diversey TASKI SV4 User manual

Version: EN0001-0620-SV4-0620-240-13A www.diversey.com

SV4

2

在首次使用设备前必须阅读使用说明和安全说明。

使用说明须保存在安全且易看到的地方,以便随时

参阅。

设备上的警告信息牌提供了安全操作指南。

除了本说明外,请遵守所在国家/地区关于事故预

防的规范。

安全

说明和设备上使用的符号。

此标志表示重要信息。如不遵守这些说明,可能会

造成人身伤害和/或严重财产损失!

此标志表示重要信息。如不遵守这些说明,可能会

造成人身伤害、设备故障和财产损失!

此标志表示重要信息。如果不遵守这些说明,可能

会造成设备故障和财产损失!

该标志表示关于高效使用产品的重要信息。如不遵

守这些说明,可能会造成故障!

-请勿触摸,表面高温

-请勿向人、动物或电器设备喷射。

Table of Contents

安全指示 ……………………………………………2

更多信息……………………………………………..3

运输与储存 ………………………………………….3

电器插座…………………………………................4

结构布局……………………………………………..4

操作程序……………………………………………..5

使用期间…………………………………………....6

安全保护措施…………………………………..……6

维护……………………………………………….....7

服务中心………………………………………..…...7

质保……………………………………………..…...7

技术数据………………………………………..…...8

附件………………………………………………..…8

设备尺寸………………………………………….….8

故障…………………………………………..……...9

废弃处理……………………………………………..9

预期用途

该设备为生成蒸汽而制造和设计。

穿戴防护鞋、手套,以及当地规定的其他个人防护

设备。

该设备为商业用途,如酒店、学校、医院、工厂、

商店、办公室和出租商店。

任何其它使用均视为不当使用。对于由不当使用造

成的任何损坏,制造商概不承担任何责任。此风险

由用户自行承担。

正确使用还包括正确操作、保养和按照Diversey规

范进行维修。

未经Diversey授权更换设备将造成安全标志和CE

认证失效。将机器用于非指定用途可能会造成人员

受伤,破坏机器和作业环境。此类行为将造成所有

质保和保险索赔终止。

安全指示

TASKI设备的设计和结构符合欧盟指令标准关于健

康和安全的基本要求;因此具有CE标志。

安全指示

该机器仅能由经过充分培训的人员使用,或能够提

供机器操作技能证明的人员使用,并明确委托其使

用该机器。

危

险

警告

小心

注意 危

险

危

险

危

险

CN

原始

說

明的翻譯

3

身体、感官或精神能力低下的人,包括儿童、缺乏

经验或知识的人,不得使用该机器。

请看管好儿童,防止其玩耍本设备。

请勿在储存或加工爆炸性、高燃性物质(如气体、

溶剂、加热燃料、灰尘等)的房间内使用本机器。

这些物质可能会被机器的电气或机械部件点燃。

请勿将本机器用于有毒、危害性、腐蚀性或刺激性

物质(如危险粉尘等)或易燃液体的真空清洁。过

滤系统无法充分过滤这些物质。

不排除可能会对使用者和第三人的健康产生影响。

注意现场情况,也要注意第三人和儿童!特别是在

别、弯道等盲区附近,请注意减速。

请勿使用本机器运送其他人员和物品。

若机器出现故障、碰撞或翻倒,必须由授权专家检

查后才能重启。如机器置于户外、浸水或受潮,也

