Dive Gear Express DGX Xtra First Stage User manual

DGX Gears XTRA Regulator

Service Manual

DGX Xtra First Stage

Copyright © 2020 Dive Gear Express

Author/Photographer – UDM Consulting

All rights reserved.

Revision 5d Published 8/17/2020

1.Overview

(1) The availability of subassemblies and components, repair parts, specialized tools, and maintenance

manualsdoesnotimplyqualificationtoassembleand/orservicescubaequipment.Improperserviceofdive

equipmentcanleadtosevereinjuryordeath.DiveGearExpressrecommendsthatnonqualifiedindividuals

seekprofessionaltraining/mentoringbeforeattemptingrepairsorservicingonanydivingequipment

Failuretofollowtheproceduresoutlinedhereinmayresultininjuryordeath!

(2)Inthefollowingpageswillbefound,thedisassembly,assembly,tuning,andtroubleshootingstepsfor

thesecomponents.Photosareusedthroughouttoillustratetheprocedures.

Pleasepayspecialattentiontoallcautionnotes!

(3)Wheneveranitemofextraimportanceneedstobeobserved,a“CautionNote:”willappear,followedby

therequiredinformation.Seebelow.

CautionNote:Thismustbereadandfollowed!

(4) Included in this manual is a list of recommended/required tools for each disassembly, assembly, and

testingsection.Theyareidentifiedineachsectionwheretheyareused.

(5) Schematics are located inthe rear of this manual. The drawings containthe detailed parts lists. The

drawingsalsoincludethetorquespecificationsforpartswhererequired.

(6)Ageneraltroubleshootingguidewithspacefornotesisalsoincludedforthoseusingaprintedversion.

Thosewhopreferanelectronicversionshouldkeepdetailednotesinanaccessiblelocationfortheirown

observationsandservicetips,aswellasarecordofservice.

(7)Throughoutthetext,partsarereferencedusingtheitemnumberontheschematictofacilitatelocating

eachindividualcomponent

(8)Photographsofthepartskitsareshowntoillustratethateachcomponentisindividuallybagged.Parts

shouldnotbetakenoutoftheirpackaginguntiltheactualassemblystageisreached,andtheuserisready

tolubricate,wherenecessary,andinstallthem.

(9) Ensure the service area is free of any environmental concerns that may cause problems during the

servicing of your regulators. The area must be clean and organized. The use of nitrile gloves is highly

recommendedforthefinalrinsingandassemblystages.Thiswillminimizetheriskofskinoils,contaminating

theinternalcomponentsoftheregulator.

(10)Ensurethatallrequiredservicing/testingairsuppliesareavailableandatthepropertestpressures,if

not using a regulated supply from a single source. This would include the use of cylinders of compressed

breathing air from an OCA grade source if you wish to maintain the oxygenclean status of the unit.

CautionNote:Onlyuseairfromabreathingairsource!

CleaningandRinsingGeneralConsiderations

(11)Cleaningandrinsingofthecomponentsshouldbedoneusingclean,freshwater.Ifavailable,distilled

waterisrecommendedtomaintainoxygencleanliness.

(12) Only use degreasers that leave no organic residue (clear Simple Green, dyefree Dawn dishwashing

liquid,orBlueGoldCleanerasexamples).

(13)Todealwithcorrosion,usea50/50vinegarwatersolutionandnylonbrushes.

(14)Allowpartstoairdrywithouttheuseofclothsthatmayleavefibers.Forregulatorsthataregoingtobe

used with Oxygen percentages above 40%, a UV light is strongly recommended to check for organic

contamination.

(15)Onceallserviceprocedureshavebeencompletedandbenchtestingdone,inwatertestinginaconfined

environment such as a swimming pool is recommended to confirm proper function before taking the

regulatoronanactualdive.

CleaningofRegulatorParts

(16)CleaningCleaningofthepartsthataregoingtobereusedisoneofthemostcriticalstepsinservicing

theregulator.Aswasstatedearlier,usethepropersolutionsforthejobathand.Vinegarandwaterarenot

asusefulforremovinglubricatinggreaseasoneofthedetergentsthatwerenoted.Bythesametoken,

thosedetergentsarenotasefficientasthevinegar/watermixindealingwithcorrosivebuildup.

(17)Therefore,whereyouhaveabuildupofcorrosion,youmayalsohavelubricantonthesurfaceofthe

part.Beforedealingwiththecorrosion,usehotsoapywaterandasoftbrushtoremovethelubricant.Then

usetheacidicsolutiontodealwiththecorrosion.

(18)Oncethecorrosionhasbeendealtwith,washthepartsusingafreshsoapandwatersolutionwhile

wearingnitrileglovestoreducetheriskofcontaminatingthepartswithskinoils.Rinsethepartswithclean

runningwater,distilledispreferred,thatisallowedtodrainfreely.Aplasticpastacolanderavailableatany

storeisexcellentforthis.Forverysmallparts,ameshstrainerforsinkdrainsworkswell.Oftensoldasa

set,theyareinexpensiveandcanbeusedformanytypesofregulatorcomponents.Seethephotographsof

eachinthetoolsection.

