Dive Gear Express XTRA Second Stage User manual

DGX Gears XTRA Regulator

Service Manual

DGX Xtra Second Stage

Copyright © 2020 Dive Gear Express

Author/Photographer – UDM Consulting

All rights reserved.

Rev.5c Published 8/17/2020

1.Overview

(1) The availability of subassemblies and components, repair parts, specialized tools, and maintenance

manualsdoesnotimplyqualificationtoassembleand/orservicescubaequipment.Improperserviceofdive

equipmentcanleadtosevereinjuryordeath.DiveGearExpressrecommendsthatnonqualifiedindividuals

seekprofessionaltraining/mentoringbeforeattemptingrepairsorservicingonanydivingequipment

Failuretofollowtheproceduresoutlinedhereinmayresultininjuryordeath!

(2)Inthefollowingpageswillbefound,thedisassembly,assembly,tuning,andtroubleshootingstepsfor

thesecomponents.Photosareusedthroughouttoillustratetheprocedures.

Pleasepayspecialattentiontoallcautionnotes!

(3)Wheneveranitemofextraimportanceneedstobeobserved,a“CautionNote:”willappear,followedby

therequiredinformation.Seebelow.

CautionNote:Thismustbereadandfollowed!

(4) Included in this manual is a list of recommended/required tools for each disassembly, assembly, and

testingsection.Theyareidentifiedineachsectionwheretheyareused.

(5) Schematics are located inthe rear of this manual. The drawings containthe detailed parts lists. The

drawingsalsoincludethetorquespecificationsforpartswhererequired.

(6)Ageneraltroubleshootingguidewithspacefornotesisalsoincludedforthoseusingaprintedversion.

Thosewhopreferanelectronicversionshouldkeepdetailednotesinanaccessiblelocationfortheirown

observationsandservicetips,aswellasarecordofservice.

(7)Throughoutthetext,partsarereferencedusingtheitemnumberontheschematictofacilitatelocating

eachindividualcomponent

(8)Photographsofthepartskitsareshowntoillustratethateachcomponentisindividuallybagged.Parts

shouldnotbetakenoutoftheirpackaginguntiltheactualassemblystageisreached,andtheuserisready

tolubricate,wherenecessary,andinstallthem.

(9) Ensure the service area is free of any environmental concerns that may cause problems during the

servicing of your regulators. The area must be clean and organized. The use of nitrile gloves is highly

recommendedforthefinalrinsingandassemblystages.Thiswillminimizetheriskofskinoils,contaminating

theinternalcomponentsoftheregulator.

(10)Ensurethatallrequiredservicing/testingairsuppliesareavailableandatthepropertestpressures,if

not using a regulated supply from a single source. This would include the use of cylinders of compressed

breathing air from an OCA grade source if you wish to maintain the oxygenclean status of the unit.

CautionNote:Onlyuseairfromabreathingairsource!

CleaningandRinsingGeneralConsiderations

(11)Cleaningandrinsingofthecomponentsshouldbedoneusingclean,freshwater.Ifavailable,distilled

waterisrecommendedtomaintainoxygencleanliness.

(12) Only use degreasers that leave no organic residue (clear Simple Green, dyefree Dawn dishwashing

liquid,orBlueGoldCleanerasexamples).

(13)Todealwithcorrosion,usea50/50vinegarwatersolutionandnylonbrushes.

(14)Allowpartstoairdrywithouttheuseofclothsthatmayleavefibers.Forregulatorsthataregoingtobe

used with Oxygen percentages above 40%, a UV light is strongly recommended to check for organic

contamination.

(15)Onceallserviceprocedureshavebeencompletedandbenchtestingdone,inwatertestinginaconfined

environment such as a swimming pool is recommended to confirm proper function before taking the

regulatoronanactualdive.

CleaningofRegulatorParts

(16)CleaningCleaningofthepartsthataregoingtobereusedisoneofthemostcriticalstepsinservicing

theregulator.Aswasstatedearlier,usethepropersolutionsforthejobathand.Vinegarandwaterarenot

asusefulforremovinglubricatinggreaseasoneofthedetergentsthatwerenoted.Bythesametoken,

thosedetergentsarenotasefficientasthevinegar/watermixindealingwithcorrosivebuildup.

