Distek 2500 Select User manual

© 2015-2017 Distek, Inc. All Rights Reserved

Model 2500

Operation

Manual

Document: 3825-0001 Rev. F

Model 2500

Operation Manual

Document 3825-0001 Rev. F

© Distek, Inc.

121 North Center Dr. • North Brunswick, NJ 08902

Phone 732.422.7585 • Fax 732.422.7310

http://www.distekinc.com

All rights reserved. No part of this work may be reproduced in any form or by any means - graphic,

electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval

systems - without the written permission of Distek, Inc.

Products that are referred to in this document may be either trademarks and/or registered trademarks of

the respective owners. Distek, Inc. makes no claim to these trademarks.

The information contained in the document is subject to change without notice.

While every precaution has been taken in the preparation of this document, Distek, Inc. assumes no

responsibility for errors or omissions, or for damages resulting from the use of information contained in

this document or from the use of programs and source code that may accompany it. In no event shall

Distek, Inc. be liable for any loss of profit or any other commercial damage caused or alleged to have been

caused directly or indirectly by this document.

Model 2500

© 2015-2017 Distek, Inc. All Rights Reserved

DISTEK, INC.

121 North Center Drive

North Brunswick, NJ 08902

Tel. 732.422.7585

Website: http://www.distekinc.com

4Model 2500

© 2015-2017 Distek, Inc. All Rights Reserved

Table of Contents

Chapter I Introduction 8

................................................................................................................................... 91 Distek Model 2500 Overview

................................................................................................................................... 112 Instrument Specification

................................................................................................................................... 123 Notices

................................................................................................................................... 144 Safety Information

................................................................................................................................... 155 Site Requirements

.......................................................................................................................................................... 16

Physical Site Consideration

.......................................................................................................................................................... 17

Electrical Requirements

................................................................................................................................... 186 Environmental Conditions

.......................................................................................................................................................... 19

Ambient Laboratory Humidity

.......................................................................................................................................................... 20

Ambient Laboratory Temperature

.......................................................................................................................................................... 21

Air Quality Considerations

.......................................................................................................................................................... 22

Environmental Considerations

Chapter II Installation 24

................................................................................................................................... 251 Unpacking

................................................................................................................................... 262 Leveling

................................................................................................................................... 273 AC Power Installation

................................................................................................................................... 284 TCS Installation

................................................................................................................................... 305 Vessel Installation

................................................................................................................................... 326 Shaft Installation

.......................................................................................................................................................... 33

Standard Shafts

.......................................................................................................................................................... 34

RTD Shafts

................................................................................................................................... 367 Paddle Installation

................................................................................................................................... 378 Basket Installation

................................................................................................................................... 389 Vessel Covers

Chapter III Installing Accessories 40

................................................................................................................................... 411 TempChek

................................................................................................................................... 422 Dosage Delivery System (DDS)

................................................................................................................................... 453 Printers

.......................................................................................................................................................... 46

Dedicated Instrument Printer

................................................................................................................................... 474 Distek Cipher Software

................................................................................................................................... 485 Agilent 8453 UV-Vis

................................................................................................................................... 496 Waters HPLC

Chapter IV Graphic User Interface (GUI) 51

................................................................................................................................... 521 2500 Dashboard

................................................................................................................................... 542 2500 RTD Dashboard

5ContentsModel 2500

© 2015-2017 Distek, Inc. All Rights Reserved

................................................................................................................................... 563 2500 Select Dashboard

................................................................................................................................... 584 Apparatus ID

................................................................................................................................... 595 Methods

................................................................................................................................... 606 Reports

................................................................................................................................... 617 Settings

................................................................................................................................... 628 Logout

................................................................................................................................... 639 On-Screen Keyboard

Chapter V Operation 65

................................................................................................................................... 661 Turning On the Instrument

................................................................................................................................... 672 Operational Checkout

................................................................................................................................... 683 Height Adjustment

.......................................................................................................................................................... 69

Baskets and Paddles

.......................................................................................................................................................... 73

Modified Baskets

.......................................................................................................................................................... 75

Modified Paddles

.......................................................................................................................................................... 77

Intrinsic

................................................................................................................................... 794 Manual Run