同样处理。

如与安全相关的部件(如电源线、接触到活零件的

外盖)受损,则必须立即中断机器。

机器不得在斜坡上停止、停放或存放。

对机器进行维护时必须关闭机器。

本机不得在>2%的斜坡上使用。

禁止在斜坡上急转弯,这会影响机器的稳定性。事

故危险。

本机仅能在固定、稳定和足够承重的表面上使用。

不遵照规定可能会发生事故。

在干燥和低粉尘的环境中操作和放置机器,温度仅

限于+10°C/+50°F和+35°C/+95°F之间。

只有熟悉本机器所有安全说明的授权专家才可维修

机械或电气部件。

只能使用本说明中规定的工具(刷子、喷嘴或类似

工具),或TASKI顾问推荐的工具。使用其他刷子

可能会对机器的安全和功能产生影响。

必须始终遵守关于个人保护和事故预防的国家规定

,以及制造商关于使用清洁解决方案的说明。

如机器漏水,必须立即关机。

未经授权,不得使用机器。因此,在离开机器之前

,要把机器放在上锁的房间里。

更多信息

本机器的

电气图见备件表。

——更多信息请联系您的客服。

这些使用说明,包括TASKI机器的所有使用说明都

可在以下网站找到。 www.taski.com/instructions-

use

运

输与储存

在运输之前,请确保所有外盖都盖上、紧固或锁住

。

只能在直立状态下运输和使用,禁止倾斜或侧卧。

设备需防雨防冻。请勿室外存放或在雨中使用。

型号牌上规定的电压必须与电源电压一致。

危

险

危

险

警告

警告

警告

危

险

危

险

危

险

危

险

危

险

危

险

危

险

危

险

小心

注意

注意

注意

危险

危

险

4

连接机器建议使用带过保护开关的剩余电流断路器

(30ms内最大电流30mA)。

请使用制造商提供的电源线,并定期检查是否损坏

。如电线损坏,请联系Diversey进行更换(使用零

件代码:11RM00061用于英国插头,11RM00062

用于欧盟插头),然后再使用机器。

若延长线使用不当,可能会发生危险。如使用加长

电线,应在户外使用,连接处必须保持干燥,离地

至少60mm。

在更换部件或清洁机器时,请关闭电源并拔掉插头

。

电器插座

本电器插座仅设计用于实现操作指导手册中定义的

使用目的。不同电器之间连接可能造成损坏。

在插入软管之前,请关闭机器,仅使用制造商规定

的软管。

该机器内置一个泄压阀,如机器压力过高,该阀将

打开。压力将从机器的底部释放,如发生这种情况

,请联系您的供应商或Diversey进行咨询和维修。

如有液体或泡沫从机器中溢出,请立即关闭电源,

联系经销商或直接联系Diversey。

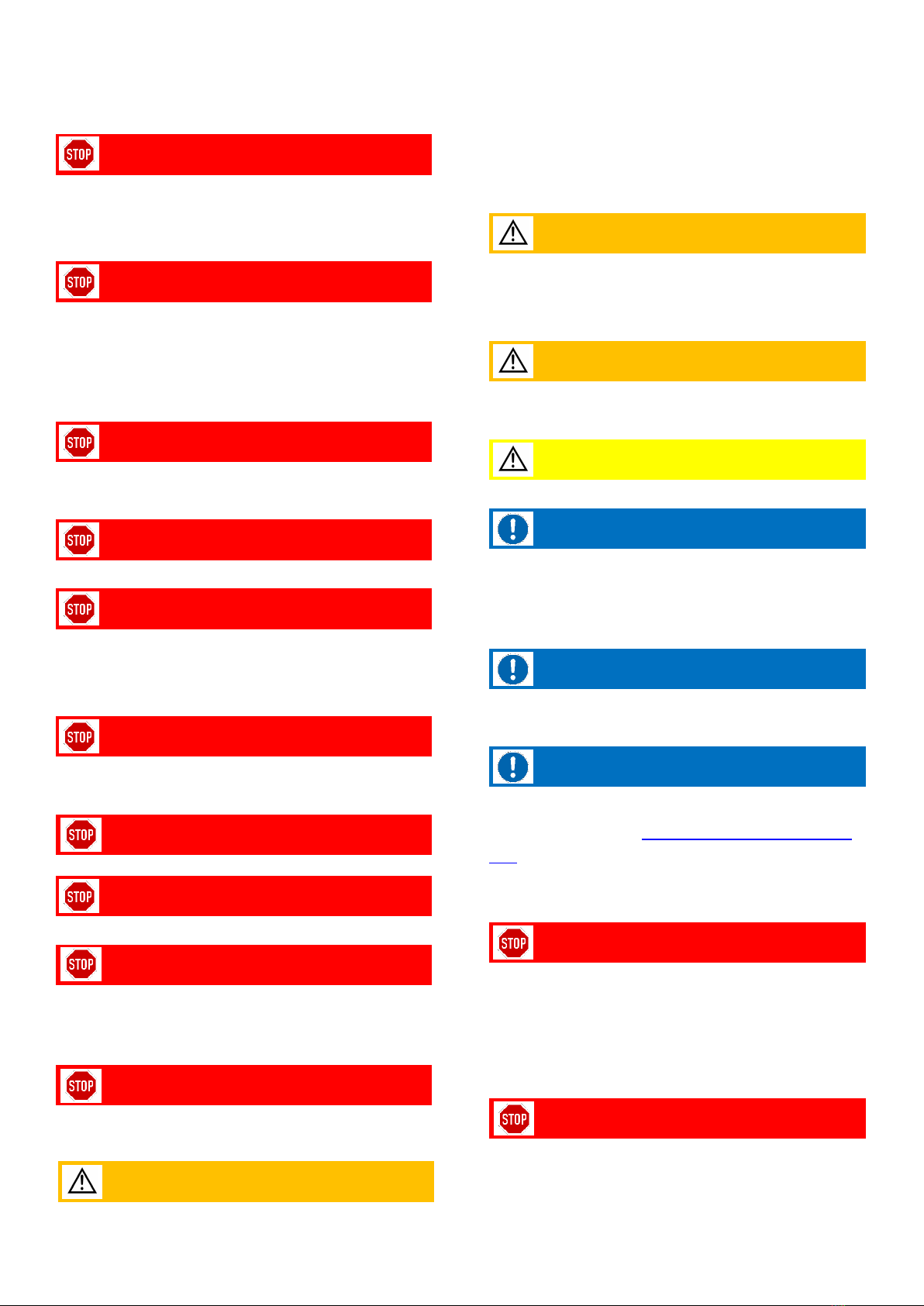

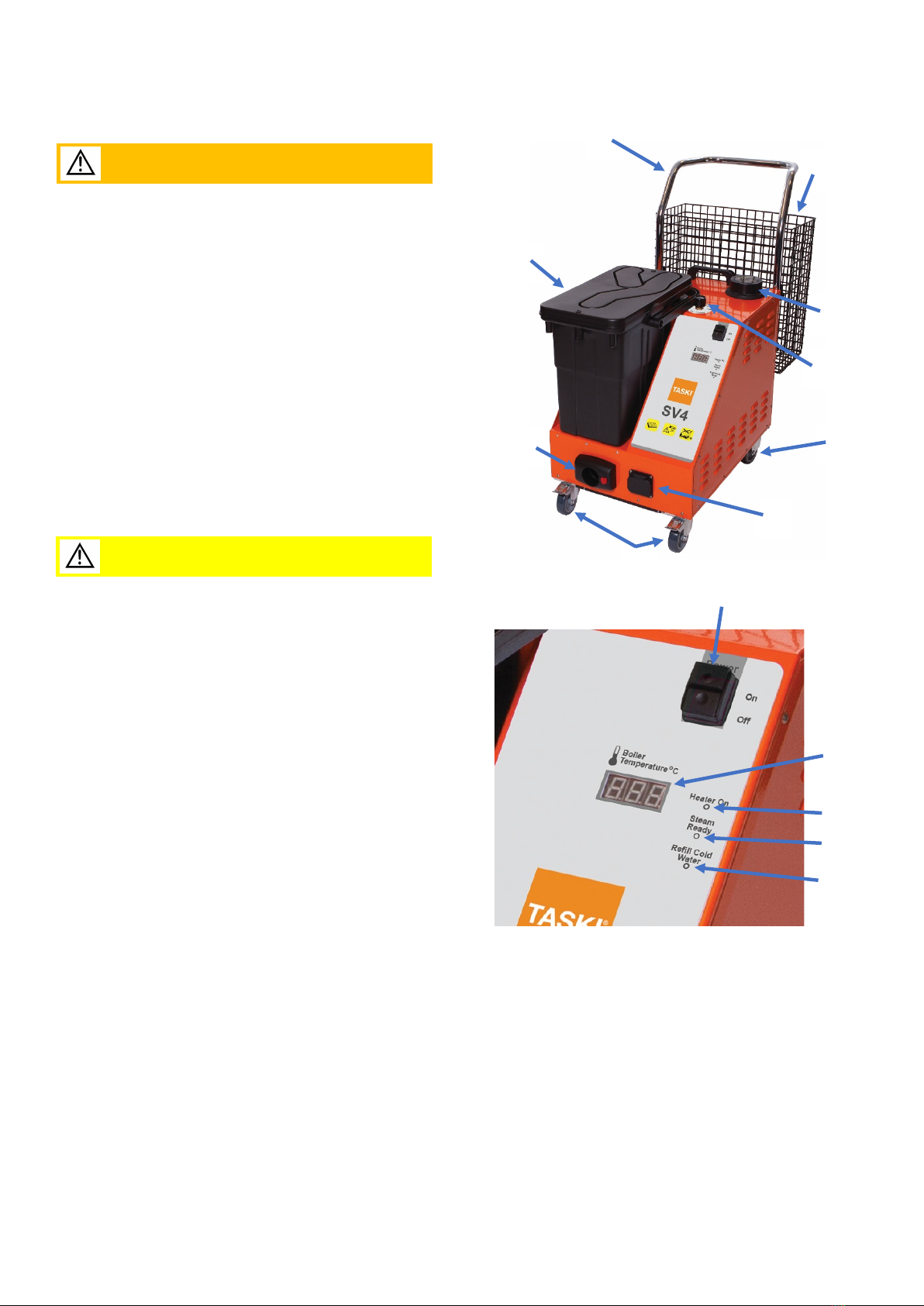

结构布局

10

1 手柄

2 配件篮

3 冷水槽

4 收集罐

5 可变蒸汽控制

6 无制动脚轮(后)

7 真空管插口

8 蒸汽软管插口

9 制动脚轮(前)

10 电源通断开关

警告

小心

6

12

14

2

1

4

5

3

7

9

13

8

11

5

11 LED温度显示屏

12 LED加热器开启

13 LED蒸汽就绪

14 LED冷水补充器

操作程序

冷水箱(3)中仅可注入清洁的冷水。

如水箱中使用的

不是清洁冷水,

制造商质保将失

效。

将真空软管连接

到机器的前部(7),确保锁定到固定位置。从插座

中拔出真空管时需将红色按钮向上滑动。

若软管发生损坏,必须更换整个软管。请勿自行操

作,请联系

Diversey

授权的供应商进行更换。

将蒸汽软管连接到机器的前部(8)