(17)Therefore,whereyouhaveabuildupofcorrosion,youmayalsohavelubricantonthesurfaceofthe

part.Beforedealingwiththecorrosion,usehotsoapywaterandasoftbrushtoremovethelubricant.Then

usetheacidicsolutiontodealwiththecorrosion.

(18)Oncethecorrosionhasbeendealtwith,washthepartsusingafreshsoapandwatersolutionwhile

wearingnitrileglovestoreducetheriskofcontaminatingthepartswithskinoils.Rinsethepartswithclean

runningwater,distilledispreferred,thatisallowedtodrainfreely.Aplasticpastacolanderavailableatany

storeisexcellentforthis.Forverysmallparts,ameshstrainerforsinkdrainsworkswell.Oftensoldasa

set,theyareinexpensiveandcanbeusedformanytypesofregulatorcomponents.Seethephotographsof

eachinthetoolsection.

(19)Afterwashingandrinsingtheregulatorparts,allowthemtoairdry.Usingadryingrackwillaidinthis,

aswellashavingtheairintheroomcirculating.Donotlaythepartsonapaperorclothtowel.Doingsoruns

theriskofhavingfiberssticktothemthatwillcauseissueswithsealing.Inadditiontothis,fiberscanbea

hazardwhenusingtheregulatorwithhighoxygencontentmixes.

(20)Oncethepartshavedriedcompletely,laythemoutinorderofassemblyonthepadusedonthework

surface.Makingsurethatithasbeencleanedandisfreeofcontaminants.Arubberorsiliconematofsuitable

sizeworkswellforthis.Youcanalsousesmallcleancontainerstokeepthepartsorganized.Oncetheparts

have beencleanedand dried,theyneed to beinspected beforestarting theassemblyprocess.Thisis to

ensure that no damage or defects exist that were hidden by corrosion, residual lubrication, or other

contaminantsthathavenowbeenremoved.

InspectionAfterCleaning

(21)Beforeassemblingtheregulator,itisnecessaryto inspectallofthecleaned components. Usingthe

magnifyingglass,checkallthecomponentsfordamagethatmayhavebeenhiddenbycorrosionorlubricant.

Lookforscratchesthatmayaffectthesealingoftheregulator.Inadarkenedroom,usetheUVlighttolook

fororganicmaterial.Itwillshowupasglowinglinesorfragments.Ifanyarepresent,thepartneedstobere

cleanedanddried!Thisiscriticalforusewithoxygenpercentagesabove50%!

(22)Anotherwaytocheckforresiduallubricantsistofillatraywithclean,fresh,waterdeepenoughtocover

thepartsbyaninchorso.Laythecomponentsinthewaterandcirculatethewateraroundthem.Allowthe

piecestosoakforseveralminutesandthewatertosettle.Onceithassettled,lookforarainbowsheenon

thesurfaceofthewater.Anyresiduallubricantswillfloatandforma“slick”onthesurface.Ifoneispresent,

thepartsmustbecleanedagain.

(23)Nowthatallpartshavebeencleanedandchecked,theassemblycanbegin.Makesurealloldpartsthat

aretobereplacedhavebeendiscardedorsegregated.Removethenewpartsfromtheservicekitbagand

laythemoutintheordertheywillbeused.Donottakethenewpartsoutofthebagsyet!

CautionNote:

Removingpartsfromtheirindividualbags,beforetheyaretobeused,runstheriskof

mixingthemup.Someoringsareverycloseinsizebutarenotinterchangeable!Keep

thepartsinthebagsuntilyouactuallyneedthem.

(24)Aswiththepartsthathavebeencleaned,itisagoodideatoinspectthenewpartsaswell.Especially

theHPseat.Makesureitisfreeofanydefects.Checkalloftheoringsandinspectthemasyouusethemfor

nicksorotherconcerns.Inspectthewasherstoensuretheyarefreeofexcessburrsorotherconcernsthat

couldaffecttheirfunction.Itisalsoagoodideatousethepartslistontheschematictoensurethatallofthe

newpartsthatareneededarepresentandaccountedforintheirrequiredquantities.

