DIVERSITECH AM Series Manual

Operation & Maintenance Manual

FILTERHAWK

AMBIENT AIR CLEANER AM SERIES

READ AND SAVE THESE INSTRUCTIONS

Visit our Website for more information on this product

www.diversitech-air.com www.diversitech.ca

1200 55th Avenue, Montreal, Quebec H8T 3J8

TABLE OF CONTENTS

SECTION 1 – SAFETY & INSPECTION ....................................................................................................................................................................................................................................................................3

1.1 Safety .................................................................................................................................................................................................................................................................................................3

1.2 Inspection .......................................................................................................................................................................................................................................................................................3

SECTION 2 – SPECIFICATIONS ..................................................................................................................................................................................................................................................................................4

2.1 Product Specifications............................................................................................................................................................................................................................................................4

2.2 Dimensions ...................................................................................................................................................................................................................................................................................4

SECTION 3 – INSTALLATION .......................................................................................................................................................................................................................................................................................5

SECTION 4 – REPLACEMENT PARTS ...................................................................................................................................................................................................................................................................6

SECTION 5 – ELECTRICAL ............................................................................................................................................................................................................................................................................................7

SECTION 6 – TROUBLESHOOTING ........................................................................................................................................................................................................................................................................7

6.1 Troubleshooting Chart ...........................................................................................................................................................................................................................................................7

6.2 Blower Operation ......................................................................................................................................................................................................................................................................8

6.3 Blower Maintenance ...............................................................................................................................................................................................................................................................8

6.4 Blower Troubleshooting Chart ..........................................................................................................................................................................................................................................9

APPENDIX 1 - MAINTENANCE RECORD ..........................................................................................................................................................................................................................................................10

NOTES ..........................................................................................................................................................................................................................................................................................................................11,12,13

TERMS AND CONDITIONS TO SALES ORDERS...................................................................................................................................................................................................................................14,15

Back Cover...............................................................................................................................................................................................................................................................................................................................16

Revised JUNE 2020 [E N]

3

SECTION 1 - SAFETY & INSPECTION

!

This manual contains specific cautionary statements related to worker safety. To protect yourself

and others, read this manual thoroughly and follow as directed before use. Not all hazards of

fume & dust control are listed in this manual, and no hazards related to welding, cutting, grinding,

painting, deburring or other applications are listed. Consult a qualified safety professional.

READ

BEFORE

USE

1.1 Safety

1.2 Inspection

• Follow all building and safety codes when installing this equipment. Pertaining but not limited to, the Occupational Safety and Health Act (OSHA),

National Electric Code (NEC), Uniform Building Code (UBC), National Fire Prevention Act (NFPA) & all state and local codes.

• All electrical connections should be performed by a qualified electrician.

• Keep Flammable Objects away from the air cleaner and under no condition should a burning object be allowed into the air cleaning system.

• Take proper caution in placing units in buildings with radiant heaters installed. Follow the radiant heater manufacturer’s guidelines for clearance

to combustibles.

• Do not mix materials collected in your Air Cleaner. Materials collected could create a hazardous environment or a condition of operation for

which the equipment was not intended. The Manufacturer is relieved of any liability if this unit is not used according to this manual.

• Do not use the Air Cleaner for an application other than for which it was intended. Consult your distributor, Applicable Codes, or call Diversitech

for application assistance.

• Fire protection is not included. Please consult your local fire protection specialist for any required extinguishing equipment.

• Diversitech reserves the right to make design changes which may improve the air cleaner.

• This unit is intended for use to collect ambient dust, smoke, fume and other airborne pollutants in industrial and manufacturing Facilities. Do not

use for the collection of flammable or explosive metals, dusts, fumes or other potentially hazardous materials.

Upon receiving your Diversitech air cleaner, please inspect for any damage incurred during shipment. Inspect carefully, some damage may not be

noticeable until the unit is installed. Notify your shipper of any damage immediately. Claims must be filed with the shipper within 15 days. Freight

damage claims are the responsibility of the purchaser.

4

SECTION 2 - SPECIFICATIONS

19

72

16

25

25

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

DIVERSITECH. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF DIVERSITECH

IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES;

FRACTIONAL:

1/16"

DECIMAL:

0.01"

ANGULAR:

1

DO NOT SCALE DRAWINGS

MATERIAL

FINISH

INVENTORY #:

DATE: 2019-10-30

DESCRIPTION:

SIZE

B

DWG. NO.

REV

WEIGHT: 422.38 lbs

SCALE: 1:16

5

SHEET 1 OF 2

1200 55th Avenue│

Montreal, QC H8T 3J8

T:1-800-361-3733

│

F:514-631-9480

│

www.diversitech.ca

DRAWN BY: LEENA

FH-A-4500

# FH-A-4500

FILE PATH: E:\!ENGINEERING\1-PRODUCT LINE\160 - AMBIENT AIR CLEANERS\T-SERIES\# FH-A-4500

2.2 Product Specifications

2.4 Dimensions

Model

Airflow

(CFM)

Motor

(H.P.)

Pre

Filter

Type

Paper

Pleated

Filter

Bag

Air

Filter

Blower

Input

Power

(v/p/hz)

F.L. A

(amps)

AM-3000 3000 1.5 (2) MERV 7 (2) MERV 8 (2) MERV 14 Belt Drive 120v/1/60Hz 15.5

AM-4500 4500 3.0 (2) MERV 7 (2) MERV 8 (2) MERV 14 Belt Drive 230/460/575v/3/60Hz 9.6/4.8/3.9

Model

Product Dimensions

(in.)