.......................................................................................................................................................... 79

2500 with Standard Shafts

.......................................................................................................................................................... 81

2500 RTD .......................................................................................................................................................... 83

2500 Select

................................................................................................................................... 855 Create a New Method

................................................................................................................................... 886 Edit Method

................................................................................................................................... 907 Method Run

.......................................................................................................................................................... 91

Selecting a Method

.......................................................................................................................................................... 92

Using the Dosage Delivery System

.......................................................................................................................................................... 93

Simultaneous Drop Using Baskets

......................................................................................................................................................... 93

2500 with Standard Shafts

......................................................................................................................................................... 97

2500 RTD-Select

.......................................................................................................................................................... 101

Simultaneous Drop Using Paddles

......................................................................................................................................................... 101

2500 with Standard Shafts

......................................................................................................................................................... 105

2500 RTD-Select

.......................................................................................................................................................... 109

Staggered Drop Using Baskets

......................................................................................................................................................... 109

2500 with Standard Shafts

......................................................................................................................................................... 114

2500 RTD-Select

.......................................................................................................................................................... 119

Staggered Drop Using Paddles

......................................................................................................................................................... 119

2500 with Standard Shafts

......................................................................................................................................................... 124

2500 RTD-Select

................................................................................................................................... 1298 Report Summary

................................................................................................................................... 1319 User Setup

.......................................................................................................................................................... 132

New User .......................................................................................................................................................... 135

Edit User .......................................................................................................................................................... 137

Delete User

................................................................................................................................... 13810 System Settings

.......................................................................................................................................................... 139

TCS Schedule

.......................................................................................................................................................... 141

Temperature Calibration

......................................................................................................................................................... 142

Accessing Calibration

......................................................................................................................................................... 144

TCS Calibration Using TempChek

6Model 2500

© 2015-2017 Distek, Inc. All Rights Reserved

......................................................................................................................................................... 146

TCS Calibration Using Reference

......................................................................................................................................................... 147

Shaft Sensor Calibration Using TempChek

......................................................................................................................................................... 150

Shaft Sensor Calibration Using Reference

.......................................................................................................................................................... 152

System Setup

......................................................................................................................................................... 156

Advanced Setup

......................................................................................................................................................... 159

LCD Calibration

.......................................................................................................................................................... 161

Service .......................................................................................................................................................... 164

Instrument Validation

.......................................................................................................................................................... 166

Battery Monitor

.......................................................................................................................................................... 168

Help

Chapter VI Maintenance 170

................................................................................................................................... 1711 General Maintenance

................................................................................................................................... 1722 Lubrication

................................................................................................................................... 1733 Belt Tension

Chapter VII Troubleshooting 175

................................................................................................................................... 1761 Prompted Messages

.......................................................................................................................................................... 177

General Messages

.......................................................................................................................................................... 180

Error Messages

.......................................................................................................................................................... 183

Warning Messages

.......................................................................................................................................................... 184

Service Messages

................................................................................................................................... 1852 LCD Display

................................................................................................................................... 1863 Power Supply

................................................................................................................................... 1874 Heating

................................................................................................................................... 1885 Stirring

................................................................................................................................... 1896 I/O Communication

................................................................................................................................... 1907 Temperature Calibration

................................................................................................................................... 1918 Mechanical

Chapter VIII Appendix A: Spare Parts and Accessories 194

Chapter IX Appendix B: Pre-Installation

Considerations 197

Chapter X Appendix C: Sample Printouts 199

Index 205

Introduction

Chapter I

IntroductionModel 2500 8

© 2015-2017 Distek, Inc. All Rights Reserved

1 Introduction

Model 2500 Overview

Instrument Specification

Notices

Safety Information

Site Requirements

Environmental Conditions

This chapter contains an overview of the instrument and safeguards that need to be followed when

installing and using the instrument.

IntroductionModel 2500 9

© 2015-2017 Distek, Inc. All Rights Reserved

1.1 Distek Model 2500 Overview

W elcome to a new innova tion in D issolution testing .

The Distek Model 2500 Dissolution Test System offers unmatched flexibility and configurability

while maintaining the user-friendliness that laboratories around the world have come to expect

from the preceding four generations of the 2100 series.