(25)LubricationofOrings;Lubricationcanbeoverdone.Doingsorunstheriskoftrappingexcessdirtor

debrisontheparts.Onewayofreducingtheriskofoverdoingitistousethelubeinabagmethod.This

involvesusingasmallcleanplasticbagandputtingasmallamountoflubeinit.Thentheoringisinserted

intothebag,workedaround,excesssqueezedoff,andtakenoutofthebag,andusedinitslocation.

Fig.1Fig.2

(26)AnotherwayistoapplyasmallamountofTribolubetotheglovedindexfingerandmassagetheoring

betweenthethumbandindexfinger.Eitherwayworks,butthebagmethodtendstogivebetterdistribution

resultsanduseslesslubricant.

(27)Undermostcircumstances,alubricantisusedcorrectlyverysparinglyornotatall.Innearlyallscuba

applications, ifyoucan see thelubricant, you’ve usedtoomuch. Before using any lubricant, any existing

lubricationshouldberemovedbeforenewisapplied.Indynamicapplications,itisusedtoreduceexcessive

wear.Staticoringsdonotgenerallyrequiretheuseoflubricant.

(28)Wherepartsarenotnecessarytobelubricated,itisgoodpracticetoavoidgettinganylubricantonthem.

PrimarilywhentheregulatorisusedwithhighO2contentmixes.Italsohelpstokeepthosepartscleanand

freeofdebristhatwillclingtothelubricant.

(29)Maintainingoxygencleanconditionsfor2ndstagesistechnicallynotmandatory.The2ndstageisalow

pressuredeviceoperatingat135psi.Regardless,bestpracticeistomaintainoxygencleanconditionsalong

withtheexclusiveuseofoxygencompatiblelubricantswhenservicingtheregulator.

Thenextsectionliststhetoolsyouwillneedtoservicetheregulator.