Net

Weight

(lbs.)

Height

(in.)

Length

(in.)

Depth

(in.)

AM-3000 25 72 25 390

AM-4500 25 72 25 428

5

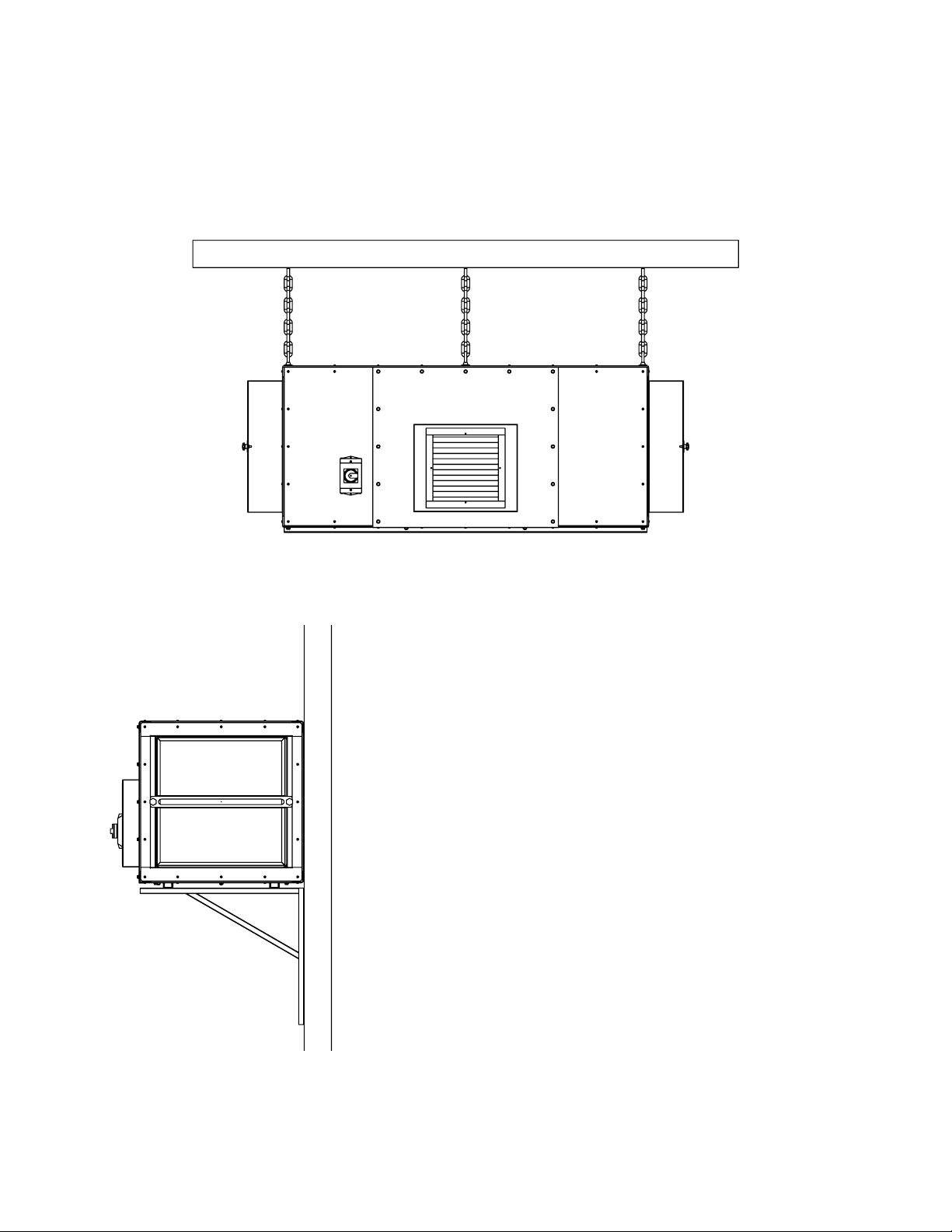

OPTION 2: ANGLED BRACES

OPTION 1: CHAIN HANGING

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

DIVERSITECH. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF DIVERSITECH

IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES;

FRACTIONAL:

1/16"

DECIMAL:

0.01"

ANGULAR:

1

DO NOT SCALE DRAWINGS

MATERIAL

FINISH

INVENTORY #:

DATE: 2019-10-30

DESCRIPTION:

SIZE

B

DWG. NO.

REV

WEIGHT: 14529.15 lbs

SCALE: 1:16

0

SHEET 1 OF 1

1200 55th Avenue│

Montreal, QC H8T 3J8

T:1-800-361-3733

│

F:514-631-9480

│

www.diversitech.ca

DRAWN BY: LEENA

INSTALLATION

# FH-A-4500

FILE PATH: E:\!ENGINEERING\1-PRODUCT LINE\160 - AMBIENT AIR CLEANERS\T-SERIES\# FH-A-4500

OPTION 2: ANGLED BRACES

OPTION 1: CHAIN HANGING

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

DIVERSITECH. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF DIVERSITECH

IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES;

FRACTIONAL:

1/16"

DECIMAL:

0.01"

ANGULAR:

1

DO NOT SCALE DRAWINGS

MATERIAL

FINISH

INVENTORY #:

DATE: 2019-10-30

DESCRIPTION:

SIZE

B

DWG. NO.