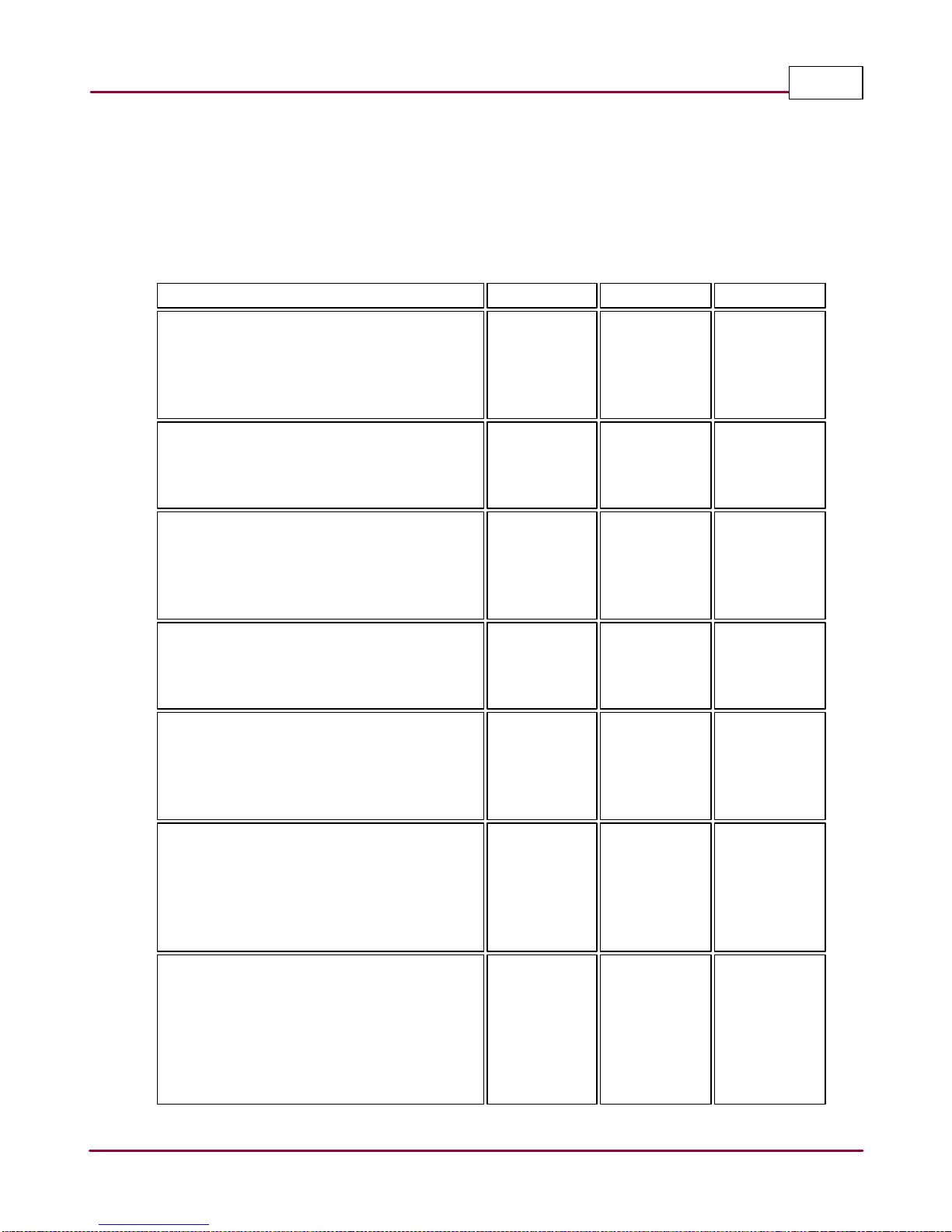

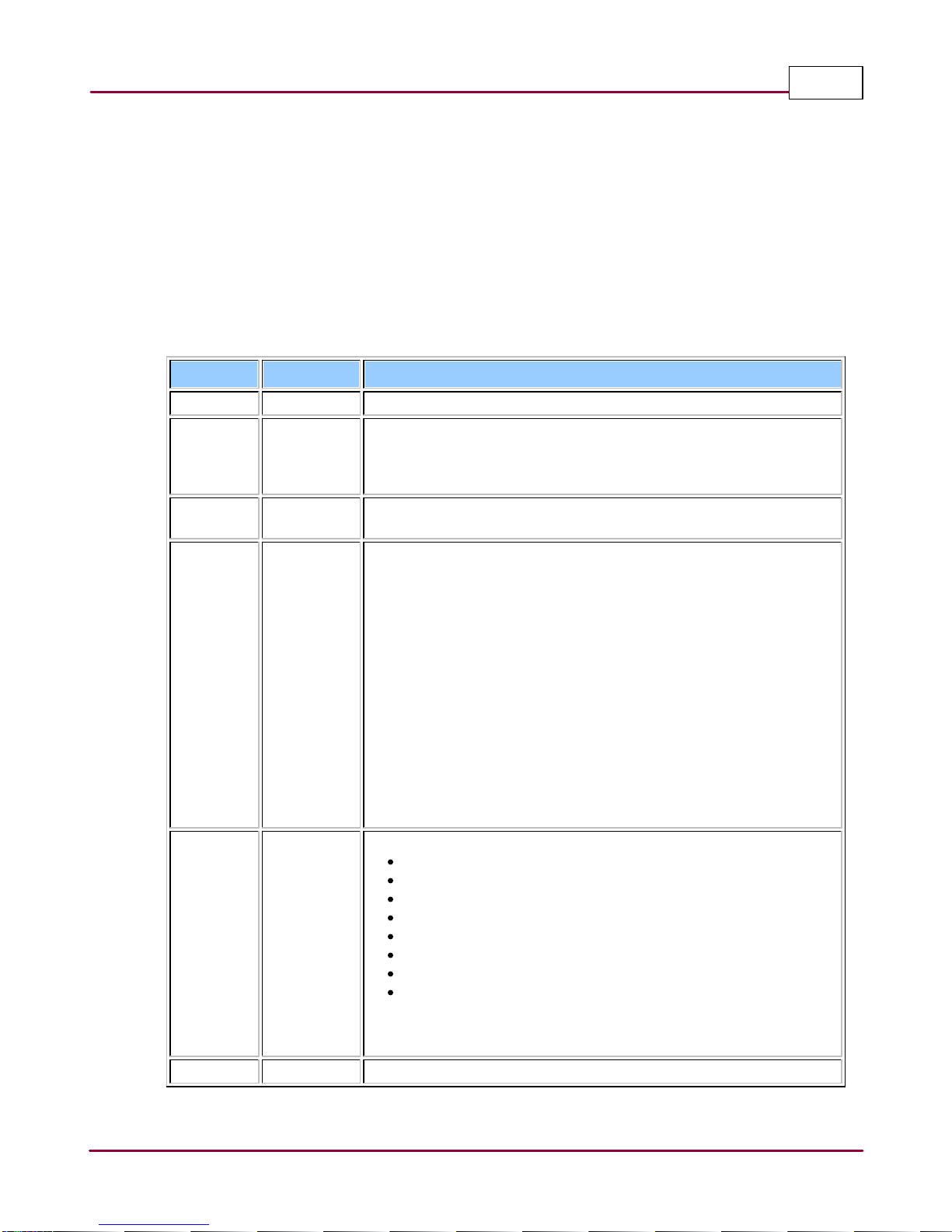

FEATURES

2500

2500 RTD

2500 SEL

Color Touch Screen Display

The icon driven user interface lowers overall

cost by reducing training time and user

errors while maximizing productivity and

command of the dissolution test.

YES

YES

YES

Electronic Qualification Guidance

Electronic qualification alerts eliminate

oversights and ensures maximum up time

and instrument availability.

YES

YES

YES

Quick Change Paddles and Baskets

Interchangeable stirring elements coupled

with the automatic height adjustment

provide a fast transition between Apparatus

1 and 2 without having to remove the shaft.

YES

YES

YES

Serialized Component Tracking

Track all serialized components including;

paddles, baskets, basket adapters, shafts

and vessels.