(19)Afterwashingandrinsingtheregulatorparts,allowthemtoairdry.Usingadryingrackwillaidinthis,

aswellashavingtheairintheroomcirculating.Donotlaythepartsonapaperorclothtowel.Doingsoruns

theriskofhavingfiberssticktothemthatwillcauseissueswithsealing.Inadditiontothis,fiberscanbea

hazardwhenusingtheregulatorwithhighoxygencontentmixes.

(20)Oncethepartshavedriedcompletely,laythemoutinorderofassemblyonthepadusedonthework

surface.Makingsurethatithasbeencleanedandisfreeofcontaminants.Arubberorsiliconematofsuitable

sizeworkswellforthis.Youcanalsousesmallcleancontainerstokeepthepartsorganized.Oncetheparts

have beencleanedand dried,theyneed to beinspected beforestarting theassemblyprocess.Thisis to

ensure that no damage or defects exist that were hidden by corrosion, residual lubrication, or other

contaminantsthathavenowbeenremoved.

InspectionAfterCleaning

(21)Beforeassemblingtheregulator,itisnecessaryto inspectallofthecleaned components. Usingthe

magnifyingglass,checkthecomponentsfordamagethatmayhavebeenhiddenbycorrosionorlubricant.

Lookforscratchesthatmayaffectthesealingoftheregulator.Inadarkenedroom,usetheUVlighttolook

fororganicmaterial.Ifanyarepresent,recleanthepart!Thisiscriticalforusewithoxygenpercentages

above50%!

(22)Anotherwaytocheckforresiduallubricantsistofillatraywithclean,fresh,waterdeepenoughtocover

thepartsbyaninchorso.Laythecomponentsinandcirculatethewater.Allowthepiecestosoakforseveral

minutes.Onceithassettled,lookforarainbowsheenonthesurfaceofthewater.Anyresiduallubricants

willfloatandforma“slick”onthesurface.Ifoneispresent,thepartsmustbecleanedagain.

(23)Nowthatallpartshavebeencleanedandchecked,theassemblycanbegin.Makesurealloldpartsthat

aretobereplacedhavebeendiscardedorsegregated.Removethenewpartsfromtheservicekitbagand

laythemoutintheordertheywillbeused.Donottakethenewpartsoutofthebagsyet!

CautionNote:

Removingpartsfromtheirindividualbags,beforetheyaretobeused,runstheriskof

mixingthemup.Someoringsareverycloseinsizebutarenotinterchangeable!Keep

thepartsinthebagsuntilyouactuallyneedthem.

(24)Aswiththepartsthathavebeencleaned,itisagoodideatoinspectthenewpartsaswell.Especially

theHPseat.Makesureitisfreeofanydefects.Checkalloftheoringsandinspectthemasyouusethemfor

nicksorotherconcerns.Inspectthewasherstoensuretheyarefreeofexcessburrsorotherconcernsthat

couldaffecttheirfunction.Itisalsoagoodideatousethepartslistontheschematictoensurethatallofthe

newpartsthatareneededarepresentandaccountedforintheirrequiredquantities.

(25)LubricationofOrings;Lubricationcanbeoverdone.Doingsorunstheriskoftrappingexcessdirtor

debrisontheparts.Onewayofreducingtheriskofoverdoingitistousethelubeinabagmethod.This

involvesusingasmallcleanplasticbagandputtingasmallamountoflubeinit.Thentheoringisinserted

intothebag,workedaround,excesssqueezedoff,andtakenoutofthebag,andusedinitslocation.

Fig.1Fig.2.

(26)AnotherwayistoapplyasmallamountofTribolubetotheglovedindexfingerandmassagetheoring

betweenthethumbandindexfinger.Eitherwayworks,butthebagmethodtendstogivebetterdistribution

resultsanduseslesslubricant.

(27)Undermostcircumstances,alubricantisusedcorrectlyverysparinglyornotatall.Innearlyallscuba

applications, ifyoucan see thelubricant, you’ve usedtoomuch. Before using any lubricant, any existing

lubricationshouldberemovedbeforenewisapplied.Indynamicapplications,itisusedtoreduceexcessive

wear.Staticoringsdonotgenerallyrequiretheuseoflubricant.

(28)Wherepartsarenotnecessarytobelubricated,itisgoodpracticetoavoidgettinganylubricantonthem.

PrimarilywhentheregulatorisusedwithhighO2contentmixes.Italsohelpstokeepthosepartscleanand

freeofdebristhatwillclingtothelubricant.

Thenextsectionliststhetoolsyouwillneedtoservicetheregulator.