确保将其全部插入,并将盖板上的销钉锁入软管上

的孔中。

确保蒸汽管无法拔

出。

重要信息

——

在连接之前,先对蒸汽销上的

"O"

型环

润滑。

——

要拔出蒸汽管,请先抬起盖板再拔出

。

——

将电源线接入

240V

电源。

重要信息

——

在每次使用前检查电线。无论何时,

如电缆损坏,必须由

Diversey

认可的经销

商更换整条电缆。

——

请勿用湿手触摸电源线或插头。

——

在不使用机器时,一定要拔掉机器插头,

包括以下情况:

o

清洁机器

o

进行任何维护工作。

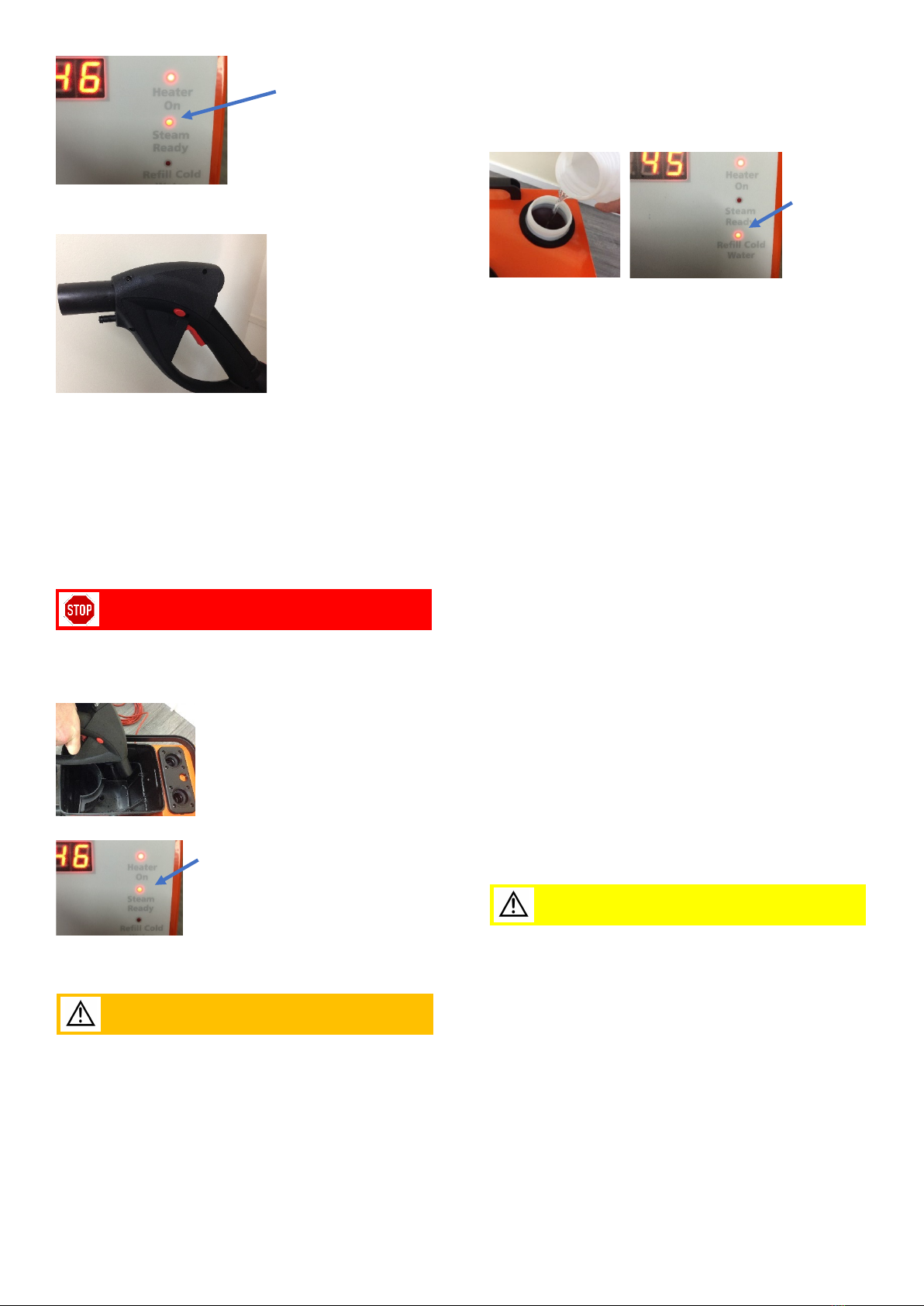

将开关(10)切换到ON位置。

加热器LED灯(12)将亮起。

让锅炉加热水约

5

分钟。

在蒸汽就绪LED灯(13)亮

起时,即可使用机器。

6

现在激活手柄控制

•软管手柄上的红色扳机在按下后会释放蒸

汽。

•手柄侧面的红色按钮会将蒸汽扳机锁定在

关闭位置。

•按下手柄顶部的左手开关,将启动真空吸

尘器

在不使用机器

时,必须将其锁定在关闭位置。

直接放入合适的容器中,排出多余的水/空气。

重新让温度升高,蒸汽就绪指示

灯重新亮起

(13)

蒸汽输出量可通过蒸汽变化控制(5)来调节

选择所需的零件安装到软管手柄上。

在使用过程中更换配件时,请注意这些配件会很烫

!