2.TOOLLIST

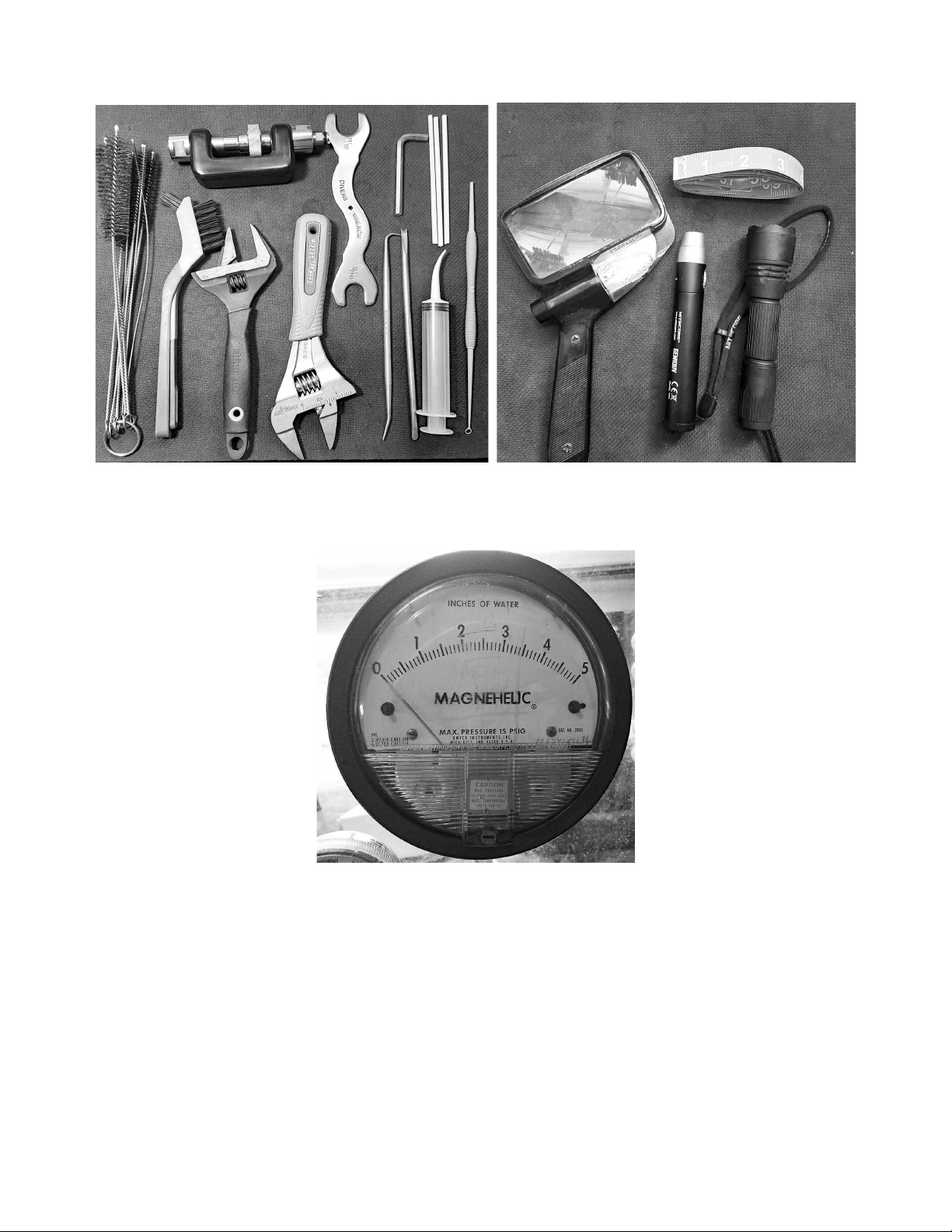

(1)Thetoollistforthesecondstageisnotasextensiveasthatforthefirststage.Theyarestilldividedinto

RequiredandRecommended.Therequiredtoolsarenecessaryforservicingtheregulator.Recommended

arethoseitemsthatmakeservicingeasierormoreefficientaswellaslesseningthechanceofdamage.

RequiredtoolsFig.3

1. 2AdjustableWrenches(thinjawed)orthin11/16wrenchandproperwrenchforLPhose

2. 3/16thhexwrench

3. BrassPicksforremovingorings

4. Tribolube71

5. SoftBristleCleaningBrushes(Nylon)

6. Inlinesecondstageadjustmenttoolwithslottedorificeselected

7. Woodenorplasticdowels

RecommendedtoolsFig.4

1.SoftRubberPad

2.MagnifyingGlass

3.Flashlight

4.UVlight

5.MagnahelicGaugewith03inchesofwaterscaleFig.5

6.WaterproofRuler/Scalefortestingwhennomagnahelicisavailable

(2)YoucanpurchasetoolsfromDiveGearExpress.TheInLineAdjustingToolwithIPgauge,BrassPicks,and

theIPGaugethatisshownthatplugsintotheLPinflatorhosecanbefoundatthelinkbelow.

https://www.divegearexpress.com/tools/scubatools

Phone:9549776009

Fig.3Fig.4

RequiredToolsRecommendedTools

Fig.5

Magnehelic

3.PreliminaryTesting

(4)Preliminarytestingoftheregulatorisnecessarytoidentifyanyissueswiththefirstandsecondstagesand

verifytheoverallregulatorfunction.Thistestingwillinclude:

1. Visualinspectionofthefirstandsecondstages

2. Inspectionofthehoses

3. IntermediatePressurecheck

4. CrackingPressureandSecondStageNegativePressureTest

Visual inspectionisdonetoidentifyissuesthatcouldaffectservicingandtoensurethat pressurizingthe

systemwillnotcompromisethesafetyoftheservicetechnician.

Thetechnicianwillcheckallconnectionstomakesuretheyaresecure.

Thetechnicianwillcheckthatonthefirststage,therearenoextrudedorings,andhosesaretight.

ThetechnicianwillchecktherearenodefectstotheSPG.

ThetechnicianwillensurethattheDINassemblyissecure,andtheOringisintactandabletoformaseal.

Thetechnicianwillinspectthefilterforsignsofdiscoloration.

DetailedInspectionofHosesisdonetoensureitissafetopressurizetheregulatorset.

Thetechnicianwillcheckallhoses,lookingforevidenceofpossiblefailure.

Thetechnicianwillcheckallhoseconnectioncrimps.Defectsmustbetakencareofbeforepressurizingthe

system!Replacementofanysuspecthosesisrecommended.

CautionNote:

Defectsinhosesrequirereplacementbeforepressurizingtheregulator!Failuretodoso

mayresultinseriousinjuryordeath!