2.TOOLLIST

(1) The tool list has been divided into two sections. Required and Recommended. Required tools are

necessaryforservicingtheregulator.Recommendedarethoseitemsthatmakeservicingeasierormore

efficientaswellaslesseningthechanceofdamage.

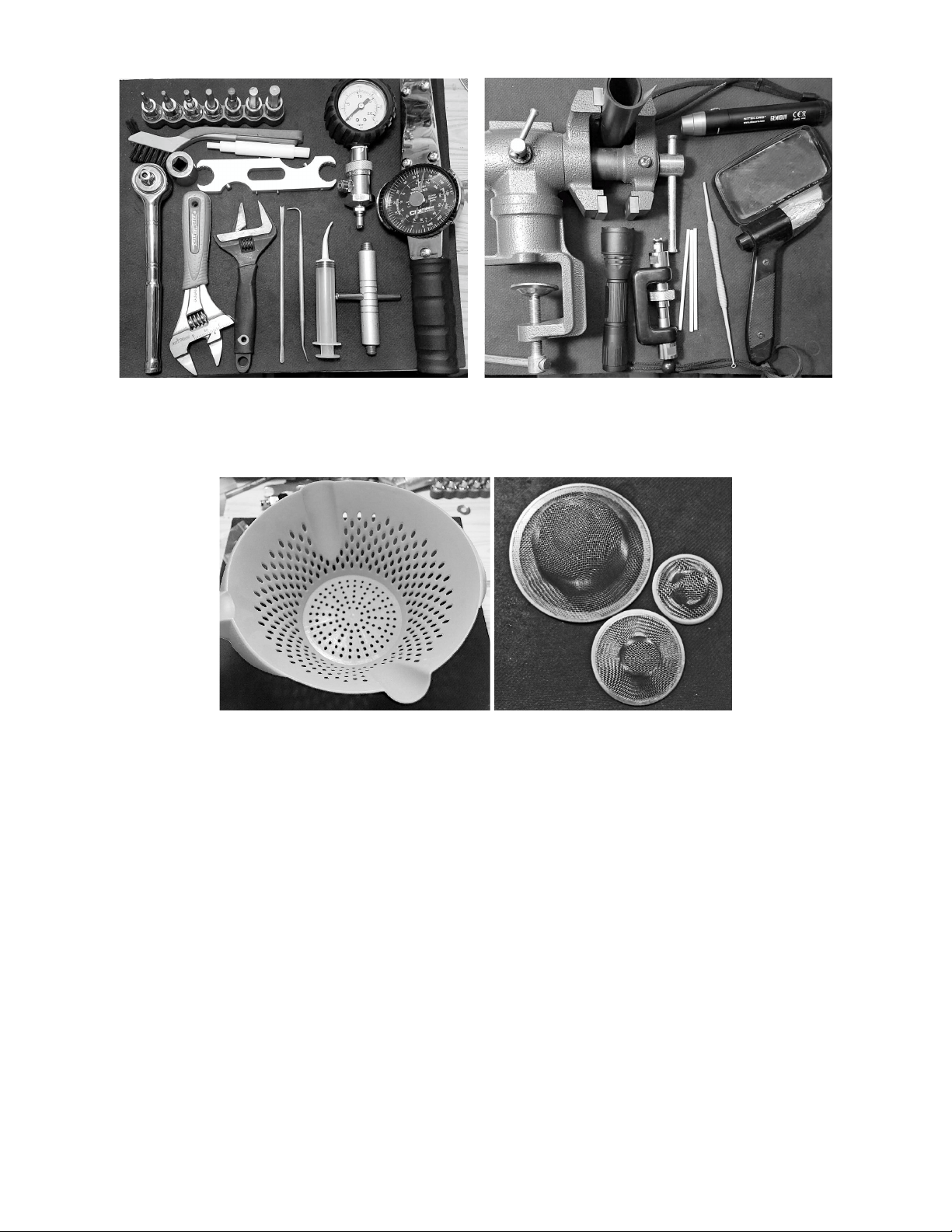

Requiredtools

1. AdjustableTorqueWrench3/8drive0300inchpoundsrange

2. PistonStemBushingAssemblyTool–ScubaToolspartnumber20150200

3. ScubaMultiTool–ScubaToolspartnumber20100200

4. 1stStageHandleforHPandLPports

5. 3/4inch3/8thdrivesocket

6. 6mm3/8inchdriveHexHeadmalesocket

7. 5mm3/8drivehexsocket

8. 4mm3/8drivehexsocket

9. 2AdjustableWrenches

10. BrassPicksforremovingorings

11. IntermediatePressureGauge

12. Tribolube71

13. SoftBristleCleaningBrushes(Nylon)

Recommendedtools

1.Inlinesecondstageadjustmenttoolwithslottedorificeselected

2.Softjawedvise

3.Woodenorplasticdowels1/8–3/16diameter

4.SoftRubberPad

5.MagnifyingGlass

6.Flashlight

7.UVlight

(2)Whereapartnumberisnoted,ScubaToolsisthesourceofthatitem.Theyalsohavesomeoftheother

toolsnotedbutarenottheonlysupplierofthem.

