Distech Controls RT Series Manual

Hardware Installation Guide

Distech Controls, Inc.

Toll-free: 1-800-404-0043

Tel. International: 450-444-9898

www.distech-controls.com

sales@distech-controls.com

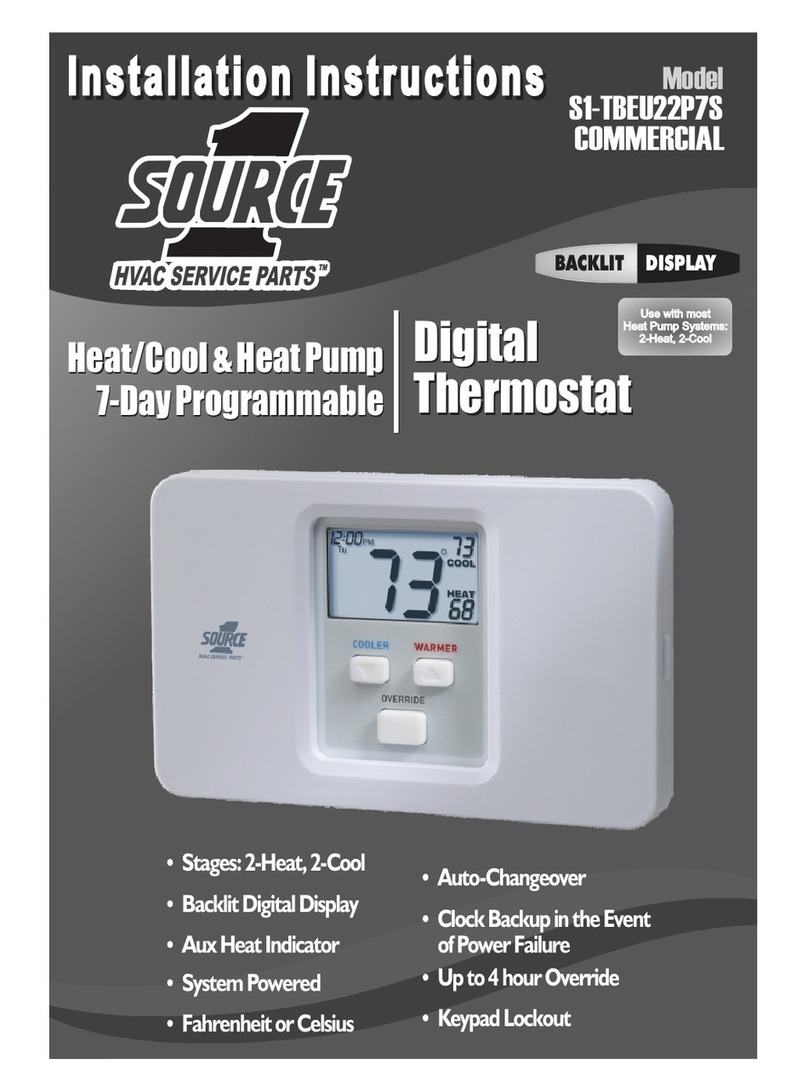

Roof Top (RT) Series: ECL-STAT-RT1P, ECL-STAT-RT2P, ECL-STAT-RT2EP,

ECB-STAT-RT1P, ECB-STAT-RT2P, ECB-STAT-RT2EP,

ECW-STAT-RT1P, ECW-STAT-RT2P, ECW-STAT-RT2EP

Heat Pump (HP) Series: ECL-STAT-HPP, ECB-STAT-HPP, ECW-STAT-HPP

Product overview

The Allure Communicating Roof Top (RT) and Heat Pump (HP) PI thermostat family

is specifically designed for single stage and multi-stage control of heating/cooling

equipment such as rooftop and self-contained units. The product features an intuitive,

menu-driven, back-lit LCD display, which walks users through the programming steps,

making the process extremely simple. Accurate temperature control is achieved due

to the product’s PI time proportional control algorithm, which virtually eliminates

temperature offset associated with traditional, differential-based thermostats.

All models contain two digital inputs, which can be set by the user to monitor filter

status, activate a remote temporary occupancy switch, and/or used as a general

purpose service indicator. In addition, depending on the model, up to three remote

sensor inputs are available. All models contain a SPST auxiliary switch, which can be

used to control lighting or disable the economizer function and a discharge air sensor

-input.

For more advanced applications, economizer control logic has been integrated onto the thermostat for use with proportional damper

economizer actuators.

The thermostats are also compatible with the new Allure Cover accessories. Thermostats equipped with a PIR motion detector cover

provide advanced active occupancy logic, which will automatically switch occupancy levels from Occupied to Unoccupied as required by

local activity being present or not. This advanced occupancy functionality provides advantageous energy savings during occupied hours

without sacrificing occupant comfort. All thermostats can be ordered with or without a factory installed PIR motion detector cover ( see

ordering notes below).

Models available

Application 1 Heat / 1 Cool 2 Heat / 2 Cool 2 Heat / 2 Cool

with economizer

3 Heat / 2 Cool

heat pump

Model (programmable) CDIVI-7652A50(X)1 CDIVI-7652B50(X)1 CDIVI-7656B50(X)1 CDIVI-7652H50(X)1

Ordering Information Notes:

-(X) model number represents available communication options: X=E for LonWorks , X=B for BACnet MS-TP and X=W for Wireless

-The Allure communicating thermostats are delivered with the Allure cover (without PIR motion detector) installed by default.

-If motion detection is required, the appropriate Allure PIR motion detector covers need to be ordered separately and installed in the field.