(5)DetailedVisualInspectionoftheSPGandconnection–ThetechnicianwillchecktheSPGforanysigns

ofcrackingof theface, waterintrusion,and corrosionaround theSPG to thehose connection.Ifusing a

consoleorboot,itisnecessarytoremovetheSPGfromtherubberboot.Oncethisisdone,theHPspool

shouldbeinspectedand,ifnecessary,replaced.

(6)CheckingofIntermediatePressure(IP)–TheIntermediatePressure(IP)ofthesystemshouldbetested

only after the preceding checks have been done to ensure technician safety. Checking of intermediate

pressureisdonebyattachinganintermediatepressuregaugetotheLPpressureinflatorhose.Thesystemis

thenpressurizedwhilepartiallydepressingthepurgebuttonononeofthesecondstages.Depressingthe

purgebuttonslightlyonthesecondstageisdonetopreventfurtherdamagetothesystembyprovidinga

reliefvalveshouldtheIPriserapidlytounsafelevels.Oncethesystemhasbeenpressurized,thepurgeis

released,andtheIPchecked.

CautionNote:

Ifthesecondstageisleakingevenslightly,IPwillbeaffected.Ifthesecondstageis

leaking,turntheadjustmentknobtostopitoruseasecondstagethatisnotleaking

throughwhenpairedwiththefirststage.Itisalsoaclearindicationthatthesecondstage

requiresrebuildingifturningtheadjustmentknobdoesnotstoptheflow.

(7)ThestandardoperatingrangeforthesystemiswithanIPof135PSI.Ideally,thesystemisoperatingat

135PSI+/5PSIandshownosignsof“creep”orinstabilityat3000PSI.

CautionNote:

“Creep”willshowastheIPsteadilyincreasingwhiletheregulatorisnotinuse.Normally

theIPwilldrop510PSIduringabreathorpurgeandthenreturntoitssetting.Itshould

notreturntothesettingandkeepincreasing.Thiswouldindicateaproblemwiththe

highpressureseat,Piston,orsealingorings.

(8)IfthesystemshowsnosignofcreeporIPinstability,itisgenerallynotnecessarytorebuildthe1ststage

withsomeexceptions.

CautionNote:

Iftheunitshowssignsofinternalcorrosionorthefiltershowsevidenceofcontamination,

theunitmustberebuilt!RegardlessoftheIntermediatePressure.

(9)Theregulatorwillrequirerebuildingifsmallbubblesareleakingfrombetweentheturretretainerand

mainbody,fromundertherubbercap,oroutofthehighpressureseatretainer.Knowledgeoffloodingof

the first stage will also require the unit to be rebuilt. Freshwater contains dissolved minerals and other

materialsthat,duetointernalcorrosionovertime,maycausetheregulatortomalfunction.

(10)AftertheIPhasbeenchecked,hosesandregulatorbodyinspected,andSPGevaluated,thesecondstage

inspectioncantakeplace.Itisnecessarytoperformaninspectionofthe1ststageandchecktheintermediate

pressure.Intermediatepressurehasadirectbearingontheperformanceofthesecondstage.IncorrectIP

cangivefalseindicationsastothelevelofservicerequiredonthesecondstage.

CautionNote:

Itmaybenecessarytoservicethesecondstagewhenthe1ststagedoesnotrequire

service.Allinspectionstepsandevaluationsshouldbedonetoensureproperoperationof

theentireassembly.

4.SecondStageEvaluation

NegativePressureandCrackingPressureevaluation–

(1)Thenegativepressuretestverifiesthemainandexhaustdiaphragmsealsaswellascaseintegrity.With

thesupplypressureoff,andattachedtoacylinder,attemptanormalbreathfromthesecondstage.You

shouldbeunabletodrawanyair.Ifaflowisobtained,removethesecondandtrywithathumbovertheair

inlettoit.Ifaflowisstillpresent,theprimaryandexhaustdiaphragmsneedtobecheckedfordamage.Salt

accumulation,sand,anddefectsinthecasewillalsoallowairflowwhentheairinletiscovered.Carefully

checkallofthese.

