3

3

This manual does not constitute a formal agreement.

ll information given in this manual is subject to

change without notice.

The KOSMOS SERIES brings a new philosophy in digital panel

instrumentation which is expressed by multipurpose,

modular-concept devices providing a rich array of basic

functions and advanced capabilities.

With a fully MODULAR DESIGN, it is possible to implement a

wide variety of applications by only adding the adequate

options.

Intelligence within it allows the instrument to recognize the

options installed and ask for the necessary parameters to

properly function within desired margins. The parameters

related to non-installed options are removed from the

program routines.

The instrument’s CALIBRATION is made at the factory

eliminating the need for adjustment potentiometers.

Any circuit or option liable to be adjusted incorporates a

memory where calibration parameters are stored, making it

possible the optional cards be totally interchangeable without

need of any subsequent adjust.

INTRODUCTION TO THE KOSMOS SERIES

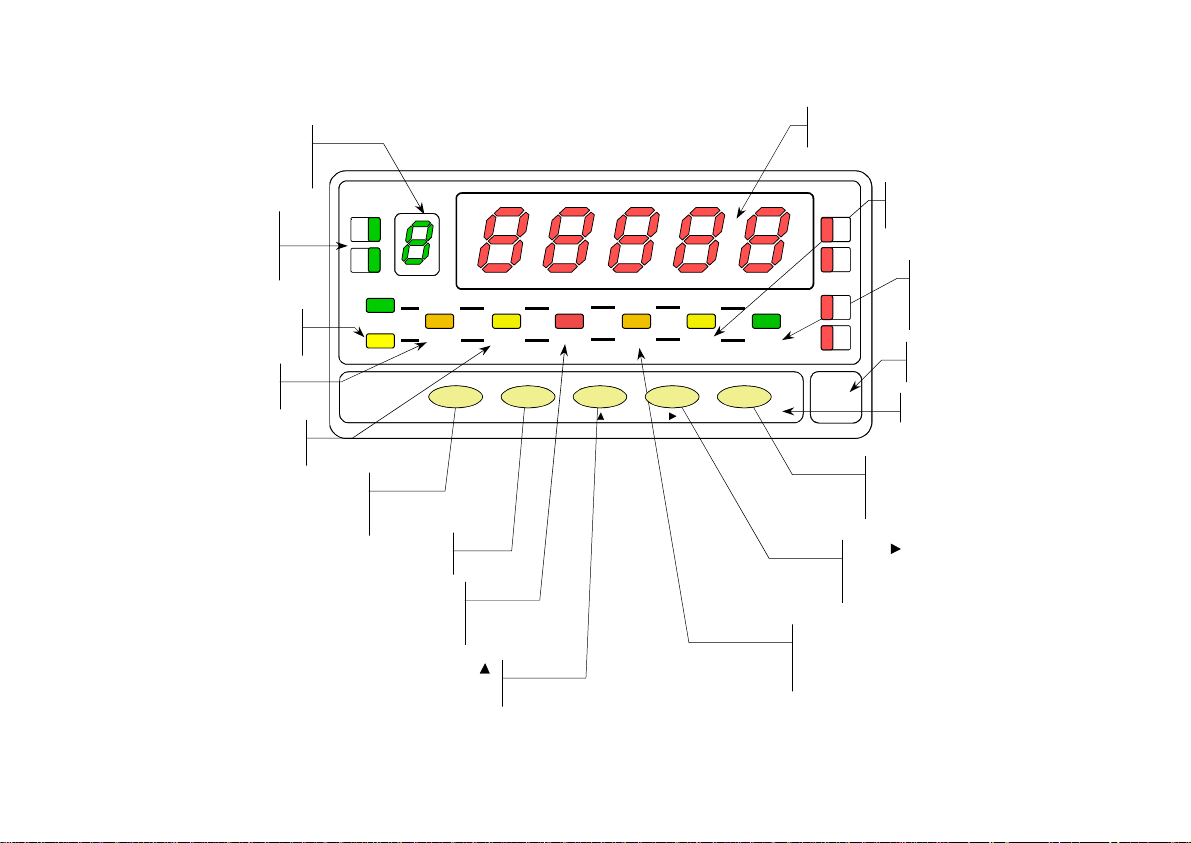

Custom CONFIGURATION for specific applications can be

made quickly and easily through five front panel keys,

following structured choice menus aided by display prompts

at each programming step.