-However, for minimum order quantities of 50 thermostats (any model), you can have your thermostat with the Allure PIR motion detector cover factory

installed. Lead time of 20 business days. In the Product Number, please replace the 3rd character from the end with a "5" (ex. CDIVI-7600A55E1.)

Features and benefits

Features

Benefits

•Advanced occupancy functions

⇒Through the network or smart local occupancy sensing

•Ready for PIR motion detector accessory cover

⇒Fully integrated advanced occupancy functionality with a PIR

accessory cover

•2 digital inputs

⇒Adds functionality

•Smart fan operation

⇒Saves energy during night mode

•Unique configuration key with password protection

⇒Minimizes parameter tampering

•Lockable keypad

⇒Tamper proof, no need for thermostat guards

•6 hour reserve time for clock

⇒No need to reprogram day/time after power shortage

•Remote room and outdoor temperature sensor

⇒Increase flexibility and functionality

•Auxiliary output

⇒Can be used for lighting and/or economizer override

•Discharge air sensor

⇒Can be used to monitor unit efficiency

•Intuitive, menu-driven programming (7 day, 2/4 events - on

programmable models only)

⇒Can be used for all types of establishments

•Economizer output 0-10 Vdc economizer models only

⇒Excellent retrofit opportunities

•3 Heat/2 Cool (on heat pump models only)

⇒Support single and two stages heat pump with one auxiliary

heat stage

Fig.1

2

Theory of operation

The Allure communicating thermostats use a proprietary adaptive

logic algorithm to control the space temperature. This algorithm

controls the heating / air conditioning system to minimize overshoot

while still providing comfort. It provides exceptional accuracy due to

its unique PI time proportioning control algorithm, which virtually

eliminates temperature offset associated with traditional,

differential-based on/off thermostats.

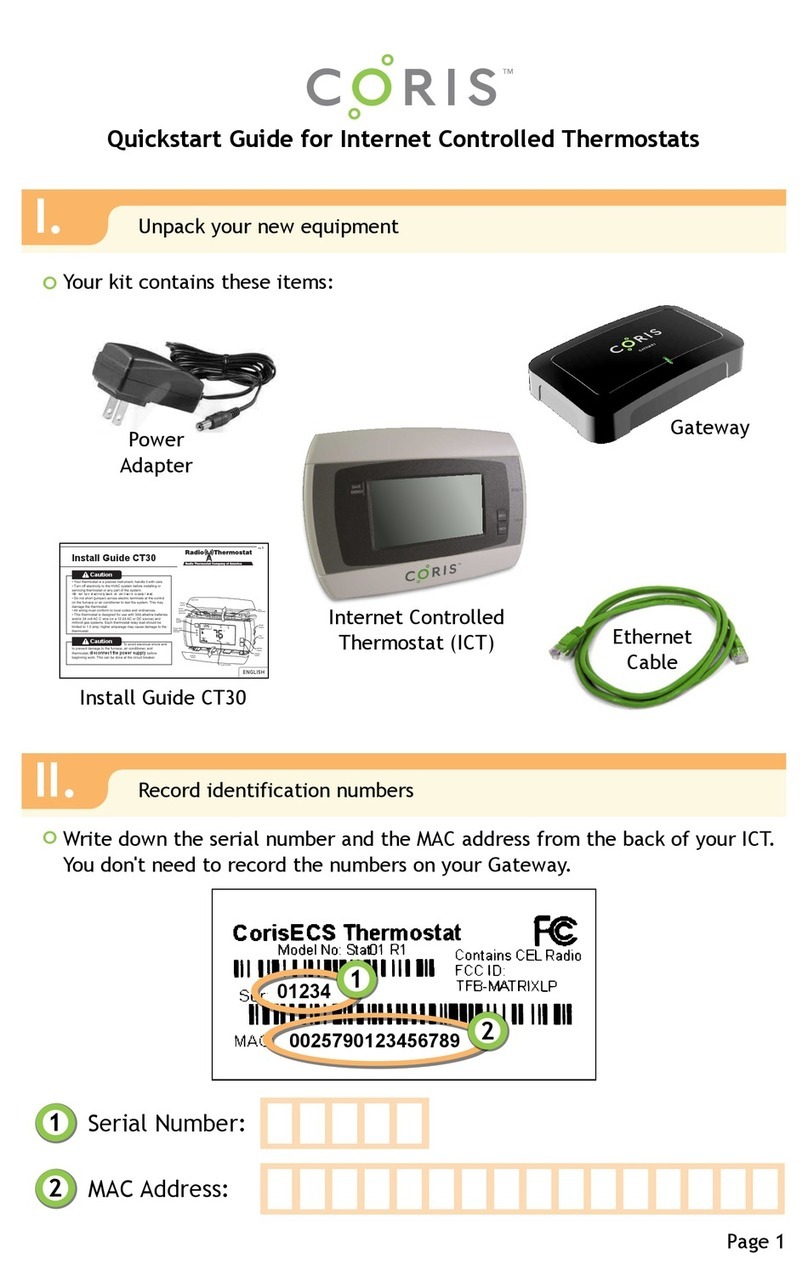

Fig.2 - On/Off mechanical control vs PI electronic control.

Features overview

•7 day programmable models, 2 or 4 events

•Gas/oil or electric system compatibility for all type of

applications

•Remote indoor averaging sensing capability

•Temperature averaging

•Remote outdoor sensing capability for added flexibility

- System mode lock out

- Heat pump balance point settings

•Remote discharge air sensor input for monitoring purpose

- System efficiency feedback

•Lockable keypads for tamper proofing. No need for thermostat

guards

•Automatic frost protection to prevents costly freeze damage

•Anti short cycle and minimum on/off run time protection.