YES

YES

YES

Wireless In-Shaft Temperature Sensors

Patent Pending wireless temperature

sensors control and monitor the

temperature without the use of a wired

sensor.

NO

YES

YES

Patented Bathless Technology

Eliminates the water bath and all associated

maintenance while heater jackets raise

media temperatures from ambient to 37°C in

less than 15 minutes with a high

temperature capability of up to 99°C.

NO

NO

YES

Self-Priming Thermocirculator

The self-priming design and microprocessor

control allow for improved temperature

uniformity and heating time while the low

profile design allows the circulator to be

stowed behind the bath, requiring

no additional linear bench space.

YES

YES

NO

IntroductionModel 2500 10

© 2015-2017 Distek, Inc. All Rights Reserved

Volume Flexibility

Accommodates up to 8 vessels ranging in

size from 100mL to 4L, allowing the user to

run a diverse range of tests.

YES

NO

NO

W orks w ith D istek line of D issolution equipment a nd softw are.

The instrument is compatible with the following equipment/software:

Eclipse 5300

EVO 4300 with Firmware Revision 3.01 or higher

Cipher Software

Distek Dosage Delivery System

Agilent UV-Vis 8453/8454 On-Line up to 4 baths

Waters HPLC instruments

IntroductionModel 2500 11

© 2015-2017 Distek, Inc. All Rights Reserved

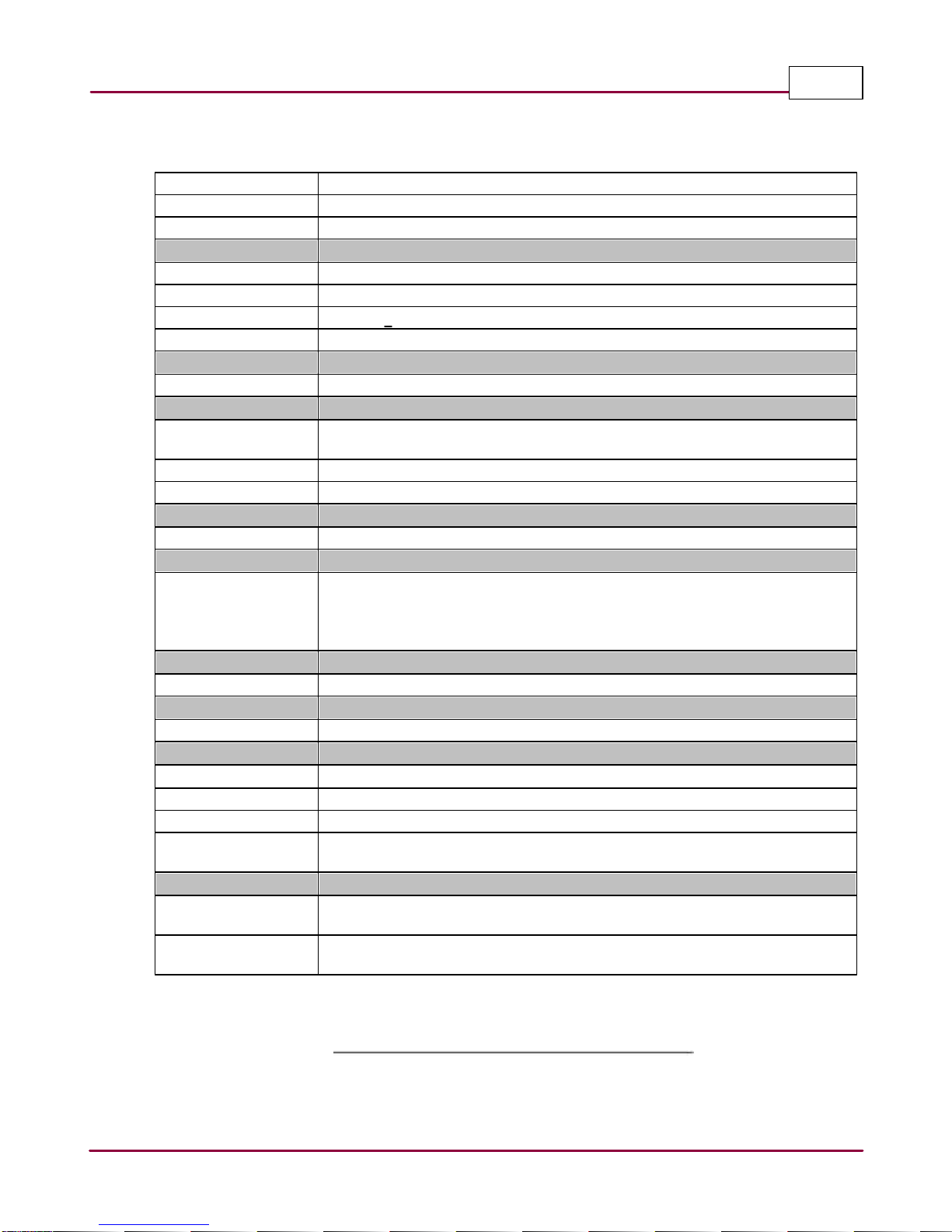

1.2 Instrument Specification

Dissolution Vessels

Six Vessels Standard (7 or 8 Optional)

Volume

500 - 1000 mL Standard (100 - 4000 mL Optional)

Bath Heating Rate

Approx. 2.0°C per minute

RPM Control Range

25-300 RPM

Resolution

0.1 RPM

Accuracy

±1.0 RPM <100 RPM and ±1.0% RPM >100 RPM

Motor

DC Motor

Display Screen

5.7 inch LCD Color Screen

Bath Temperature

Control

20 - 65°C *

Display Resolution

0.1 °C

Accuracy

±0.25 °C

Shaft Wobble

Less than 0.010” (0.254mm) Total Indicator Runout

Program Modes

oManual

oAutomatic (100 maximum saved Pre-Programmed Methods)

oDistek EVO 4300, Distek OPT-DISS 405 UV, Agilent UV-Vis 8453, Waters 2695D

HPLC

User Management

Manage up to 50 Users with Multiple Access Level

Interface Ports

1 RS-232, 1 RS-485, 1 USB, 1 LAN

Dimensions

Model 2500

27.5”(W) x 38.5”(H) x 19.5”(D) (69.9cm x 97.8cm x 49.5cm)

TCS-0500

11.5"(W) x 8.5”(H) x 7”(D) (29.2cm x 21.6cm x 17.8cm)

Weight

80 lbs. (36.3 kg) Dissolution Unit