Other features of the KOSMOS family include:

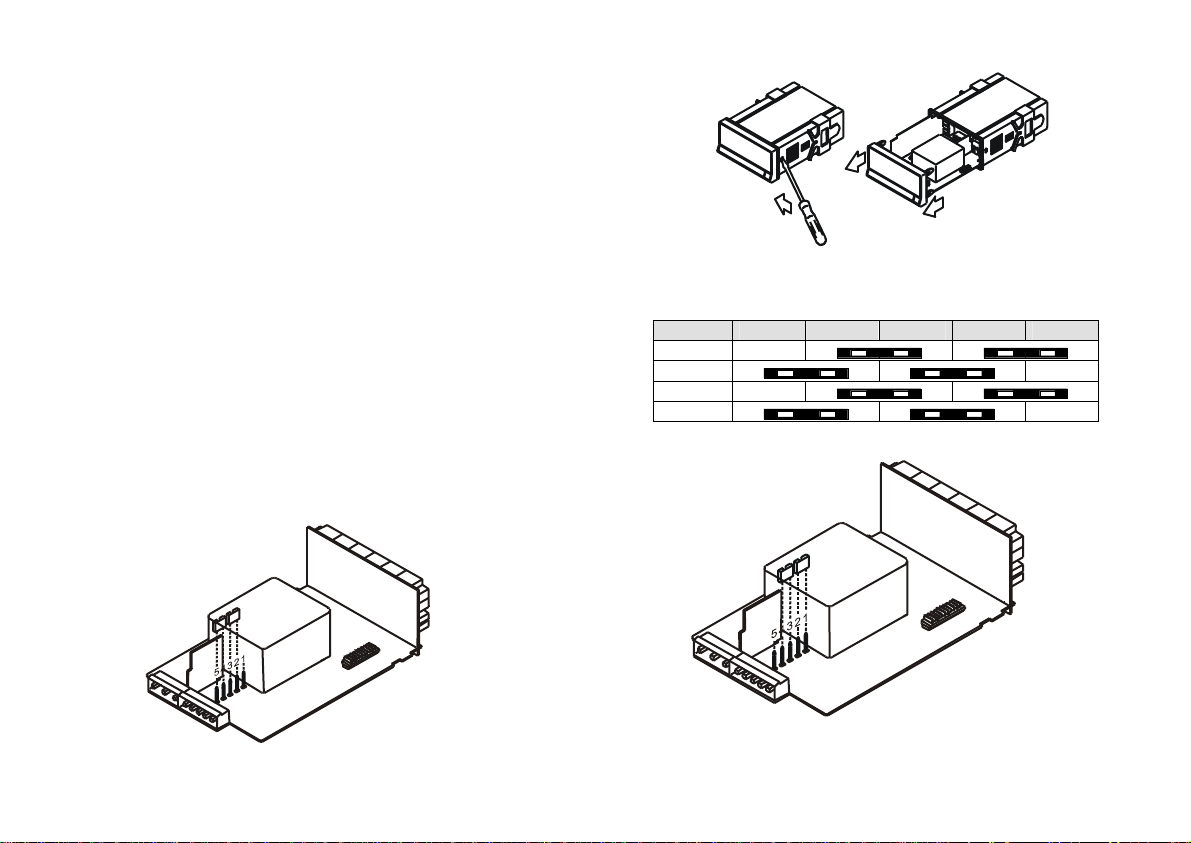

•CONNECTIONS via plug-in terminal blocks without

screws and CLEMP-WAGO clips cable retention system

•DIMENSIONS

Models ALPHA & BETA 96x48x120 mm DIN 43700

Models MICRA & JR/JR20 96x48x60 mm DIN 43700

•CASE MATERIAL UL-94 V0-rated polycarbonate.

•PANEL INSTALLATION without screws by means of

single part fastening clips

To guarantee the meter's technical specifications, it is

recommended to recalibrate the meter at periodical intervals

according to the ISO9000 standards for the particular

application operating criteria. Calibration should be performed

at the factory or in a qualified laboratory.

This manual does not constitute a formal agreement.

ll information given in this manual is subject to

change without notice.

The KOSMOS SERIES brings a new philosophy in digital panel

instrumentation which is expressed by multipurpose,

modular-concept devices providing a rich array of basic

functions and advanced capabilities.

With a fully MODULAR DESIGN, it is possible to implement a

wide variety of applications by only adding the adequate

options.

Intelligence within it allows the instrument to recognize the

options installed and ask for the necessary parameters to

properly function within desired margins. The parameters

related to non-installed options are removed from the

program routines.

The instrument’s CALIBRATION is made at the factory

eliminating the need for adjustment potentiometers.

Any circuit or option liable to be adjusted incorporates a

memory where calibration parameters are stored, making it

possible the optional cards be totally interchangeable without

need of any subsequent adjust.

INTRODUCTION TO THE KOSMOS SERIES

Custom CONFIGURATION for specific applications can be

made quickly and easily through five front panel keys,

following structured choice menus aided by display prompts

at each programming step.

Other features of the KOSMOS family include:

•CONNECTIONS via plug-in terminal blocks without

screws and CLEMP-WAGO clips cable retention system

•DIMENSIONS

Models ALPHA & BETA 96x48x120 mm DIN 43700

Models MICRA & JR/JR20 96x48x60 mm DIN 43700

•CASE MATERIAL UL-94 V0-rated polycarbonate.

•PANEL INSTALLATION without screws by means of

single part fastening clips

To guarantee the meter's technical specifications, it is

recommended to recalibrate the meter at periodical intervals

according to the ISO9000 standards for the particular

application operating criteria. Calibration should be performed

at the factory or in a qualified laboratory.