Reduces wear and maximizes life span of mechanical

equipment.

•2 programmable digital inputs for added flexibility. Each input

can be programmed as the following:

- None: No function will be associated with the input

- Service: a backlit flashing Service alarm will be displayed on

the thermostat LCD screen when the input is energized. It

can be tied in to the AC unit control card, which provides an

alarm in case of malfunction.

- Filter: a backlit flashing Filter alarm will be displayed on the

thermostat LCD screen when the input is energized. It can be

tied to a differential pressure switch that monitor filters

- Rem NSB: remote NSB timer clock input. Will disable the

internal scheduling of the thermostat. The scheduling will now

be set as per the digital input. The menu part related to

scheduling is disabled and no longer accessible. It provides low

cost setback operation via occupancy sensor or from a dry

contact

- RemOVR: temporary occupancy contact. Disables all override

menu function of the thermostat. . The override function is now

controlled by a manual remote momentarily closed contact.

When configured in this mode, the input operates in a toggle

mode.

With this function enabled it is now possible to toggle between

unoccupied & occupied setpoints for the amount of time set by

parameter (TOccTime) temporary occupancy time.

-Fan lock: used in conjunction with a local air flow sensor

connected to the input. Locks out the thermostat heating and

cooling action and displays a local alarm if no air flow is

detected 10 seconds after the fan ( G terminal ) is energized.

•Programmable smart fan operation saves energy during

night mode

•Non volatile EEPROM memory prevents loss of parameters

during power shortage

•Built in default profile set-up for easier start up and

commissioning

•Configurable SPST output relay on programmable models

for lighting, exhaust fan or fresh air control

•6 hour typical reserve time for clock in case of power loss

•0 to 10 Vdc economizer output for more retrofit opportunities

- Built in dry bulb economizer logic using outdoor

temperature sensor

- Input for supply/mixed air temperature sensor

Heat pump model specific features

•Selectable single or dual stage compressor stages

•High balance point:

Locks out auxiliary heating when outside air temperature is

above this value

•Low balance point:

Locks out heat pump compressor operation when outside air

temperature is below this value

•Comfort/economy mode:

In economy mode, heat pump use is maximized before

turning On auxiliary heating

•Compressor/auxiliary interlock:

Adds flexibility by locking out heat pump operation during

auxiliary heating to prevent high pressure trip when the coil

is downstream of the auxiliary heat source.

Fig.2

3

Installation

•Remove security screw on the bottom of thermostat cover.

•Open up by pulling on the bottom side of thermostat.

•Remove Assembly and remove wiring terminals from sticker. (Fig. 3)

•Please note the FCC ID and IC label installed in the cover upon removal of cover

for the wireless products.

A) Location:

1- Should not be installed on an outside wall.

2- Must be installed away from any heat source.

3- Should not be installed near an air discharge grill.

4- Should not be affected by direct sun radiation.

5- Nothing must restrain vertical air circulation to the thermostat.

B) Installation:

1- Swing open the thermostat PCB to the left by pressing the PCB locking tabs.

(Fig. 4)

2- Pull out cables 6” out of the wall.

3- Wall surface must be flat and clean.

4- Insert cable in the central hole of the base.

5- Align the base and mark the location of the two mounting holes on the wall.

Install proper side of base up.

6- Install anchors in the wall.

7- Insert screws in mounting holes on each side of the base.

(Fig. 4)

8- Gently swing back the circuit board on the base and push on it until the tabs lock

it.

10- Strip each wire 1/4 inch.

11- Insert each wire according to wiring diagram.

13- Gently push back into hole excess wring (Fig. 5)

14- Re-Install wiring terminals in correct location. (Fig. 5)

15- Reinstall the cover (top side first) and gently push back extra wire length into the

hole in the wall.

16- Install security screw.

•If replacing an old thermostat, label the wires before removal of

the old thermostat.

•Electronic controls are static sensitive devices. Discharge

yourself properly before manipulation and installing the

thermostat.

•Short circuit or wrong wiring may permanently damage the

thermostat or the equipment.

•Anti-short cycling can be set to 0 minutes for equipment that

posses their own anti cycling timer. Do not use that value

unless the equipment is equipped with such internal timer.

Failure to do so can damage the equipment.

•All Allure communicating thermostats are to be used only as

operating controls. Whenever a control failure could lead to

personal injury and/or loss of property, it becomes the

responsibility of the user to add safety devices and/or alarm

system to protect against such catastrophic failures.