7 lbs. (3.2 kg) TCS-0500

Batteries (option for

2500 Wireless)

AA Lithium 3.6 volts

Electrical Power

Voltage pre-set at factory (115V ± 15V 50/60Hz @ 10.0A

or

230V ± 15V 50/60Hz @

6.0A )

* 2500 Select as an option can go as high as 99°C

IntroductionModel 2500 12

© 2015-2017 Distek, Inc. All Rights Reserved

1.3 Notices

© Distek, Inc. 2015-2017

No part of this document may be reproduced in any form or by any means without written

consent from Distek Inc., as governed by United States and/or International copyright laws.

Manual Part Number

3825-0001

Document Revision History

Revision

Date

Comments

A

08 Jan 2012

Initial document created.

B

Feb 2012

Changes with the following items:

1. Electrical power requirements

2. Added step to lower drive head

3. Added functionality: back light, touch tone and tablet dropper

C

05 Oct 2012

Waters HPLC serial controls were updated.

Update RPM accuracy specification.

D

08 April 2014

Changes with the following items:

1. Manual Run > In 'Note' added feature to change RPM during test

2. Create a New Method > Added method parameter for Infinity Sampling

3. Method Run > In 'Note' added Lot and Batch identification entry for

operator at beginning of test

4. Selecting a Method > Added command button for importing and

exporting methods

5. Report Summary > In 'Note' added feature for exporting reports

6. User Setup > Change user access permission for System Setup and

Instrument Validation

7. System Setup > Added feature parameter for changing user interface

language

8. Advanced > In 'Note' added feature when External Control is set for

Waters to display a vial icon

9. Advanced Setup > Update the parameters: IP Address, Subnet Mask and

Default Gateway

E

May 2015

1. Update the following items to include 2500RTD as an option:

Instrument Overview

Instrument Specification

Notices

Installation of RTD shaft

Added 2500RTD Dashboard section

Update Create Method section

Update System Settings section

Added Battery Monitor section

2. Update LCD calibration login screen feature

3. Update Report screen functions

4. Update Appendix A

F

Jun 2017

Update to include 2500SEL

IntroductionModel 2500 13

© 2015-2017 Distek, Inc. All Rights Reserved

Warranty

The Material in this document is provided "as is", and is subject to changes without notice in

future revisions.