ScubaTools

www.scubatools.com

Phone:3366432599

(3)YoucanalsopurchasetoolsfromDiveGearExpress.The1ststagehandle,InLineAdjustingToolwithIP

gauge,PinSpanner,BrassPicks,andtheIPGaugethatisshownthatplugsintotheLPinflatorhosecanbe

foundatthelinkbelow.

https://www.divegearexpress.com/tools/scubatools

Phone:9549776009

Fig.3Fig.4

RequiredToolsRecommendedTools

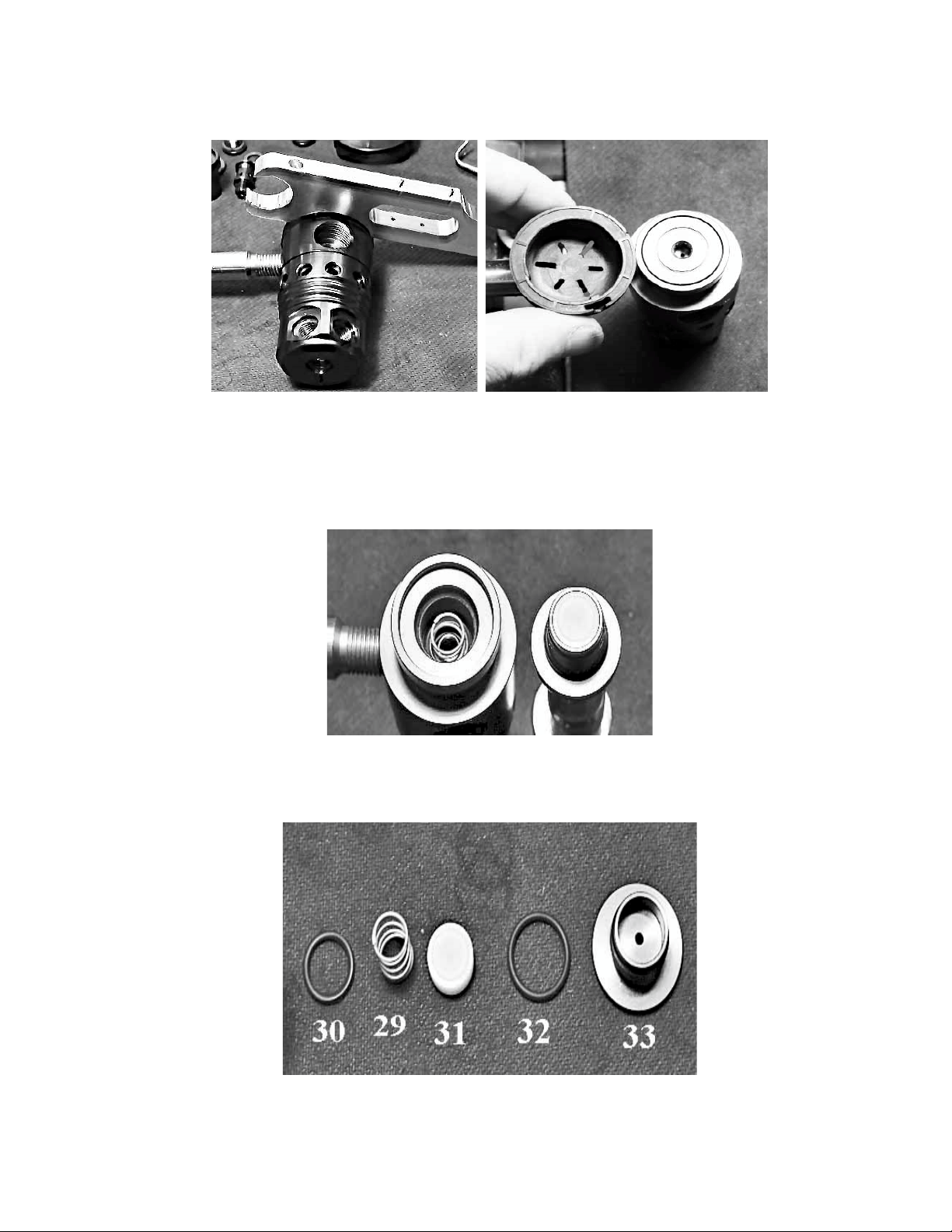

Fig.5Fig.6

ColanderStrainers

3.PreliminaryTesting

(1)Preliminarytestingoftheregulatorisnecessarytoidentifyanyissueswiththefirstandsecondstagesand

verifytheoverallregulatorfunction.Thistestingwillinclude:

1. Visualinspectionofthefirstandsecondstages

2. Inspectionofthehoses

3. IntermediatePressurecheck

4. CrackingPressureandSecondStageNegativePressureTest

Visual inspectionisdonetoidentifyissuesthatcouldaffectservicingandtoensurethat pressurizingthe

systemwillnotcompromisethesafetyoftheservicetechnician.