REV

WEIGHT: 14529.15 lbs

SCALE: 1:16

0

SHEET 1 OF 1

1200 55th Avenue│

Montreal, QC H8T 3J8

T:1-800-361-3733

│

F:514-631-9480

│

www.diversitech.ca

DRAWN BY: LEENA

INSTALLATION

# FH-A-4500

FILE PATH: E:\!ENGINEERING\1-PRODUCT LINE\160 - AMBIENT AIR CLEANERS\T-SERIES\# FH-A-4500

SECTION 3 - INSTALLATION

The system’s weight must be taken into account when choosing the proper installation method (see specification). Follow all applicable building

and electrical codes.

There are three main ways of installing your air cleaner, Chain Hanging (eye bolts factory installed), rod & cradle , or angle braces. Figure 2

illustrates these methods.

Mounting materials must be able to support the weight of the air cleaner plus the additional

weight of the material collected. Consult your local building code for proper installation

methods and materials. Failure to use the proper materials could result in injury or damage

equipment and will void the warranty.

6

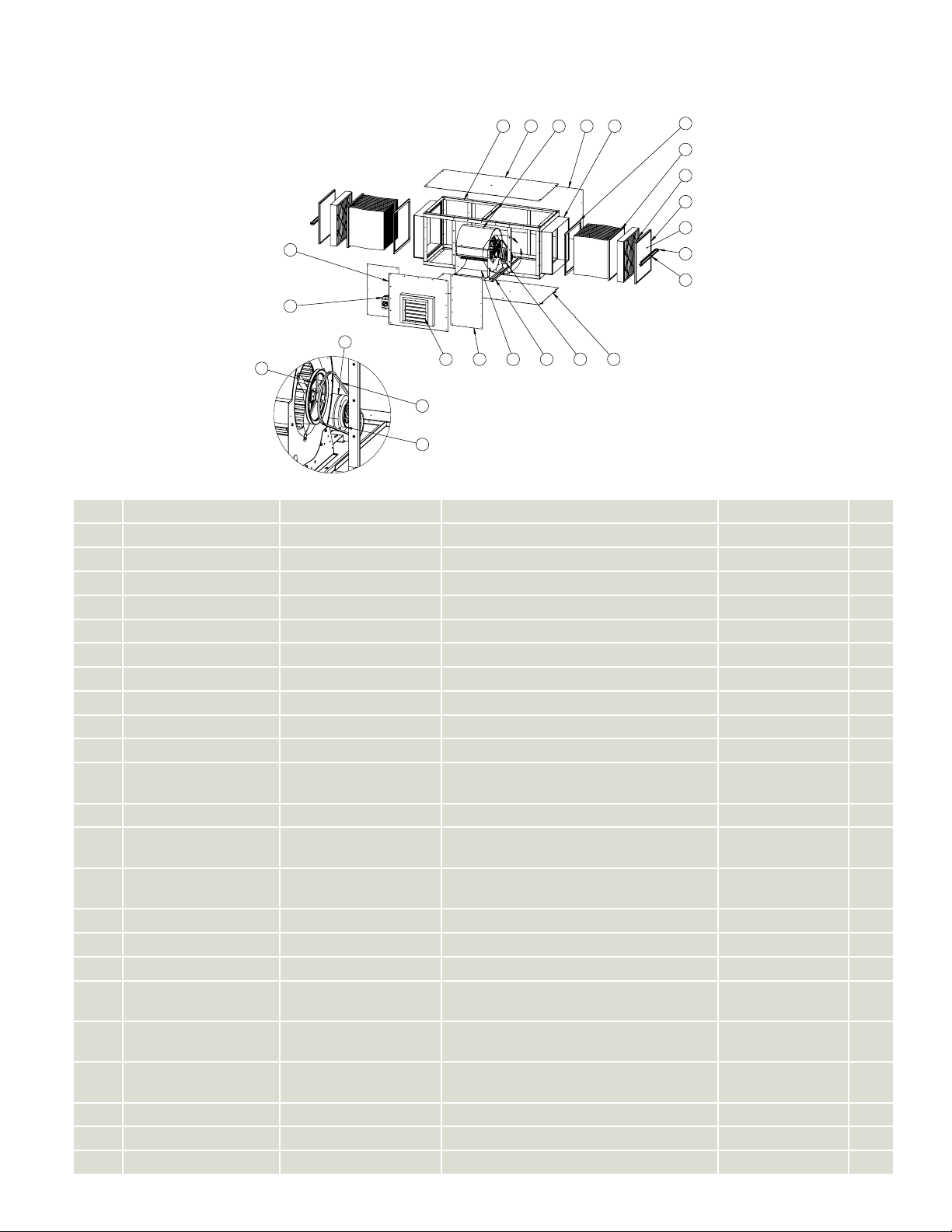

SECTION 4 - REPLACEMENT PARTS

A

1 3 18

21

20

10

7

4

16

19

23

9

8

6

5

17

211

11

22

DETAIL A

SCALE 1 : 8

15

12

14

13

ITEM

#

PART #

INVENTORY #

DESCRIPTION

MATERIAL

1

AC_FRAME

SUB ASSEMBLY

FRAME

CRS SHEET [12ga] 1

2

AC_BOTTOM

SUB ASSEMBLY

BOTTOM

CRS SHEET [14ga] 1

3

AC_TOP PLATE

INV-AC-TOPPLATE

TOP PLATE, 66.5 X 29.5

CRS SHEET [18ga] 1

4

AC_FRONT

SUB ASSEMBLY

FRONT COVER

CRS SHEET [18ga] 1

5

AC_FRONT PLATE 02

INV-AC-FSPLATE-02

FRONT SIDE PLATE

CRS SHEET [18ga] 2

6

AC_BACK PLATE

INV-AC-BACKPLATE

BACK PLATE, 66.5 X 29

CRS SHEET [18ga] 1

7

AC_BLOWER PLATE

01

INV-AC-BPLATE

BLOWER PLATE

CRS SHEET (12ga) 1

8

AC_MOTOR BRACKET

SUB ASSEMBLY

MOTOR BRACKET

CRS SHEET [12ga] 1

9

AC_FILTER HOUSING

SUB ASSEMBLY

FILTER SIDE

CRS SHEET [16ga] 2

10

AC_FILTER BRACKET

INV-AC-FBRACKET

FILTER BRACKET

CRS SHEET [16ga] 2

11

HARD

INV-MOTR-0731

DELHI G-SERIES DOUBLE INLET BLOWER,

MODEL G15

STEEL

1

12

HARD

INV-145T-030-5-

ODP-1800

MOTOR, 3HP, 575V, 60HZ, 3PH, 1725 RPM

1

13

HARD

INV-MISC-1389

PULLEY, 4L, A V-BELT, 10"OD FOR 1" SHAFT

DIA

1

14

HARD

INV-MISC-1400

V-BELT-PULLY, 4L, A, AX AND 5L, B, BX

BELTS, 4.95"PD, FOR 5/8" SHAFT

1

15

HARD

INV-MISC-1393

V-BELT, A56, 58" DOUTER CIRCUMFERENCE

1

16

HARD

INV-DUCT-1733

FIXED-BLADE WALL LOUVER

1

17

HARD

INV-CRTL-0090

ON-OFF SWITCH

1

18

HARD

INV-SEAL-1037