Location of PCB retaining tabs

Re-install terminal blocks

Thermostat assembly

Fig.6

Fig.3

Fig.5

Fig.4

4

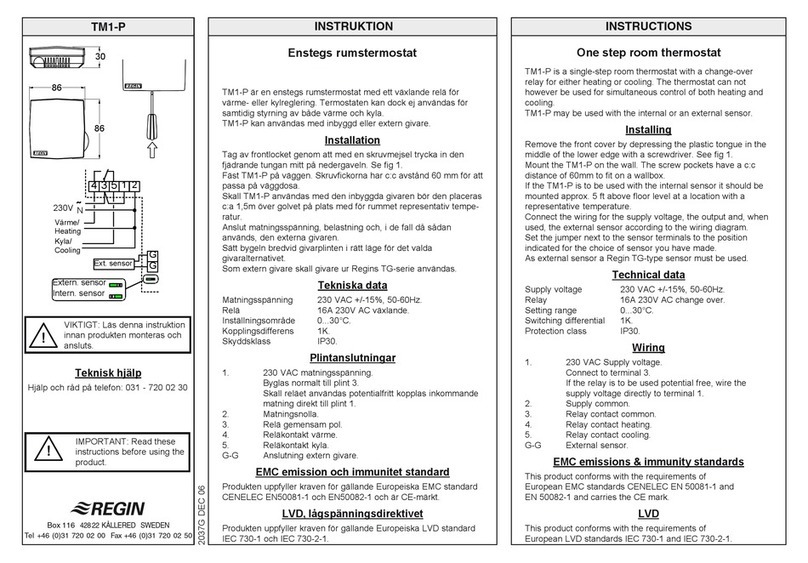

Wiring identification & screw terminal arrangement

Multistage

1H / 1C

Heat Pump

Product Name

STAT-RT2EP

STAT-RT2P

STAT-RT1P

Product Name

STAT-HPP

Programmable

Yes

Yes

Yes

Programmable

Yes

Top left terminal block

Top left terminal block

Y2

X

X

Y2

X

Y1

X

X

X

Y1

X

G

X

X

X

G

X

RC

X

X

X

RC

X

C

X

X

X

C

X

Top right terminal block

Top right terminal block

RH

X

X

X

RH

X

W1

X

X

X

W1

X

W2

X

X

O/B

X

Bottom terminal block

Bottom terminal block

Econo

X

Aux

X

X

X

Aux

X

DI1

X

X

X

DI1

X

DI2

X

X

X

DI2

X

RS

X

X

X

RS

X

Scom

X

X

X

Scom

X

OS

X

X

X

OS

X

MS

X

X

X

MS

X

Screw terminal arrangement

Wiring notes:

Note 1: If the same power source is used for the heating stages, install jumper across RC & RH. Maximum current is 2.0 amps.

Note 2: If auxiliary output is used to toggle occupancy of the electronic control card inside the equipment, configure the relay parameter

(Aux cont ) to the N.O. setting. A second relay can be added for additional functionality of the occupancy output.

Note 3: Economizer output uses a half bridge rectifier. Reference of the control signal is the common of the power supply of the

thermostat. (terminal C)

Note 4: Electromechanical contacts are to be used with the digital inputs. Electronic triacs cannot be used as mean of switching for the

input. The switched leg to the input for the input to activate is terminal C ( common )

Note 5: The transformer of the unit provides power to the thermostat and the additional loads that will be wired to the thermostat.

EC

AU

D1

D2

RS

Scom

OS

MS

Y2

Y1

G

RC

C

RH

W1

W2

O/B

5 pole left top connector

3 pole left top connector

8 pole bottom connector

Fig.7

5

Detailed wiring diagrams for selected models

CDIVI-7656B5XE1

2 Heat / 2 Cool / Economizer / Programmable

Heat

Stage 2

Cool

Stage 1

System wiring

Thermostat internal wiring

Jumper J1 T1

24 Vac

Cool

Stage 2

Y2 Y1

Jumper J1

See note 1

(previous

page)

Fan

RCG C

Heat

Stage 1

W1RH W2

Auxiliary

Output

Field contacts

Com24V

Remote

Outdoor

Sensor

Digital Input #2

Digital Input #1

Remote

Room

Sensor

0-10 Vdc

EC AU DI1 DI2 RS

Remote

Mixed Air

Sensor

MSScom OS

CDIVI-7652H5XE1

Heat pump / Programmable

Auxiliary

Heat

W1

System wiring

Jumper J1

Thermostat internal wiring

Compressor

Stage 1

24 Vac

T1

Compressor

Stage 2

Y2

Jumper J1

See note 1

(previous

page)

Fan

G

Y1

RC

C

RH

Remote

Room

Sensor

Field contacts

Reversing

Valve

Digital Input #2

Digital Input #1

Auxiliary

Output

O/B

AU

DI1

DI2

Scom

RS

Remote

Outdoor

Sensor

Remote

Mixed Air

Sensor

MS

OS

Thermostat Terminals -

STAT-HPP

Y2

DI1

DI2

AU

Y1

RC

G

O/B

OS

RS

Scom

RH

C

W1

MS

Thermostat Terminals -

STAT-RT2EP

Y2

EC

RC

G

Y1

AU

DI1

DI2

W2

MS

W1

RH

C

Scom

RS

OS

6

Remote sensor accessories

Model no.

Description

PDITE-SENSORX0

Wall mounted temperature sensor

PDITE-SENSOROX0

Wall mounted temperature sensor w/ override button and occupancy status LED

PDIGR-TE200F Series

Outdoor temperature sensor

PDIGR-TE200D Series

Averaging temperature sensor

PDIGR-TE200B Series

Duct mounted temperature sensor

PDITE-SENSOROX0, remote wall mount temperature sensors use 10K NTC thermistors.

This sensor can be used for:

•Various averaging combinations

•Optional occupancy led

•Optional override key

Fig.8 –

PDITE-SENSOROX0

PDIGR-TE200B SERIES, remote duct mounted temperature sensor.

This sensor can be used for:

•Remote return air temperature sensing with the sensor mounted on

the return air duct.

•Outside air temperature sensing with the sensor installed in the fresh

air plenum.

•Supply air temperature sensor

Fig.9 – PDITE-TE200B Series (shown with standard

ABS enclosure)

PDIGR-TE200D SERIES, remote averaging duct mounted temperature sensor c/w junction box.

This sensor can be used for:

•Remote averaging return air temperature sensing with the sensor mounted on the return air duct.