(2)Crackingpressuretestingismostaccuratelydonewiththe useofamagnahelicgauge.Acontainerof

watercanbeusedbymeasuringthedepthtowhichastagecanbesubmergedfacedownparalleltothe

water.Thisgivesanindicationatwhichlevelofeffortthesecondstagewillopen.Thenormalrangeforthe

adjustablesecondstageis1.0to2.2inchesofwater.Lesspressuremaybedesiredbythediver,buttheinitial

factorysettingof1.1shouldbeused.ThispermitsabreakinperiodfortheLPseat.Itisnormaltoseethis

initialsettingdropastheLPseattakesaset.

SecondStageCaseIntegrity–

(3)Thecaseshouldbeinspectedforsignsofdamage.Scratches,gouges,missingparts,damagedexhaust

ports,orloosefaceplatethatwillnottightenmaybeanindicationofadamagedcase.

(4)Useanegativepressuretest,testthepurgebutton,andlookfordefects.Checktheleverandbreathing

effortknob.Dotheymovefreelyandwithnoindicationofstiffness?Dotheyfeellikethereissandorgritin

them?

(5) A problem with case integrity should be dealt with before starting the rebuild. A defective case will

compromisefinaltestingandposeasafetyhazardtotheuser.

CautionNote:

Adamagedcase,purgecover,ordiaphragmcannotberepaired.Theymustbereplaced.

(6)Havingcompletedtheinitialevaluationanddeterminedserviceisnecessary,therebuildoftheregulator

cantakeplace.

5.SecondStageDisassembly

(1)Inthefollowingsteps,thepartnumbersfromtheschematicwillbeusedwiththeirdescription.Havethe

schematicinfrontofyouwhilefollowingtheinstructions!Besuretokeepalloldpartsorganizedandseparate

fromnewonesintheservicekit!

1.RemovetheSecondStagefromthehoseafterdepressurizingthesystem.UnscrewtheCaseCover(41)

fromtheCase(11)andremovetheCover(3),DiaphragmCover(4),andtheDiaphragm(06)andDiaphragm

Disc(05)assembly.Fig.6ThisrevealstheValveSpindleAssemblyinthecase.Fig.7

Fig.6Fig.7

2.RemovetheRetainingNut(08).HoldingtheLever(20)down,slide/pulltheValveSpindleAssemblyoutof

thecaseasoneunit.Fig.8

Fig.8

3.SlidetheVenturiLever(18)offofthespindlewhileholdingdowntheLever(20).Becarefulaftersliding

theVenturiLever(18)offtoallowittocomeupslowly.Fig.9

Fig.9

4. With the lever off, using the brass pick blunt end or another suitable tool, press the Spring Pin (21) out of

the Valve Spindle (19). Notethatthismayrequiresomeforcetoremove.Securethespindleasneeded.

This will allow the Adjusting Screw (30) to be removed. Remove the Rubber Cap (35) from the Adjusting Screw

(30). Using the 3/16th hex wrench, unscrew the Adjusting Spring (34) from the Adjusting Screw. – Fig. 10

Fig. 10

5. Holding the lever upright, use the 1/8th inch plastic or wooden dowel to push the assembly consisting of

the LP seat (24), Shuttle Valve (25), Orings (26), Spring (27), and Counter Balance Cylinder (28) out of the

Spindle. You may hear a slight click as you do this when the LP seat end passes the lever. Fig.11 Analternative

methodistocarefullyremovetheleverbyliftingonelegoutoftheholeandrotatingthespindletoallowthe

othersidetocomeout.DONOTBENDTHELEGSOFTHELEVERTODOTHIS!