使用期

间

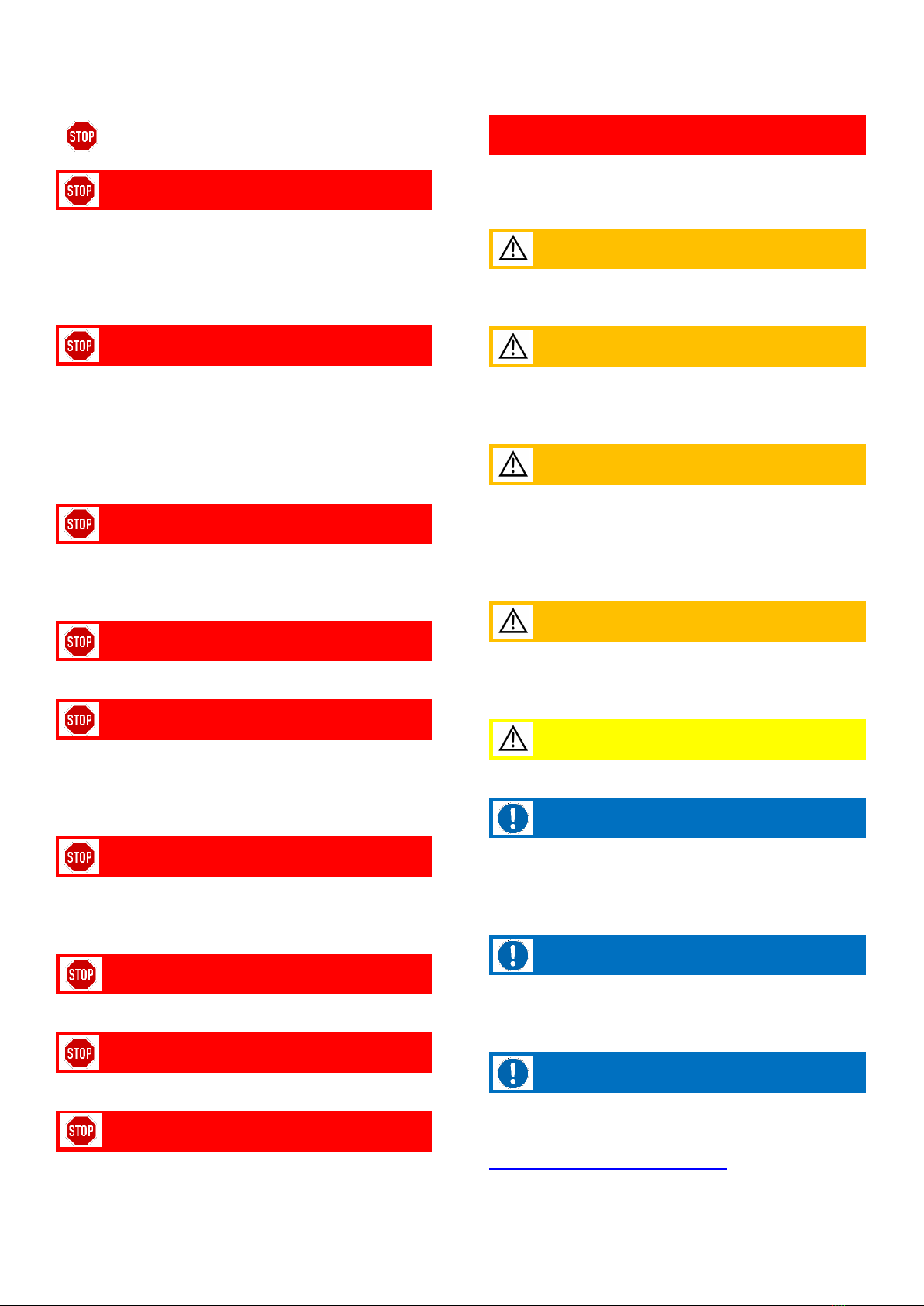

空冷水箱

(3)

当加注冷水箱LED(14)亮起时,给冷水箱(3)加水。

在按下手柄上的蒸汽开关时,会有蜂鸣器响起,蒸

汽不再从喷嘴中喷出。

冷水箱无水,水泵将停止工作。

冷水加注LED灯亮起,锅炉加热器将开启30分钟。

在机器电源接通情况下,如果30分钟内没有给冷水

箱加水,锅炉加热器就会关闭。

在每次给冷水箱加水时,请清空收集箱(4)。

集水箱

满(4)

每次给冷水箱加水前,一定要清空集水箱。

电机噪音的音调发生变化,喷嘴处没有吸力。

关机,清空收集罐,冲洗干

净。

使用后

储存软管

在使用结束后将软管从机器前部取出,冷却后存放

在厂家提供的篮子/袋子里。

安全保

护措施

本机

仅能由经过培训的操作人员使用。

允许事项

•在插入之前,请检查电缆和插头是否安全

和完好无损。

•必要时,放置“正在清洁中”的标志

•在使用过程中,请将蒸汽喷嘴远离您的身

体。

•在每次使用后清空并清洁机器

警告

小心

危

险

7

禁止事项

•在人、儿童或动物附近使用机器

•将蒸汽对准电器

•使用设备清理设备自身

•请勿用于天鹅绒、缎面或皮革上。

•让机器无人看管

维护

机器的维护是保证机器正常运行、使用寿命长的前提。

仅使用TASKI原厂配件;否则,任何保修和责任索

赔都将失效。

为了排除机器的非预期功能,在开始维修工作前,

必须始终进行以下工作。

——必须关闭机器

日常维护

每天或每运行

8

小时维护一次。

1. 给蒸汽管中蒸汽销的“O”型圈润滑。

2.从盆中吸一或两升水到集水箱中清洗软

管。

3.清空集水箱,冲洗并擦拭干净。

4.取下泡沫过滤器,用水清洗后重新安装

。

5.注意不要损坏过滤网。如有破损,请勿

使用本机,并立即更换损坏部件。

6.用干净的湿布擦拭机身

7.使用热肥皂水清洗配件。(

请勿将机器

或软管浸入水中

)

8. 将电源线包好后再存放。

每周维护

每周或每运行

50

小时维护一次。

除了每日保养外,还包括以下事项:

1. 检查电源线是否有损坏的迹象。如有损

坏请勿维修,请与本产品的供应商联系

。在维修前,请勿使用电源线。.

2. 检查软管组件是否有任何损坏的迹象。

如有损坏请勿维修,请与本产品的供应

商联系。在维修前,请勿使用电源线。

3. 检查脚轮,确保所有固定螺栓完全拧紧

。

服

务中心

在您下订单或机器发生故障要与我们联系时,请务

必注明机器的型号和编号。

您的机器铭牌上提供了所需的信息。

本使用说明的最后一页提供离您最近的TASKI服务

合作伙伴的地址。

质保

如本设备,或其任何部件因工艺或材料问题而被证

明存在缺陷。请与您购买的供应商联系,由其自行

决定维修或更换,人工和材料免费的前提是:

•本设备的安装和使用符合我们的操作和维

修说明。

•如设备被未经本公司授权的任何人进行过

保养、维护、维修、修改、拆开或篡改,

则本公司对其工艺缺陷引起的任何故障不

承担任何责任。

•在使用非本公司提供和推荐的备件而造成

的设备故障,本公司不承担质保责任。

•正常磨损而需要更换的部件,如软管、喷

嘴和附件,不在质保范围内。

注意

8

技

术数据

锅炉

功率

2100

瓦特

种类粉末涂层

容量

1.8

升

连续填充 是

蒸汽压力

4.5

巴

蒸汽源

165°C >

真空

种类完整的

电机

850

瓦特

噪声级

67 dB(A)

电气

电压 240V ~单相

低压控制

5V

电源线长度

10m

额定输入功率

2950

瓦特

手臂振动水平

<2.5m/s

容量

锅炉

1.8

升

冷水槽

2.5

升

(

易充

)

收集罐

12

升

附件

No.

项目.