GASKET, CELL NEOPRENE 1/4" THK X 1"W X

8FT

2

19

HARD

INV-FILT-0141

BAG AIR FILTER, MERV 14, 21" X 24" X 24",

10 POCKET

2

20

HARD

INV-FILT-0142

PAPER PLEATED AIR FILTER, 4" X 24" X 24",

MERV 8.

2

21

HARD

INV-FILT-8759

PRE-FILTER FRAME, , 1" X 24" X 24"

2

22

HARD

INV-FILT-0751

FILTER SAVER PAD, 27'' X 27'' X 2'', MERV 7

2

23

HARD

INV-HARD-0464

NYLON KNOB - 0.25''-20 X 3/4''

4

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

DIVERSITECH. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF DIVERSITECH

IS PROHIBITED.

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES;

FRACTIONAL:

1/16"

DECIMAL:

0.01"

ANGULAR:

1

DO NOT SCALE DRAWINGS

MATERIAL

FINISH

INVENTORY #:

DATE: 2019-10-30

DESCRIPTION:

SIZE

B

DWG. NO.

REV

WEIGHT: 422.38 lbs

SCALE: 1:24

5

SHEET 2 OF 2

1200 55th Avenue│

Montreal, QC H8T 3J8

T:1-800-361-3733

│

F:514-631-9480

│

www.diversitech.ca

DRAWN BY: LEENA

FH-A-4500

# FH-A-4500

FILE PATH: E:\!ENGINEERING\1-PRODUCT LINE\160 - AMBIENT AIR CLEANERS\T-SERIES\# FH-A-4500

Figure 4

Item # Part # Inventory # Description Material

1 AC_FRAME SUB ASSEMBLY FRAME CRS SHEET [12ga] 1

2 AC_BOTTOM SUB ASSEMBLY BOTTOM CRS SHEET [14ga] 1

3 AC_TOP PLATE INV-AC-TOPPLATE TOP PLATE, 66.5 X 29.5 CRS SHEET [18ga] 1

4 AC_FRONT SUB ASSEMBLY FRONT COVER CRS SHEET [18ga] 1

5 AC_FRONT PLATE 02 INV-AC-FSPLATE-02 FRONT SIDE PLATE CRS SHEET [18ga] 2

6 AC_BACK PLATE INV-AC-BACKPLATE BACK PLATE, 66.5 X 29 CRS SHEET [18ga] 1

7 AC_BLOWER PLATE 01 INV-AC-BPLATE BLOWER PLATE CRS SHEET [12ga] 1

8 AC_MOTOR BRACKET SUB ASSEMBLY MOTOR BRACKET CRS SHEET [12ga] 1

9 AC_FILTER HOUSING SUB ASSEMBLY FILTER SIDE CRS SHEET [16ga] 2

10 AC_FILTER BRACKET INV-AC-FBRACKET FILTER BRACKET CRS SHEET [16ga] 2

11 HARD INV-MOTR-0731 DELHI G-SERIES DOUBLE INLET BLOWER,

MODEL G15

STEEL 1

12 HARD INV-145T-030-5-ODP-1800 MOTOR, 3HP, 575V, 60HZ, 3PH, 1725 RPM 1

13 HARD INV-MISC-1389 PULLEY, 4L, A V-BELT, 10”OD FOR 1” SHAFT

DIA

1

14 HARD INV-MISC-1400 V-BELT-PULLY, 4L, A, AX AND 5L, B, BX

BELTS, 4.95”PD, FOR 5/8” SHAFT

1

15 HARD INV-MISC-1393 V-BELT, A56, 58” DOUTER CIRCUMFERENCE 1

16 HARD INV-DUCT-1733 FIXED-BLADE WALL LOUVER 1

17 HARD INV-CRTL-0090 ON-OFF SWITCH 1

18 HARD INV-SEAL-1037 GASKET, CELL NEOPRENE 1/4” THK X 1”W

X 8FT

1

19 HARD INV-FILT-0141 BAG AIR FILTER, MERV 14, 21” X 24” X 24”,

10 POCKET

2

20 HARD INV-FILT-0142 PAPER PLEATED AIR FILTER, 4” X 24” X 24”,

MERV 8.