Thetechnicianwillcheckallconnectionstomakesuretheyaresecure.

Thetechnicianwillcheckthatonthefirststage,therearenoextrudedorings,andhosesaretight.

ThetechnicianwillchecktherearenodefectstotheSPG.

ThetechnicianwillensurethattheDINassemblyissecure,andtheOringisintactandabletoformaseal.

Thetechnicianwillinspectthefilterforsignsofdiscoloration.

DetailedInspectionofHosesisdonetoensureitissafetopressurizetheregulatorset.

Thetechnicianwillcheckallhoses,lookingforevidenceofpossiblefailure.

Thetechnicianwillcheckallhoseconnectioncrimps.Defectsmustbetakencareofbeforepressurizingthe

system!Replacementofanysuspecthosesisrecommended.

CautionNote:

Defectsinhosesrequirereplacementbeforepressurizingtheregulator!Failuretodoso

mayresultinseriousinjuryordeath!

(2)DetailedVisualInspectionoftheSPGandconnection–ThetechnicianwillchecktheSPGforanysigns

ofcrackingof theface, waterintrusion,and corrosionaround theSPG to thehose connection.Ifusing a

consoleorboot,itisnecessarytoremovetheSPGfromtherubberboot.Oncethisisdone,theHPspool

shouldbeinspectedand,ifnecessary,replaced.

(3)CheckingofIntermediatePressure(IP)–TheIntermediatePressure(IP)ofthesystemshouldbetested

only after the preceding checks have been done to ensure technician safety. Checking of intermediate

pressureisdonebyattachinganintermediatepressuregaugetotheLPpressureinflatorhose.Thesystemis

thenpressurizedwhilepartiallydepressingthepurgebuttonononeofthesecondstages.Depressingthe

purgebuttonslightlyonthesecondstageisdonetopreventfurtherdamagetothesystembyprovidinga

reliefvalveshouldtheIPriserapidlytounsafelevels.Oncethesystemhasbeenpressurized,thepurgeis

released,andtheIPchecked.

CautionNote:

Ifthesecondstageisleakingevenslightly,IPwillbeaffected.Ifthesecondstageis

leaking,turntheadjustmentknobtostopitoruseasecondstagethatisnotleaking

throughwhenpairedwiththefirststage.

(4)ThestandardoperatingrangeforthesystemiswithanIPof135PSI.Ideally,thesystemisoperatingat

135PSI+/5PSIandshownosignsof“creep”orinstabilityat3000PSI.

CautionNote:

“Creep”willshowastheIPsteadilyincreasingwhiletheregulatorisnotinuse.Normally

theIPwilldrop510PSIduringabreathorpurgeandthenreturntoitssetting.Itshould

notreturntothesettingandkeepincreasing.Thiswouldindicateaproblemwiththe

highpressureseat,Piston,orsealingorings.

(5)IfthesystemshowsnosignofcreeporIPinstability,itisgenerallynotnecessarytorebuildthe1ststage

withsomeexceptions.

CautionNote:

Iftheunitshowssignsofinternalcorrosionorthefiltershowsevidenceofcontamination,

theunitmustberebuilt!RegardlessoftheIntermediatePressure.

(6)Theregulatorwillrequirerebuildingifsmallbubblesareleakingfrombetweentheturretretainerand

mainbody,fromundertherubbercap,oroutofthehighpressureseatretainer.Knowledgeoffloodingof

the first stage will also require the unit to be rebuilt. Freshwater contains dissolved minerals and other

materialsthat,duetointernalcorrosionovertime,maycausetheregulatortomalfunction.

(7)AftertheIPhasbeenchecked,hosesandregulatorbodyinspected,andSPGevaluated,theserviceofthe

1ststagecantakeplaceifitisdeterminedthatserviceisnecessary.

4.FirstStageDisassembly

(1)1ststagedisassembly–Ensurethesystemisdepressurized.Documentthepositionofallhosesandport

plugs.Theuseofsmall,cleancontainerstoholdpartsisrecommended.

(2)Inthefollowingsteps,thepartnumbersfromtheschematicwillbeusedwiththeirdescription.Havethe

schematicinfrontofyouwhilefollowingtheinstructions!Besuretokeepalloldpartsorganizedandseparate

fromnewonesintheservicekit!

1.Removeallhosesandportplugs–Fig.7.

Fig.7

2.RemovetheDINShuttervalve(D2)usinga4mmhexandDINshuttercrown(D4),whichcontainstheSpring

(D6)andtwosmallnylonwashers(D5)–Fig.8.Washersarereplacedasindicatedbythe*symbol.