数量

7523547 2.5m蒸汽、真空和洗涤

剂软管 X1

7523548 延长管 X2

7523552 250mm玻璃扒头X1

7523553 家私吸尘工具 X1

7523549 300mm地刷喷嘴 X1

7523550

300mm

刮刀插件

X1

7523551

300mm

地毯插件

X1

吸缝扒头 X1

7523556 短蒸汽喷枪 X1

7523557

95mm

三角刷

X1

7523570 服务工具包组合 X1

7523554 尼龙细节刷 X5

7523555 黄铜细节刷 X5

设备尺寸

尺寸

高度

58cm

加手柄和篮子的高度

82cm

深度

57cm

加手柄和篮子的深度

80cm

宽度

40cm

净重

25kg

包装高度

88cm

包装深度

70cm

包装宽度

52cm

包装毛重

32kg

9

故障

表

现

可能的原因

需采取的行

动

未通

电

墙上插座故障或未连接 检查墙壁插座和插座开关的连接情况。尝试其他

墙面插座

开关不亮 按到打开的位置

保险丝烧断

用经批准的13A保险丝更换原保险丝(仅限英国

机器)。

未知 请求服务

无蒸汽

蒸汽控制装置顺时针转到最下方 将控制器转到一半

蒸汽机未准备就绪 等待机器前面的"蒸汽就绪"指示灯亮起。

清洁水箱水位低(蜂鸣声和"加注

清水"灯亮起)。

将清洁的冷水倒入清洁水箱。哔哔声会停止。等

待"蒸汽就绪"灯亮起。

未知 请求服务

没有蒸汽,只

有水

蒸汽机未准备就绪 等待机器前面的"蒸汽就绪"指示灯亮起。

锅炉处于压力状态,不加热(温

度低于110℃)。

按住蒸汽开关开启约一分钟,即使只是出水。这

将导致加热器重启。

未知 请求服务

前排插座漏出

蒸汽

"O"型圈分裂 更换并重新润滑 "O"形环。为了避免发生这种情

况,确保"O"型环在每次使用前都进行了润滑。

"O"型环磨损

更换并重新润滑 "O"形环。为了避免发生这种情

况,确保"O"型环在每次使用前都进行了润滑。

真空功率低

高音调电机噪音

关闭机器,清空集水箱。将清洁的水重新注入集

水箱,使水位达到标记位置,然后重新开始工作

。

未知 请求服务

显示CLD 机器冷冻或环境温度低于3 ºC。

将机器放置在较温暖环境中一小时,然后再开机

。如问题依然存在,请联系我们

显示PFT 锅炉/水泵故障 请求服务

废弃处理

在产品使用期限到期后,必须完全按照国家规定对机器及附属部件进行处理。

-

请联系您的

Diversey

服务合作伙伴寻求帮助。

注意

10

Always read the instructions of use and the safety

instructions before using the machine for the first

time. The instructions of use must be kept in a

safe and well accessible place so that you can

refer to them at any time.

Warnings and information plates on the machine

provide directions for safe operation.

Apart from the instructions provided please

observe any legislation for prevention of

accidents in the country/place of use.

Symbols used throughout the safety

instructions and on the machine

This sign designates important information.

Failure to follow these instructions may result in

danger to persons and/or extensive damage to

property!

This sign designates important information.

Failure to follow these instructions may result in

danger to persons, malfunction and damage to

property!

This sign designates important information.

Failure to follow these instructions may result in

faults and damage to property!

This sign designates important information

regarding the efficient use of the product. Failure

to follow these instructions may result in faults!

-Do not touch surface may be hot

-Do not point or spray toward people,

animals or any electrical appliances

Table of Contents

Safety Instructions………………………………...10

Further Information………………………………..11

Transport & Storage………………………………12

Appliance Socket………………………………….12

Structural Layout…………………………………..12

Operating Instructions…………………………....13

During Use…………………………………..........14

Safety Precautions………………………….........14

Maintenance……………………………………….15

Service Centre………………………………........15

Guarantee………………………………………….15

Technical Data…………………………………….16

Accessories………………………………………..16

Machine Dimensions……………………………...16

Malfunctions………………………………………..17

Disposal…………………………………………….17

Intended Use

The machine is manufactured and designed to

generate steam.

Wear safety shoes and gloves and any other PPE

as specified by local regulations.

The appliance is suitable for commercial use e.g.

in hotels, schools, hospitals, factories, shops,

offices and hire shops.

Any other use is considered as improper use.

Diversey accepts no liability for any damage

resulting from such use. The risk is solely borne

by the user.

Proper use also includes correct operation,

service and repair specified by Diversey.

Changes to the machine that have not been

authorized by Diversey will lead to the expiry of

safety marks and CE conformity. Using the

machine for purposes other than the intended

purpose can cause injuries to persons, and

damage to the machine and the working

environment. Such cases will usually result in the

termination of any warranty and possible

guarantee claims.

Safety instructions

Due to their design and construction, TASKI

machines comply with the relevant essential

health and safety requirements of the EC

directives; they therefore have the CE sign.

Safety Instructions

The machine may only be used by persons who

are adequately trained for the use of the machine

or who have provided proof of their skills

regarding the use of the machine and who are

explicitly commissioned to use the machine.

Danger

Warning

Caution

Notice

Danger

Danger

Danger

EN Translation of the original

instructions

11

The machine must not be used by people with

reduced physical, sensory or mental capacities,

including children or people who lack experience

or knowledge.

Children must be supervised to ensure that they do not

play with the machine.

Do not use the machine in rooms where explosive

or highly combustible substances (e.g. gas,

solvents, heating fuel, dust, etc.) are stored or

processed.

These substances could be ignited by the electrical or

mechanical components of the machine.

Do not use the machine for the vacuum cleaning

of toxic, harmful, corrosive or irritant substances

(e.g. dangerous dust, etc.) or flammable liquids.

The filter system does not adequately filter out

these kinds of substances.

Possible impacts on the health of the user or third

persons cannot be ruled out.

Pay attention to the local situation as well as to

third persons and children! In the vicinity of blind

spots such as doors or curves in particular, it is

important to reduce speed.

Do not transport other persons and objects with

this machine.

In case of malfunction or defect or after collisions

or toppling over, the machine must be inspected

by an authorized expert before restarting. The

same applies if the machine was left outdoors,

immersed in water or subjected to moisture.

The machine must be stopped immediately in the

event of damage to safety-relevant parts such as

power supply cords, or covers that enable access

to live parts.

The machine must not be stopped, parked or

stored on slopes.

The machine must be switched off for any work

carried out on the machine.

The machine must not be used on slopes >2%.

Sharp cornering on slopes can affect the stability

of the machine and is therefore prohibited.

Danger of accident.

The machine may only be used on a fixed, stable

and sufficiently load-bearing surface.

In the case of non-adherence there is a risk of

accidents.

Operate and keep the machine in a dry and low-

dust environment at temperatures between

+10°C / + 50°F and +35°C/ + 95 °F degrees only.

Only authorized experts who are familiar with all

safety instructions relevant for this machine are

allowed to repair mechanical or electrical machine

parts.

Only tools (brushes, nozzles or similar) that are

specified in these instructions of use under

accessories, or which have been recommended

by a TASKI consultant, may be used. Any other

brushes might impair the safety and functions of

the machine.

National regulations for personal protection and

accident prevention as well as the manufacturer's

instructions for the use of cleaning solutions must

be consistently observed.

In case of water leakage from the machine, the

unit must be switched off immediately.

The machine must be protected against

unauthorized use. Therefore, keep the machine in

a locked room before leaving it.

Further Information

The electric diagram of this machine is

provided in the spare parts list.

-Please contact your customer service for further

information.

These instructions of use as well as all

instructions of use for TASKI machines are

available on the following website:

www.taski.com/instructions-use

Danger

Warning

Warning

Warning

Warning

Danger

Danger

Danger

Danger

Danger

Danger

Danger

Danger

Caution

Notice

Notice

Notice

Danger

12

Transport and Storage

Before transporting make sure all the lids are on

and fully tightened or locked in place.

Only transport and use in an upright position, do

not tilt or lie on its side.

Protect the unit from rain and frost. Do not store

outside or use in the rain.

The voltage specified on the type plate must

correspond to the voltage of the electrical source.

It is recommended that the machine is connected

via a residual current circuit breaker with

overprotection switch (max 30mA for 30ms).

Please use the mains cable provided by the

manufacturer and check for damage regularly. If

the cord becomes damaged please contact

Diversey for a replacement (using part code:

11RM00061 for UK plug and 11RM00062 for EU

Plug) prior to using the machine again.