2

21 HARD NV-FILT-8759 PRE-FILTER FRAME, , 1” X 24” X 24” 2

22 HARD INV-FILT-0751 FILTER SAVER PAD, 27’’ X 27’’ X 2’’, MERV 7 2

23 HARD INV-HARD-0464 NYLON KNOB - 0.25’’-20 X 3/4’’ 4

7

SECTION 5 - ELECTRICAL

SECTION 6 - TROUBLESHOOTING

3 PHASE ELECTRICAL DIAGRAM

!

Recommended Maintenance: Remove dirt accumulations in and around vent openings, by

vacuuming. Dirt accumulations can cause motor overheating and a fire hazard. Enclosed motors

can be cleaned with an air jet; wear eye protection.

Periodically inspect the installation. Check for dirt accumulations; unusual noises or vibration;

overheating; worn or loose couplings, sheaves and belts; high motor current; poor wiring or

overheated connections; loose mounting bolts or guards; and worn motor starter contacts.

WARNING!

Additional wiring will be required to get power to unit, which is not supplied with this product.

Motor Starters, disconnect, wiring, overloads, and thermal protection are NOT provided by the Manufacturer

All Field wiring should be performed by a qualified electrician and must meet all local, NFPA and NEC codes. Failure to install the proper electrical

wiring, thermal protection, and controls will void the warranty.

After completion of the field wiring, turn the unit on to check for proper rotation. Rotation is marked on the side of the blower housing. Backward

rotation will result in a much lower air flow, louder noise, and will over amp the motor. Check the motor nameplate before switching wires and

reversing rotation, to ensure the unit is operating at or below rated amp draw.

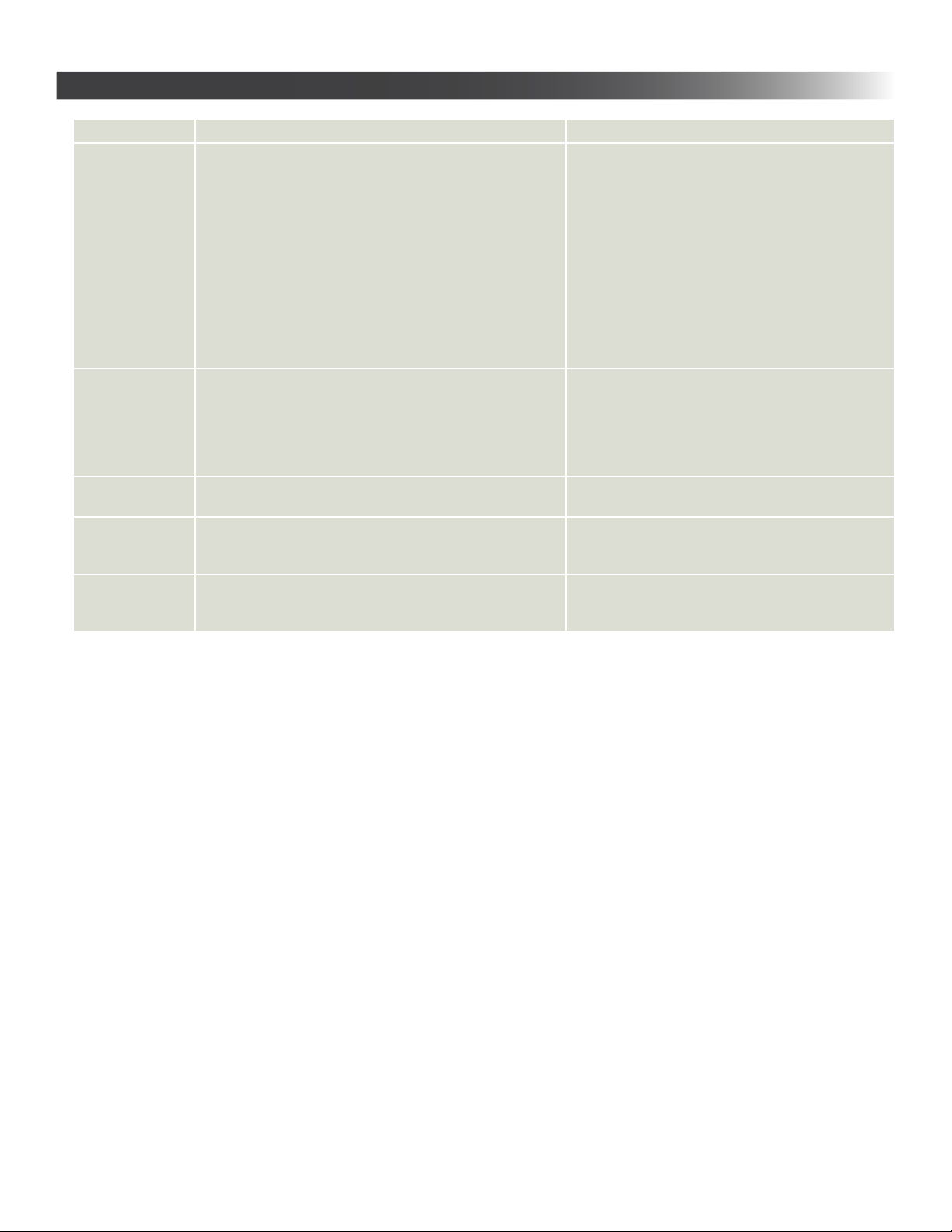

This chart suggests common answers to electric motor problems. The information is not all-inclusive and does not necessarily apply in all cases.