Fig.8

Thenumbersonthephotocorrespondwiththepartslistontheschematic.Thisisdonetoaidinthe

identificationofindividualitems.Itemsintheservicekitsareidentifiedinthesameway.

3.RemovetheRetainerHousing(D8)withthe4mmhexandlifttheDINHandwheeloffofthebody–Fig.9.

Fig.9

4.Insertthe1ststagehandleintooneofthehighpressureportsandclampthehandleintoavise–Fig.10.

NEVERCLAMPTHE1stSTAGEBODYINTOTHEJAWSOFAVISE!

Fig.10

CautionNote:

Clampingthebodyoftheregulatorintothejawsofavisemayresultindamagetothe

bodythatwillrequirereplacementoftheregulator.Alwaysusea1ststagehandleto

securetheregulator.

5. Using a ¾ inch socket and ratchet loosen the Filter Retainer DIN (D10) – Fig. 11. Be sure to hold the socket

firmly so that it doesn’t slip. Use steady, even pressure. Remove the Retainer and Saddle (08).

Fig. 11

6. Carefully remove the orings from the DIN Shutter Valve, Retainer Housing, Filter Retainer, and DIN Shutter

Crown – Fig. 12. Use the pinch method and a brass or nylon pick. Do not use a steel pick that could damage

the sealing surface. Set aside the Spring (D6) and filter (D11) with the parts to be reused. The washers (D5)

will be replaced.

Fig. 12

Caution Note:

Take whatever steps are necessary for keeping track of items that are part of an

assembly. This degree of organization will reduce the risk of mistakes that can result in

a failure of the regulator.

7. Using the Multitool or Pin Spanner, carefully remove the rubber End Cap (34) – Fig. 13. This exposes the

HP Seat Retainer (33) – Fig. 14.