Fig.11

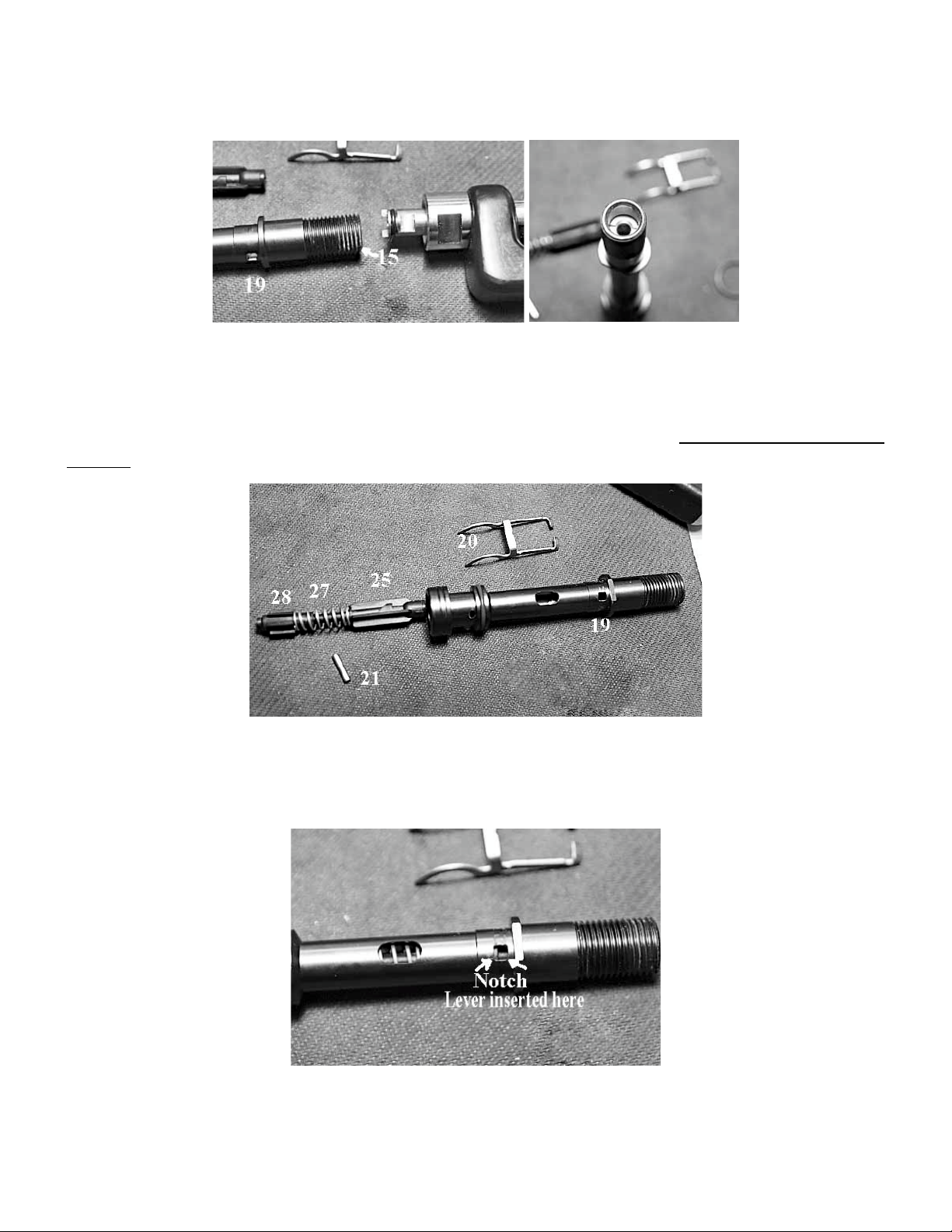

6. Once you have removed the assembly from the Spindle (19), use the slotted end of the inline adjustment

tool to remove the Orifice (15) from the Spindle(19). The photo below shows all of the parts to the Spindle

Assembly. Item Oring (23) is located in a groove on the inside of the Spindle. Fig 12.

Fig. 12

7. Using a brass pick, carefully remove Oring (23) from the Spindle. – Fig.13. Confirm that Oring (09) from

the air inlet side of the Case has been removed from the groove that contains it. Fig. 14

Fig. 13 Fig. 14

8. Using the pinch method or a brass/plastic pick, remove all of the Orings from the Lever (18), Orifice (15),

Shuttle Valve (25), Adjusting Screw (30), and Adjusting Spring (34). Fig. 15. Confirm that all are accounted

for and segregate them with the other replaceable parts.

Fig. 15

9. Carefully cut the zip tie on the Mouthpiece (14) and remove it from the case. Using a blunt pick or

wooden dowel, press the small tab slightly on the adjustment/lever side of the case in the exhaust port to

remove the Cover Exhaust Valve (13). Fig. 16. Becarefulnottosnapthetaboff!Gentlyremovethecover

asyoupressthetab.Donottrytopryitoffwithoutpressingthetab!The Exhaust Valve (12) can be

removed by pulling it out of the hole intact or by cutting the stem inside the case and pulling it out.