When unusual operating conditions, repetitive failures, or other problems occur, consult an electric motor service firm for assistance.

Symptom Possible Cause(s) Corrective Action

Motor fails to start

1. Blown fuses

2. Voltage too low at motor terminals due to line drop

3. Overload in motor starter tripped

4. Overload (internal thermal protector) tripped

5. Improper line connections

6. Motor may be overloaded

7. Defective motor or starter.

1. Replace with time-delay fuses. Check for grounded

winding

2. Consult local power company. Increase wire size (refer to

Tables A & B). Check for poor connections

3. Check and reset overload relay in starter. Check heater

rating against motor nameplate current rating

4. Check motor load. If motor has an automatic or manual

reset thermal protector, check if tripped

5. Check connections against diagram supplied with motor

6. Reduce load or increase motor size

7. Repair or replace

Motor does not come

up to speed or takes too

long to accelerate

1. Not applied properly.

2. Voltage too low at motor terminals

3. Starting load too high.

4. Excess loading; tight belts

5. Defective motor

6. Inadequate starting torque. High inertia load

1. Consult motor service firm for proper type. Use larger

motor.

2. Increase wire size (refer to Tables A & B). Check for poor

connections. Check for voltage unbalance (3-Phase)

3. Check load motor is carrying at start.

4. Reduce load; adjust belts. Increase motor size.

5. Repair or replace

6. Replace with larger motor

Motor stalls during

operation

1. Overloaded motor

2. Low motor voltage

1. Reduce load or increase motor size

2. Verify that nameplate voltage is maintained

6.1 Troubleshooting Chart

8

Symptom Possible Cause(s) Corrective Action

Motor vibrates or is

excessively noisy

1. Motor shaft misaligned

2. 3-phase motor running on single phase

3. High or unbalanced voltages

4. Worn, damaged, dirty or overloaded bearings

5. Defective winding. Bent or bowed shaft

6. Loose sheave or misaligned coupling

1. Realign

2. Check for open circuit, blown fuses or unbalanced voltages

3. Check wiring connections. Consult local power company

4. Replace bearings; check loading and alignment

5. Repair or replace

6. Tighten set screw(s); realign coupling

Motor overheats while

running under load

1. Overloaded

2. Dirt blocking

3. If 3-Phase, one phase may be open

4. Unbalanced supply voltage

5. Faulty connection

6. High or low voltage

7. Defective motor

1. Reduce load; adjust belts. Increase motor size.

2. Clean motor

3. Check lines for open phase. Check voltage with motor

disconnected, one fuse may be blown.

4. Check for faulty connections. Voltage on all three lines

should be balanced within 1%. Balance single phase loads.

5. Clean, tighten, or replace

6. Check voltage at motor, should not be more than 10%

above or below rated

7. Repair or replace

6.2 Blower Operation

6.3 Blower Maintenance

After electrical connections are completed, start motor briefly to determine the direction of wheel rotation. If necessary to reverse the rotation,

follow instructions given on the motor nameplate or terminal box cover.

With air system in full operation, and with all ducts attached and inspection door(s) closed, measure the current input to the motor and compare

with nameplate rating to determine if the motor is operating under safe load conditions.

1. After electrical connections are completed, start motor briefly to determine the direction of wheel rotation. If necessary to reverse. The rotation,

follow instructions given on the motor nameplate or terminal box cover.