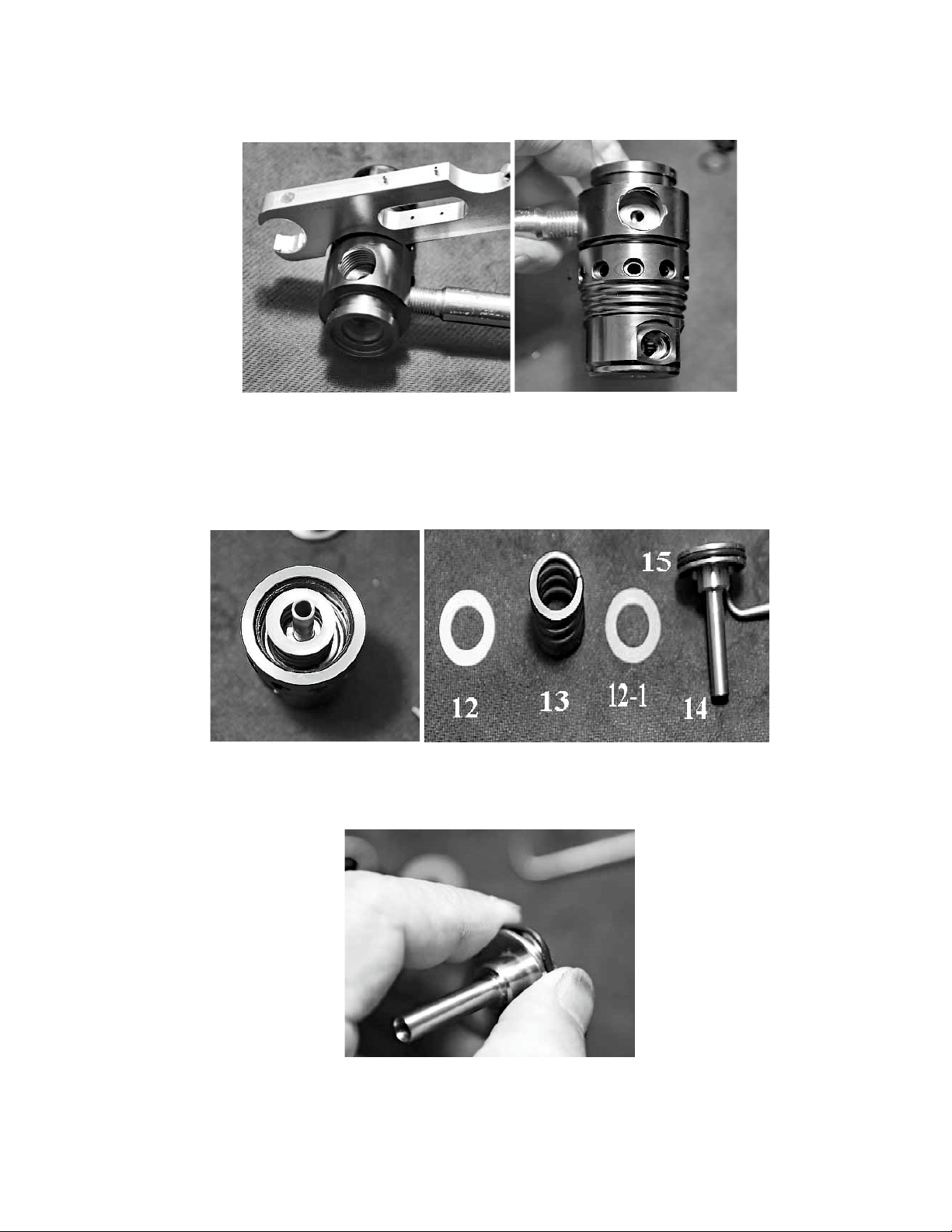

Fig. 13 Fig. 14

8. Loosen the HP Seat Retainer with a 5mm hex wrench and remove it from the body, exposing the HP Seat

(31) – Fig. 15, (push out the HP seat with a blunt pick), remove Oring (32), Oring (30) and, Spring (29) – Fig.

16.

Fig. 15

9. Remove Oring 30 with a brass or nylon pick from its groove in the body of the regulator.

Fig. 16

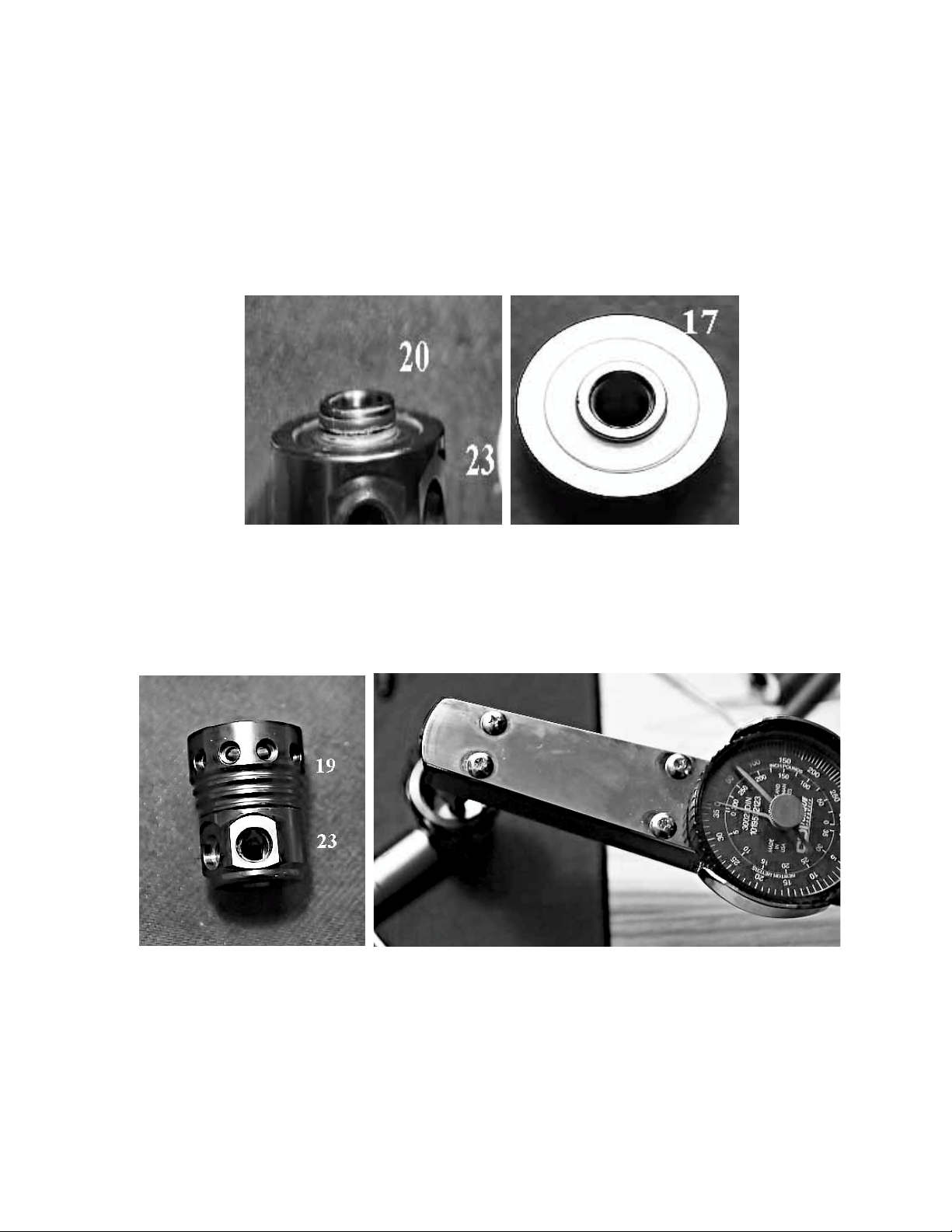

10. Using the universal wrench or a pin spanner with an appropriate pin, and the 1st stage handle secure –

Fig. 17, loosen the End Cap (19) so that a gap is visible – Fig. 18.