Distek disclaims all warranties, either express or implied, with regard to this manual and any

information contained herein, including but not limited to the implied warranties of

merchantability and fitness for a particular purpose.

Distek shall not be liable for errors or for incidental or consequential damages in connection

with the furnishing, use, or performance of this document or of any information contained

herein.

IntroductionModel 2500 14

© 2015-2017 Distek, Inc. All Rights Reserved

1.4 Safety Information

The following general safety precautions must be observed during all phases of operation, repair

and service of this instrument. Failure to comply with these precautions or warnings elsewhere

in this manual violates the safety standard of the design, manufacture and intended use of this

instrument. Distek Inc. assumes no liability for the customer or end-user to comply with these

requirements.

Operation

Before applying power, make sure the instrument complies with the installation requirements.

Additionally, the following must be observed:

Do not remove instrument covers when operating.

Instrument must be connected to a protective earth ground socket. Any interruption of the

protective earth grounding will cause a potential shock hazard that could result in serious

personal injury.

Make sure that only fuses with the required current rating and of the specified type are used

for replacement.

Any service should be only carried out by a skilled person who is aware of the hazard involved

and properly trained in the service and repair of the instrument.

Do not replace any components with power cable connected.

Do not operate the instrument in the presence of flammable gases or fumes.

Do not install substitute parts or make any unauthorized modification to the instrument.

Safety Symbols

SYMBOL

Description

WARNING: This symbol denotes a hazard. It calls attention to the

operating procedures and safety practices to prevent injury to personnel.

HIGH VOLTAGE: This symbol denotes the presence of high voltage.

CAUTION: This symbol denotes a hazard. It calls attention to the

operating procedures and safety practices to prevent damage to

equipment.

NOTES: This symbol denotes helpful information.

IntroductionModel 2500 15

© 2015-2017 Distek, Inc. All Rights Reserved

1.5 Site Requirements

Physical Site Consideration

Electrical Requirements

This chapter contains information regarding the recommended minimum available bench space,

electrical requirements and environmental conditions when installing your instrument.

IntroductionModel 2500 16

© 2015-2017 Distek, Inc. All Rights Reserved

1.5.1 Physical Site Consideration

The dimensional requirements specified below are adequate for the installation of the Model 2500

Dissolution System:

1 The minimum bench depth needed (front edge of bench to the back splash or wall) is 22

inches (56cm). However, the minimum recommended bench depth is 25 inches (64cm) for

proper ventilation.

2 The minimum linear bench space requirement is 28 inches (71cm). Distek recommends

that at least 33 inches (84cm) be allocated whenever manual operations are required to be

performed adjacent to the system.

3 There must be no obstruction (cabinet, shelf, or outlet) that intrudes into the minimum

footprint of the unit up to a height of 39 inches (99cm) above the bench surface where the

unit is to be installed.

4 The bench must be capable of sustaining the weight of the unit and all of its accessory

parts without significant bending. Because the entire mass of the unit is transferred to the

bench surface through four (4) circular padded, adjustable leveling feet, the bench surface

should be strong enough to withstand a load of 60 pounds per square inch (4 kilograms per

square centimeter).

5 Because of the limitation in travel of the leveling feet, the bench slope should be less than

0.75” (1.9cm) from front to back or from side to side over the unit’s foot print.

IntroductionModel 2500 17

© 2015-2017 Distek, Inc. All Rights Reserved

1.5.2 Electrical Requirements

Your instrument can operate on line voltage of 115V ± 15V 50/60Hz or

230V ± 15V 50/60Hz . Since

the instrument is pre-configured for either 115 VAC or 230 VAC, there is no voltage selector and

no external accessible fuses to replace. Refer to Instrument Specification regarding the current

rating depending on the number of modules or positions of the instrument.

