2© 2020 DJI All Rights Reserved.

Disclaimer

Thank you for purchasing the ROBOMASTERTM Development Board Type C (hereinafter referred to

as “Board Type C”). Read this disclaimer carefully before using this product. By using this product,

you hereby agree to this disclaimer and signify that you have read it carefully. Install and use this

product in strict accordance with all related documents. Users bear the responsibilities in all the

consequences caused by using this product. DJITM will not bear any legal responsibilities for any

damages due to improper use, installation, or modication.

DJI and ROBOMASTER are trademarks of DJI and its affiliated companies. Names of products,

brands, etc., appearing in this document are trademarks or registered trademarks of their respective

owner companies. This product and document are copyrighted by DJI with all rights reserved. No

part of this product or document shall be reproduced in any form without the prior written consent or

authorization of DJI. The nal interpretation right of this disclaimer is reserved by DJI.

This document and all other collateral documents are subject to change at the sole discretion of DJI.

For up to date product information, visit http://www.robomaster.com and click on the product page for

this product.

Warning

1. Connect the cables correctly by following the instructions in this document. Otherwise, the cables

or the Board Type C may be seriously damaged.

2. Make sure there are no short-circuits and all the cables are in good condition. DO NOT use cables

that have been damaged in any way.

3. Make sure to use the product in strict accordance with the specications listed in this document,

including those related to voltage and temperature. Failure to do so may reduce the product

service life or even lead to permanent damage.

4. To avoid physical damage, make sure to assemble the Board Type C correctly.

5. If you detect any ames, smoke, strange smells, or other abnormalities, disconnect the Board Type

C from the power source immediately.

6. DO NOT open the silicone case. Otherwise, foreign objects may fall inside and the performance of

the Development Board Type C may be negatively affected.

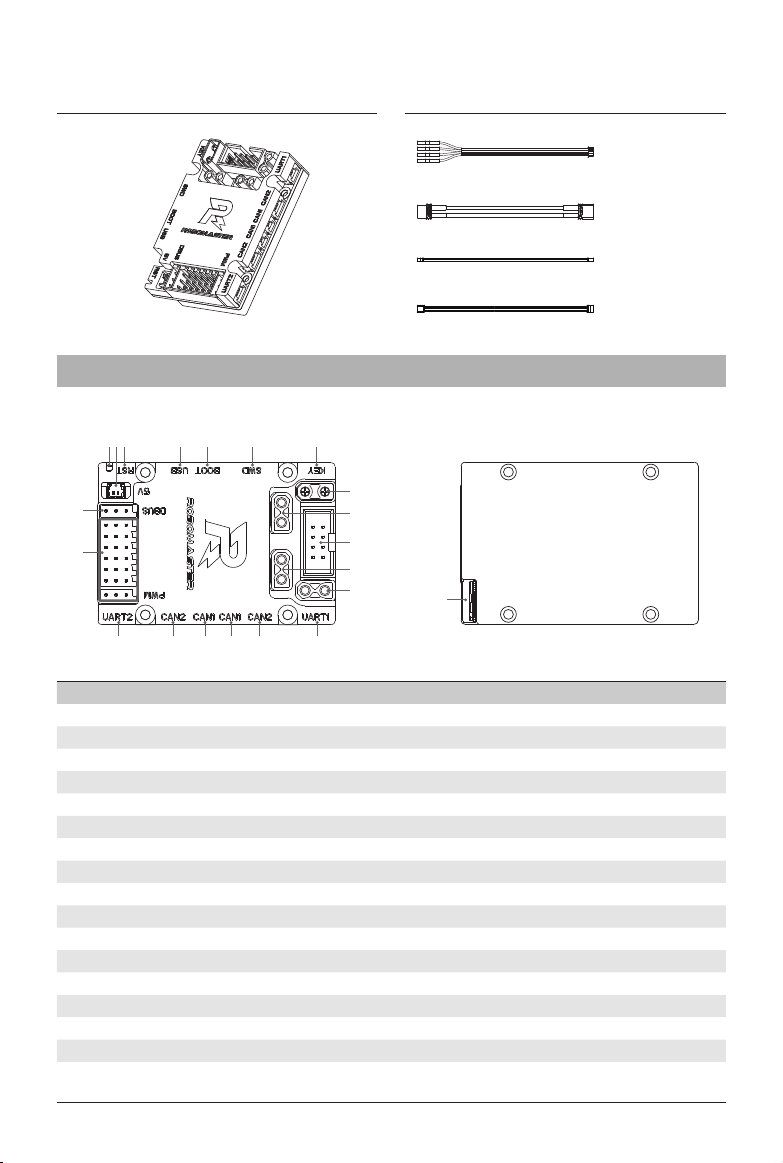

RoboMaster Development Board Type C

Introduction

Designed to work with the products of RoboMaster and other accessories, the compact Development

Board Type C uses a high-performance STM32 microcontroller chip and supports a wide range of

voltage inputs. The highly integrable Board Type C boasts an expansion interface, communication

interface, and high precision IMU sensors and features an anti-reverse connection and anti-

overvoltage protection. The Board Type C provides rich routines and can be widely used in elds

such as robotics competitions, research and education, and automation equipment.