•Outside air temperature averaging sensing with the sensor installed in the fresh air plenum.

•Mixed air temperature averaging sensor for economizer models with the sensor in the mixing plenum.

PDIGR-TE200F SERIES, outdoor air temperature sensor

This sensor can be used for:

•Outside air temperature sensing with the sensor installed directly exposed to the elements.

•Sensor uses a weather resistant enclosure for outdoor applications

WIRING PDITE-SENSORX0, PDITE-SENSOROX0, PDIGR-TE200B Series, PDIGR-TE200D Series and PDIGR-TE200F Series

Remote wiring 1 sensor Remote wiring 4 sensors

10 K 10 K 10 K 10 K 10 K

Scom

MS

Scom

OS

Scom

RS or

or Scom

MS

Scom

OS

Scom

RS or

or

(

7

LonWorks Wiring Guide

Overview

For clarity we will use the term “Device” to represent any product with an active LonWorks network

connection, including Distech Controls and non-Distech Controls controllers.

Summary Specifications:

Parameter

Details

Network Wiring

24 to 16AWG, twisted pair

Maximum total wire length

1

1600 feet (500 meters) in free topology

Maximum device-to-device distance

1600 feet (500 meters) in free topology

Polarity

Polarity insensitive

Multi-drop

Free Topology

Termination for Free Topology Network Segment

One RC network with Ra = 52.3Ω±1%, 1/8W

Termination for Doubly Terminated Bus Network

Segment

Two RC network with Ra = 105

Ω

±1%, 1/8W

Number of transceivers per segment

Up to 64

Baud rate

78000 bits per second

1Network segment length varies depending on wire type.

Table 1: Summary of Specifications for a Distech Controls’ LON Network

Network Configuration

The LonWorks network is designed to support free topology wiring and will accommodate bus, star, loop or

any of these topologies. LonWorks devices can be located at any point along the network wiring.

Figures 3.1 to 3.5 present five different network topologies. The actual termination circuit will vary by

application.

8

LonWorks Wiring Guide

9

LonWorks Wiring Guide

Maximum Number Of Devices

Up to 64 transceivers are allowed per network segment. If your network requires more than 64 transceivers a

repeater is then required to extend your network

Maximum Cable Length

The maximum length of a chain is related to its transmission speed. The longer the chain, the slower the

speed. Using proper cable, LonWorks supports a baud rate of 78 kilobits per second for distances up to

1600-ft (500 m) in free topology and 8800 ft (2700 m) in bus topology with double terminations.

If you require a maximum network length of more than 1600-ft (500 m) or 8800 ft (2700 m), then a

repeater is required to extend the network.

Repeater

In the event that the limits on the number of transceivers or total wire distance are exceeded, a physical

layer repeater can be added to interconnect two or more network segments. A repeater will double the

overall channel capability, including node count and network extent, but not bandwidth. Note that only

one physical layer repeater should be placed in series between any two nodes on a channel. If

additional cabling or network bandwidth is required, then a LonWorks Router should be used in place of

a repeater.

Terminators

LonWorks network segments requires termination for proper data transmission performance. The type of

terminator varies depending on whether shielded or unshielded cable is used. Free topology and Bus

networks also differ in their termination requirements. The following sections describe the various terminators

and terminations procedure.

Free Topology Network Segment

In a free topology segment, only one termination is required and may be placed anywhere on the

free topology segment. There are two choices for the termination:

1. RC network with Ra = 52Ω±1%, 1/8W

2. LPI-10 Link Power Interface, with jumper at “1 CPLR” setting.

Doubly Terminated Network Segment

In a doubly terminated bus topology, two terminations are required, one at each en of the bus.

There are two choices for each termination:

1. RC network with Ra = 105Ω±1%, 1/8W

2. LPI-10 Link Power Interface, with jumper at “2 CPLR” setting.

Only one LPI-10 interface is supported per segment. The other terminator must be an RC-type.

LonWorks Wiring Guide

10

Grounding Shielded Twisted Pair Cable

When using Shielded Twisted Pair, terminate the twisted pair as listed in the previous section and

ground the cable shield by using a capacitor, to tie the shield to earth ground, and a large-value

resistor to bleed off any static charge on the shield. Tying the shield to earth ground through a

capacitor will avoid DC and 50/60Hz ground paths from being formed through the shield. Typical

values for resistor and capacitor are as follows:

Capacitor = 0.1µF, 10%, Metalized Polyester, ≥100V

Resistor = 470kΩ, 1/4W, ±5%

The cable shield should be grounded at least once per segment, and preferably at each node.

Grounding the shield at every node will assist in suppressing 50/60Hz standing waves.

Network adapter

Although network connections are polarity insensitive, it is good practice to keep polarity consistent

throughout the entire site. Figure 4 shows a network connection example and the location of the Status LED.

This Status LED may help to troubleshoot network problems.

Figure 4: Network connections and location of the Status LED on a LON module

Table 2 shows the different possibilities with the Status LED behaviour of the LON module.

Condition of the Status LED

Explanation

Continuously ON

The device has no application loaded in its memory and is

Un-configured

Flashing at a rate of 1/2Hz

The device has an application loaded in its memory but is Un-

configured. When a device is in the un-configured state, it

does not know which devices to communicate with. A network

management tool is used to logically bind the node to another

in a LonWorks network.

Continuously OFF

The device has an application loaded into its memory and is

bound onto a LonWorks network.

Table 2: Status LED condition

11

BACnet Wiring Guide

Overview

Distech Controls uses EIA-485 as the physical layer between their devices and supervisory controllers

For clarity we will use the term “Device” to represent any product with an active EIA-485 network

connection, including Distech Controls and non-Distech Controls controllers.

