EC-Smart-Vue

sensors to have network access.

Allure EC-Smart-Vue sensor’s motion detector window indicator is always ON and the Motion output of the associated ComSensor block always reads

NULL in EC-

gfx

Program

Does the connected controller have Allure EC-Smart-Vue sensor

firmware that supports the motion sensor?

When the Allure EC-Smart-Vue sensor is connected to a controller, its firmware is

loaded from the controller. In this case, the controller has an earlier version of Allure

EC-Smart-Vue sensor firmware that does not support the motion sensor. To upgrade

to the latest Allure EC-Smart-Vue sensor firmware, download the firmware from

SmartInstaller and refer to the firmware upgrade procedure in the EC-

gfx

Program

User Guide.

The CO2 output of the associated ComSensor block always reads NULL in EC-

gfx

Program

Does the connected controller have Allure EC-Smart-Vue sensor

firmware that supports the CO2 sensor?

When the Allure EC-Smart-Vue sensor is connected to a controller, its firmware is

loaded from the controller. In this case, the controller has an earlier version of Allure

EC-Smart-Vue sensor firmware that does not support the CO2 sensor. To upgrade to

the latest Allure EC-Smart-Vue sensor firmware, download the firmware from

SmartInstaller and refer to the firmware upgrade procedure in the EC-

gfx

Program

User Guide.

The CO2 sensor readings are too high, too low, or inconsistent between sensors

Immediately after installing the Allure EC-Smart-Vue sensor with

CO2 sensors, are the CO2 sensor readings incoherent?

If the CO2 sensor readings seem unusual or show inconsistencies between sensors in

the same building right after installation, the following reasons should be taken into

consideration:

£Concentration levels in each space may be different

£The installer may have unintentionally blown into the sensor while installing it.

£The sensor may have been dropped or mishandled during shipment causing a

minor shift in the original factory calibration.

Allow up to 14 days of operation (without power interruptions) for the sensor to

calibrate itself according to its new environment.

Error Code Interpretation

Clock icon flashing for 15 seconds Cannot communicate

with controller.

Wait for the communication link to the controller to be

established.

After 15 seconds: Flashing error code 1 with Bell icon Verify wiring

Verify that all Allure EC-Smart-Vue sensor’s Subnet IDs are

unique for this controller. See Setting the Communicating

Sensor Subnet ID [pg.8].

Flashing error code 2 with Bell icon Invalid configuration. In EC-

gfx

Program, resynchronize the code with the controller.

Contact Distech Controls Customer Support.

Flashing error code 3 with Bell icon Allure EC-Smart-Vue

sensor is not properly

configured in the

controller

With EC-

gfx

Program, check the configuration of the sensor,

for example, is the ComSensor block enabled? Refer to the

EC-

gfx

Program User Guide for more information.

16 / 16 EC-Smart-Vue_IG_26_EN

©, Distech Controls Inc., 2010 - 2018. All rights reserved.

Images are simulated. While all efforts have been made to verify the accuracy of information in this manual, Distech Controls is not responsible for damages or claims arising from the use of this manual.

Persons using this manual are assumed to be trained HVAC specialist / installers and are responsible for using the correct wiring procedures and maintaining safe working conditions with fail-safe environ-

ments. Distech Controls reserves the right to change, delete or add to the information in this manual at any time without notice.

Distech Controls, the Distech Controls logo, Open-to-Wireless, Innovative Solutions for Greener Buildings, and Allure are trademarks of Distech Controls Inc. BACnet is a registered trademark of ASHRAE.

Global Head Office - 4205 place de Java, Brossard, QC, Canada, J4Y 0C4 - EU Head Office - ZAC de Sacuny, 558 avenue Marcel Mérieux, 69530 Brignais, France

This manual suits for next models

28

Table of contents

Other Distech Controls Accessories manuals

Distech Controls

Distech Controls UNIWAVE User manual

Distech Controls

Distech Controls EC-Multi-Sensor Series Manual

Distech Controls

Distech Controls GS-AQR Manual

Distech Controls

Distech Controls Allure UNITOUCH Manual

Distech Controls

Distech Controls EC-Multi-Sensor-BLE User manual

Distech Controls

Distech Controls HS-THX User manual

Distech Controls

Distech Controls Allure EC-Smart-Air Series User manual

Distech Controls

Distech Controls Allure EC-Sensor Series Manual