Replacing the valve is optional. Fig. 17

Fig. 16 Fig. 17

This completes the disassembly of the second stage. Refer to the Cleaning Section in the Overview for

instructions before assembly.

Second Stage disassembled

Second Stage Service Kit

6.SecondStageAssembly

(1) Before starting the assembly of the second stage, complete a thorough inspection of all parts to be re

used. Refer to the Overview Inspection section for details. At this time, open the service kit and lay out the

parts. Use the schematic to identify each part.

(2) Using the method described in the Overview, prepare to lubricate the dynamic orings. Remember to not

use excessive amounts of lubrication.

1. Locate the orings for the following assemblies: Orings (31 and 33) for the Adjusting Spring (34). Lubricate

them and install them on the Adjusting Spring. Place Oring (16) on the Orifice (15). Install Orings (26) on the

Shuttle Valve (25). Install Oring (29) on the Adjusting Screw (30). At this time, the LP Seat (24) can be placed

into the end of the Shuttle Valve (25). Fig. 18.

Fig. 18

2. Install Oring (22) on the Valve Spindle (19) after lubricating it. Install Oring (23) in the interior groove of

Valve Spindle on the side shown in Fig. 19.

Fig. 19

3.UsingtheInLineTool,inserttheOrifice(15)intothethreadedendoftheSpindle(19)–Fig.20,andwhen

thethreadsengage,turnitin34turns.ActualadjustingoftheOrificewillbedonelater.–Fig.21

Fig.20Fig.21

4. Assemble the Shuttle Valve (25), Spring (27), and Counter Balance Cylinder (28). With the assembly

oriented,asshowninFig.22,insertitintotheSpindle(19).Payspecialattentiontothepositionofthenotch

on the Shuttle Valve. This is where the Lever (20) engages the Shuttle Valve. It must be orientedin this

manner.NotealsothepositionoftheholefortheSpringPin(21).–Fig.22.Leverremovedforclarity.

Fig.22

5.Carefullyinserttheassemblytherestofthewayintothespindle.Itiscriticaltomaintainthisorientation.

Slideitinuntilthenotchisclearlyvisibleinthesmallsquarewindow.–Fig.23.

Fig.23

6.Oncethenotchislinedup,carefullyinsertonetabofthelevertoengageitandrotatethespindlesothat

theotherlegoftheleverdropsintothecorrespondingwindowontheotherside.Donotbendthelegsof

thelever!–Fig.24.

Fig.24

7.Allowthelevertocomedowntorestandcarefullysettheassemblyaside.Fig.25.

Fig.25

8.AssembletheAdjustingScrew(30)andAdjustingSpring(34)–Fig.26.Atraceoflubricantonthethreads

ofthesewillhelptoensuresmoothoperation.TheinitialadjustmentontheAdjustmentSpringistohave

approximately1mmofthespringendshowingabovetheendoftheAdjustingScrew(34),asshown.–Fig.

27

Fig.26Fig.27

9.CarefullyinserttheAdjustmentScrew(30)andSpring(34)assemblyintotheSpindle(19)andbeginto

screwitin.Theleverwillriseasthisisdone.Screwtheassemblyinuntilyoucanseeclearlythroughthehole

fortheSpringPin(21).–Fig.28

Fig.28

10.Insertthespringpinandpushitintoplacewiththebluntendofthebrasspick.Fig.29.Thesharpbrass

pickmaybeusedtoguideitin.Anequalamountofpinshouldbepresentoneachside.Ifthisisnotdone,

theVenturiLevermayhanguponthepinthatisstickingtoofarout.

Fig.29

11.PlacethelubricatedOring(17)ontheVenturiLever(18)andslideitontotheSpindle/Leverassembly.

MakesurethatitmovesfreelyaroundtheSpindle(19).Notethepositionoftheleverrelativetotheair

outlet.Fig.30.

Fig.30

Table of contents

Other Dive Gear Express Diving Instrument manuals

Dive Gear Express

Dive Gear Express DGX Gears D6 User manual

Dive Gear Express

Dive Gear Express DGX Xtra First Stage User manual

Dive Gear Express

Dive Gear Express DGX Gears BCI Backup Regulator User manual

Dive Gear Express

Dive Gear Express DGX Gears XTRA User manual

Dive Gear Express

Dive Gear Express DGX Gears FIRST User manual