Summary Specifications:

Parameter

Details

Media

Twisted pair 22AWG-24 AWG, shielded recommended

Characteristic Impedance

100-130 ohms

Distributed capacitance

Less than 100 pF per meter (30 pF per foot)

Maximum length per segment

1200 meters (4000 feet) Note: AWG 18 cable

Polarity

Polarity sensitive

Multi-drop

Daisy-chain (no T connections)

Terminations

1. Distech Controls’ thermostats are installed at both

ends of the MSTP network:

120 Ohms resistor should be installed at each end.

2. A Distech Controls thermostat is installed at one end of

the MSTP network and a 3rd party device is installed at

the other end:

Install an End-Of-Line resistor value that matches the 3 rd

party device instruction regarding the End-Of-Line resistors

3. 3rd party devices are installed at both ends of the MSTP

network:

Follow the 3rd party device instructions regarding the End-

Of-Line resistors.

Network Bias Resistors

510 ohms per wire (max. of two sets per segment)

Maximum number of nodes per

segment

64 (Distech Controls devices only)

Maximum number of nodes per

network

128

Baud rate

9600, 19200, 38400, 76800 (Auto detect)

Table 1: Summary of Specifications for a Distech Controls’ EIA-485 Network

12

BACnet Wiring Guide

Cable Type

Distech Controls recommends the use of balanced 22-24 AWG twisted pair with a characteristic impedance

of 100-130 ohms, capacitance of 30 pF/ft or lower. A braided shield is also recommended.

Impedance

A value based on the inherent conductance, resistance, capacitance and inductance that represent the

impedance of an infinitely long cable. The nominal impedance of the cable should be between 100Ωand

120Ω. However using120Ω will result in a lighter load on the network.

Capacitance (pF/ft)

The amount of equivalent capacitive load of the cable, typically listed in a per foot basis. One of the factors

limiting total cable length is the capacitive load. Systems with long lengths benefit from using low capacitance

cable (i.e. 17pF/ft or lower).

Network Configuration

EIA-485 networks use a daisy chain configuration. A daisy chain means that there is only one main cable

and every network device is connected directly along its path.

Figure 3 illustrates two improper network configurations and the proper daisy chain configuration.

Other methods of wiring an EIA-485 network may give unreliable and unpredictable results. There are no

troubleshooting methods for these types of networks. Therefore, a great deal of site experimentation may

have to be done, making this a difficult task with no guarantee of success. Distech Controls will only support

daisy chain configurations.

Figure 3: Three different network configurations: star, bus, and daisy chain. Only

the daisy chain configuration is correct for an EIA-485 network.

13

BACnet Wiring Guide

Maximum Number of Devices

A maximum of 64 nodes is allowed on a single daisy chain segment. A node is defined as any device (Panel,

Zone, Repeater, etc) connected to the RS485 network. Terminators do not count as a node.

To determine the number of nodes on a network, add the following:

One node for each device, including main panels

One node for each repeater on the chain

For the example in Figure 4, we have one node for the main Panel, plus 4 for the controllers, for a total of 5

nodes.

Figure 4: Five nodes network example.

If you have more than 64 devices, then repeaters are required to extend the network.

Maximum Cable Length

The maximum length of a chain is related to its transmission speed. The longer the chain, the slower the

speed. Using proper cable, the maximum length of an EIA-485 daisy chain is 4000-ft (1200 m). This will

only work reliably for data rates up to 100,000 bps. Distech Controls’ maximum data rate is 76,800 bps.

If you require a maximum network length of more than 4000 feet, then repeaters are required to extend

the network.

EIA-485 Repeaters

If you have more than 64 devices, or require a maximum network length of more than 4000 feet, then

repeaters are required to extend the network. The best configuration is to daisy chain the repeaters to

the main panel. From each of these repeaters, a separate daisy chain will branch off. Figure 5

demonstrates a valid use of repeaters in an EIA-485 network.

14

BACnet Wiring Guide

Figure 5: Correct usage – repeaters are daisy chained to the supervisory

controller and separate daisy chains branch from each repeater.

Do not install repeaters in series, as this may result in network reliability problems. Figure 6 demonstrates an

incorrect use of a repeater in an EIA-485 network.

Figure 6: Incorrect usage – the second repeater in series may result in

an unreliable system

15

BACnet Wiring Guide

End Of Line (EOL) Resistors

MS/TP network must be properly terminated. For daisy chain configurations, you must install an EOL resistor

at each end of the daisy chain. Depending on your MSTP network configuration, the resistance value of the

EOL resistor may change:

•Distech Controls thermostats are installed at both ends of the MSTP network:

120 Ohms resistor should be installed at each end.

•A Distech Controls thermostat is installed at one end of the MSTP network and a 3rd party

device is installed at the other end:

Install an End-Of-Line resistor value that matches the 3rd party devices instructions regarding its

EOL resistor value;

•3rd party devices are installed at both ends of the MSTP network:

Follow the 3rd party devices instructions regarding its EOL resistor value.

Network Adapter

The polarity of the connection to the cable is important. From one module to the other it is important that the

same colored wire be connected to “plus” or “+” and the other colored wire be connected to the “minus” or ”-

“. Figures 7 shows the proper MS/TP connections and the location of the Status LED. This Status LED may

help to troubleshoot network problems.

Figure 7: Correct MS/TP connections and location of a Status LED on a BACnet module

IMPORTANT NOTE: The Ref terminal should NEVER be used to wire shields. The 2 shields from each feed

of the network connection to a thermostat should be wired together in the back of the thermostat and properly

protected to prevent any accidental connection to the ground.