2. Follow motor manufacturer’s instructions for motor lubrication. Remove excess lubricant.

3. Follow Replacement Parts Manual for blower bearing lubrication.

4. Check wiring to make sure it is secure and well insulated.

9

Symptom Possible Cause(s) Corrective Action

Excessive noise

and/or vibration

1. Foreign object

2. Wheel rubbing on housing

3. Loose wheel or sheave on shaft

4. Motor or blower not secure

5. Belt(s) too loose/too tight

6. Worn belt(s)

7. Mismatched belt(s)

8. Loose or worn bearings

9. Bearing or drive alignment

10. Accumulation of material on wheel

11. Motor out of balance

12. Wheel out of balance

13. Sheaves eccentric or out of balance

1. Remove

2. Center the wheel

3. Tighten all set screws

4. Tighten Mounting

5. Adjust Tension

6. Replace

7. Replace

8. Replace

9. Realign

10. Clean

11. Replace

12. Replace or Re-balance

13. Replace

Insufficient air flow

1. Blower speed too low

2. Dampers or registers closed

3. Dirty or clogged filters

4. Leaks in duct work

5. Elbows, cabinet walls, or other obstructions

6. Belt slippage

1. Check for correct drives

2. Open

3. Clean or replace

4. Repair

5. Correct

6. Adjust or replace

Too much air flow 1. Blower speed too high

2. Filter(s) not in place

1. Check for correct drives

2. Install filter(s)

Unit fails to operate

1. Blown fuse or open circuit breaker

2. Broken fan belt

3. Defective motor and/or capacitor

1. Replace or reset

2. Replace

3. Replace

Motor overloads

or overheats

1. Blower speed too high or motor horsepower too low

2. System static pressure too low

3. Shorted windings in motor

1. See Specifications for correct drives and HP

2. Check static pressure and correct system

3. Replace

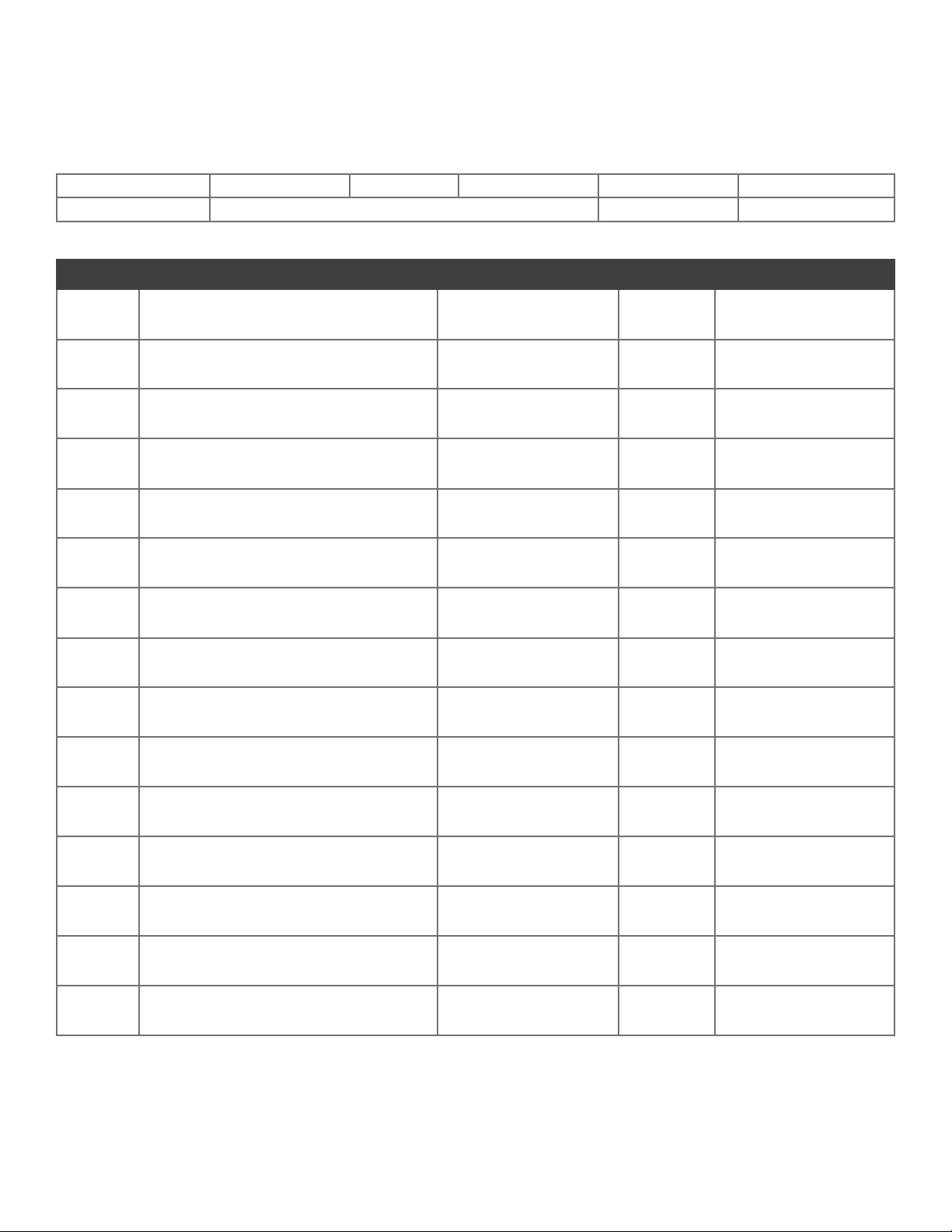

6.4 Blower Troubleshooting Chart

10

APPENDIX 1 - MAINTENANCE RECORD

Diversitech Inc. authorizes this page to be photocopied or otherwise reproduced as needed for management of maintenance records.

MANUFACTURER: DIVERSITECH INC. MODEL N° AMBIENT AIR CLEANER SERIAL N°

SERVICE LOCATION: CONTROL N°

Date Description of Service Serviced By Location Comments

Only use manufacturer approved replacement parts on this unit.

11

NOTES

12

NOTES

13

NOTES

14

TERMS AND CONDITIONS TO SALES ORDERS

1. INTERPRETATION

1.1. All references to “we” herein mean Diversitech Equipment and Sales (1984) Ltd.

1.2. All references to “you” herein mean:

(a) the “Customer” referred to herein and in the Sales Order joining these presents (such Sales Order together with any amendments, supplements

and additional agreements related thereto and all annexes and schedules in respect thereof, collectively the “Sales Order”); and

(b) any affiliates and any party related, whether directly or indirectly, to such “Customer”.

2. LIMITED WARRANTY AND LIABILITY

2.1. All units and equipment sold by us to you (collectively “Units”) pursuant to the Sales Order are warranted to be free from defects in material

for a period of 2 years from the date of purchase (the “Warranty Period”).