To disconnect the instrument from the line, pull out the power cord. The power supply still

stores some power, even if the power switch is turned off or the power cable is unplugged.

Other accessories, such as printers, accept nominal line voltage of 115 or 230 VAC at 50 or 60 Hertz.

For more information, see the documentation that came with your accessories.

Do not connect your instrument to a line voltage that is higher than the specified voltage.

Shock hazard or damage to your instrument can occur.

Power cords are offered in different configurations depending on the particular country or region

of intended use. For all cables, the female end of the supplied power cord is identical and it

plugs into the power inlet socket located on the right side of the instrument. The male end of

each supplied power cord is different and designed to match the wall outlet of the intended

country or region of use.

Always use the power cord supplied with your instrument. Always plug in your instrument

with a properly grounded wall outlet.

IntroductionModel 2500 18

© 2015-2017 Distek, Inc. All Rights Reserved

1.6 Environmental Conditions

Ambient Laboratory Humidity

Ambient Laboratory Temperature

Air Quality Considerations

Environmental Considerations

This chapter contains information regarding the recommended laboratory conditions such as

humidity, room temperature and air quality when installing your instrument. It also contains

information regarding environmental considerations when disposing of the instrument.

IntroductionModel 2500 19

© 2015-2017 Distek, Inc. All Rights Reserved

1.6.1 Ambient Laboratory Humidity

Distek recommends that the laboratory humidity control system fans be kept on at all times, if

possible.

Maximum:

The Model 2500 Series may add to the humidity of the laboratory during operation. Any vessels

filled and left uncovered can raise humidity levels. Water vapor and/or hydrogen chloride vapor

from dissolution media can cause serious effects when condensed on electrical components and

contacts. The lab’s environmental controls should maintain the humidity level below the dew

point (70%) to minimize the risk of condensation.

Minimum:

The Model 2500 Series utilizes solid-state semiconductor devices. It is important that the

humidity level be kept at or above 25% relative humidity, to minimize the risk of damage to

control circuits caused by static discharge.

IntroductionModel 2500 20

© 2015-2017 Distek, Inc. All Rights Reserved

1.6.2 Ambient Laboratory Temperature

Distek recommends that the laboratory temperature control system be kept on at all times.

Maximum Conditions:

To achieve the full range of controlled operation (20 to 65°C) within specified tolerances, the

Model 2500 Series Dissolution System is designed to be installed and operated in laboratories

where the maximum operating temperature does not exceed 25°C. The maximum allowable

ambient operation temperature is 30°C.

Operating environments above 25°C limit the range for satisfactory operation of the system to

between 20°C and 65°C.

Minimum Conditions:

To assure controlled operation within specified tolerances, the Model 2500 Series is designed to

be operated in laboratories where minimum operating temperatures do not drop below 20°C.

Variability or Short Term Fluctuations:

To assure controlled operation within specified tolerances, the system used to control the

temperature of the laboratory where the Model 2500 Series Dissolution System is installed must

be able to maintain the ambient air temperature within ±2.5°C of set point (worst case).

Thermal Loading:

Each unit contributes an average thermal load of about 0.6 kW when operating. The lab’s cooling

systems must have sufficient excess cooling capacity to handle the aggregate thermal load for all

systems installed. The heating system must also be able to respond to the increased loading from

the units by appropriately throttling back.

For laboratories where temperature control is critical, installation of several dissolution units

may require that the system be re-balanced. Thermostats may need to be relocated to

maintain temperature uniformity inside the laboratory.

Other manuals for 2500 Select

2

This manual suits for next models

2

Table of contents

Other Distek Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Ellab

Ellab TrackSense LyoPro user manual

INTEGRA Biosciences

INTEGRA Biosciences VIAFLO 96 quick start guide

Agilent Technologies

Agilent Technologies PlateLoc user guide

Azure Biosystems

Azure Biosystems Azure Cielo Dx AIQ314 user manual

cytiva

cytiva OligoPilot 400 operating instructions

Pacific Sun

Pacific Sun Kore 7th user manual