The joined shield connection should then be grounded at a SINGLE point on the whole segment. More than

one ground connection to a shielded wire may induce ground loop noises and affect communication.

Table 2 shows the different possibilities with the Status LED behaviour for a BACnet module.

16

BACnet Wiring Guide

Condition of the Status LED

Possible Cause

Solution

BACnet communication NOT active

at default MAC address = 254

Change MAC address to

another value from 0 to 127

1 short blink

Incorrect module has been

installed

Incorrect module has been

installed

2 short blink (no wires

connected to the module) The right module has been installed

on the right thermostat model N/A

2 short blink (wires

connected to the module) Module is not at the same baud rate

as the network

Power off and on the

thermostat

2 short blinks and a longer

blink (wires connected to

the module)

The module has detected the

presence of a network N/A

Right after power is

applied: 2 long blinks and

then no blinking

Polarity has been reversed at the

module

Reverse polarity at the

module

Table 2: Status LED condition and possible solutions

17

User menu flow chart:

Schedule

set? Y/N

Sys mode

set? Y/N

Clock

set? Y/N

Temperat

set? Y/N

Schedule

hold Y/N

Exit

menu Y/N

Unocc HT

set? Y/N

°F/°C

set? Y/N

Heating

set? Y/N

Unocc CL

set? Y/N

Cooling

set? Y/N

°C

°F

Exit?

Y/N

Temperature

Temperature

Temperature

Temperature

MENU

12/24hrs

set? Y/N

12 / 24

Time

set? Y/N

Time

Day

set? Y/N

Day

Fan mode

set? Y/N

On

Smart

Auto

Sunday

set? Y/N

Saturday

set? Y/N

Friday

set? Y/N

Thursday

set? Y/N

Wednesda

set? Y/N

Tuesday

set? Y/N

Monday

set? Y/N

Exit?

Y/N

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Occupied

day? Y/N

Occupied

12:00 pm

Time

Unoccup

12:00 pm

Time

Resume

Occ Hold

Uno Hold

Exit?

Y/N

off

emergenc

heat

cool

auto

Override

schd Y/N

Cancel

ovrd Y/N

If status is:

Unoccupied

If status is:

Temporary Occupied Time,

18

Programming and status display instructions

1. Status display

The thermostat features a two-line, eight-character display. There is a low level back-light level that is always active and can only be

seen at night. When left unattended, the thermostat has an auto scrolling display that shows the actual status of the system. Each

item is scrolled one by one with the back lighting off. Pressing any key will cause the back light to come on.

Sequence of auto-scroll status display:

Room

temperature

Clock status

System mode

Schedule status

Outdoor

temperature

Alarms

RoomTemp

Monday

Sys mode

Occupied

Outdoor

Service

x.x °C or °F

12.00 AM

auto

x.x °C or°F

Sys mode

off

Occupied

hold

Frost ON

Sys mode

heat

Unoccup

SetClock

Sys mode

cool

Unoccup

hold

Filter

Sys mode emergenc

Override

Fan lock

Manual scroll of each menu item is achieved by pressing the Yes ( scroll ) key repetitively. The last item viewed will be shown on the

display for 30 seconds before returning to automatic scrolling. Temperature is automatically updated when scrolling is held.

Outdoor air temperature display is only enabled when an outdoor air temperature sensor is connected.

•A maximum range status display of 50 °C ( 122 °F ) indicates a shorted sensor. Associated functions, such as mode lockouts and

economizer function are automatically disabled.

•A minimum range status -40 °C ( -40 °F ) is not displayed and indicates an opened sensor or a sensor not connected. Associated

functions, such as mode lockouts and economizer function are automatically disabled.

If alarms are detected, they will automatically be displayed at the end of the status display scroll. During an alarm message display,

the back lit screen will light up at the same time as the message and shut off during the rest of the status display. Two alarms

maximum can appear at any given time. The priority for the alarms is as follows:

Frost ON

Indicates that the heating is energized by the low limit frost protection room temperature setpoint 5.6 °C ( 42 °F )

SetClock

Indicates that the clock needs to be reset. There has been a power failure which has lasted longer than 6 hours

Service

Indicates that there is a service alarm as per one of the programmable digital input ( DI1 or DI2 )

Filter

Indicates that the filters are dirty as per one of the programmable digital input ( DI1 or DI2 )

Fan lock

Indicates that the heating and cooling action are locked out due to a defective fan operation

Three status LEDs on the thermostat cover are used to indicate the status of the fan, a call for heat, or a call for cooling.

LED

operation

Heatpump models CDIVI-76xxH

Multistage and single stage models

CDIVI-7652A & CDIVI-7652B

Multistage economizer models

CDIVI-7656B

Fan LED on

When G Fan terminal operates

When G Fan terminal operates

When G Fan terminal operates

Heating LED

on

When Y1 and / or W1 terminal(s)

operate in heating mode

When W1 terminal operate in heating

mode

When W1 terminal operate in heating

mode

Cooling LED

on

When Y1 terminal operate in cooling

mode

When Y1 terminal operate in cooling

mode

When Y1 terminal operate in cooling

mode and or economizer output is in

function

Fig.10 – Heatpump, multistage and single stage models

19

2. User programming instructions menu

The Allure communicating thermostats feature an intuitive, menu-driven, back-lit LCD display that walks users through the programming steps,

making the programming process extremely simple. This menu is typically accessed by the user to set the parameters such as temperature and

time events, system mode, fan mode, etc.