2.2. We will repair or replace, at our discretion, any defective parts that fail during the Warranty Period, returned to the manufacturer’s plant with

freight prepaid. This warranty is limited to replacement parts ONLY, subject to on-site or in- house evaluation of defective materials and does

not apply to any personal liability or property loss that occurs due to the use or installation of this equipment.

2.3. We expressly exclude all warranties whatsoever, other than those included in Section 2.1 hereof, express or implied, legal or conventional,

including, without limitation, any and all warranties of quality, merchantability and fitness for a particular purpose.

2.4. To the extent that any Units are integrated with any products, equipment, units, connections and/or systems of a third-party (“Third-Party Products”),

we hereby expressly exclude all of the following warranties, express or implied, namely:

(a) warranty against defects of any kind (latent or apparent), fitness for purpose, merchantability or functionality to the extent of any such Third-Party

Products; and

(b) any warranty against any defects or problems of any kind, whether latent or apparent, in respect of Units or a Third-Party Product, caused or arising

directly or indirectly as a result of the integration with or use of Units in connection with any Third-Party Product.

2.5. You hereby expressly waive and renounce to any and all claims against us relating to loss of profits, loss of business or goodwill, interruption

of business and all indirect, special, incidental or consequential damages of any kind whether arising from or in connection with the Sales

Order or from the use of Units, however caused, and whether in the nature of breach of obligations, breach of warranty, repudiation of

contract, tort, negligence (save in the event of gross negligence or intentional fault) or otherwise. Accordingly, save in the event of gross

negligence or intentional fault, we shall have no liability whatsoever towards you under this agreement for any losses or damages, direct or

indirect, consequential, exemplary, incidental or otherwise, regardless of whether we received advanced notice or were advised of the possibility of

such claim, loss or damage.

2.6. You are solely responsible for determining if Units fit your particular purpose and are suitable for your designated process, application, fitment,

tooling, set-up and uses(s).

3. FREIGHT CLAIMS

3.1. Shipments must be inspected by you upon arrival. All Units are sold ex-plant. Therefore, it is the receiver’s responsibility to file any freight

claims with the carrier for obvious or concealed damages. Damaged shipments must be refused at the time of receipt.

4. RETURN MATERIAL POLICY

4.1. Prior to the return of material, for whatever reason, a return merchandise authorization number (“RMA#”) is required from our customer service

department. This procedure is necessary for proper control and handling of returned materials. Call 1-800-361-3733 or email [email protected]

to obtain a RMA #. All material must be returned prepaid. Credit will be given for returns for warranty repair or replacement. Freight collect

shipments will not be accepted. It is the shipper’s responsibility to ensure that material being returned to us is adequately packaged for

shipment in order to prevent damages.

15

5. FEES AND CANCELLATION CHARGES

5.1. You will be responsible for any additional charges and fees not expressly included in the Sales Order, including, without limitation, any fees

or charges relating to installation, service calls, consulting, installation, customization, “right-sizing”, engineering, maintenance and/or repair. For

greater certainty, unless expressly provided in the Sales Order, we do not provide you with any form of service with respect to Units, including,

without limitation, installation, repair and maintenance services.

5.2. In the event that you:

(a) cancel the Sales Order at any time whatsoever, including, without limitation, prior to shipment;

(b) refuse to honour the Sales Order; or

(c) fail to take possession of any Units for any reason whatsoever,

you will be responsible for reimbursement to us of any and all costs, expenses and charges we have incurred to date.

5.3. In the event that:

(a) the Sales Order is for a customized product, including, without limitation, any custom engineered product; and

(b) an event set forth in Section 5.2 hereof occurs,

you will be responsible for payment of the entire amount of the Sales Order in addition to the reimbursement set forth in Section 5.2 hereof.

6. JURISDICTION AND ATTORNMENT

6.1. The interpretation, validity and enforcement of these presents and the Sales Order shall be subject to and governed by the laws of the Province of

Quebec and the laws of Canada applicable therein.

6.2. The parties hereto expressly submit, attorn and consent to the exclusive jurisdiction of the appropriate Court for the District of Montreal,

Province of Quebec, with respect to any controversy arising out of or relating to these presents and the Sales Order, or any supplement hereto

or to any transactions in connection therewith. To the extent permitted by applicable law, you irrevocably waive any objection (including any

claim of inconvenient forum) that you may now or hereafter have to the venue of any legal proceeding arising out of or relating to these presents

and the Sales Order in such courts.

7. GENERAL

7.1. If any provision of these presents or the Sales Order shall be held to be invalid, illegal or unenforceable, the validity, legality and enforceability

of the remaining provisions shall in no way be affected or impaired thereby.

7.2. These presents and the Sales Order shall be binding upon and inure to the benefit of the parties’ respective successors and assigns.

7.3. The parties hereto acknowledge that they have requested and are satisfied that the foregoing as well as the Sales Order and all notices, actions

and legal proceedings be drawn up in the English language. / Les parties à cette convention reconnaissent qu’elles ont exigé que ce qui

précède ainsi que le « Sales Order » et tous avis, actions ou procédures légales soient rédigés et exécutés en anglais et s’en déclarent satisfaites.

An Absolent

Group Company

For full product support, visit our website;

https://bit.ly/2JEcj2B

Scan above on mobile

1200 55th Avenue

Montreal, Quebec H8T 3J8

Email: [email protected]

This manual suits for next models

2

Table of contents

Other DIVERSITECH Air Cleaner manuals