Fig. 17 Fig. 18

11. Holding the regulator vertical, with the end cap/turret on the bottom, unscrew the assembly from the

main body – Fig. 19. This allows access to the Piston (14), Washer (12), Spring (13), Washer (121), and Oring

(15) – Fig. 20.

Fig. 19 Fig. 20

12. Remove Oring 15, also using the pinch method to avoid scratching the piston sides – Fig. 21.

Fig. 21

13. Carefully remove the following components from the HP side of the regulator body. Washer (28), Oring

(27), and Teflon Washer (26) using the Piston Stem Bushing Assembly Tool – Fig.22. Turn the body over and

remove the other Oring (27) with a brass or nylon pick – Fig. 23.

Fig. 22 Fig. 23

14. Disassemble the turret by inserting a 1st stage handle into one of the low pressure ports. Using a 6 mm

hex wrench, unscrew the Nut (16) from the Port Swivel (23) Fig. 24.

Fig. 24

15. This allows access to the Washer (17). Remove the Washer. Pull the End Cap (19) from the Port Swivel

and remove the Washer (17) and Oring (20) from the Port Swivel – Fig. 25.

Fig. 25

This completes the disassembly of the 1st stage.

(3) The photographs below show the disassembled first stage – Fig. 26 and 1st stage service kit – Fig. 27. All

of the parts not in the service kit need to be washed, rinsed, and dried, as discussed previously.

Fig. 26

Disassembled 1st Stage

Fig. 27

1st Stage Service Kit

5. First Stage Assembly

(1) Before starting the assembly of the second stage, complete a thorough inspection of all parts to be re

used. Refer to the Overview Inspection section for details. At this time, open the service kit and lay out the

parts. Use the schematic to identify each part.

1. The first step in assembling the now cleaned 1st stage is to assemble the turret. Lubricate the Oring (20)

and install it on the port swivel (23) Fig. 28, along with Washer (17) Fig. 29.

Fig. 28 Fig. 29

2. Next, take the End Cap (19) and press it onto the Port Swivel (23) – Fig. 30. Install the other Washer (17),

as shown below. Install Nut (16) and torque this to 70 in lbs/81 kgf cm/8 Nm using a 6mm hex, and the 1st

stage handle installed in one of the open LP ports – Fig.31.

Fig. 30 Fig. 31

3. Set this assembly aside and install one of the Orings (27) into the groove on the regulator body that the

End Cap/Port Swivel assembly screws onto – Fig.32. Use the Piston Stem Bushing Assembly Tool and on the

narrower end place in the following order Washer (28), lubricated Oring (27), and Teflon Washer (26) – Fig.

33.

Fig. 32 Fig. 33

4. Next, lubricate Oring (15) Fig. 34 and install it on the Piston (14). Place the Washer (121) on the Piston,

followed by the Spring (13) Fig. 35, and the Washer (12) Fig. 36.

Fig. 34 Fig. 35 Fig. 36

5. Carefully slide the Piston Assembly into the End Cap/Port Swivel Assembly – Fig. 37. Using the previously

assembled Washer/Oring/Teflon Washer stack Fig. 38, insert the stack into the HP side of the regulator

Body (11), as shown on the schematic. Slightly twist the tool, and the stack will come off in the body.

Fig. 37 Fig. 38

6. Reverse the tool to hold the stack and protect the Piston end Fig. 39. Insert the Piston/End Cap/Port

Swivel assembly into the regulator and screw it on hand tight Fig. 40.

Fig. 39 Fig. 40

7. Install the 1st stage handle into a highpressure port Fig. 41. Use the MultiTool to tighten the End Cap/Port

Swivel assembly to the body. A piece of rubber may be used to lessen the chance of scratching the End Cap

Fig. 42. Tighten the connection so that no gap is visible, and the connection is secure. There is no torque

specification for this.

Fig. 41 Fig. 42

8. Set the assembly aside and install the Oring (30) in the HP side of the body, as shown using the blunt brass

or plastic pick Fig. 43. Install the Oring (32) onto the HP Seat Retainer and place the HP seat (31) into the

HP Seat Retainer. Orient the seat with the concave side towards the Piston and the flat side facing the HP

Seat Retainer Fig. 44.

Fig. 43 Fig. 44

This manual suits for next models

1

Table of contents

Other Dive Gear Express Diving Instrument manuals

Dive Gear Express

Dive Gear Express DGX Gears XTRA User manual

Dive Gear Express

Dive Gear Express DGX Gears D6 User manual

Dive Gear Express

Dive Gear Express DGX Gears FIRST User manual

Dive Gear Express

Dive Gear Express XTRA Second Stage User manual

Dive Gear Express

Dive Gear Express DGX Gears BCI Backup Regulator User manual