It is possible to bring up the user menu at any time by depressing the MENU key. The status display automatically resumes after exiting the user-

programming menu.

If the user pauses at any given time during programming, Auto Help text is displayed to help and guide the user through the usage and

programming of the thermostat.

Ex.:

Press yes key to change cooling temperature setpoint

Each of the sections in the menu are accessed and programmed using 5 keys on the thermostat cover.

The priority for the alarms is as follows:

The YES key is used to confirm a selection, to move onto the next menu item and to manually scroll through the displayed

information.

The NO key is used when you do not desire a parameter change, and to advance to the next menu item. Can also be used to

toggle between heating and cooling setpoints.

The MENU key is used to access the Main User Menu or exit the menu.

The down arrow key is used to decrease temperature setpoint and to adjust the desired values when programming and

configuring the thermostat.

The up arrow key is used to increase temperature setpoint and to adjust the desired values when programming and

configuring the thermostat.

When left unattended for 45 seconds, the display will resume automatic status display scrolling.

To turn on the back light, press any key on the front panel. The back lit display will turn off when the thermostat is left unattended for 45 seconds

Sequence of user menu:

Override

Resume

Temperature

setpoints

System mode

setting

Fan mode setting

Schedules setting

Clock setting

Override

schd Y/N

Temperat

set Y/N

Sys mode

set Y/N

Fan mode

set Y/N

Schedule

set Y/N

Clock

set Y/N

Appears only in

unoccupied mode

Cancel

ovrd Y/N

Appears only in

override mode

There is a default profile set in the thermostat from the factory.

This enables the thermostat to operate as a non-programmable unit in day mode operation at start up.

Programmed default temperature setpoints:

Programmed default modes:

Occupied cooling setpoint = 24 °C ( 75 °F )

System mode = Auto

Occupied heating setpoint = 22 °C ( 72 °F )

Fan mode = Smart (for models with a communication module

Unoccupied cooling setpoint = 28 °C ( 82 °F )

Unoccupied heating setpoint = 18 °C ( 65 °F )

Programmed default schedules:

Fahrenheit scale

Monday through Sunday

Setpoint type = permanent

Occupied time is: 12 00 AM

Unoccupied time is: 11:59 PM

There will be a 1 minute unoccupied period every night at 11:59 PM with this default configuration.

20

A) Override an unoccupied period

Override

schd Y/N

This menu will appear only when the thermostat is in unoccupied mode. The unoccupied mode is enabled either by the internal timer scheduling or

by a remote NSB contact via DI1 or DI2.

If DI1 or DI2 is configured to operate as a remote temporary override contact, this menu will be disabled.

Answering yes to this prompt will cause the thermostat to go into occupied mode for an amount of time equal to the parameter “TOccTime” (1 to 12

hours).

B) Resume regular scheduling

Cancel

ovrd Y/N

This menu does not appear in regular operation. It will appear only when the thermostat is in Unoccupied override mode.

Answering “Yes” to this question will cause the thermostat to resume the regular programmed setpoints & scheduling.

C) Temperature setpoints

Permanent setpoint changes

Temperat

set Y/N

This menu permits the adjustment of all permanent temperature setpoints (occupied and unoccupied) as well as the desired temperature units (°F

or °C). Permanent setpoints are written to RAM and EEPROM

Cooling setpoint

Occupied mode

Heating setpoint

Occupied mode

Cooling setpoint

Unoccupied mode

Heating setpoint

Unoccupied mode

°F or °C

display setting

Cooling

set? Y/N

No next →

Yes down

↓

Heating

set? Y/N

No next →

Yes down

↓

Unocc CL

set? Y/N

No next →

Yes down

↓

Unocc HT

set? Y/N

No next →

Yes down

↓

°F or °C

set? Y/N

No next →

Yes down

↓

Use ▲▼ keys to set value, Yes key to confirm

Cooling

70.0 °F

Use ▲▼

To set

value

Heating

68.00 °F

Use ▲▼

To set

value

Unocc CL

80.0 °F

Use ▲▼

To set

value

Unocc HT

60.0 °F

Use ▲▼

To set

value

Units

°F

Use ▲▼

To set

value

Temporary setpoint changes

Temporary setpoints can be modified through the Up arrow key (▲) and the Down arrow keys (▼).

User will be prompted with the present mode (Heating or Cooling) of the thermostat and its setpoint.

The Up (▲) arrow key will increment the setpoint by 0.5 degree (F or C).

The Down (▼) arrow key will decrement the setpoint by 0.5 degree (F or C).

Press the Yes key to accept the new setpoint.

Local changes to the heating or cooling setpoints made by the user directly using the up or down arrow are temporary.

They will remain effective for the duration specified by ToccTime.

Setpoints will revert back to their default value after internal timer ToccTime expires.

If a permanent change to the setpoints is required, use the Temperat set ? menu

D) System mode setting

Sys mode

set Y/N

This menu is accessed to set system mode operation

Use ▲▼ to set value, Yes key to confirm

Sys mode

auto

Automatic mode

Automatic changeover mode between heating and cooling operation

Sys mode

cooling

Cooling mode

Cooling operation mode only

Sys mode

heating

Heating mode

Heating operation mode only

Sys mode

emergency

Emergency heat mode ( heat pump models only )

Forced auxiliary heat operation mode only

Sys mode

off

Off mode Normal cooling or heating operation disabled

If enabled in installer parameters, only the automatic heating frost protection at 50 °F ( 10 °C ) is enabled

This manual suits for next models

13

Table of contents

Other Distech Controls Thermostat manuals