Inadequate extension cords can be dangerous. If

an extension cord is used, it should be suitable

for outdoor use and the connection has to be kept

dry and off the ground by at least 60mm.

Turn off and remove the plug from the power

source when replacing parts or cleaning the

machine.

Appliance Socket

The appliance socket is only designed for the

purposes defined in the operating instructions.

The connection of different appliances can result

in damage.

Prior to plugging in the hose, switch off the

machine and only use the hoses as specified by

the manufacturer.

The machine has a pressure release valve built

into the unit which will open if the machine

pressure ever gets too high. This will release from

the bottom of the machine, if this happens please

contact your supplier or Diversey for repair or

information

If liquid or foam escapes from the machine,

switch off immediately and contact the distributor

or Diversey direct.

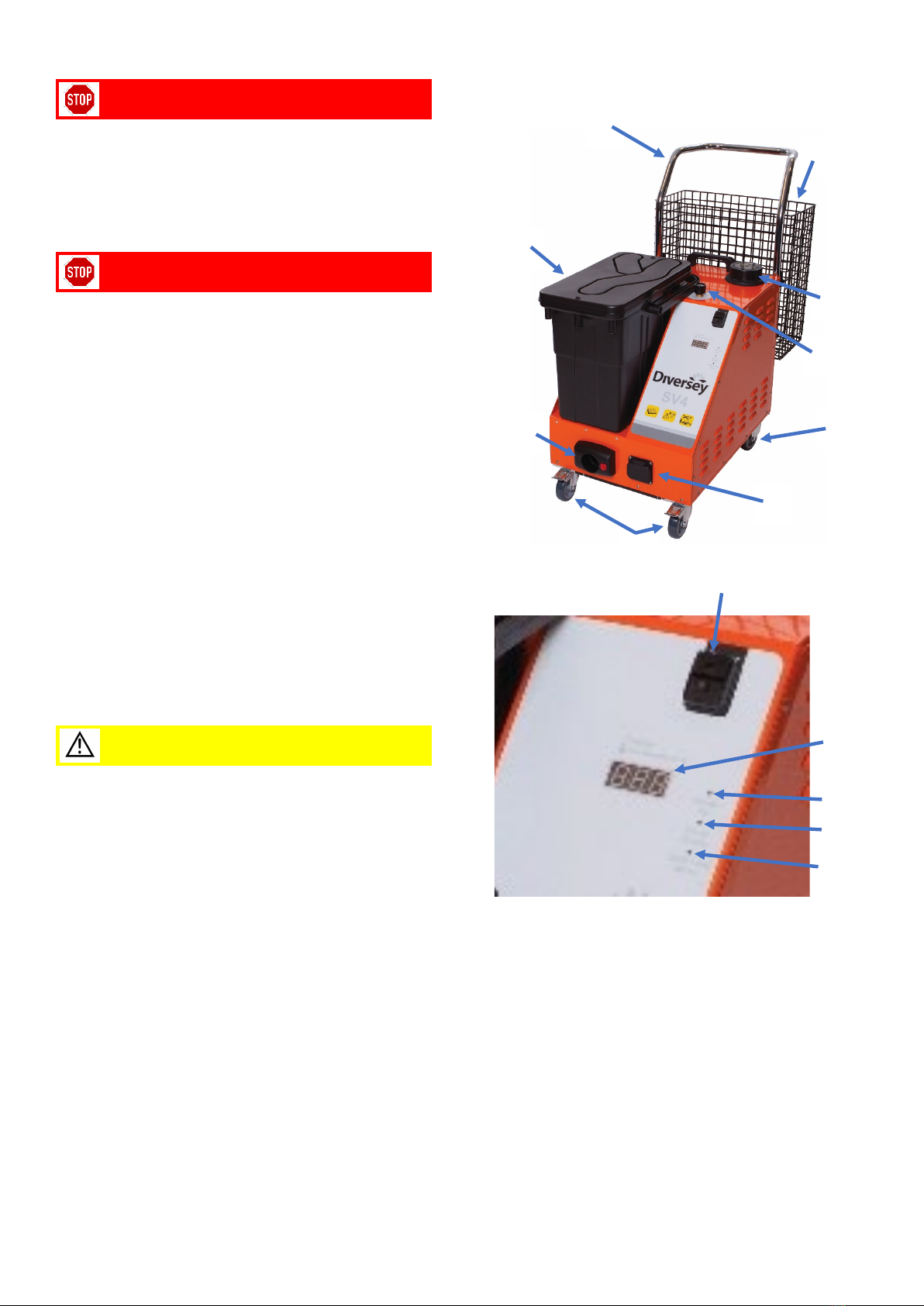

Structural Layout

10

1 Handle

2 Accessory basket

3 Clean water tank

4 Collection tank

5 Variable steam control

6 No braked casters (rear)

7 Vacuum hose socket

8 Steam hose socket

9 Braked casters (front)

10 Power on/off switch

11 LED temperature display

12 LED heater on

13 LED steam ready

14 LED cold water refill

Danger

Danger

Caution

6

12

14

2

1

4

5

3

7

9

13

8

11

13

Operating Procedures

Fill the cold water tank (3)with clean cold water

only.

Anything other

than clean cold

water used in

the water tank

will void the

manufacturer’s

warranty.

Connect the Vacuum Hose to the front of the

machine (7) ensuring it locks into position. To

release the vacuum hose from the socket slide

the red button upwards at the same time as

pulling the hose out.

If the Hose becomes damaged the complete hose

must be replaced. Do not attempt this task

yourself, contact a Diversey approved supplier for

replacement.

Connect the Steam Hose to the front of the

machine (8)

Ensuring it is pushed in all the way and the pin on

the flap locks into the hole on the hose.

Ensure the

steam hose

cannot be pulled

out.

IMPORTANT

-Grease “O” rings on steam pin before

connecting.

-To release the steam hose, lift the flap

and pull.

-Plug the power cable into a 240 Volt

supply.

IMPORTANT

-Inspect the electric cable before every

use. If the cable becomes damaged at

any time the complete cable must be

replaced by a Diversey approved

distributor.

-Never touch the power cable or plug with

wet hands

-Always unplug the machine when the

machine is not in use when:

oCleaning the machine

oAny maintenance work is being

carried out

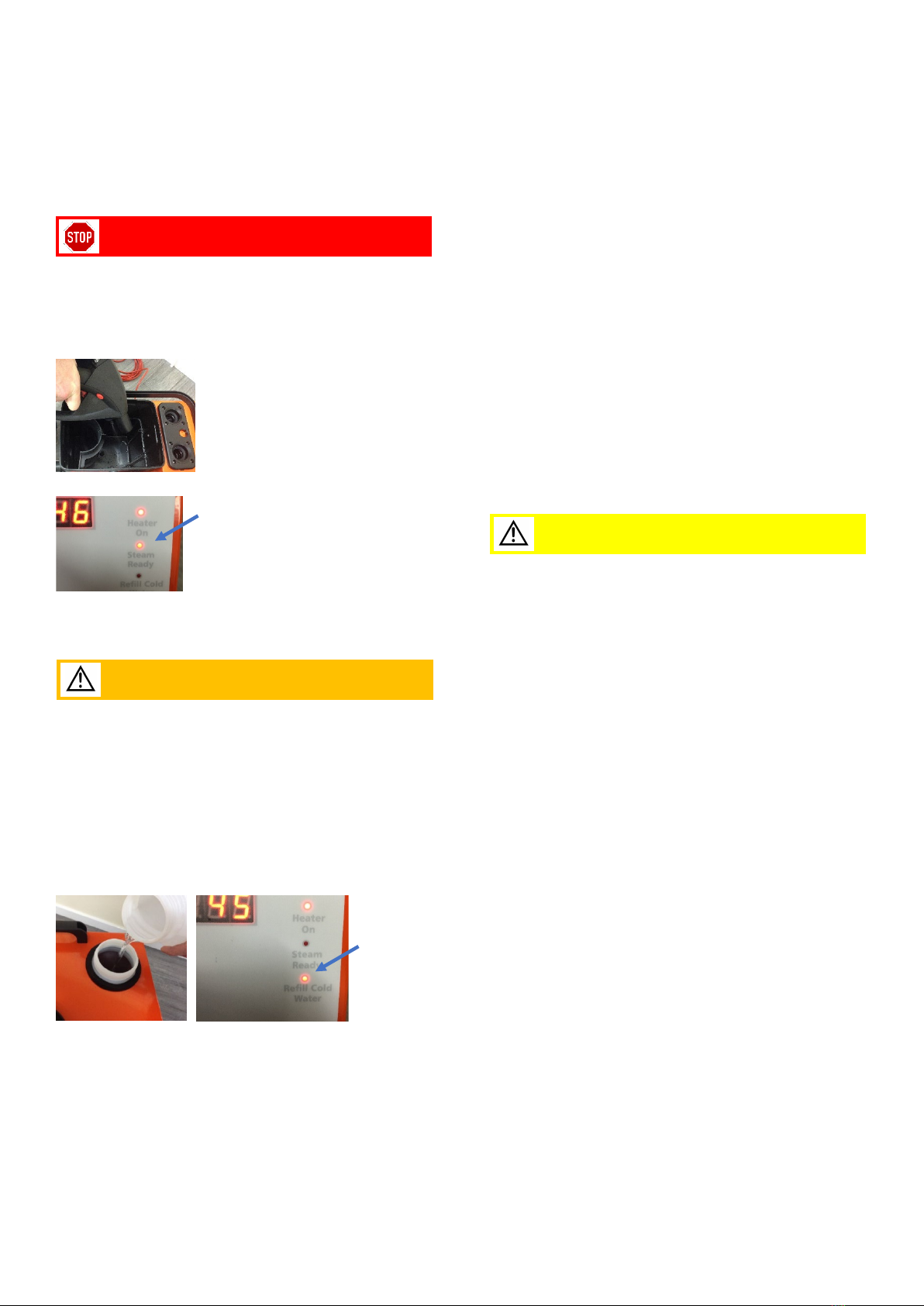

Switch the On/Off switch (10) to the ON position.

The Heater On light LED (12)will illuminate.

Allow approximately 5

minutes for the boiler to

heat the water

When the Steam Ready LED (13) illuminates the

machine is ready to be used.

The handle controls are now active.

14

•The red trigger on the hose handle will

release steam when pressed.

•The red button on the side of the handle will

lock the steam trigger in the off position.

•Pressing the left hand switch on top of the

handle will activate the vacuum

Whenever the machine is not in use this must

be locked in the off position

Direct into a suitable container to allow any

excess water/air to escape.

Re-allow the temperature to

increase and the steam ready

light will re illuminate (13)

The steam output can be adjusted by the variable

steam control (5)

Choose and fit the required accessory to the hose

handle.

When changing accessories during use please

note these will be hot!!

During Use

Cold water tank empty (3)

Refill the cold water tank (3) when the refill cold

water LED (14) is illuminated.

Abuzzer will sound and the steam will no longer

come out of the nozzle when the steam switch on

the handle is pressed.

The pumps will not work when the cold-water tank

is empty.

Once the cold water refill LED is illuminated the

boiler heater will remain on for 30 minutes. If the

cold-water tank is not refilled within 30 minutes

and the machine is left powered on the boiler

heater will switch off.

Always empty the collection tank (4) each time

the cold-water tank is refilled.

Collection tank full (4)

Always empty the collection tank each time the

cold-water tank is refilled

The pitch of the motor noise changes and there is

no suction at the nozzle

Switch off the machine, empty the collection

tank and rinse clean

Storing the hose after use

On completion remove the hose from the front of

the machine and store in basket/bag provided,

once cooled.

Safety Precautions

This machine is to be used by trained

operatives only

DO

•Check the cable and plug are safe and intact

before plugging the machine in.

•Place cleaning in progress signs where

necessary

•Point the steam nozzle away from your body

during use

•Empty and clean machine after each use

DON’T

•Use the machine near people, children or

animals

•Point steam at electrical apparatus

•Use the machine to clean the machine down

•Do not use on Velvet, satin or leather

•Leave the machine unattended

Warning

Caution

Danger

15

Maintenance

The maintenance of the machine is a prerequisite for

impeccable operation and a long service life.

Use original TASKI parts only; otherwise, any

warranty and liability claims will expire.

In order to rule out unintended machine functions,

before starting maintenance works the following

must always be carried out

-the machine must be switched off,

Daily Maintenance

To be carried out every day or every 8 hours of

operation.

1. Grease “O” rings on the steam pin in the

steam hose

2. Wash the hose by sucking one or two litres of

water from a basin into the collection tank

3. Empty the collection tank, rinse and wipe

down

4. Remove the foam filter, wash in water and re

fit.

-Take care not to damage the filter mesh.

If it becomes torn do not use the machine

and replace damaged parts immediately

5. Wipe down the body of the machine with a

clean damp cloth

6. Always wash the accessories in hot soapy

water. (Do not immerse the machine or

hose in water)

7. Wrap the power cable up before storing

away.

Weekly Maintenance

To be carried out every week or every 50 hours of

operation.

As for daily maintenance plus the following:

1. Inspect the power cable for any signs of

damage. If damaged do not repair, contact

the supplier of this product. Do not use

until repaired.

2. Inspect the hose assembly for any signs of

damage. If damaged do not repair, contact

the supplier of this product. Do not use

until repaired.

3. Inspect castors to ensure all securing bolts

are fully tightened.

Service Centre

Please always indicate the type and number of

the machine whenever you contact us for order

placing or in case of malfunctions.

The required data are provided on the nameplate

of your machine.

The address of your closest TASKI service

partner is provided on the last page of these

instructions of use.

Guarantee

If this appliance, or any parts thereof, is proved to

be defective by reason of faulty workmanship or

materials. Please contact the supplier you

purchased from, and at their option repair or

replace the same free of charge for labour and

materials, provided that:

•The appliance has been installed and

used in accordance with our operating and

servicing instructions.

•If the appliance has been serviced,

maintained, repaired, modified taken apart

or tampered with by any person not

authorised by us, then we will not be liable

under this guarantee for any fault arising

from their defective workmanship.

•We shall not be liable under this

guarantee for any fault in the appliance

arising from the use of spare parts not

supplied and recommended by us.

•Excluded from this guarantee are parts

that need replacement due to normal wear

and tear such as hoses, nozzles and

accessories.

