2 | OPC503V man.

TABLE OF CONTENTS

SECTION I: ASSEMBLY ............................................................3

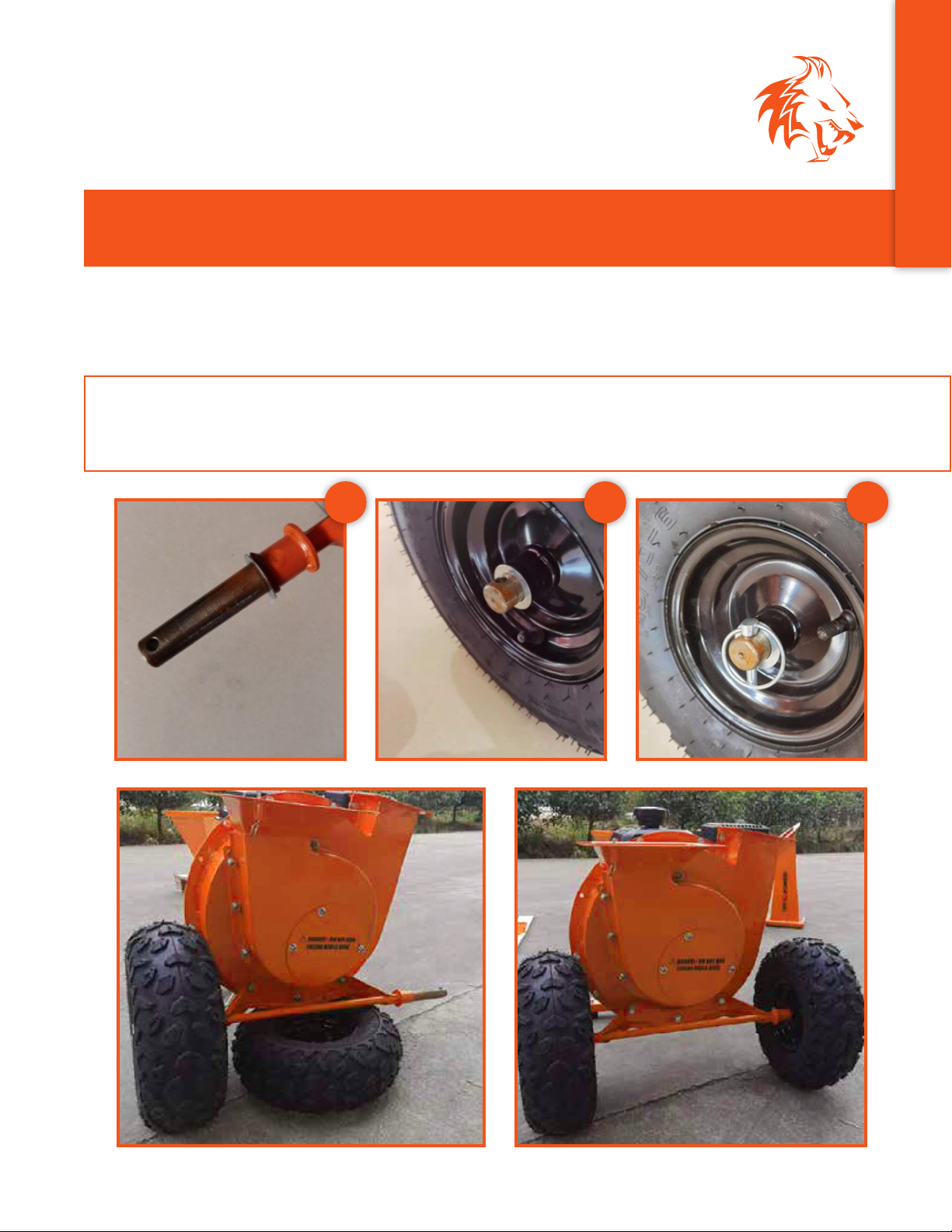

STEP 1: AXLE.........................................................................4

STEP 2: WHEELS .....................................................................5

STEP 3: DROP STAND & TOW BAR .....................................................6

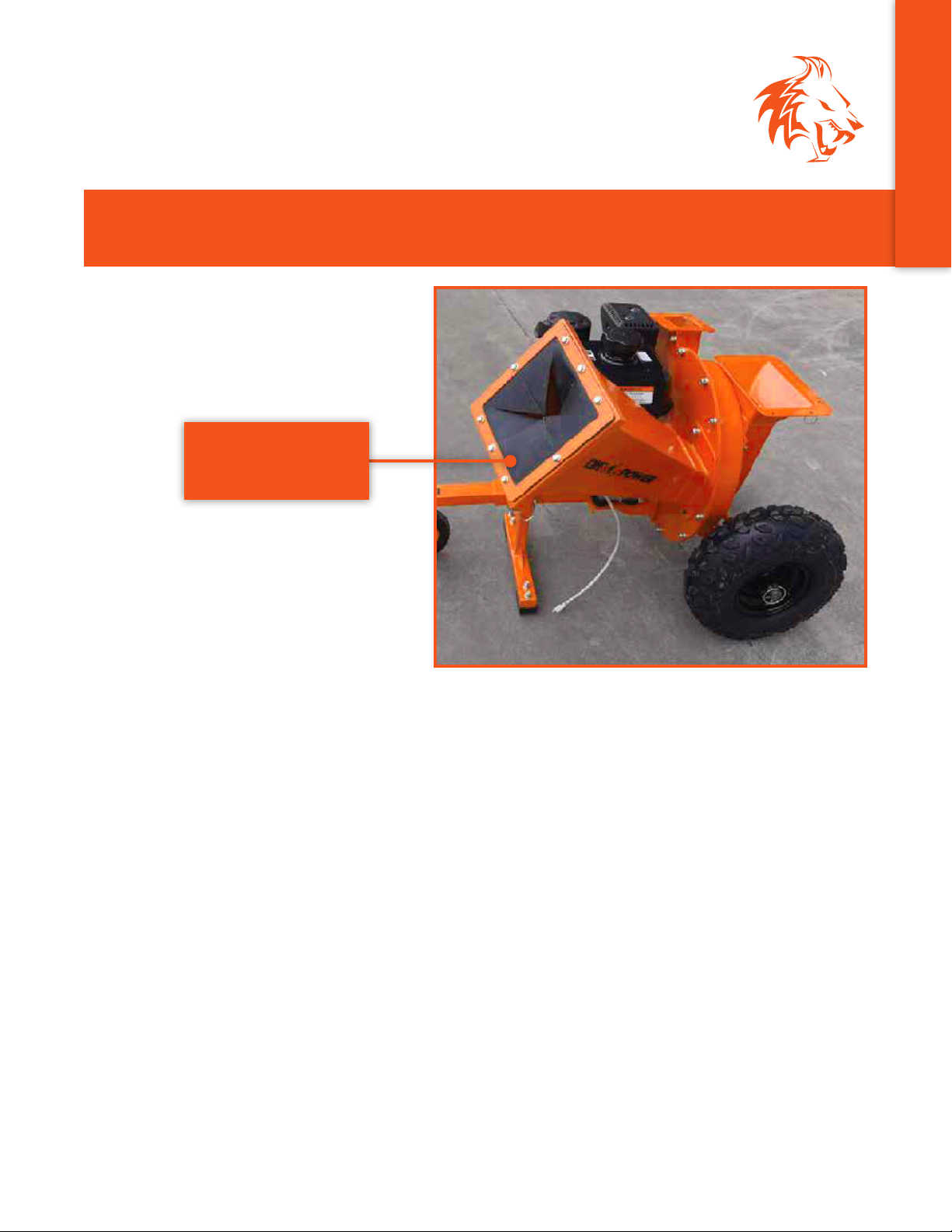

STEP 4: SIDE FEED CHUTE ............................................................7

STEP 5: TOP LOADING FEED CHUTE HANDLE ...........................................8

STEP 6: TOP LOADING FEED CHUTE ...................................................9

STEP 7: CHIP CHUTE.................................................................10

STEP 8: HOSE ASSEMBLY .............................................................11

STEP 9: HOSE INSTALLATION.........................................................12

SECTION II: SAFETY & OPERATION ................................................13

YOUR KOHLER ENGINE ..............................................................14

SAFE PRACTICES & GENERAL INFORMATION ..........................................15

SECTION III: PARTS & SCHEMATICS ................................................16

SCHEMATICS ....................................................................... 17

PARTS LIST .........................................................................18

WARRANTY .....................................................................19

ENGLISH