Notice

16

Technical data

Boiler

Wattage

2100 watts

Type

Powder coated

Capacity

1.8 Litres

Continuous Fill

Yes

Steam pressure

4.5 bar

Steam at Source

165°C >

Vacuum

Type

Integral

Motor

850 watts

Noise level

67 dB(A)

Electrical

Voltage

240V ~ single phase

Low voltage controls

5V

Power cable length

10m

Nominal input power

2950 watts

Hand-arm vibration level

<2.5m/s

Capacities

Boiler

1.8 Litres

Cold water tank

2.5 litres (easy-fill)

Collection tank

12 litres

Accessories

No.

Item.

Qty

7523547

2.5m Steam, vac and

detergent hose

X1

7523548

Extension tube

X2

7523552

250mm Glass Washer

X1

7523553

Upholstery Suction

Tool

X1

7523549

300mm Floor Brush

Nozzle

X1

7523550

300mm Squeegee

Insert

X1

7523551

300mm Carpet Insert

X1

Crevice Tool

X1

7523556

Short Steam Lance

X1

7523557

95mm Triangular Brush

X1

7523570

Service Kit Matrix

X1

7523554

Nylon detail brush

X5

7523555

Brass detail brush

X5

Machine Dimensions

Dimensions

Height

58cm

Height with handle and basket

82cm

Depth

57cm

Depth with handle and basket

80cm

Width

40cm

Net weight

25kg

Packaging height

88cm

Packaging depth

70cm

Packaging width

52cm

Packaging gross weight

32kg

17

Malfunctions

Symptom

Possible Cause

Action Required

No Power

Faulty wall socket or not connected

Check connection to wall socket and

socket switch. Try other wall socket

On/Off switch not illuminated

Press to the On position

Fuse Blown

Replace fuse with approved 13A fuse

(UK machines only)

Unknown

Call for service

No Steam

Steam Control turned down fully

clockwise

Turn the control half way

Steamer not ready

Wait for the “Steam Ready” light on the

front of the machine to illuminate

Clean water tank is low (Beeping

Sound & “Refill Clean Water” light

is illuminated)

Pour CLEAN COLD WATER into the

clean water tank. The beeping will stop.

Await for the “Steam Ready” light to

illuminate.

Unknown

Call for service

No Steam, Just

Water

Steamer not ready

Wait for the “Steam Ready” light to

illuminate

Boiler at pressure and not heating

(temperature less than 110 ºC

Hold the steam switch on for

approximately one minute, even if just

water is coming out. This will result in

the heater coming back on

Unknown

Call for service

Steam Leaking

from front

socket

“O” Rings split

Change and re grease “O” Rings. To

avoid this happening ensure “O” rings

are grease before every use

“O” rings worn

Change and re grease “O” Rings. To

avoid this happening ensure “O” rings

are grease before every use

Vacuum power

low

High pitch motor noise

Switch the machine off and empty the

collection tank. Refill the collection tank

with clean water to the mark and

recommence work

Unknown

Call for service

CLD on display Machine frozen or ambient

temperature is below 3 ºC

Place machine in a warmer environment

for an hour and then turn on the

machine again. If the problem persist

call for service

Pft on display

Boiler/pump fault

Call for service

Disposal

After withdrawal from service, the machine and

Accessory parts must be adequately disposed of

in compliance with the national regulations.

-Please contact your Diversey service partner for help.

Notice

AT

Diversey

BE

Diversey Belgium BVBA

CH

Diversey Europe B.V.,

CZ

Diversey

Austria Trading GmbH

Haachtsesteenweg 672

Utrecht

Ceska republika, s.r.o

Guglgasse 7-9

1910 Kampenhout

Zweigniederlassung

K Hájum 1233/2

1030 Wien

Tel (32) 16 61 77 06

Münchwilen

155 00 Praha 5

Tel (43) 1 605 57 0

Eschlikonerstrasse

Tel (420) 296 357 460

9542 Münchwilen

Tel (41) 71 969 27 27

DE

Diversey

DK

Diversey Danmark ApS

ES

Diversey España S.L.

FI

Diversey

Deutschland

Teglbuen 10

C/Orense 4, 5 planta

Eliel Saarisentie 2

GmbH & Co. OHG

2990 Nivaa

28020 Madrid

00400 Helsinki

Mallaustrasse 50-56

Tel (45) 70 10 66 11

Tel (34) 91 394 01 75

Tel (358) 20 747 42 30

68219 Mannheim

Tel (49) 0800 82 75 473

FR

Diversey (France) S.A.S

GB

Diversey Limited

GR

Diversey Hellas S.A.

HU

Diversey Ltd.

9/11, avenue du Val de

Weston Favell Centre

5 Himaras St

Puskás Tivadar u. 6.

Fontenay

NN3 8PD Northampton

15125 Marousi

2040 Budaors

94133 Fontenay sous

Tel (44) 1604 405 311

Tel (30) 210 638 59 00

Tel (36) 23 509 100

Bois Cédex

Tel (33) 1 45 14 76 76

IE

Diversey Hygiene Sales

IT

Diversey S.r.L.

MT

Forestals (Appliances)

NL

Diversey B.V.

Limited

Via Meucci 40

Ltd

Maarssenbroeksedijk 2

Ballyfermot office Westlink

20128 Milano

The Strand

P.O. Box:40441

industrial estate Kylemore

Tel (39) 02 25 80 32 33

SLM 07 Sliema

3542 DN Utrecht

Road

Tel (356) 21 344 700-7

Tel (31) 30 247 69 11

Dublin 10

Tel (353) 1 626 11 82

NO

Lilleborg Profesjonell

PL

Diversey Polska Sp.

PT

Diversey Portugal

RO

Diversey Romania

Postboks 673 – Skøyen

z.o.o

Sistemas de Higiene e

S.R.L

0214 Oslo

Ul.Fabryczna 5a

Limpeza Unipessoal Lda

Baneasa Business

Tel (47) 815 36 000

04-028 Warszawa

Z. Ind.Abrunheira

Center, Etaj 5

Tel (48) 22 516 30 00

2714-505 Sintra

Sos.Bucuresti – Ploiesti

Tel (351) 2 191 57 000

17-21

Sector 1, Bucuresti

Tel (40) 21 233 3894

RU

LLC Diversey

SV

Diversey Sverige AB

SK

Diversey Slovensko

SL

Diversey d.o.o.

125445, Russia,

Liljeholmsvägen 18

s.r.o

Trzaska cesta 37a

Moscow

Box 47313

Rybničná 40

2000 Maribor

24D Smolnaya str,

10074 Stockholm

831 06 Bratislava

Tel (386) 2 320 7000

Meridian Commercial

Tel (46) 877 99 300

Tel (421) 2 4445 4895

Tower 2d floor

Tel (7) 095 970 17 97

TR

Diversey Sanayi ve

US

Diversey

CA

Diversey

Ticaret A.S.

2415 Cascade Pointe

3755 Laird Road

İçerenköy Mahallesi,

Boulevard

Mississauga, Ontario

Bahçelerarası Sok.No:43

Charlotte, NC

CANADA L5L 0B3

34752 Ataşehir / İstanbul,

USA, 28277

Tel 1-800-827-5487

Türkiye

Tel 1-800-827-5487

Tel (90) 216 57 86 400

Other manuals for TASKI SV4

1

Table of contents

Other diversey Kitchen Appliance manuals